A slotted circular waveguide circular polarizer with high power capacity and its processing method

A circular polarizer and circular waveguide technology, applied in the direction of electrical components, antennas, etc., can solve the problems of circular polarizers that can meet high power capacity, miniaturization and broadband performance at the same time, so as to avoid the limitation of available bandwidth, Good axial ratio and broadband performance, the effect of low reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

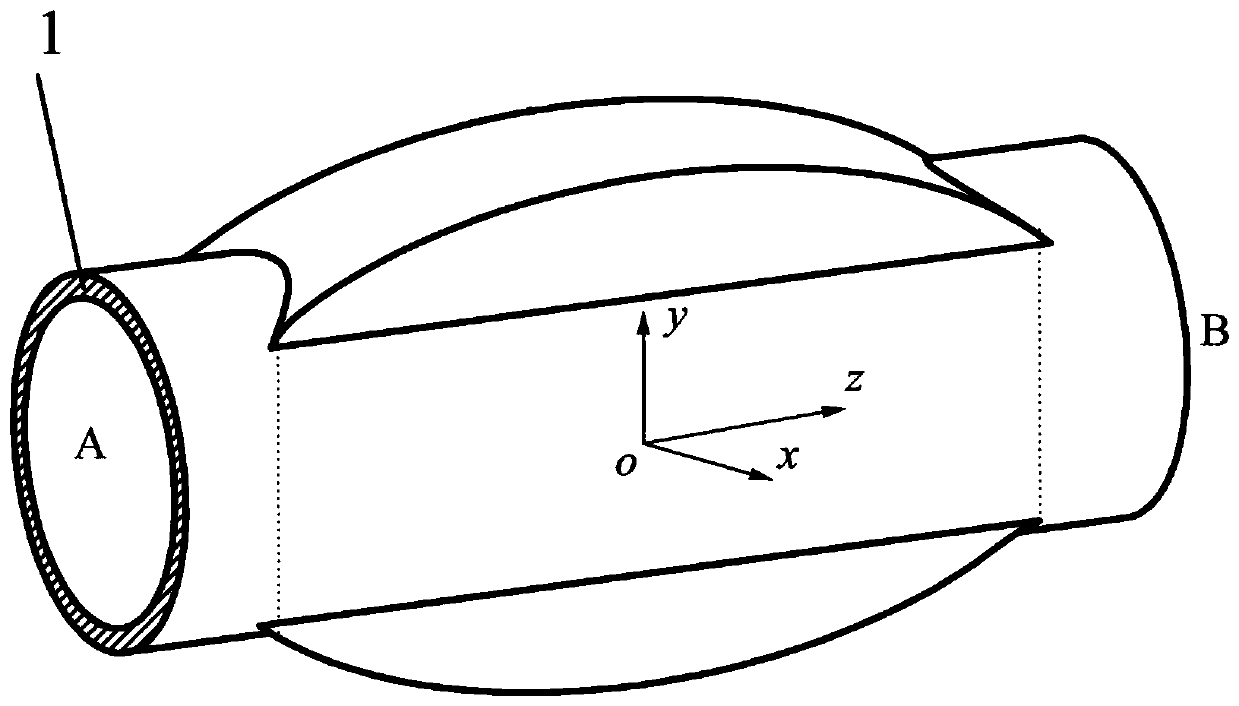

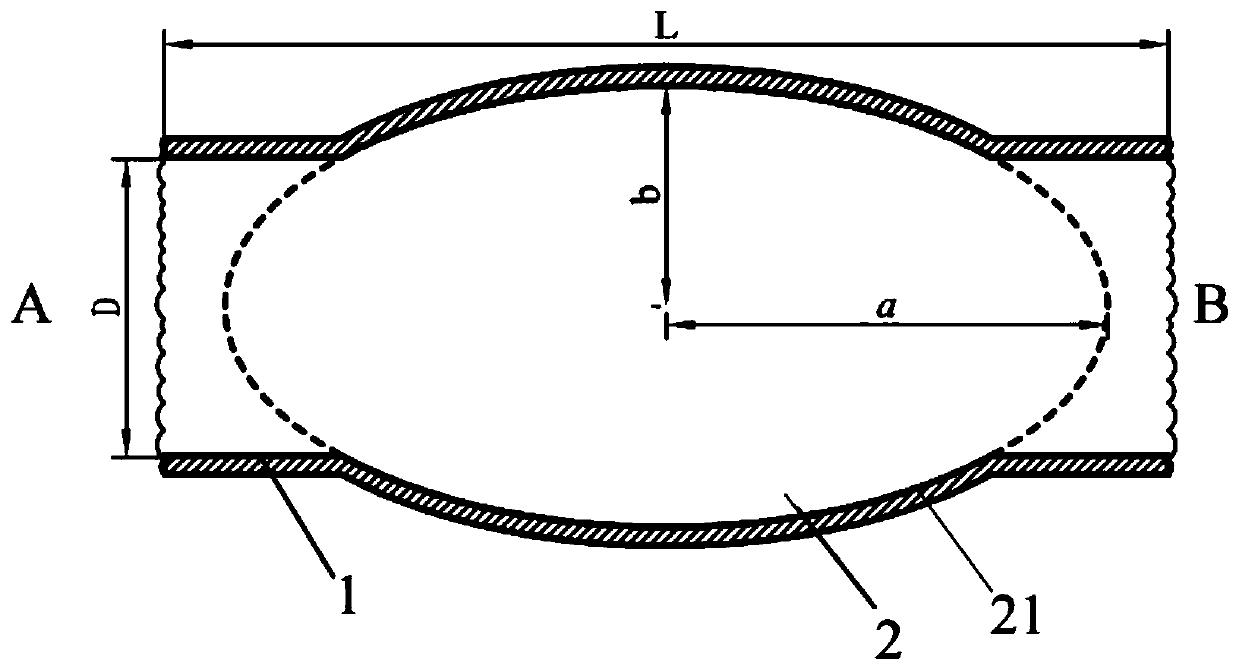

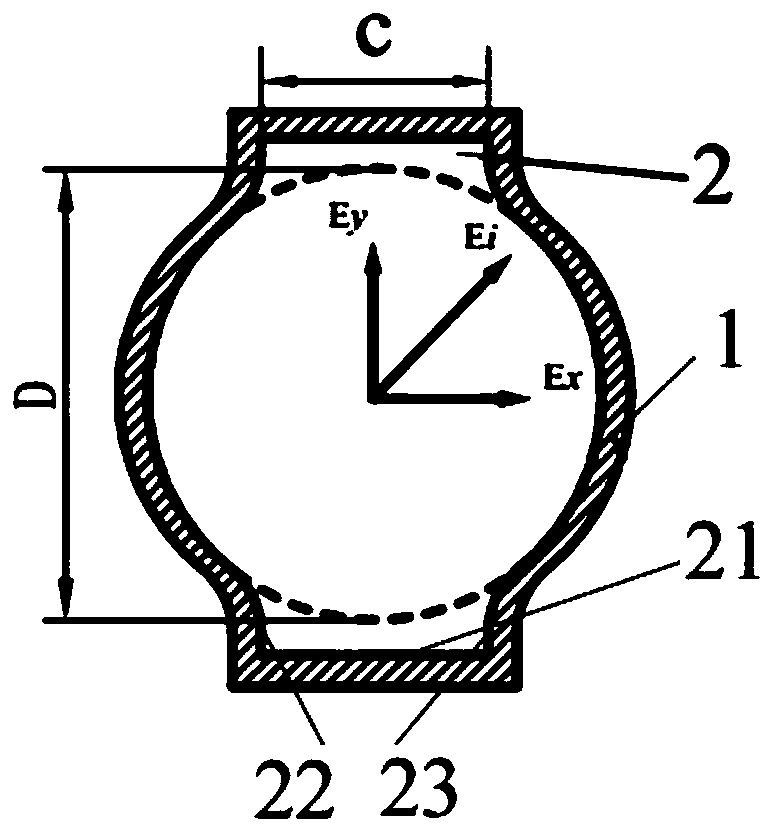

[0040] Please refer to Figure 1 ~ Figure 3 , the present embodiment provides a slotted circular waveguide circular polarizer with high power capacity, including a circular waveguide 1, which is an overmolded circular waveguide; two compensation slots 2 are arranged on the inner wall of the circular waveguide 1, and the two compensation slots 2. Arranged symmetrically with respect to the central axis of the circular waveguide 1; the compensation groove 2 is opened along the length direction of the circular waveguide 1, and is a gradual deformation groove. Compared with the sudden deformation groove, the gradual deformation groove structure can avoid Exciting high-order modes improves the axial ratio performance of circular polarizers. The compensation groove 2 includes an arc-shaped groove surface 21, and two flat groove surfaces 22, 23 respectively connected with two arc-shaped sides of the arc-shaped groove surface. The design of the corner structure makes it characterized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com