Job shop scheduling scheme robust optimization method based on non-forced idle time

A technology of idle time and scheduling schemes, applied in genetic models, genetic rules, instruments, etc., can solve problems such as optimization of robust scheduling schemes in job shops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

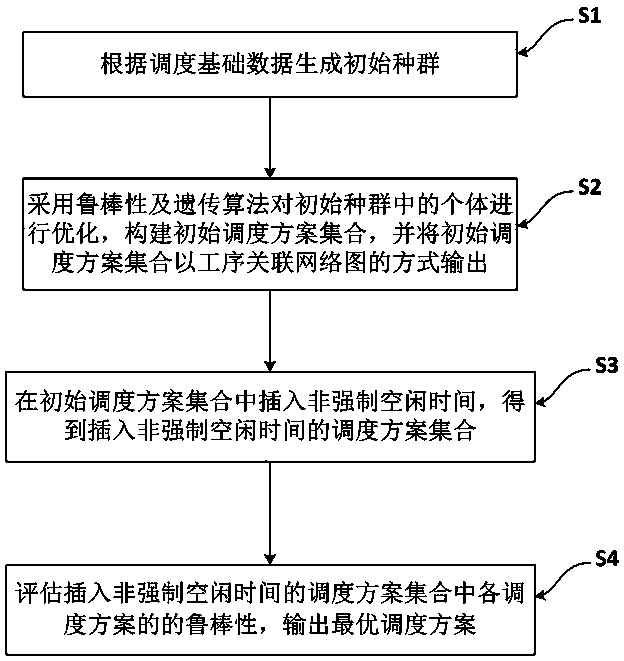

[0067] Embodiment 1: as attached figure 1 As shown, the robust optimization method for job shop scheduling based on unforced idle time includes the following steps:

[0068] S1, generate an initial population according to the scheduling basic data, and the initial population includes several original scheduling schemes;

[0069] When generating the initial population based on the scheduling basic data, it is necessary to perform data preprocessing on the scheduling basic data. The data preprocessing process includes a, obtaining order data, delivery date, process route of each workpiece, processing time of each process in the workpiece, Probability distribution of machine failure and maintenance time; b. Organize the obtained data into the standard format required for scheduling, and organize and generate the initial population; the above initial population is the set of original scheduling schemes.

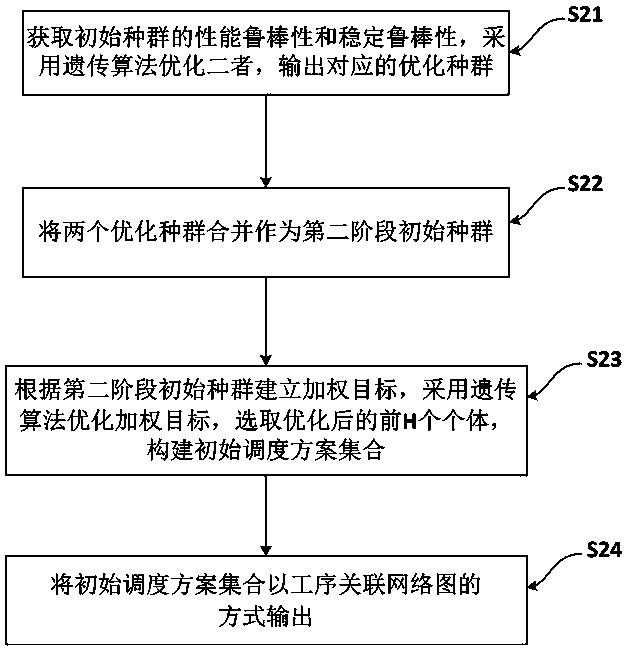

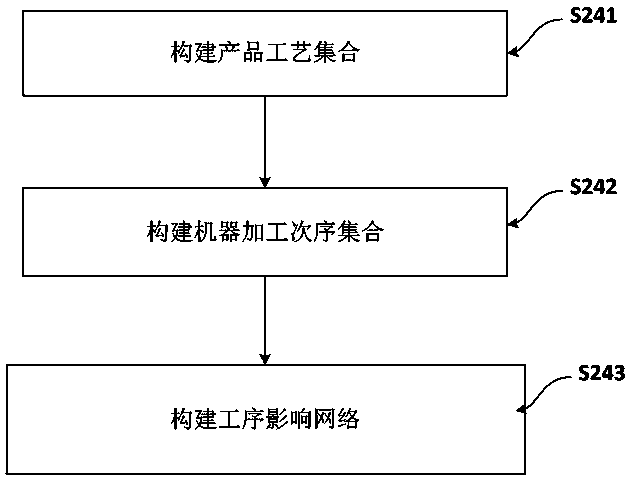

[0070] S2, optimize the individuals in the initial population based on robu...

Embodiment 2

[0157] Embodiment 2: as attached Figure 6 , 7 , as shown in Table 1, this method designs performance robustness degradation rate (Performancerobustness degradation rate, PRDR), stable robustness improvement rate (Stable robustness improvement rate, SRIR), scheduling target improvement rate (Comprehensive improvement rate, CIR) three The indicators are as follows:

[0158] 1. Performance robustness degradation rate PRDR(S 1 ,S 2 ), which means that under the machine failure environment, S 1 and S 2 Relative ratio of performance robustness.

[0159]

[0160] Among them, when PRDR(S 1 ,S 2 )>0, it means S 1 relative to S 2 Deterioration has occurred, PRDR(S 1 ,S 2 ) The larger the degree of deterioration is, the more serious it is.

[0161] 2. Stable robustness improvement rate SRIR(S 1 ,S 2 ), which means that under the machine failure environment, S 1 and S 2 Relative ratio of stability robustness.

[0162]

[0163] Since the non-mandatory idle time can ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap