A method and application of early dismantling construction and setting out that is conducive to beam bottom positioning and inspection and correction

A construction line and inspection line technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of construction quality impact, waste of concrete materials, positioning accuracy, construction convenience, and insufficient inspection and re-accounting, etc., to achieve Not easy to play the wrong line, easy to calibrate and check, and reduce the effect of review work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

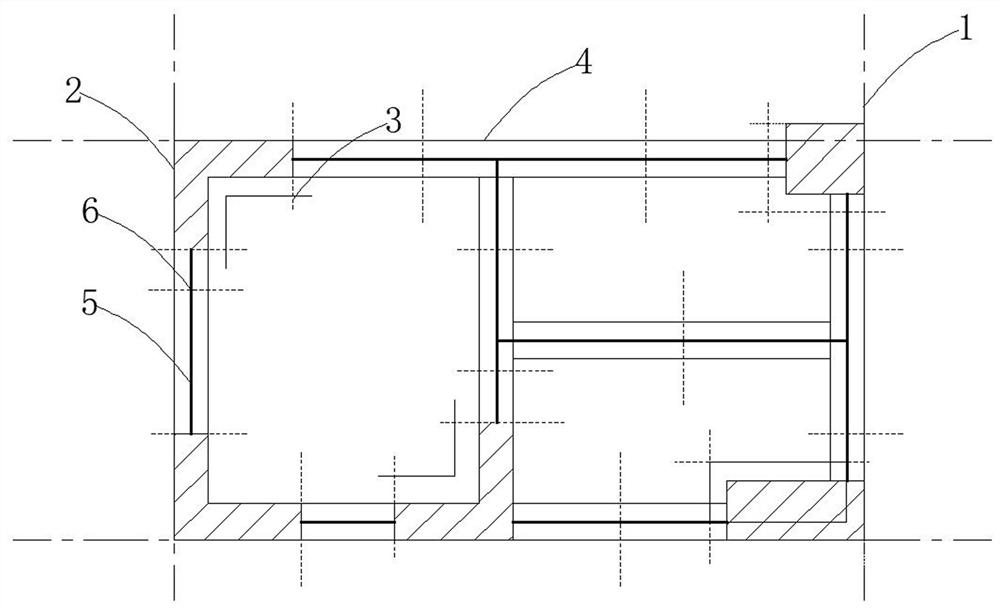

[0039] This embodiment mainly provides a method of setting out wires for early demolition construction that is beneficial to beam bottom positioning and inspection and correction. The specific setting out conditions are as follows: figure 1 As shown, the specific steps are as follows:

[0040] (1) Preparatory work: According to the relevant design drawings of the building, draw the construction drawing of the complete beam and slab early dismantling line, including the clearance size of the construction interface, the size of the junction point of the primary and secondary beams and the connection point of the wall column, the position of doors and windows, Dimensions such as space elevation and equipment openings are measured, etc.;

[0041] (2) Draw a well-shaped horizontal and vertical reference control axis: According to the construction drawing of the early dismantling and setting-out line of the beam and slab, two groups of axes that do not overlap are popped out at the ...

Embodiment 2

[0047] On the basis of the above-mentioned embodiments, this embodiment provides the specific application process of the above-mentioned construction setting-out method for beam bottom positioning:

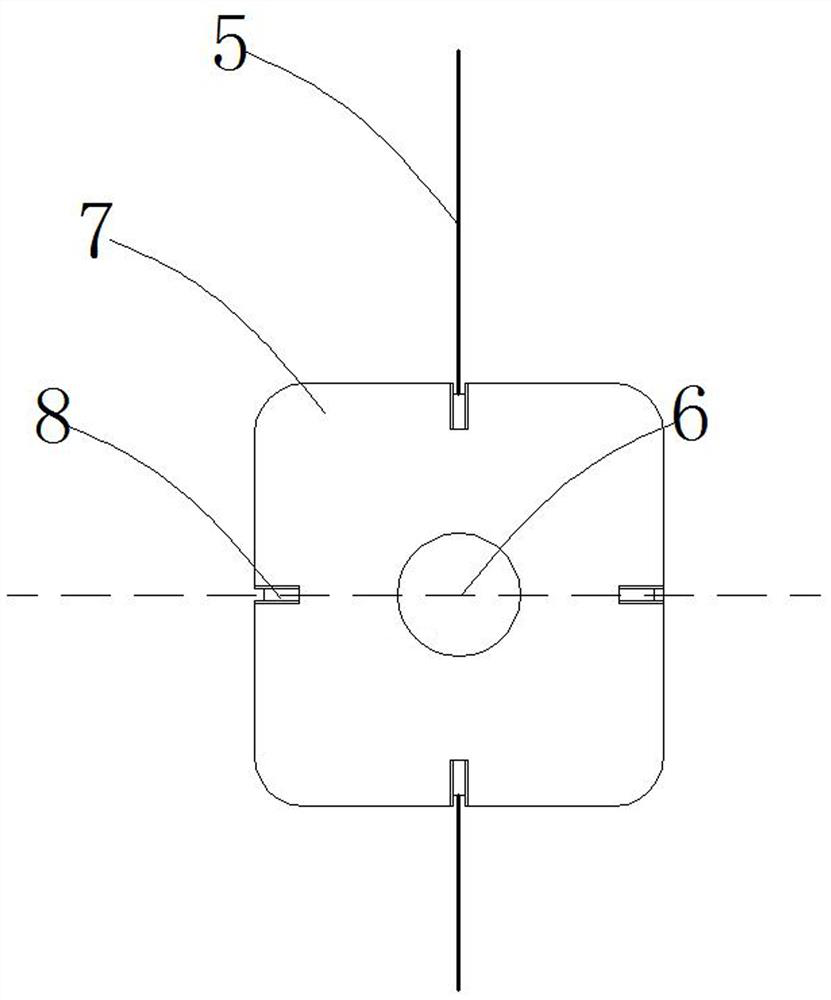

[0048] Fix the beam bottom support bar according to the beam center line that pops up from the construction interface. The upper part of the beam bottom support bar has a fixing piece that can be supported in the middle of the beam bottom, and the lower part is provided with a positioning component that accurately locates the beam center line, and is supported by the beam bottom. The positioning ability of the rod realizes the accurate positioning of the bottom of the beam.

[0049] Specific positioning situations, such as figure 2 As shown, the positioning assembly is a 100mm-300mm concrete protection positioning base chassis 7, the concrete protection positioning base chassis 7 is a square shape, and four positioning positioning components in a cross distribution are also arran...

Embodiment 3

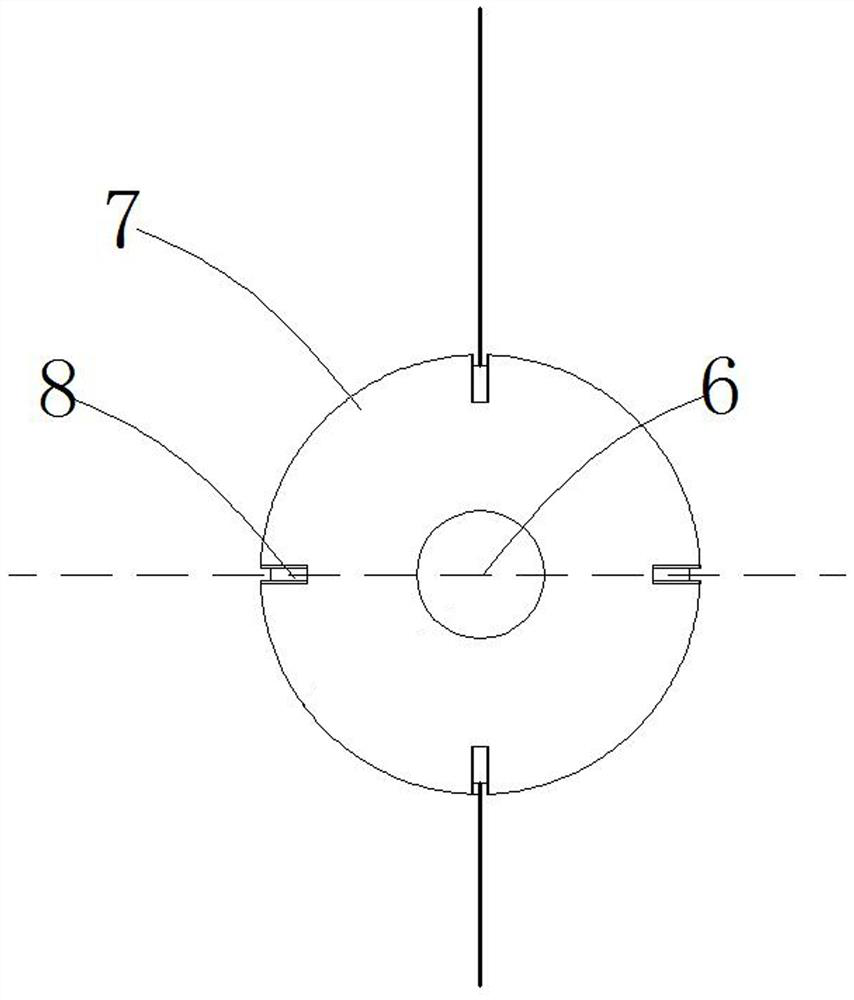

[0090] On the basis of the above-mentioned embodiments, this embodiment further defines the shape of the concrete positioning base chassis 7, such as image 3 As shown, the concrete protection positioning base chassis 7 is circular, and the outer edge of the circular concrete protection positioning base chassis 7 is four positioning grooves 8 distributed in a cross. The width of the positioning groove is 2-5mm, and the depth is 2-5mm, length 10-30mm. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com