Industrial equipment predictive maintenance method based on cloud edge cooperation

A kind of industrial equipment and predictive technology, applied in the direction of prediction, transmission system, instrument, etc., can solve the problem of incomplete edge data, achieve the effect of improving model accuracy and saving waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

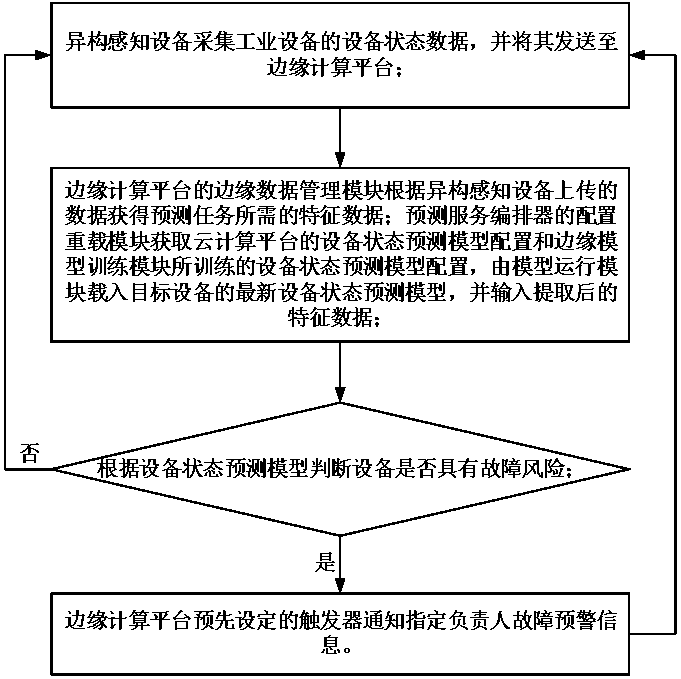

[0030] Such as figure 1 As shown, the specific steps of a predictive maintenance method for industrial equipment based on cloud-edge collaboration are as follows:

[0031]S1: Heterogeneous sensing equipment collects equipment status data of industrial equipment and sends it to the edge computing platform;

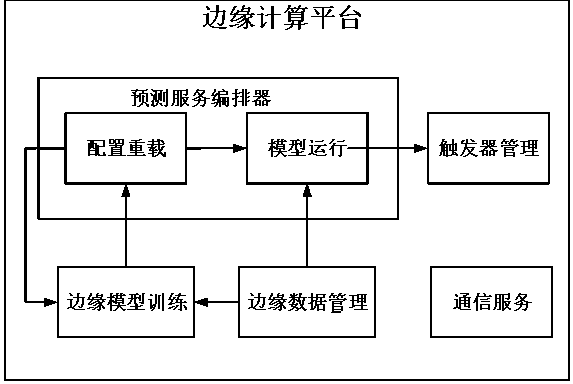

[0032] S2: The edge data management module of the edge computing platform obtains the feature data required for the target device prediction task according to the data uploaded by the heterogeneous sensing device; the configuration overload module of the prediction service orchestrator obtains the device state prediction model configuration and edge The equipment state prediction model configuration trained by the model training module is loaded into the latest equipment state prediction model of the target equipment by the model operation module, and the extracted feature data is input; according to the output data of the model operation module, it is judged whether the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com