Sand core hanging nose fixing structure and its application method

A technology of fixing structure and positioning structure, applied in casting and forming equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inaccurate installation of the sand core lifting nose, difficulty in installing the sand core lifting nose, difficulty in taking out the positioning device, etc. Eliminate hidden dangers in operation, reduce bumps and damages, and have the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

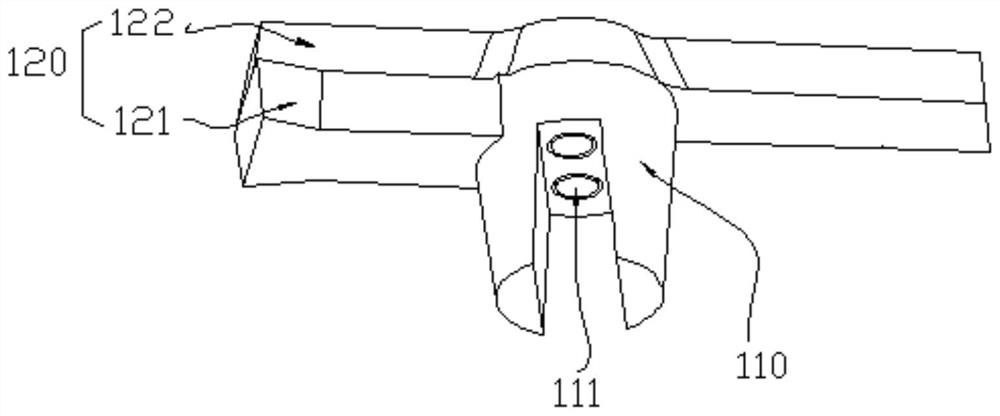

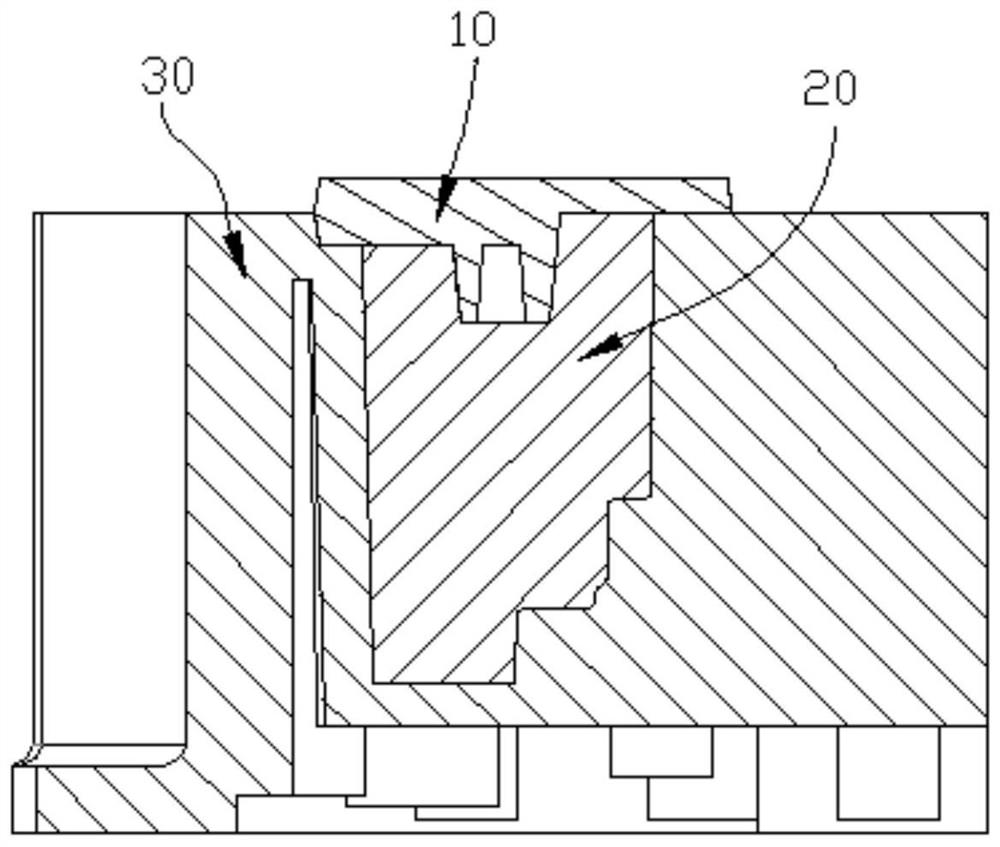

[0028] A sand core hanging nose fixing structure, the sand core hanging nose fixing structure 10 is used in conjunction with the sand core mold in the form of a loose block, and is arranged between the sand core upper mold and the sand core lower mold; the sand core hanging nose structure is used for Fixing the sand core hanging nose, including: fixing seat 110, positioning structure 120; the fixing seat 110 is used to fix the sand core hanging nose; On the sand core mould, a groove is provided on the opposite end face of the fixing seat 110 connected to the positioning structure 120, the depth of the groove is greater than or equal to 20 mm, and the width of the groove is 1 mm to 2 mm larger than the cross-sectional diameter of the sand core hanging nose; At least one installation hole 111 is arranged on the inner wall of the bottom of the groove, and a magnet is installed in the installation hole 111, and the sand core suspension nose is fixed by the magnetic force of the mag...

Embodiment 2

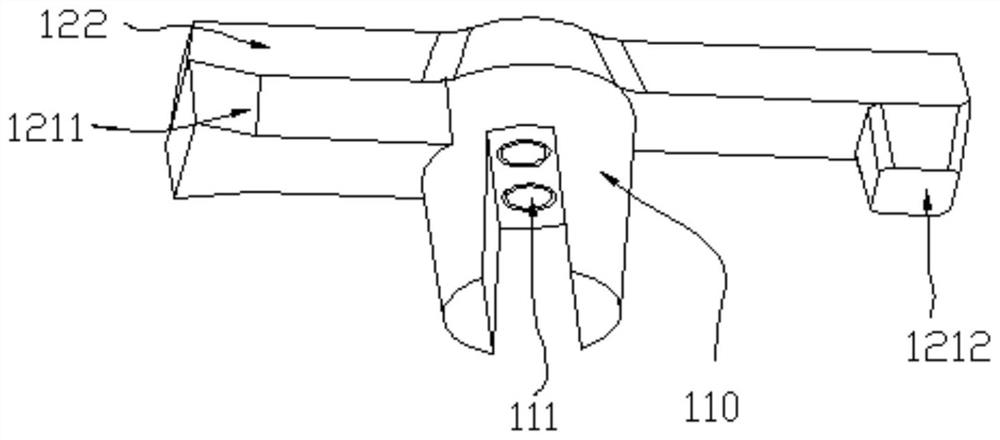

[0041] Different from Embodiment 1, the lower mold positioning structure 121 includes a lower mold positioning structure a1211 and a lower mold positioning structure b1212, and the lower mold positioning structure a1211 and the lower mold positioning structure b1212 are respectively arranged on both sides of the fixing seat 110. This further accurately locates the position of the sand core suspension nose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com