Piston type fire extinguishing device and pressure relief method thereof

A fire extinguishing device and piston type technology, which is applied in fire rescue and other fields, can solve the problems of fire extinguishing agent residue in the fire extinguishing agent delivery pipeline, high pressure of driving gas, residue, etc., and achieve the effect of eliminating potential safety hazards, low cost, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

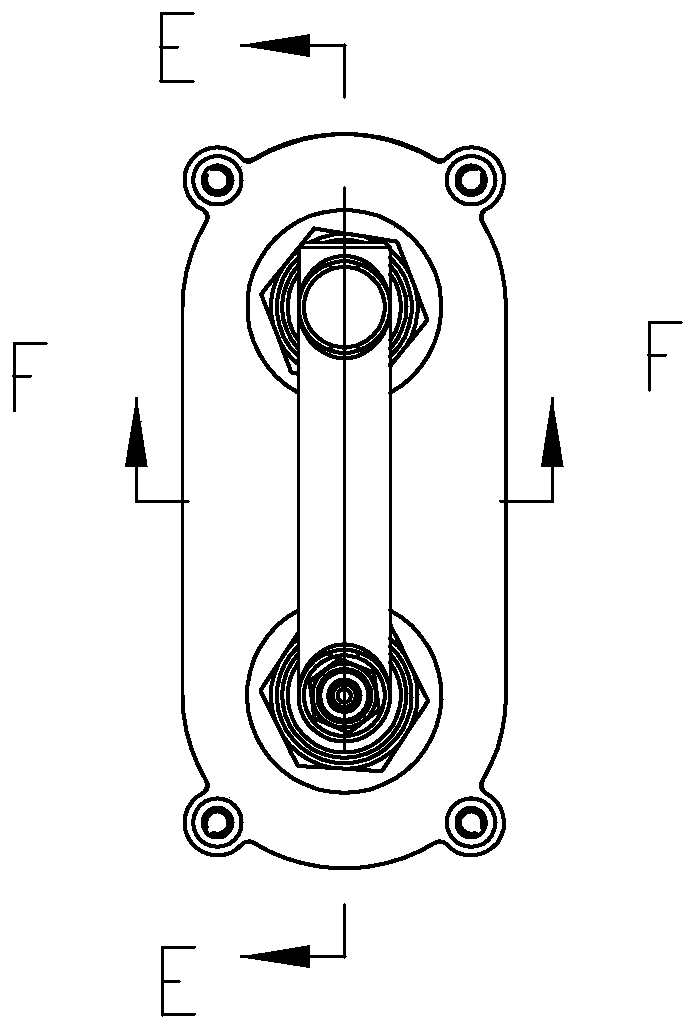

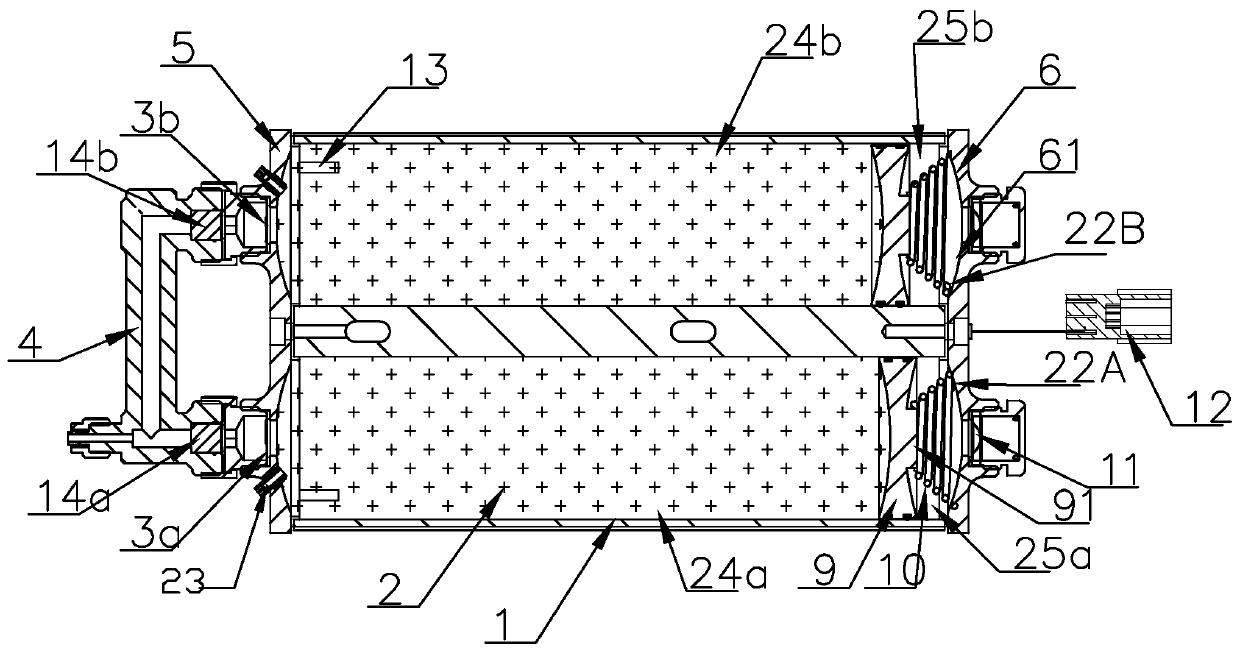

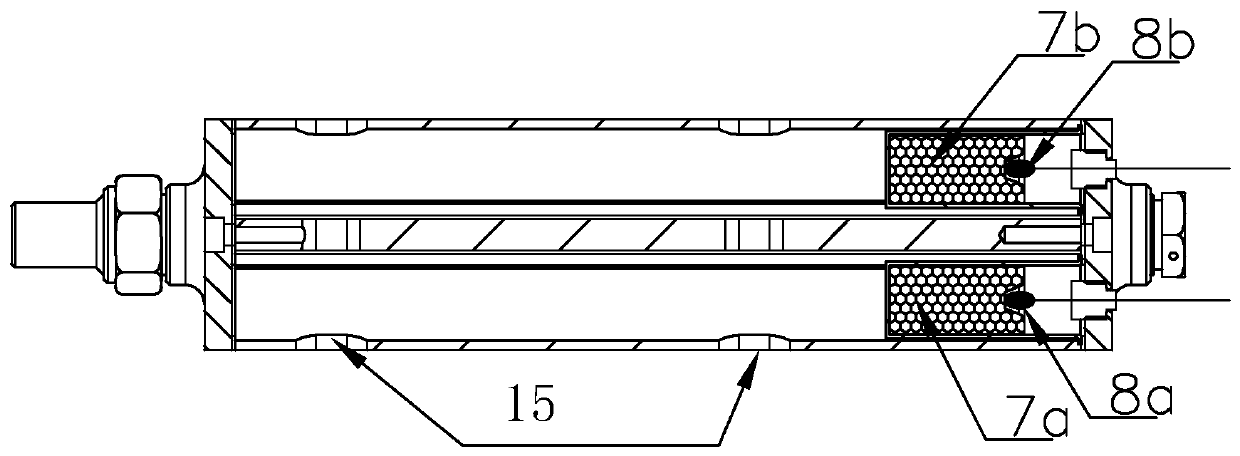

[0030] Examples, see Figure 1-Figure 5 As shown, a piston type fire extinguishing device of the present invention includes a storage tank, and the storage tank is provided with several first chambers, specifically two first chambers, but not limited thereto, the two first chambers The chambers 20a, 20b are arranged side by side, and the two first chambers 20a, 20b are respectively slidingly provided with a piston 9, and the piston 9 divides the first chamber 20a / 20b into a fire extinguishing agent chamber 24a / 24b and a driving air chamber 25a / 25b. The two first chambers 20a, 20b are filled with water-type fire extinguishing agent 2, but not limited thereto. The end of each fire extinguishing agent chamber 24a / 24b away from the driving air chamber 25a / 25b is provided with a fire extinguishing agent outlet. In the state where the piston 9 moves to the preset position along the direction that makes the space of the fire extinguishing agent chamber 24a / 24b smaller, the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com