Ammonia spraying grille device for realizing automatic regulation, simultaneously reinforcing mixing and preventing blockage and ammonia spraying method thereof

A technology of automatic adjustment and ammonia injection grid, which is applied in chemical instruments and methods, separation methods, gas treatment, etc. problems, to achieve the effect of low equipment and operation and maintenance costs, avoid serious uneven ammonia injection, and avoid nozzle blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0024] Example.

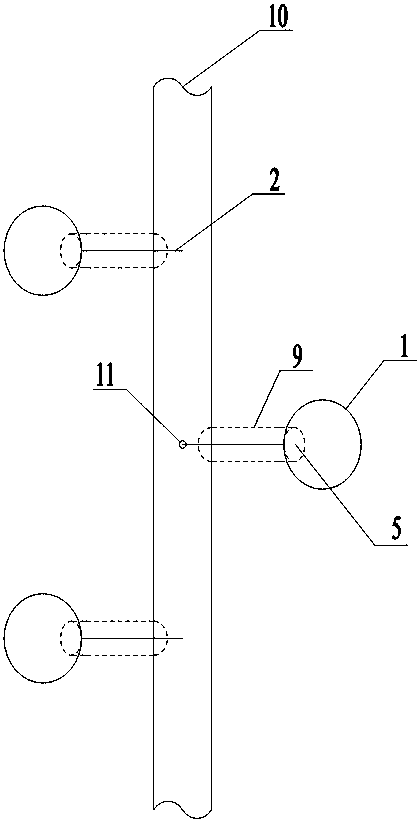

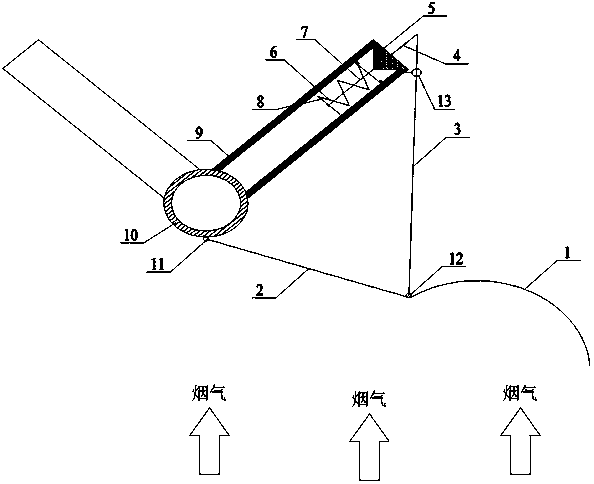

[0025] see Figure 1 to Figure 2 , an ammonia injection grid device that automatically adjusts and simultaneously strengthens mixing and anti-blocking, including a flue gas flow rate tracking device 1, a No. 1 lever 2, a No. 2 lever 3, a connecting part 4, a nozzle opening adjustment valve 5, and an elastic part 6 , connecting rod 7, support ring 8, nozzle 9, ammonia injection branch pipe 10, No. 1 rotating shaft 11, No. 2 rotating shaft 12 and guide ring 13.

[0026] The flue gas velocity tracking device 1 is rigidly connected to one end of the No. 1 lever 2, and there is no elastic deformation within 500°C. The other end of No. 1 lever 2 is connected with ammonia injection branch pipe 10 by No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com