Spraying arm of dish washing machine and manufacturing method thereof

A technology of spray arm and dishwasher, which is applied to the washing machine/washing machine for tableware, the parts of washing machine/rinsing washing machine for tableware, cleaning equipment, etc., can solve the problem of low manufacturing precision, poor spraying effect, spraying The hole angle cannot be adjusted, etc., to achieve precise adjustment and improve the effect of spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

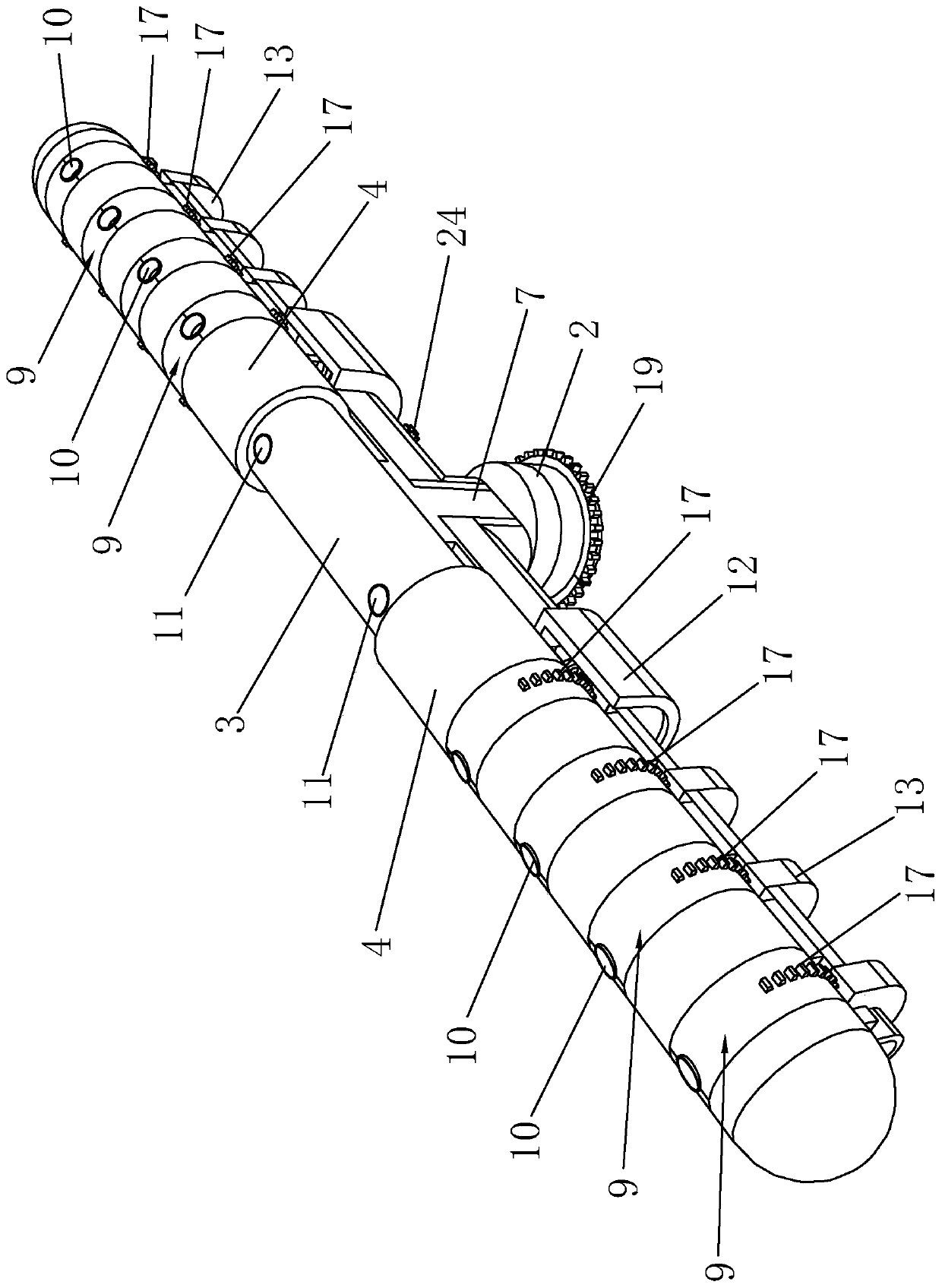

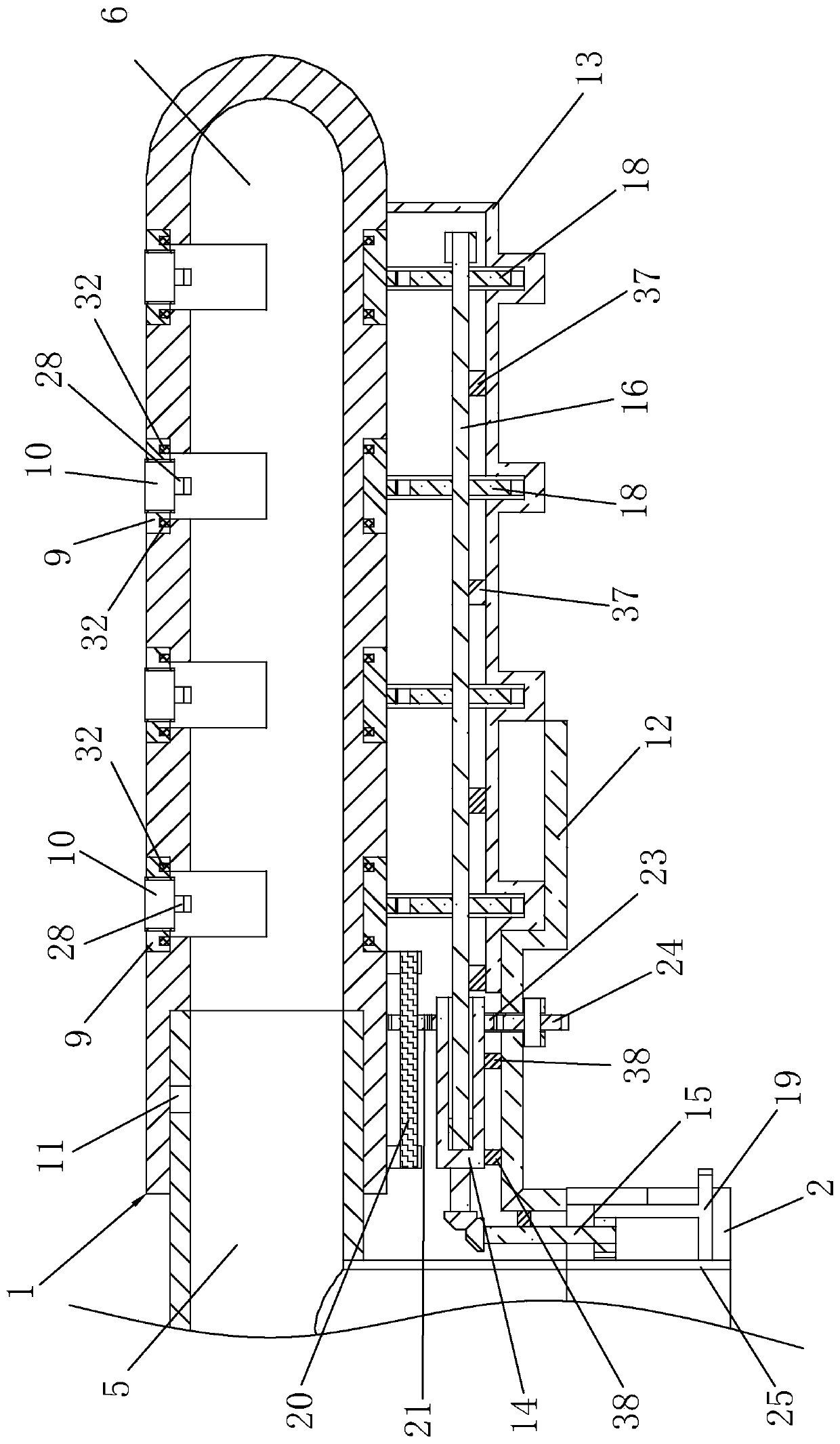

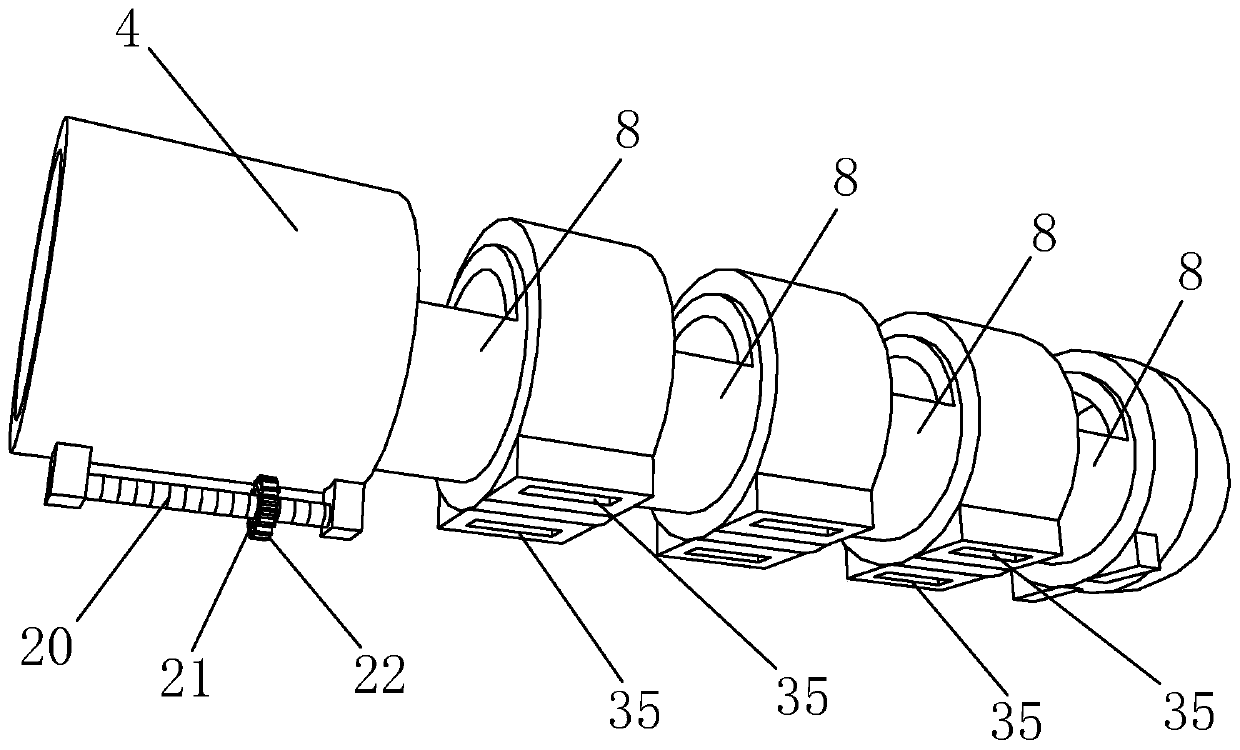

[0034] Such as Figure 1 to Figure 6 As shown, it is a spray arm of a dishwasher according to the present invention, which includes a spray arm body 1 and a mounting seat 2. The spray arm body 1 includes a connecting arm 3 and a telescopic arm 4. The connecting arm 3 is provided with a first cavity 5. The telescopic arm 4 is provided with a second cavity 6, the connecting arm 3 is connected with the telescopic arm 4, the first cavity 5 and the second cavity 6 are connected, the connecting arm 3 is provided with a connecting seat 7, and the connecting seat 7 is provided On the mounting base 2, the telescopic arm 4 is provided with an annular groove 8, the annular groove 8 is provided with a rotary sleeve 9, the rotary sleeve 9 is rotatably connected with the telescopic arm 4, the rotary sleeve 9 is provided with a spray hole 10, and the spray hole 10 is connected to the first The two cavities 6 are connected. Through the rotational connection between the rotary sleeve 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com