Discharging structure for coffee vending machine and vending machine

A technology of vending machine and drive structure, applied in applications, coin-operated equipment for controlling the dispensing of fluid/granular materials from containers, household appliances, etc. Cup distance, affecting the overall size of the coffee vending machine, etc., to increase the space, reduce the density, and reduce the probability of coffee splashing out of the cup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

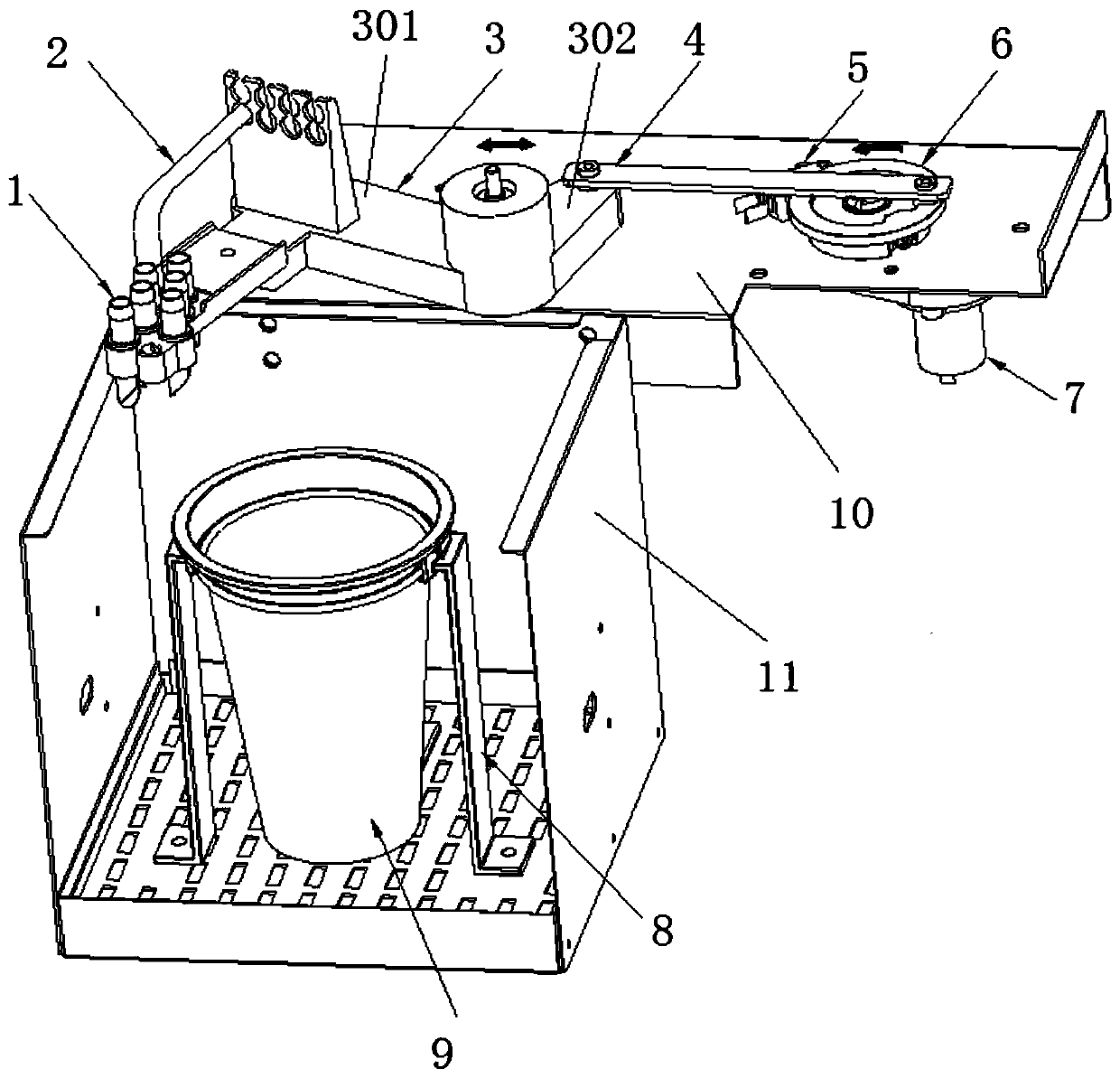

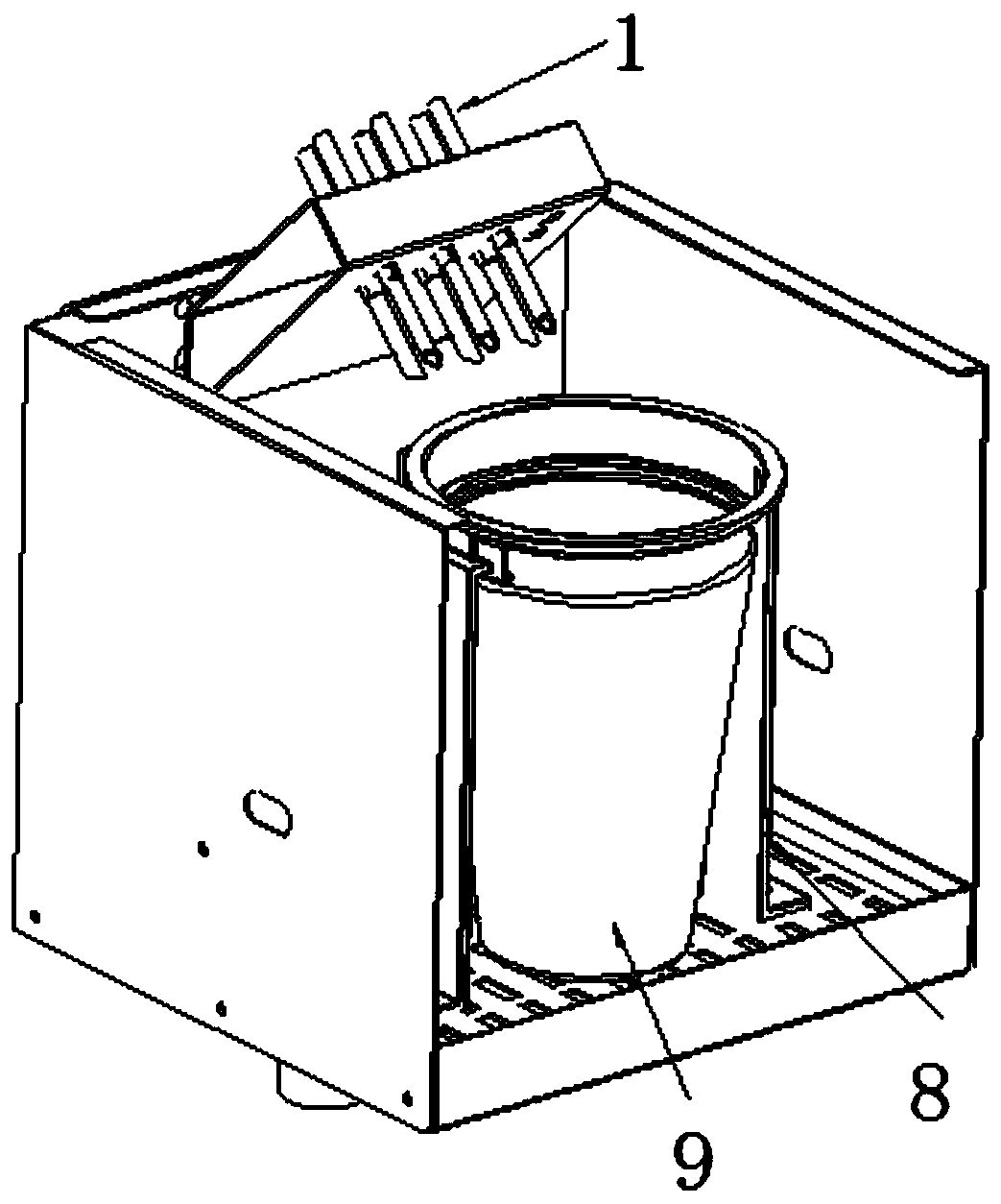

[0037] Such as figure 1 As shown, a discharge structure for a coffee vending machine includes a swing plate 3 rotatably connected to the frame structure in the coffee vending machine, a cup holder 8 located at the discharge port of the coffee vending machine, and vertically arranged nozzles 1. The upper end of the nozzle 1 is used to connect the feeding pipe 2, and the lower end is used to spray coffee.

[0038] Specifically, the number of nozzles 1 can be one or multiple; when multiple nozzles 1 are used to spray coffee, the injection speed of a single nozzle 1 can be reduced while satisfying the total flow of coffee, so as to avoid nozzle 1 spraying coffee. Too much foam caused by coffee too fast.

[0039] The swing plate 3 is used to install the nozzle 1, and the swing plate 3 can swing in the horizontal plane with a set rotation axis to drive the swing of the nozzle 1, and the nozzle 1 has a first station and a second station in the horizontal plane .

[0040]Specifical...

Embodiment 2

[0057] This embodiment provides a coffee vending machine, which utilizes the discharge structure for the coffee vending machine. The coffee vending machine has a discharge port, and a cup holder 8 is installed at the discharge port. The nozzle 1 is arranged above the feed port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com