Method for monitoring an operating state of a pumping device

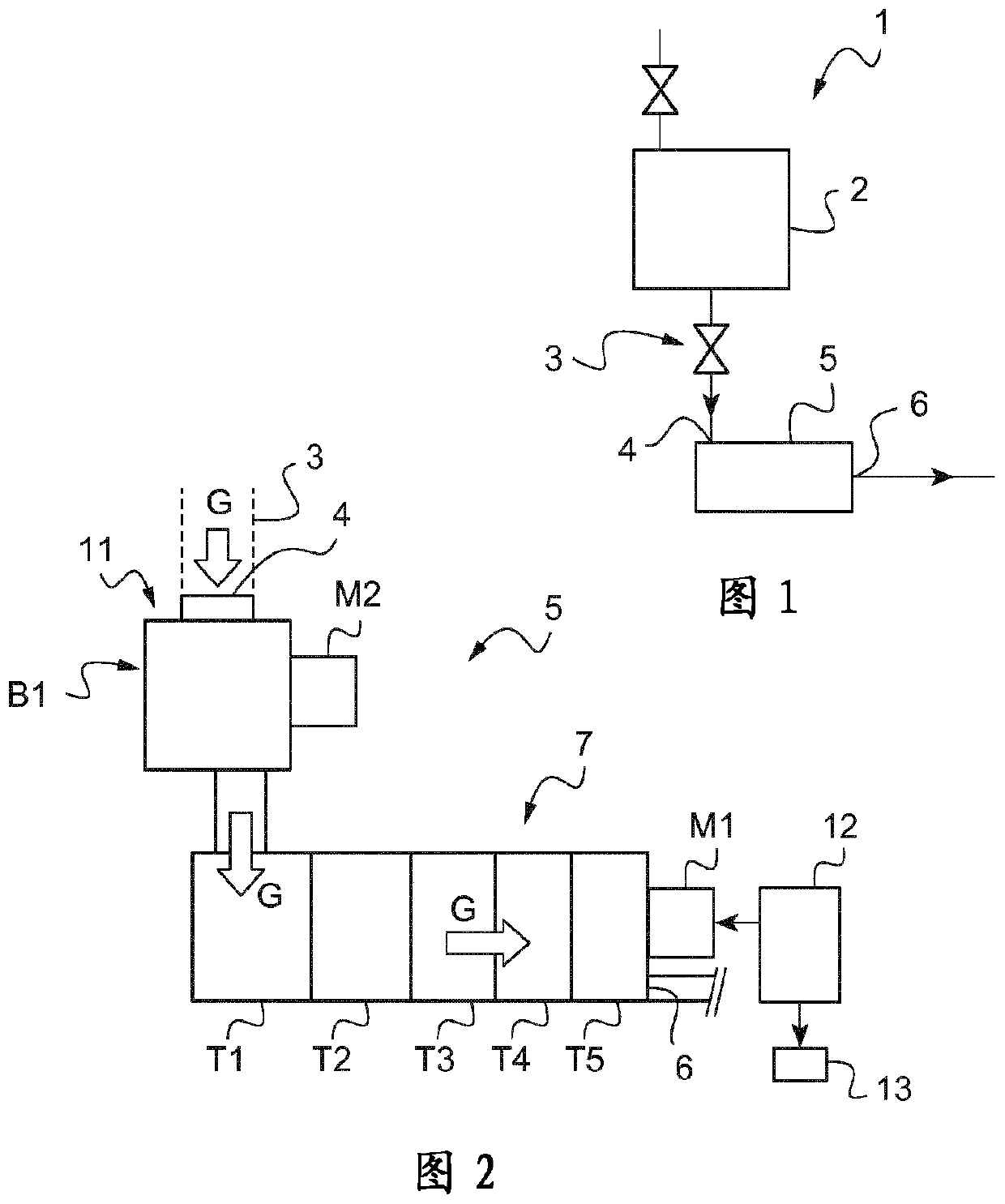

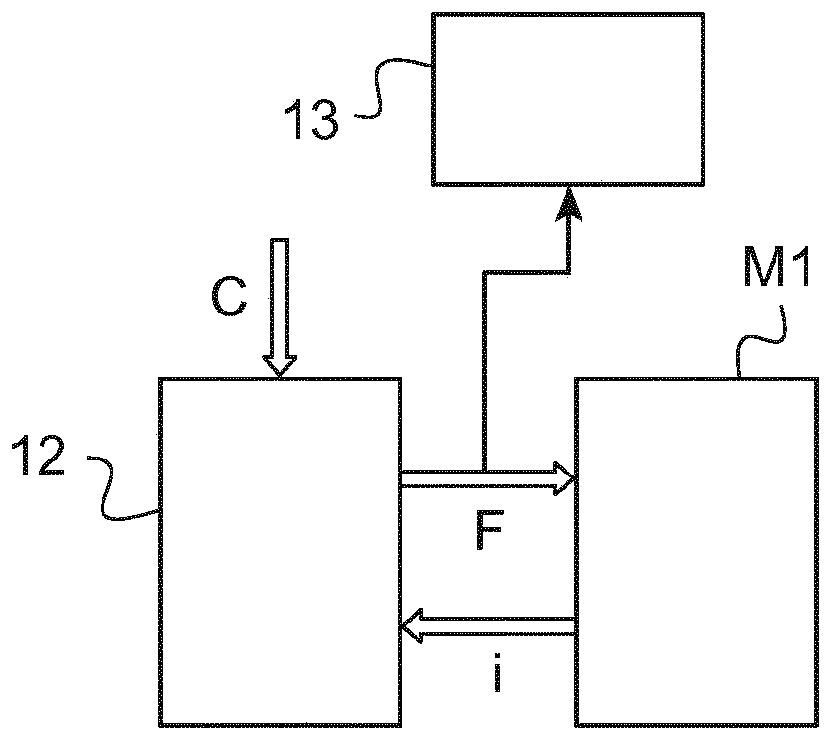

A pumping device, operating state technology, applied in the direction of pump combinations, pumps, pump elements, etc. for elastic fluid rotary piston type/oscillating piston type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following embodiments are examples. Although the description refers to one or more embodiments, this does not necessarily mean that every talk is about the same embodiment, or that these features are only applicable to one embodiment. Single features of different embodiments may be equivalently combined or interchanged to provide other embodiments.

[0042] Roughing pumps are defined as positive displacement roughing pumps which, by means of two rotors, suck in, transfer and then discharge the gas to be pumped at atmospheric pressure. The rotor is carried by two shafts which are driven in rotation by the motor of the roughing vacuum pump.

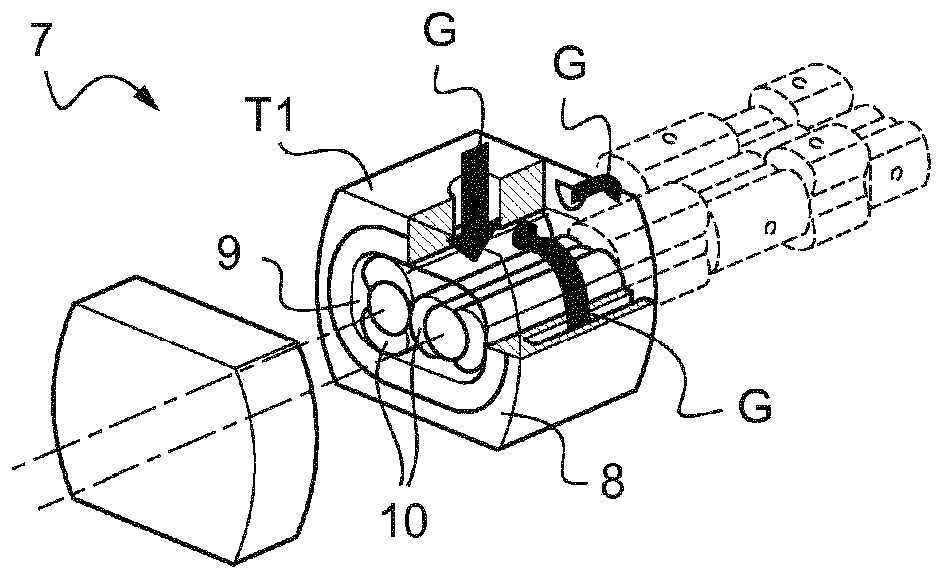

[0043] A Roots blower is defined as a positive displacement vacuum pump which takes in, transfers and then discharges the gas to be pumped by means of a Roots-type rotor. The vacuum pump is installed on the upstream side of the rough vacuum pump and is in series with it. The rotor is carried by two shafts which are driven in r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com