Patents

Literature

38results about How to "Eliminate operational hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

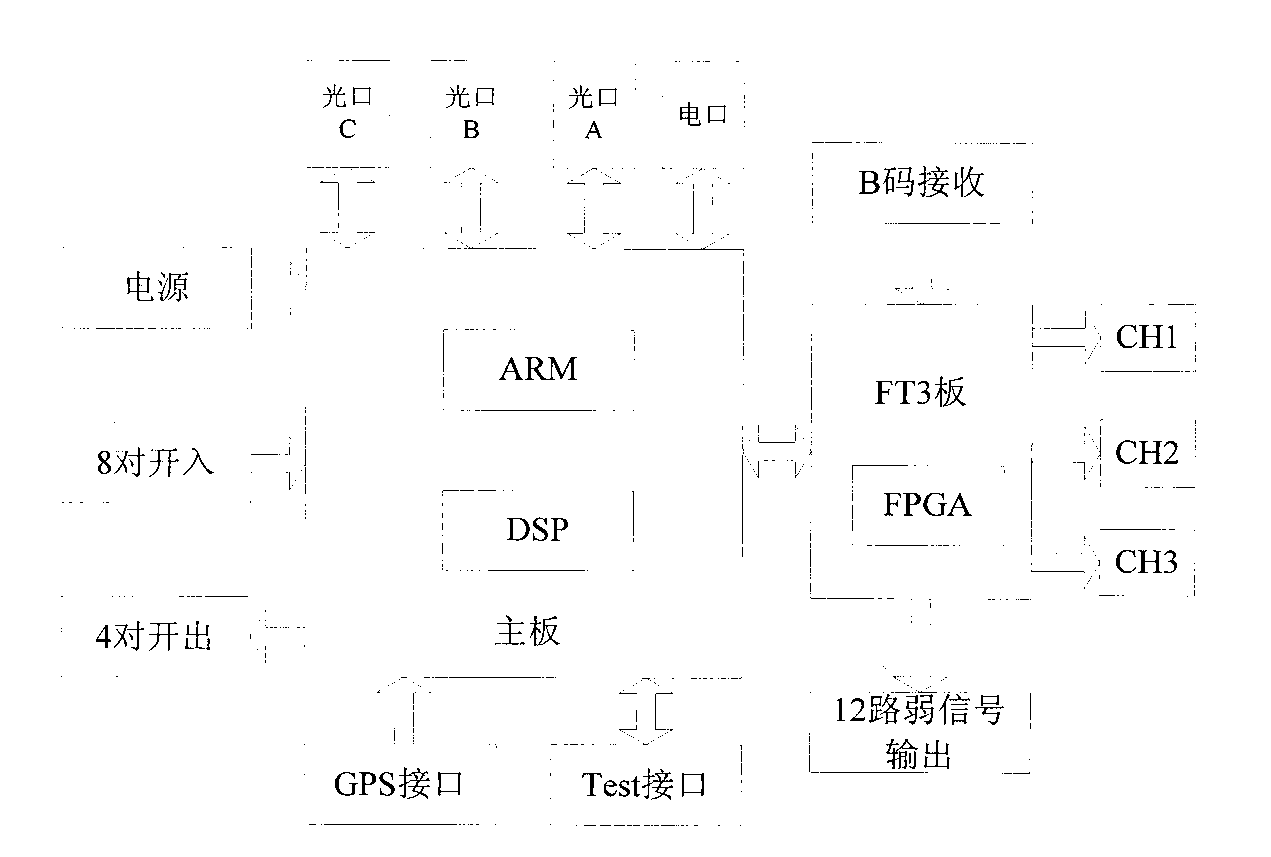

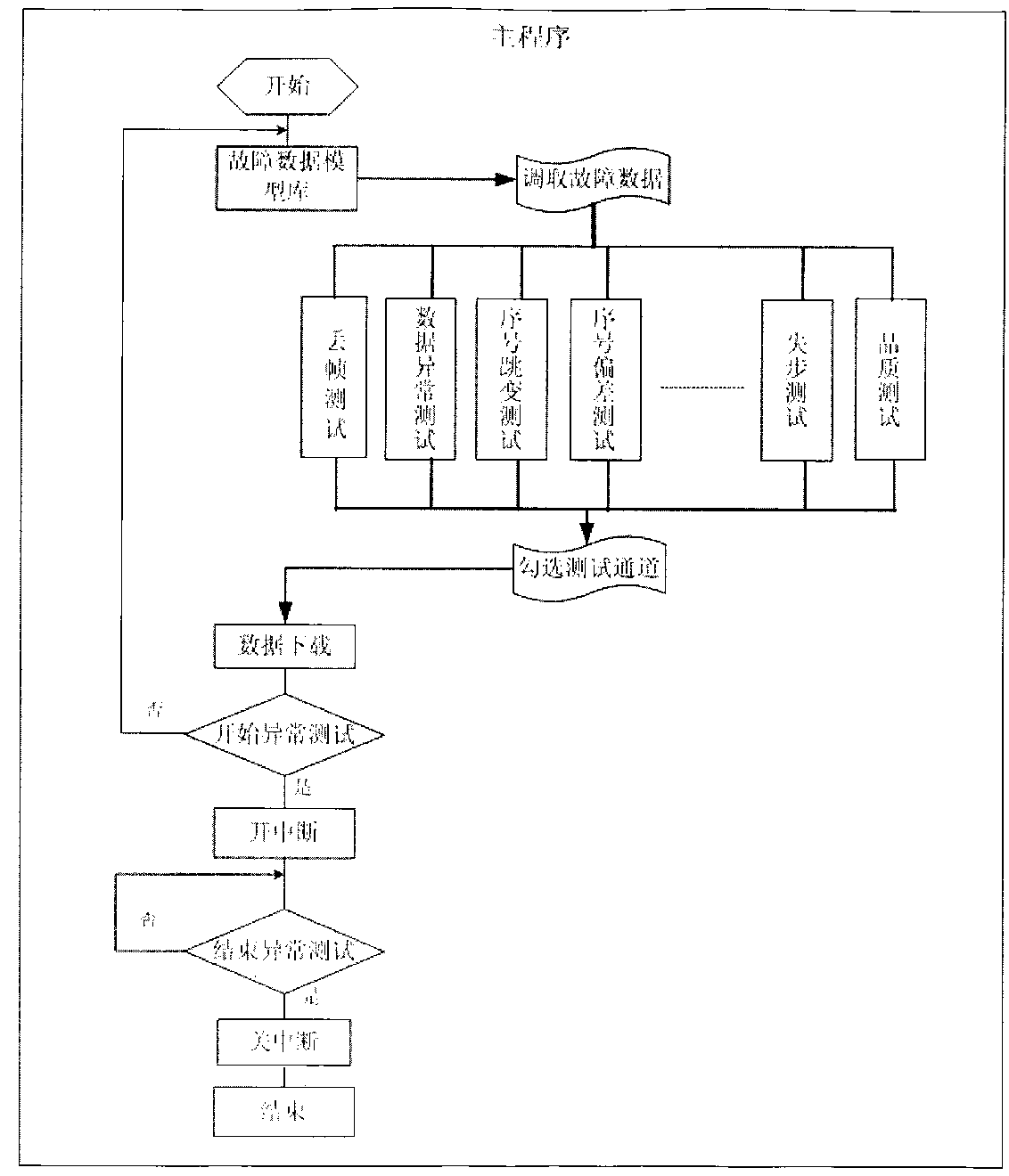

Testing method of digital protection tester with fault data model base for protection testing

ActiveCN102175940AEliminate operational hazardsPerfect debugging projectElectrical testingSpecial data processing applicationsTester deviceParallel I/O

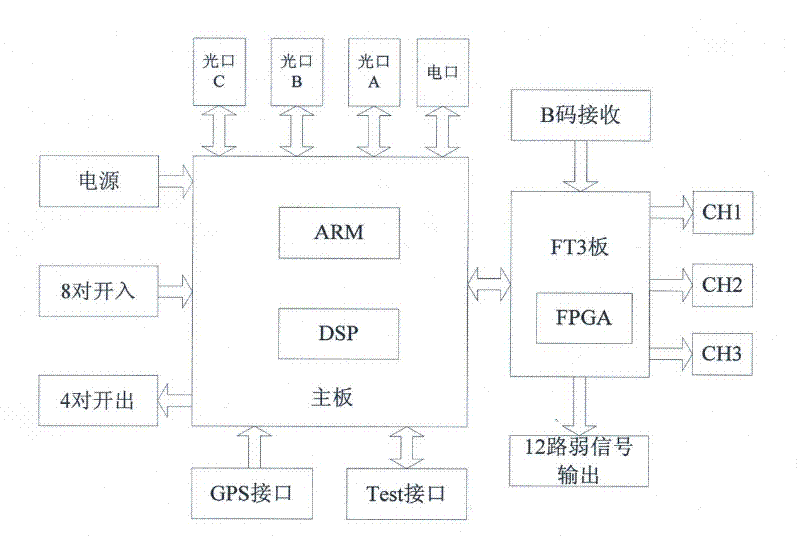

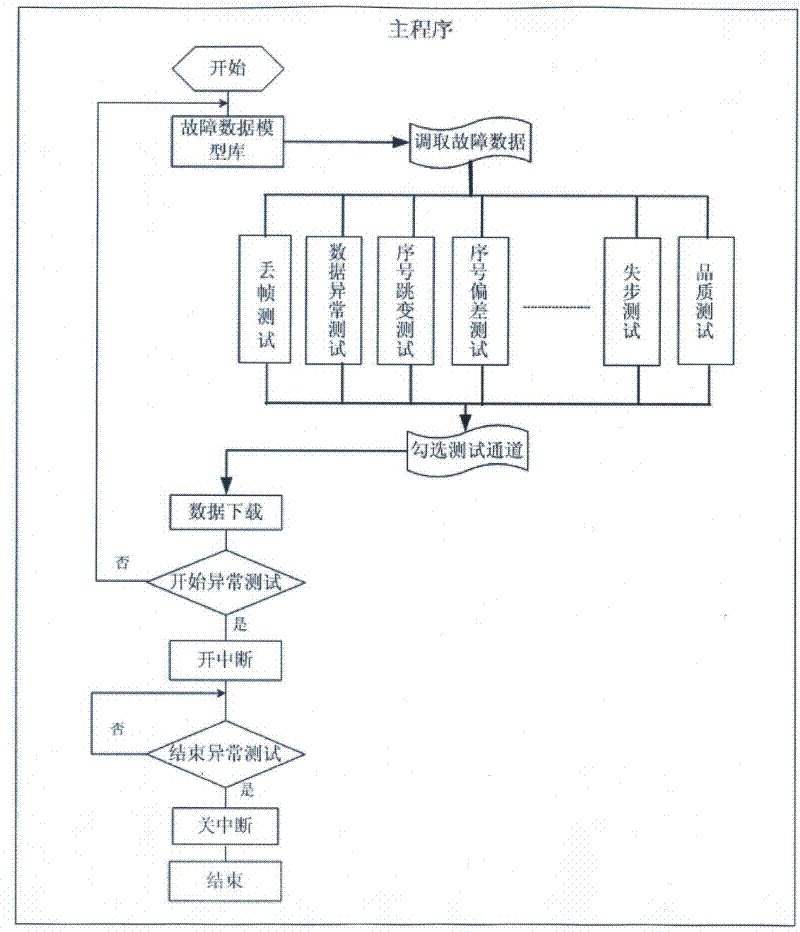

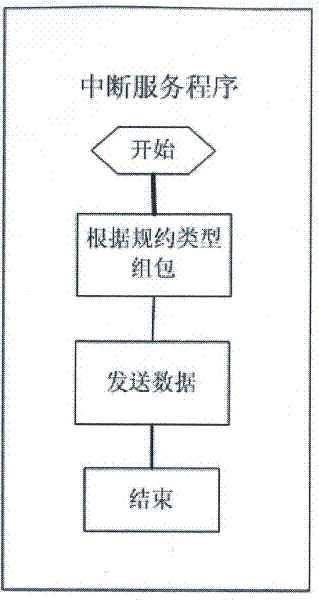

The invention relates to a digital protection tester with a fault data model base for protection testing, comprising an ARM (Advanced RISC Machines) processor, a DSP (digital signal processor), 8 inputs and 4 outputs, a FT3 plate, and a GPS (global positioning system) interface, wherein the ARM processor is connected with a host computer through an Ethernet interface, and are respectively connected three optical interfaces (A,B, C) to output data messages to a digital protection device to be tested through the Ethernet; the DSP is connected with the ARM processor through an HPI (hardware platform interface); the 8 input paths and 4 output paths are hung an external parallel I / O bus of the DSP; the FT3 plate is hung on the external parallel I / O bus of the DSP; the FT3 plate on an FPGA (Field Programmable Gate Array) has 12 weak signal output terminals and 3 groups of message output terminals and optical B-code interfaces meeting the standard of IEC60044-8; and the GPS interface is connected with the ARM processor; and the digital protection tester also has an abnormal data restoration and reproduction device. The digital protection tester can determine the effectiveness of the malfunction prevention measures of the digital protection device according to the fault data model base, thereby perfecting the performance of the digital protection device.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

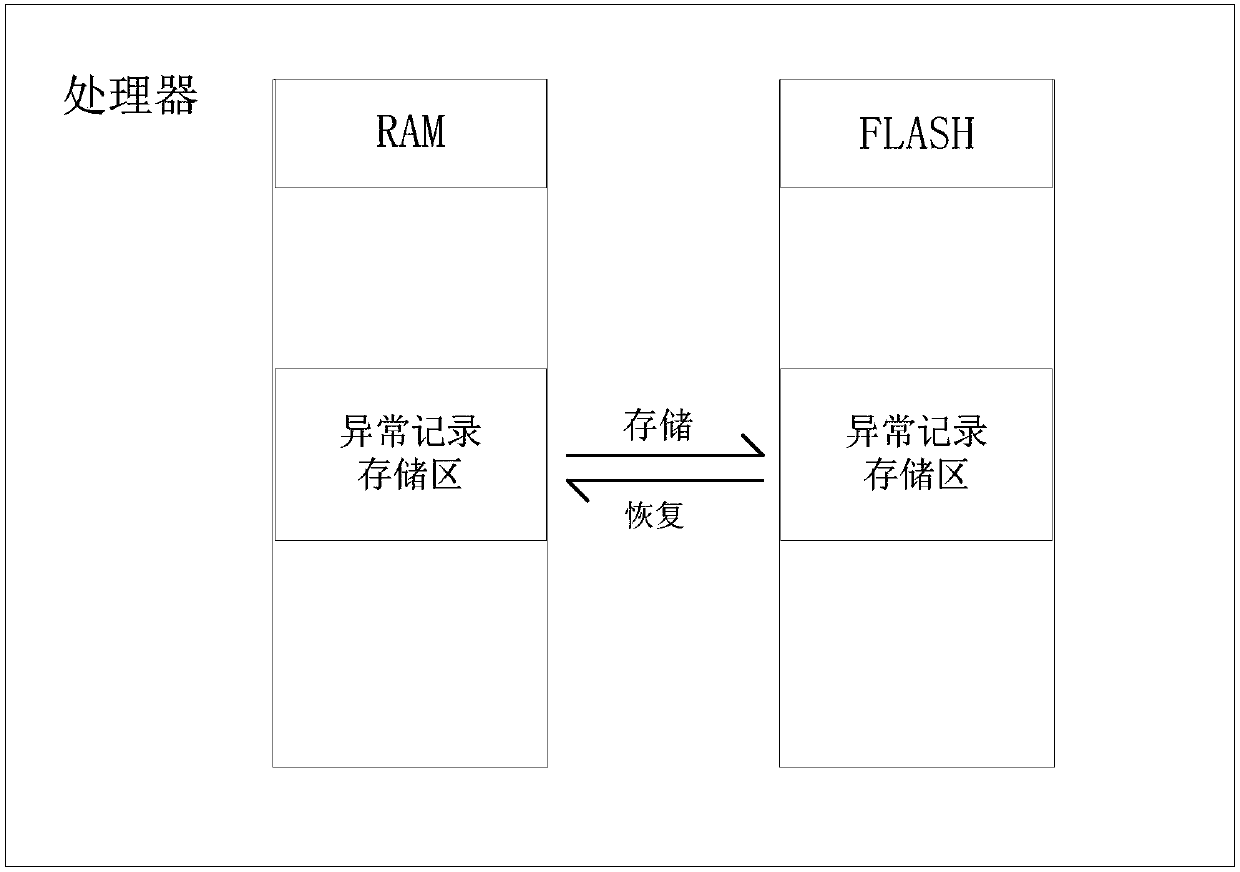

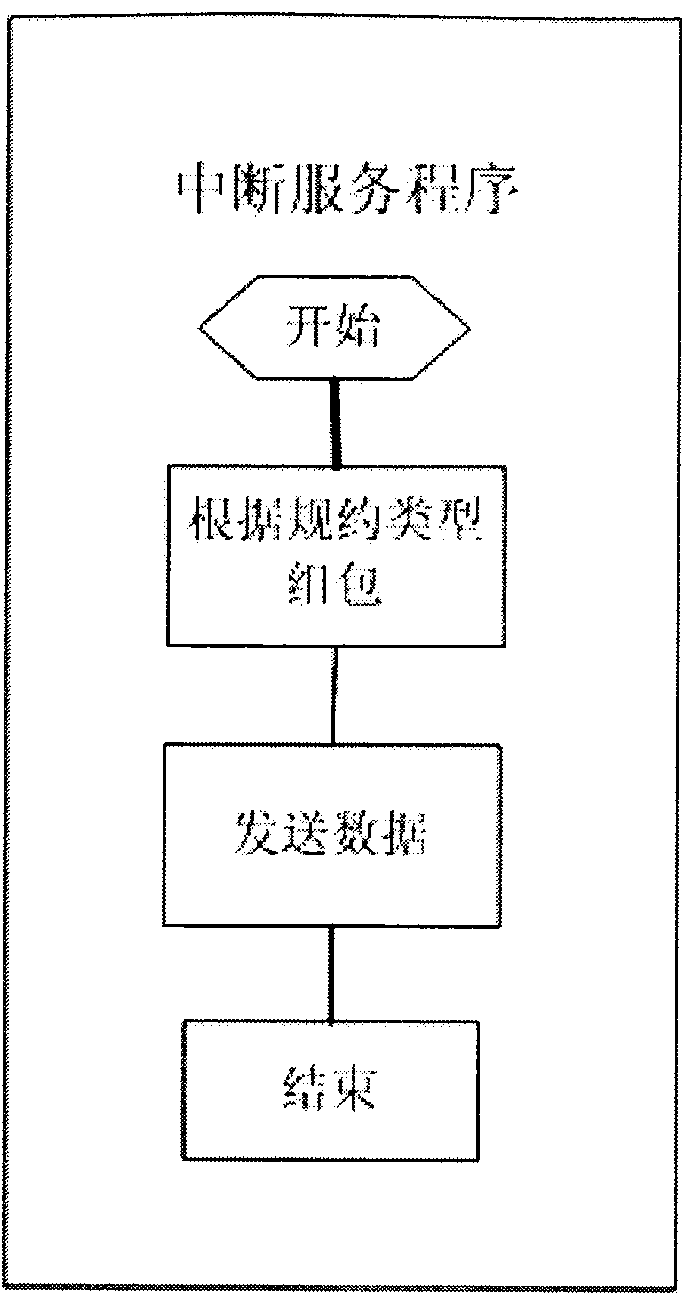

Recording and displaying method for exception record of embedded system

ActiveCN107908495AEasy to locate the cause of the abnormalityEliminate operational hazardsFault responseEmbedded system

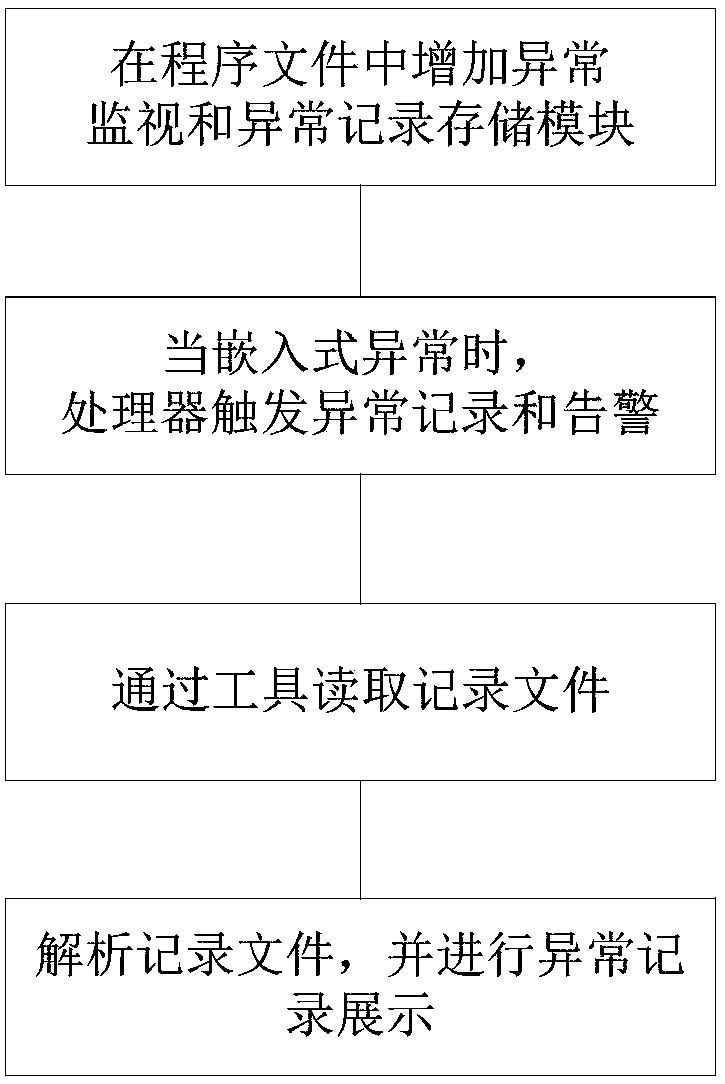

The invention discloses a recording and displaying method for the exception of an embedded system. The method comprises the following steps that: S1: in the embedded system, setting an exception monitoring module and an exception recording and storing module; S2: when the exception monitoring module monitors that the embedded system is exceptional, triggering the exception recording and storing module, and giving an alarm; S3: recording an exception recording file; and S4: analyzing the recording file, and displaying the exception recording. By use of the method, the processor state information and the system operation information when the embedded system is abnormal are recorded on line, and the recorded file is selected to be read online or offline according to a device resetting situation. Then, the processor exception information is displayed so as to conveniently position exception reasons. A visual and accurate basis is provided for problem positioning, so that operation hidden dangers are eliminated in time, and system operation reliability is improved.

Owner:NR ELECTRIC CO LTD +1

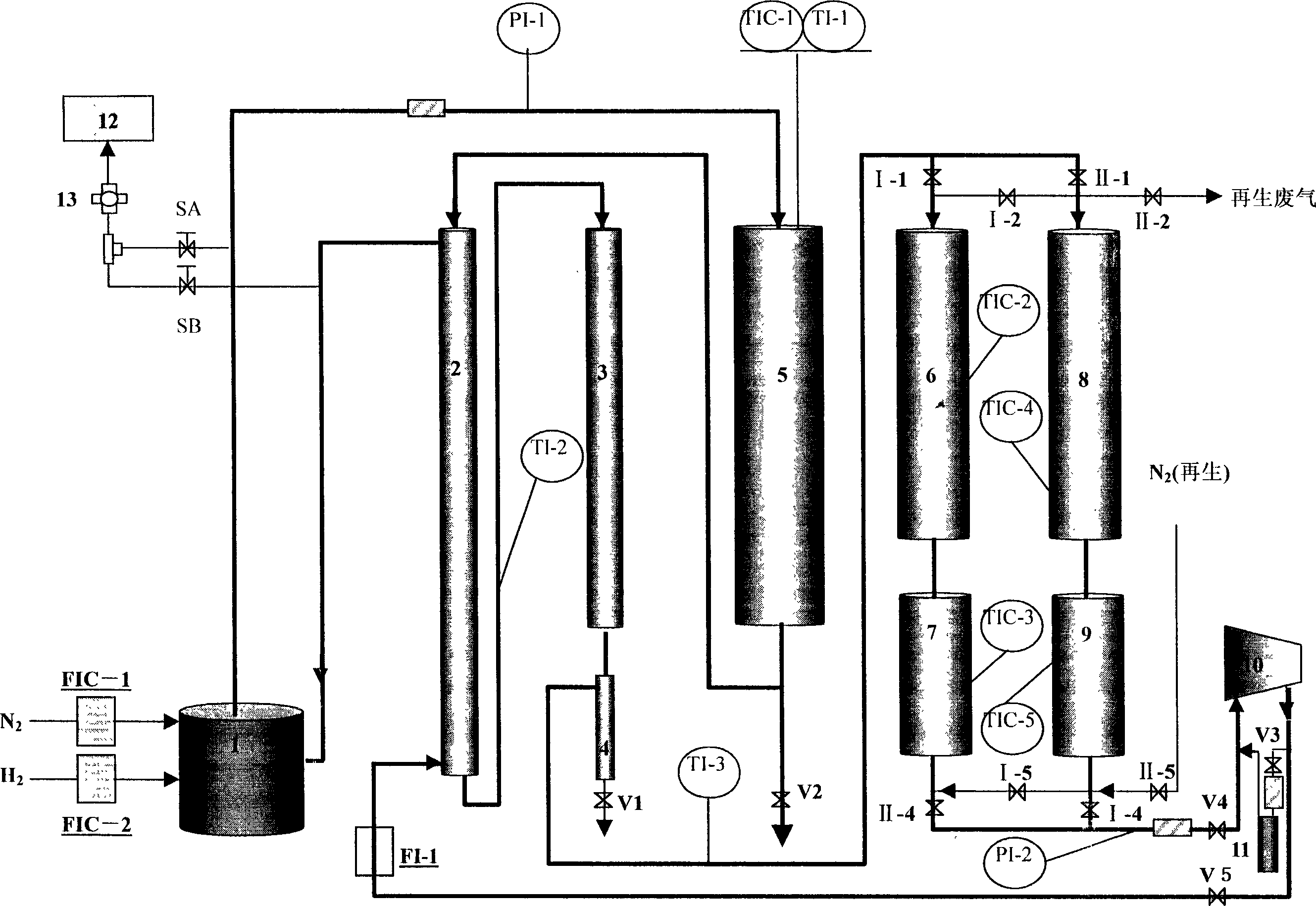

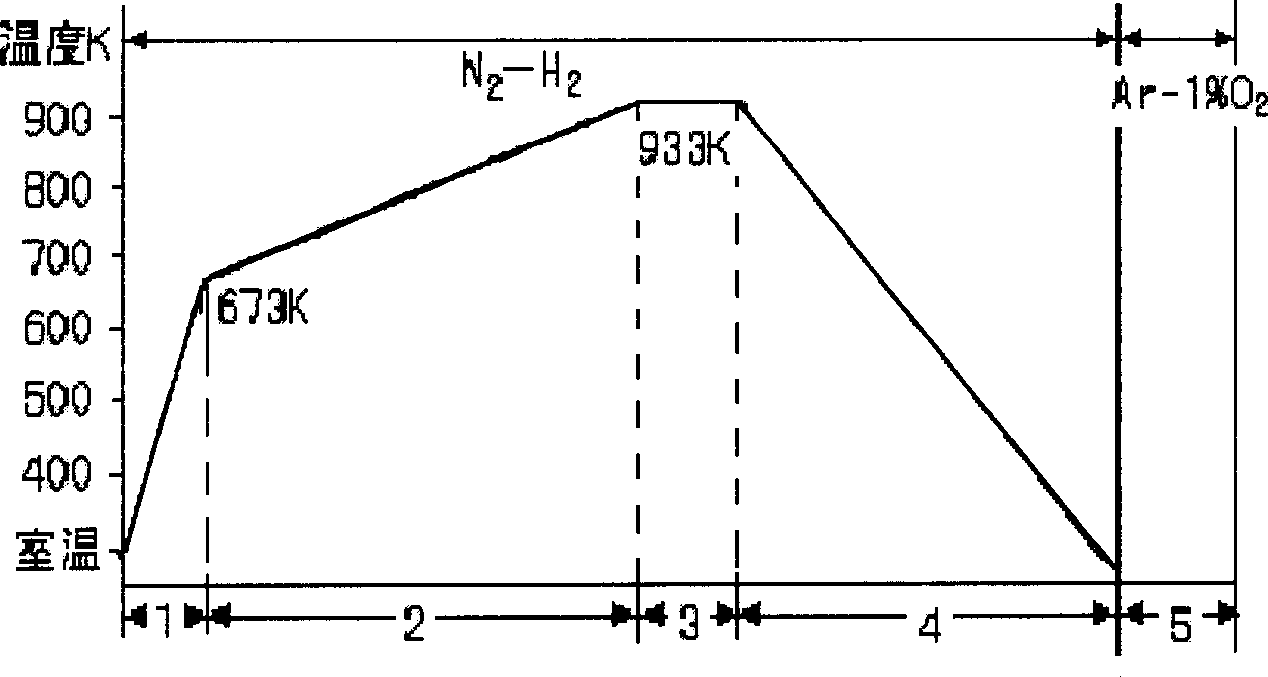

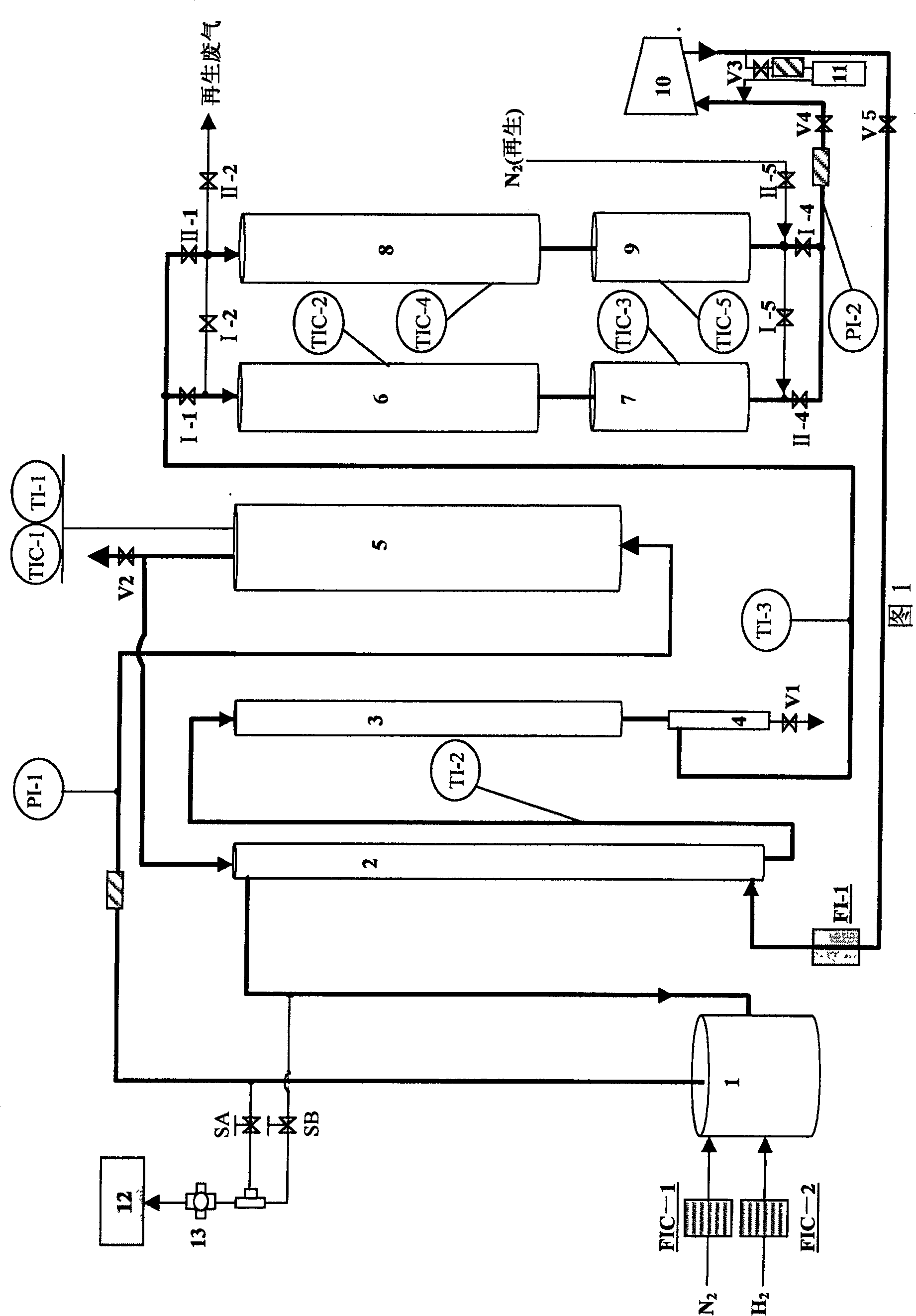

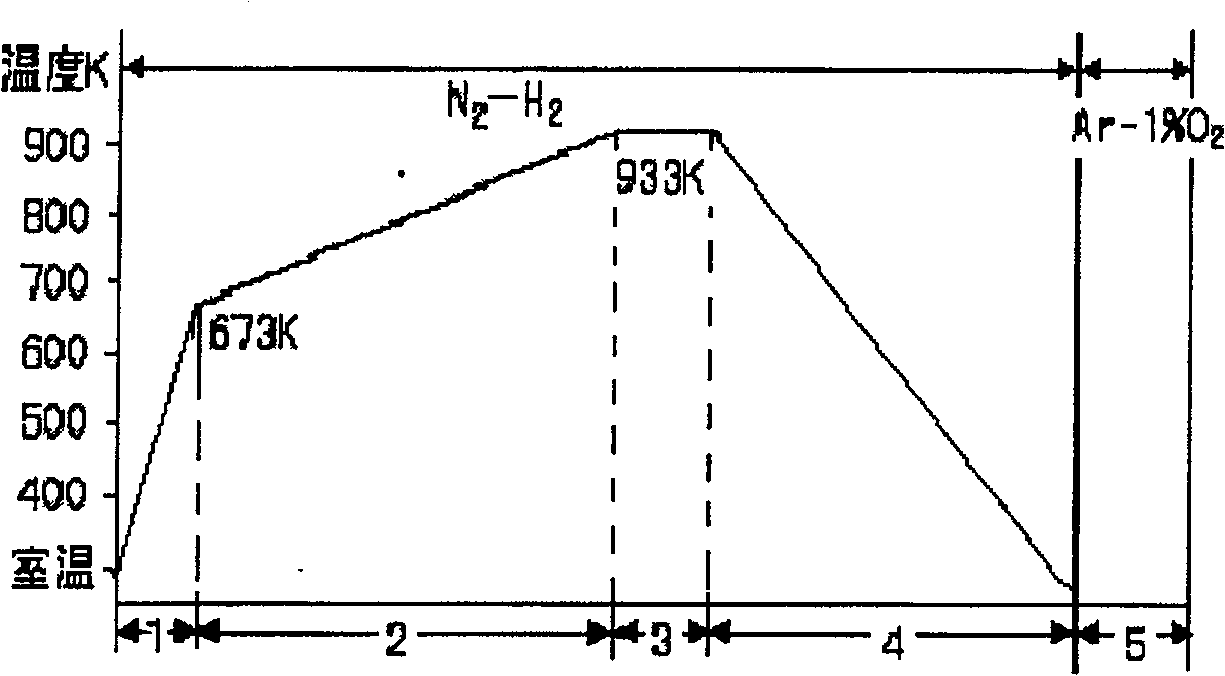

Process and apparatus for preparing metal nitride catalyst material

InactiveCN1887421AIncrease surface areaLarge specific surface areaCatalyst activation/preparationReaction temperatureNitride

The present invention relates to catalyst technology, and is especially process and apparatus for preparing metal nitride catalyst material (gamma-Mo2N). MoO3 / TiO2, MoO3 / NiO-TiO2, MoO3 / Al2O3-TiO2 or MoO3 / Al2O3 is set in a reactor to replace MoO3 with reducing N2-H2 so as to prepare supported metal nitride catalyst Mo2N / TiO2, Mo2N / NiO-TiO2, Mo2N / Al2O3-TiO2 or Mo2N / Al2O3. The reaction conditions include N2-H2 ratio in the gas mixture of 1 / (3-5), reaction temperature of 933K+ / -10K and holding time of 0.5-1 hr. The apparatus includes mainly a mixer, a reactor, a heat exchanger, and a gas chromatogaph connected through pipeline. The present invention can prepare gamma-Mo2N with specific surface area as great as 150 sq m / g, and the preparation process has its operation simpler than that with NH3.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

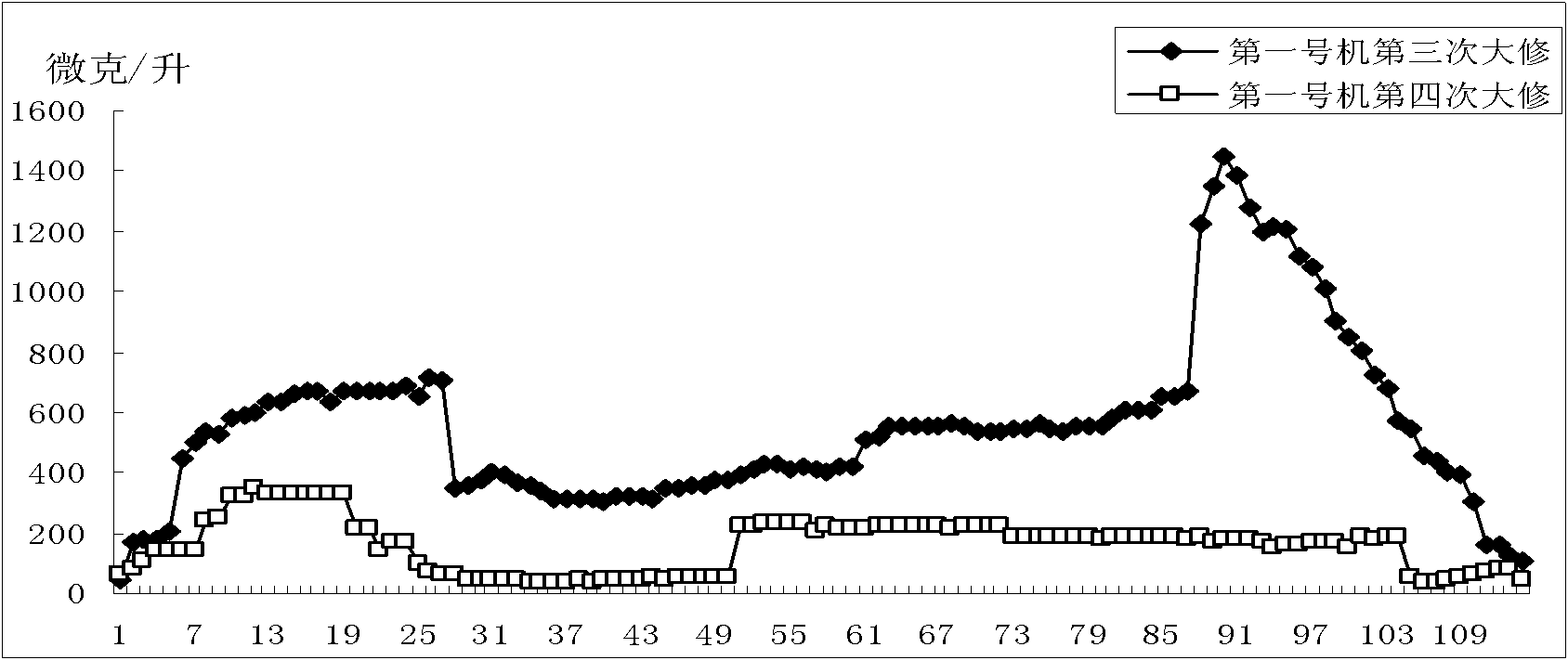

Method for controlling concentration of sulfate radical of pressurized water reactor nuclear power plant unit-loop

ActiveCN103177781AGood control effectIncreased operating lifeNuclear energy generationNuclear monitoringWater storageSulfate radicals

The invention provides a method for controlling concentration of sulfate radical of a pressurized water reactor nuclear power plant unit-loop. The method comprises the following steps of (1) clearing cation resin in a purification unit B of a spent fuel pool and boron box water purification system (3); (2) circulating according to an order of a boron water storage system (2), the spent fuel pool and boron box water purification system (3), the spent fuel pool (1) and the boron water storage system (2) after a nuclear power plant unit is shut down in a cold state; (3) restoring a mode of two cation beds and an anion bed of the spent fuel pool and boron box water purification system (3) to run when the concentration of the sulfate radical of a loop cooling agent is controlled below 500mug / L; and (4) stopping circulating when the concentration of the sulfate radical is greater than 500mug / L, clearing the cation resin in the purification unit C, and running in a mode of a single anion bed. An extra system facility does not need to be increased; the extra chemical agent does not need to be added to change the water quality; and the target of removing the sulfate radical can be achieved by adjusting the running mode of the purification system.

Owner:JIANGSU NUCLEAR POWER CORP

Composite insulator and its production

The invention is concerned with the high-voltage transformer equipment, especially the compound insulator and the manufacture technics, the technics processes are: 1) disposes the surface of the preparing rubber-setting part; 2) sets rubber; 3) disposes the surface of the preparing vulcanization part; 4) vulcanize the formed umbrella cover; the processes can cycle timely. The compound insulator includes the main body (-) of the insulator, the porcelain mandrel (-) on the main body (-)of the insulator, and the silicon rubber umbrella-skirt (-), the characteristic is: the porcelain mandrel (-) on the main body (-)of the insulator covers the integrative silicon rubber umbrella-skirt (-) outside. The invention is simple technics, easy clean, high efficiency.

Owner:西安电瓷研究所有限公司

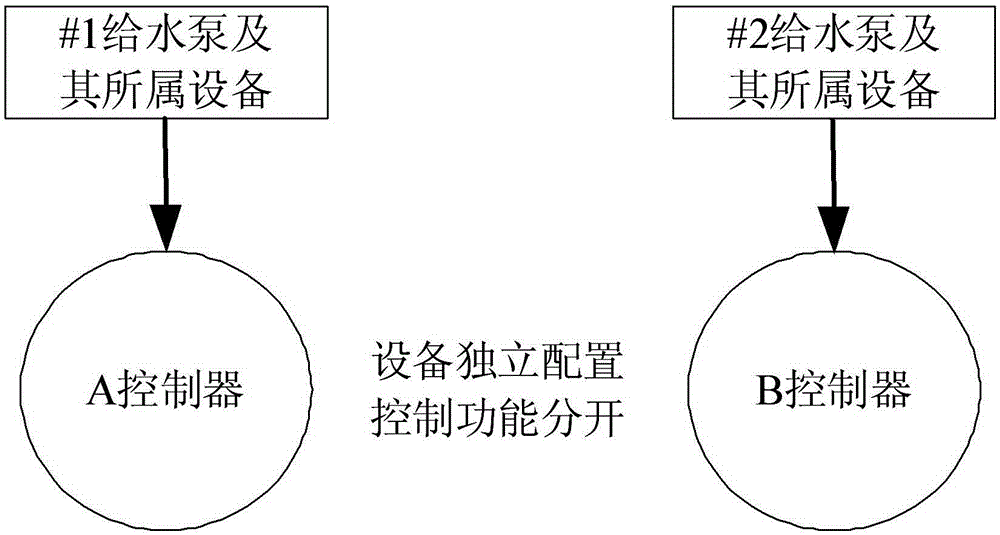

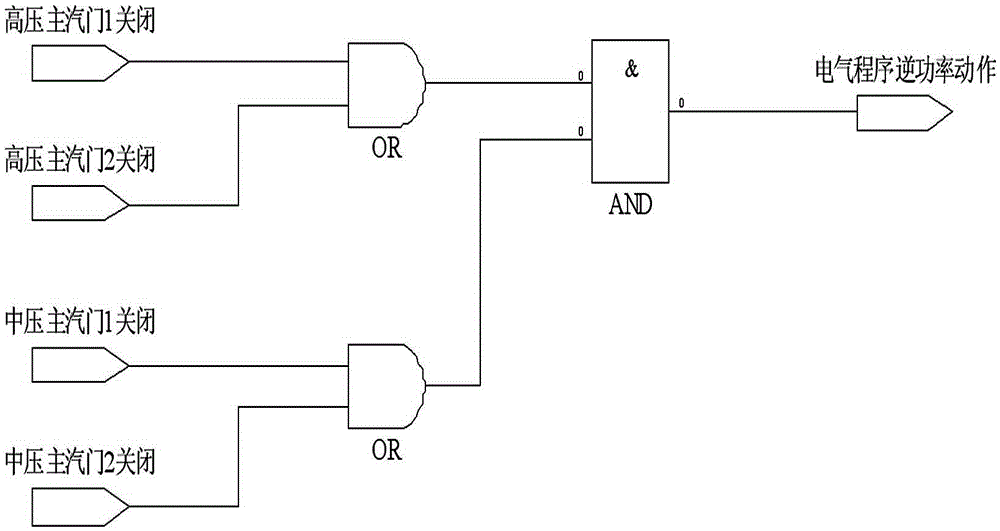

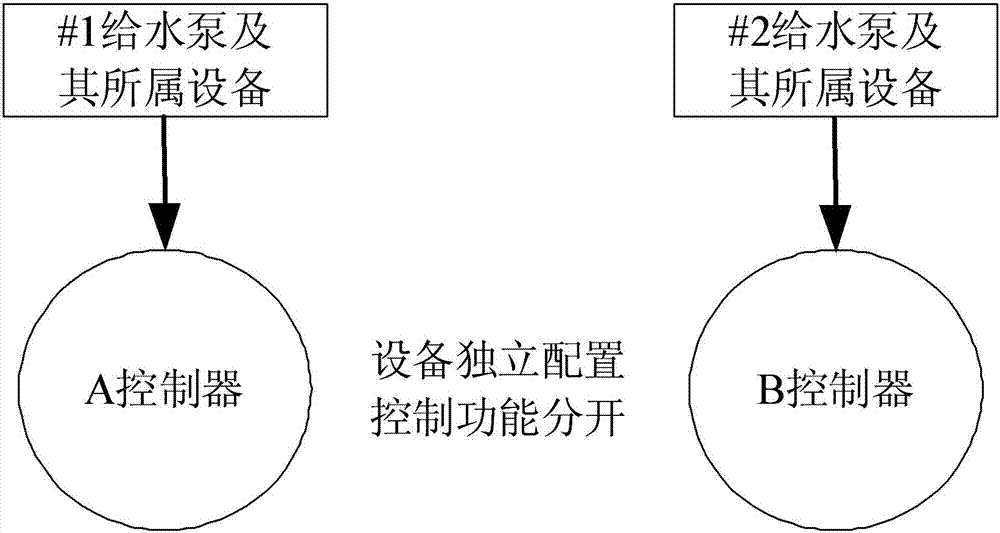

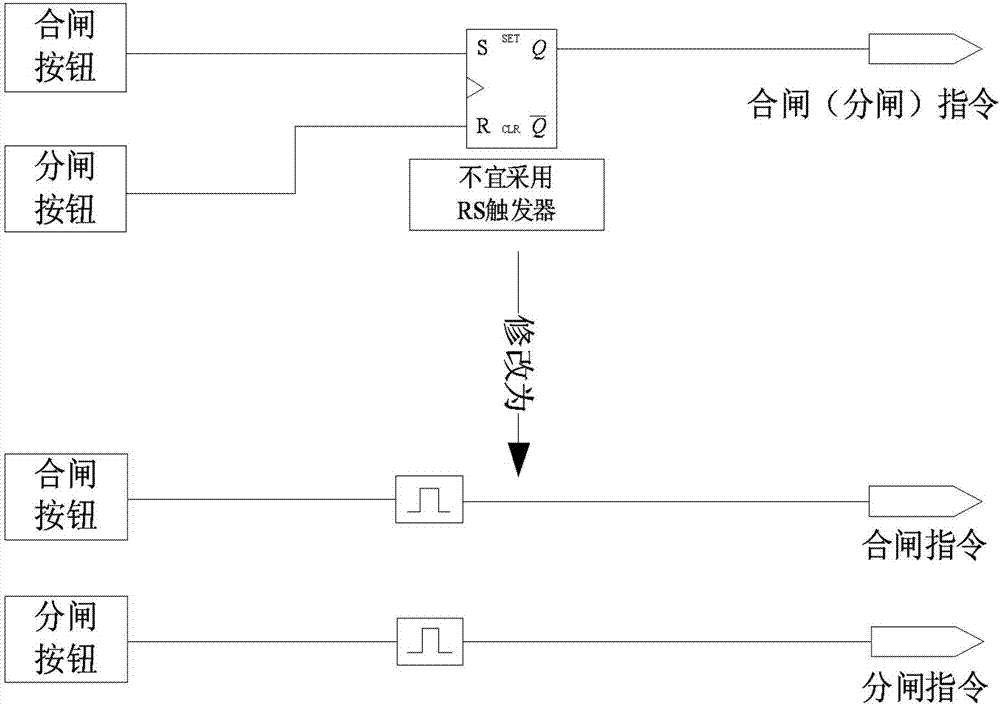

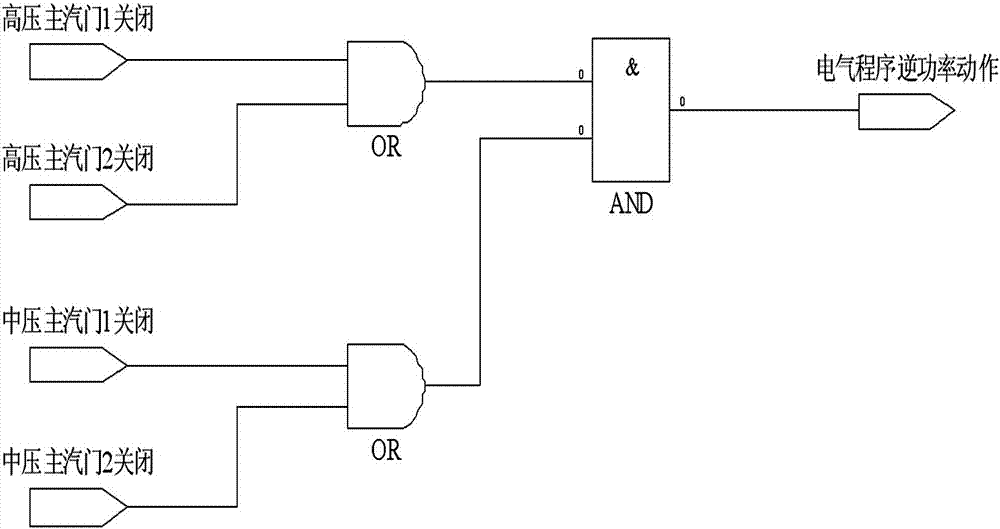

Checking method for preventing failure of thermal process protection system of thermal generator set

ActiveCN105332744ACoverage determinationVerification steps are concise and clearMachines/enginesSafety/regulatory devicesAutomatic controlEngineering

The invention belongs to the technical field of automatic control of thermal generator sets, and particularly relates to a checking method for preventing failure of a thermal process protection system of a thermal generator set. The thermal process protection system comprises the following elements: design of the logic of a main protection system of the set, design of an important auxiliary engine protection system of the set, measuring and sampling by an instrument, and allocation of DCS hardware addresses; the inspection method comprises the following steps: collecting the design data of the thermal process protection system, and knowing the composition condition, the operation mode and the operation parameters of the thermal process protection system of the thermal generator set; checking the thermal process protection system of the thermal generator set by referencing to the latest national electric power industry regulations and specifications, and finding design defects and potential safety hazards; proposing a regulating solution for on-site regulation, finishing a static test and a dynamic test, and putting the thermal generator set into safe operation; and if the requirements are not met, returning to the regulation and test steps till meeting the requirement. The checking method has the advantages that the checking steps are simple and clear, the safety and the reliability are realized, the on-site debugging process is simple, and the operation and the implementation are convenient.

Owner:STATE GRID CORP OF CHINA +1

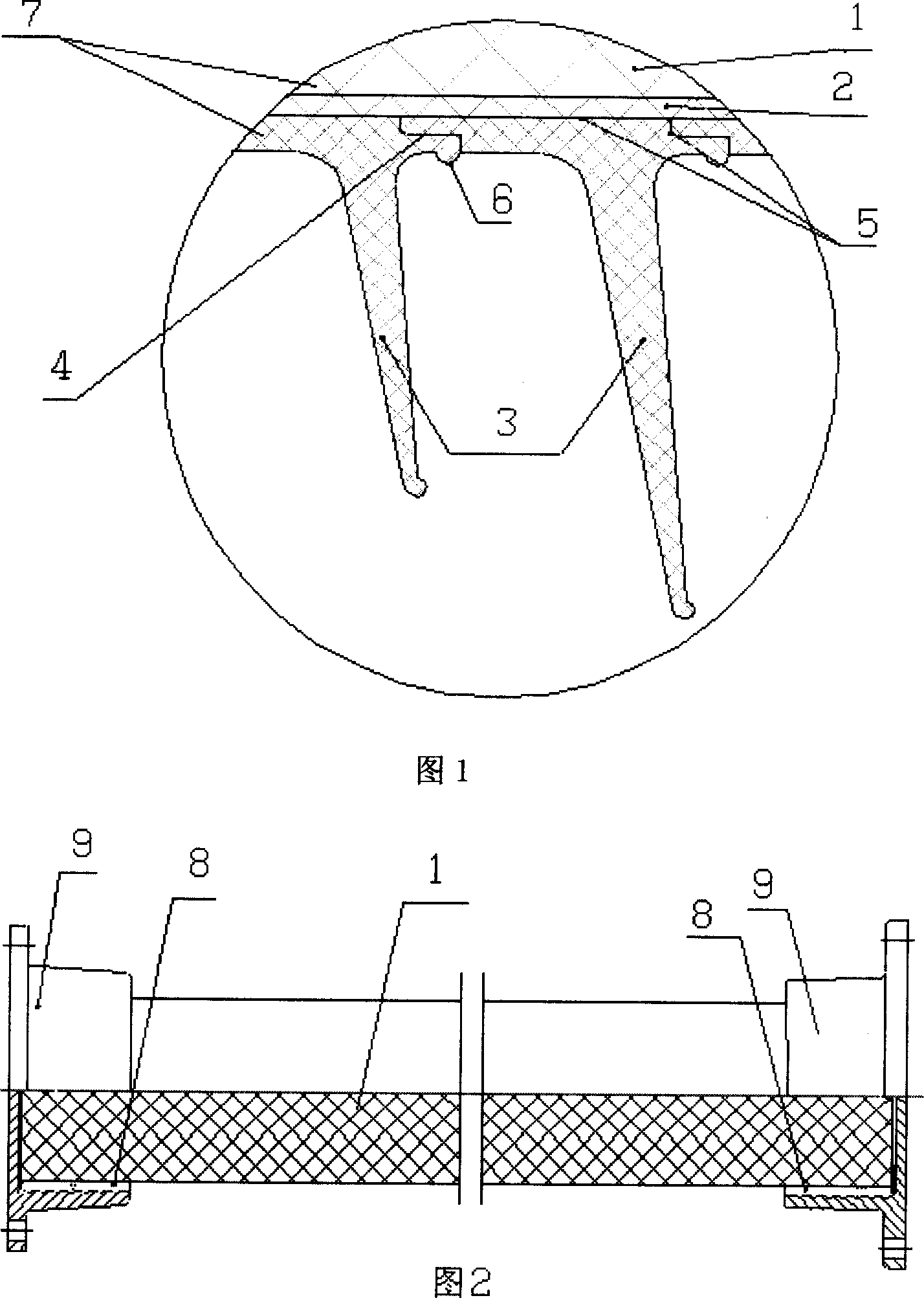

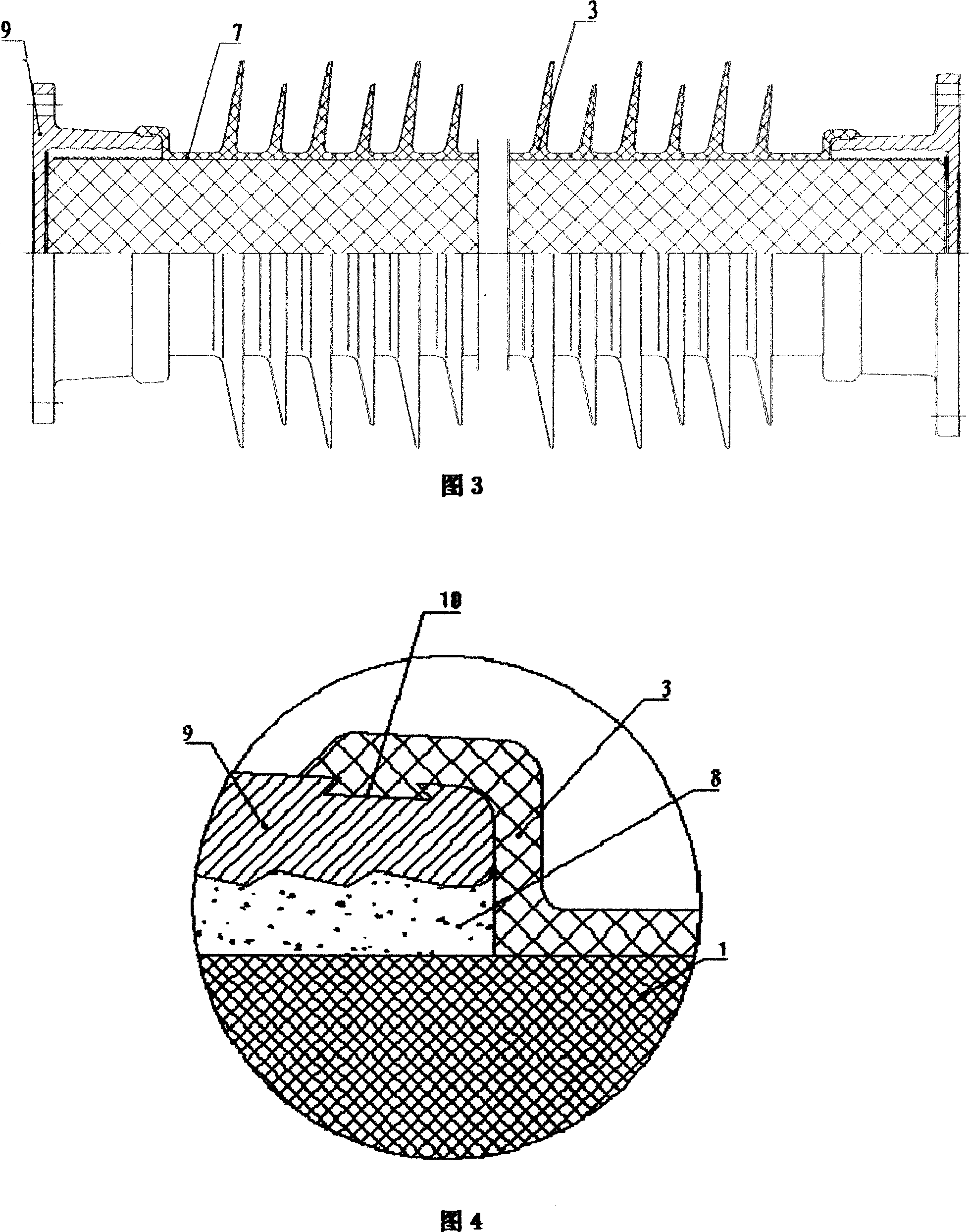

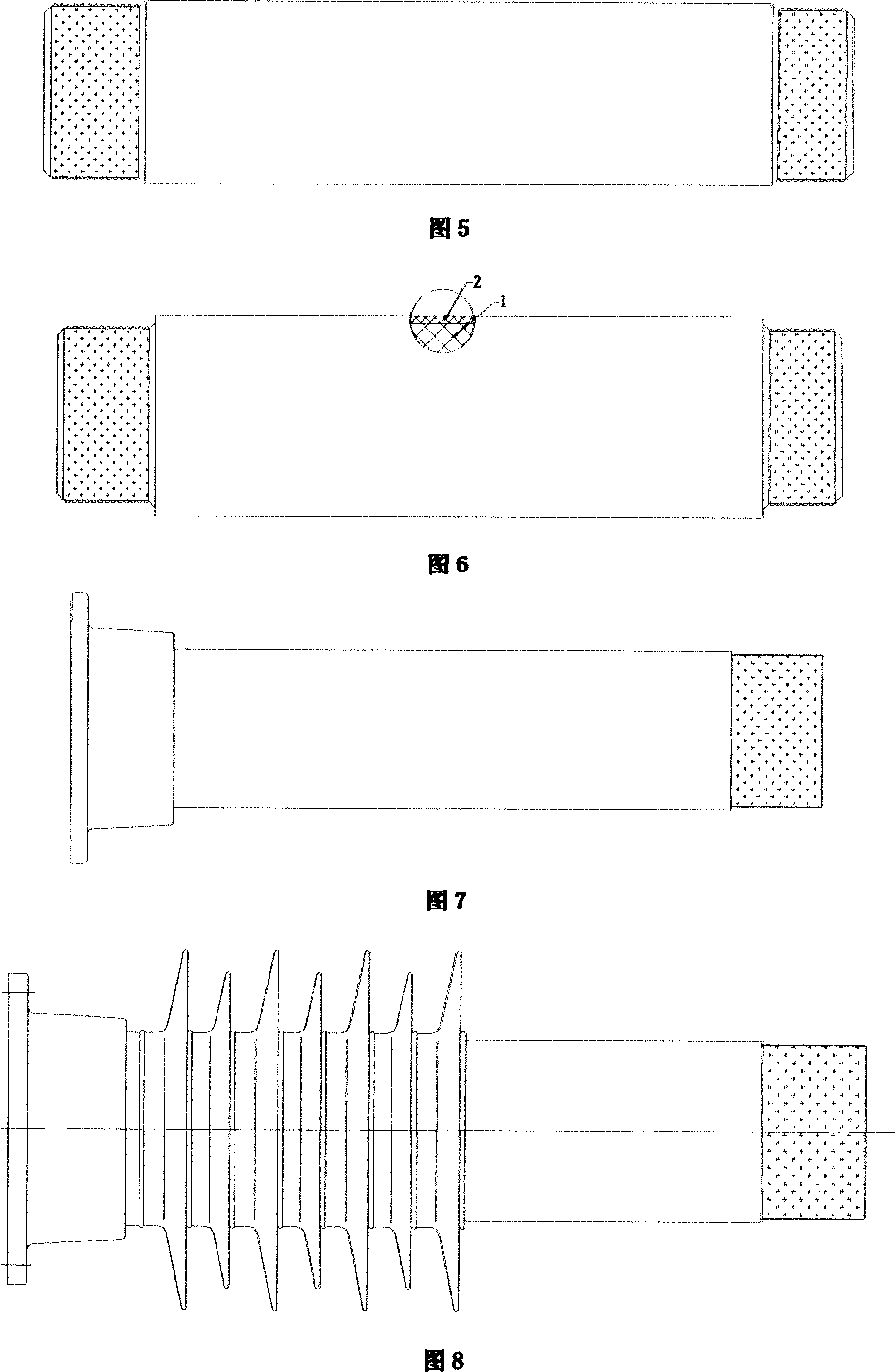

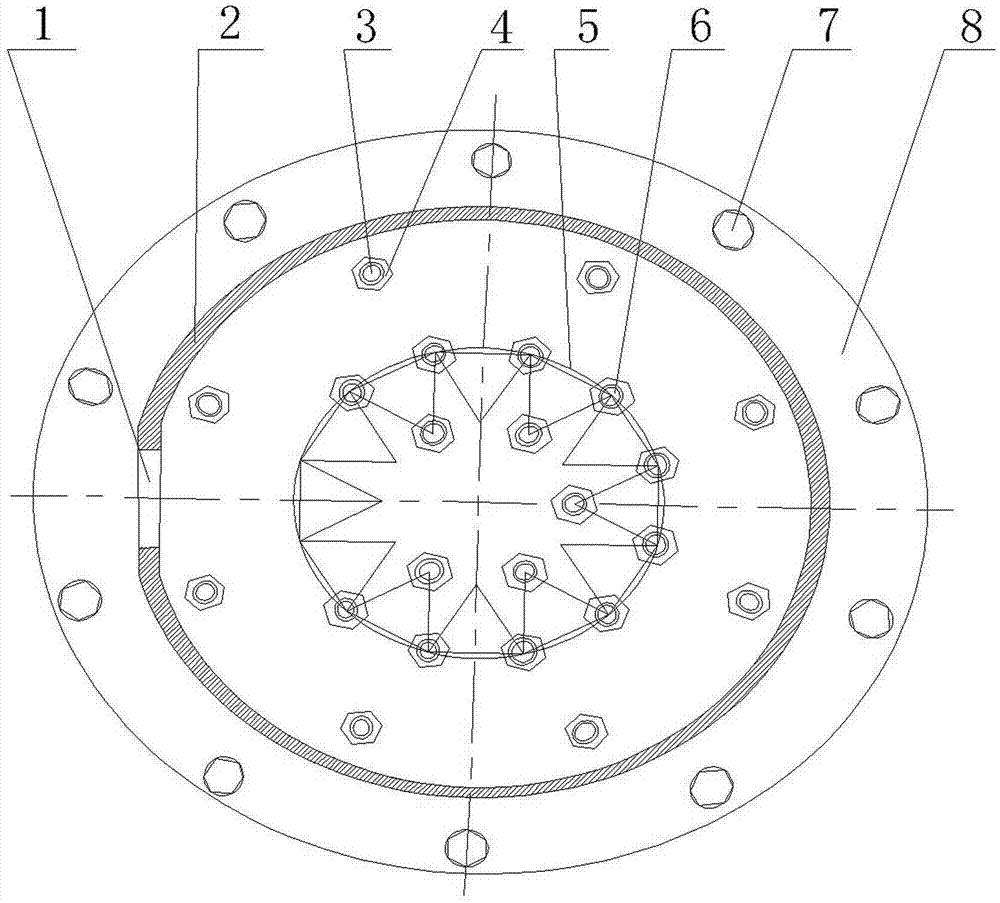

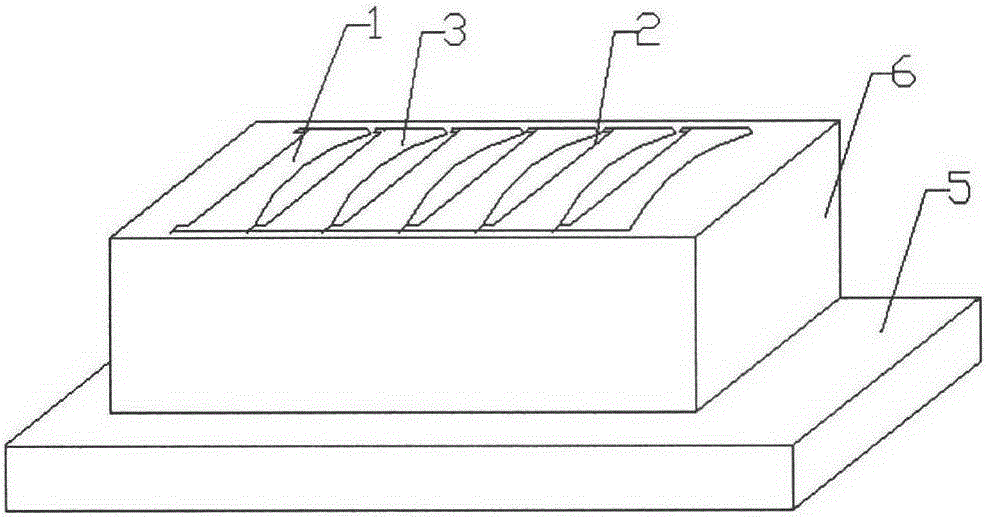

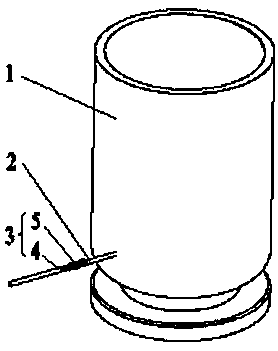

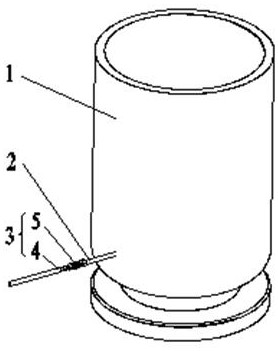

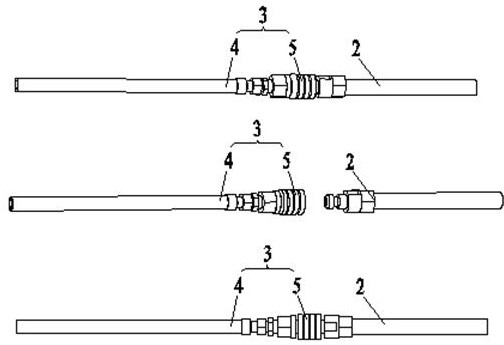

Drum type compensator for main pipe of coke oven gas and manufacturing method thereof

InactiveCN103557400AExtended operating cycleEliminate operational hazardsPipeline expansion-compensationArc welding apparatusNitrogenNitrogen gas

The invention relates to a drum type compensator for a main pipe of coke oven gas. The drum type compensator comprises a 1# arc plate 1, a 2# arc plate 2, a 3# arc plate 3 and annular vertical plates 4, and is characterized in that the 1# arc plate 1, the 2# arc plate 2 and the 3# arc plate 3 are same in shape and have same radian of 120 degree; spaced ripples 8 are arranged on a middle part of each arc plate along a direction parallel to an arc edge; after the straight edges of adjacent arc plates are welded together, a cylinder is formed; spaced annular ripples are formed on a middle section of a side wall of the cylinder; two end faces of a cylinder shell are respectively welded with the annular vertical plates 4; the inner diameter of the annular vertical plates 4 is matched with the outer diameter of the main pipe 9 of the coke oven gas; a bleeder threaded head 5 and a reserved bleeder threaded head 6 are respectively arranged on a side wall of the cylinder shell; and symmetrical with the bleeder threaded head 5 and the reserved bleeder threaded head 6, a reserved nitrogen pipe threaded head 7 is arranged on the side wall of the cylinder shell. The drum type compensator can prevent a serious accident caused by gas leakage after a compensator for the main pipe of coke oven gas has a leakage point. The production safety can be ensured.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

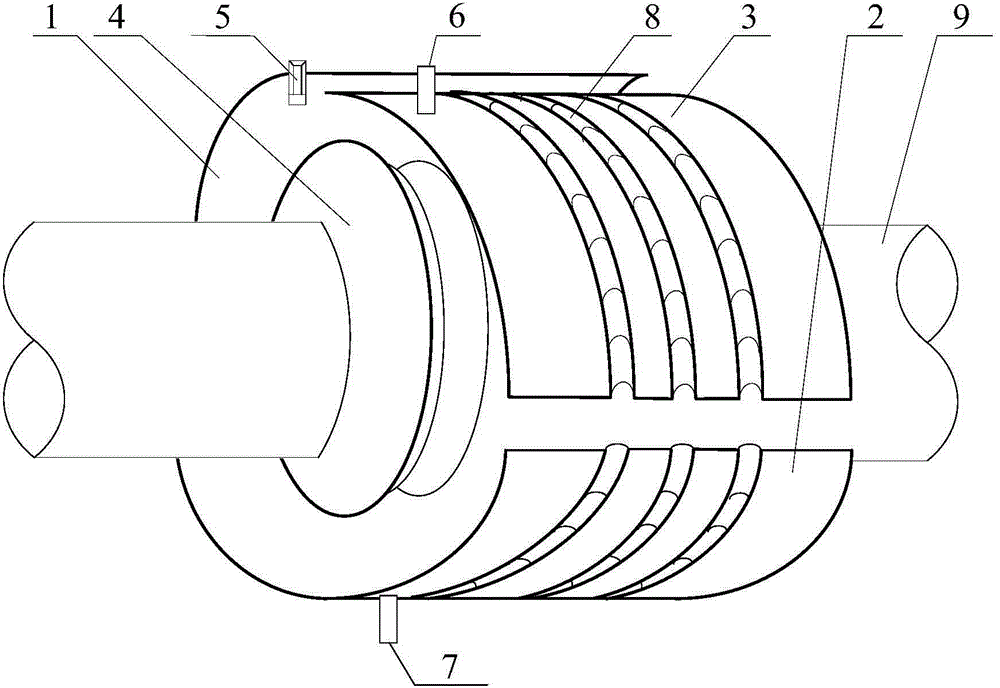

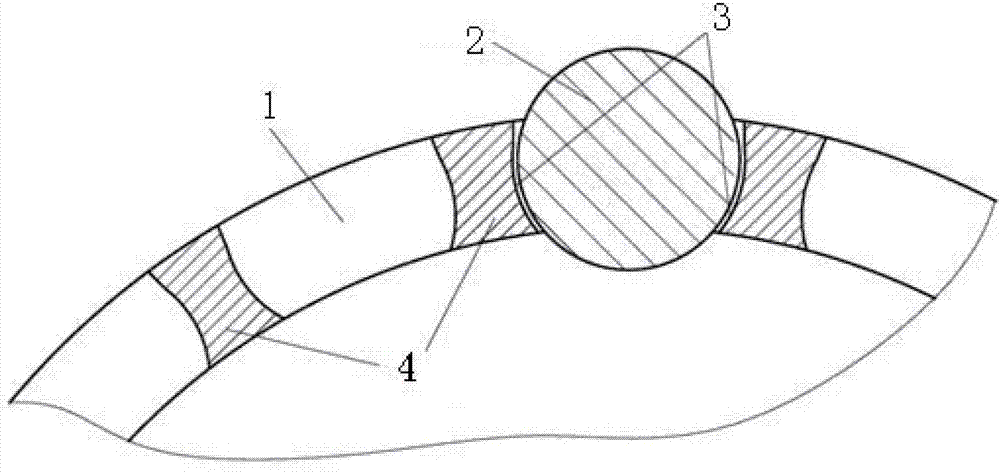

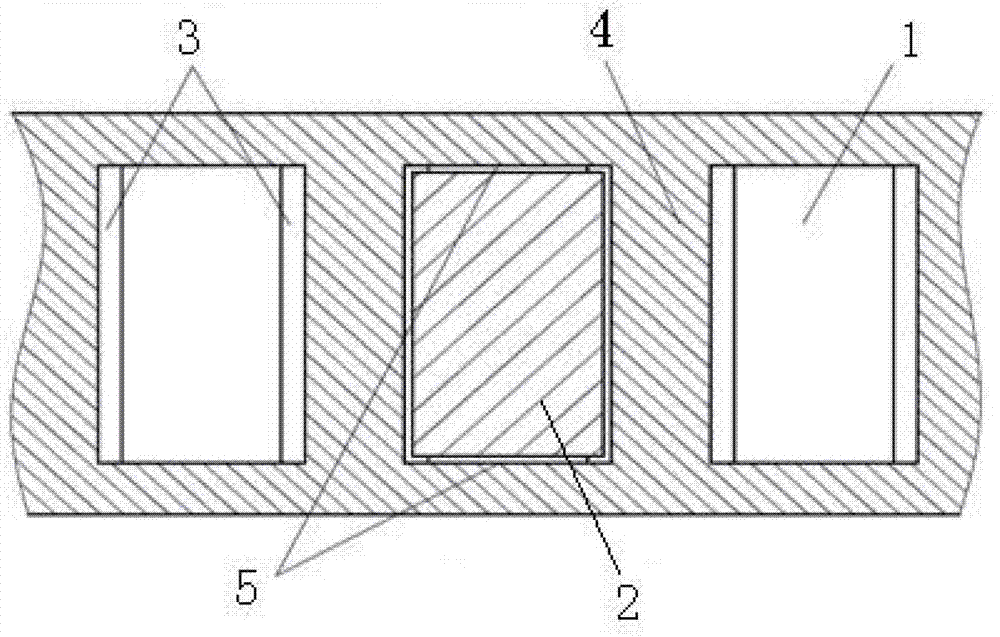

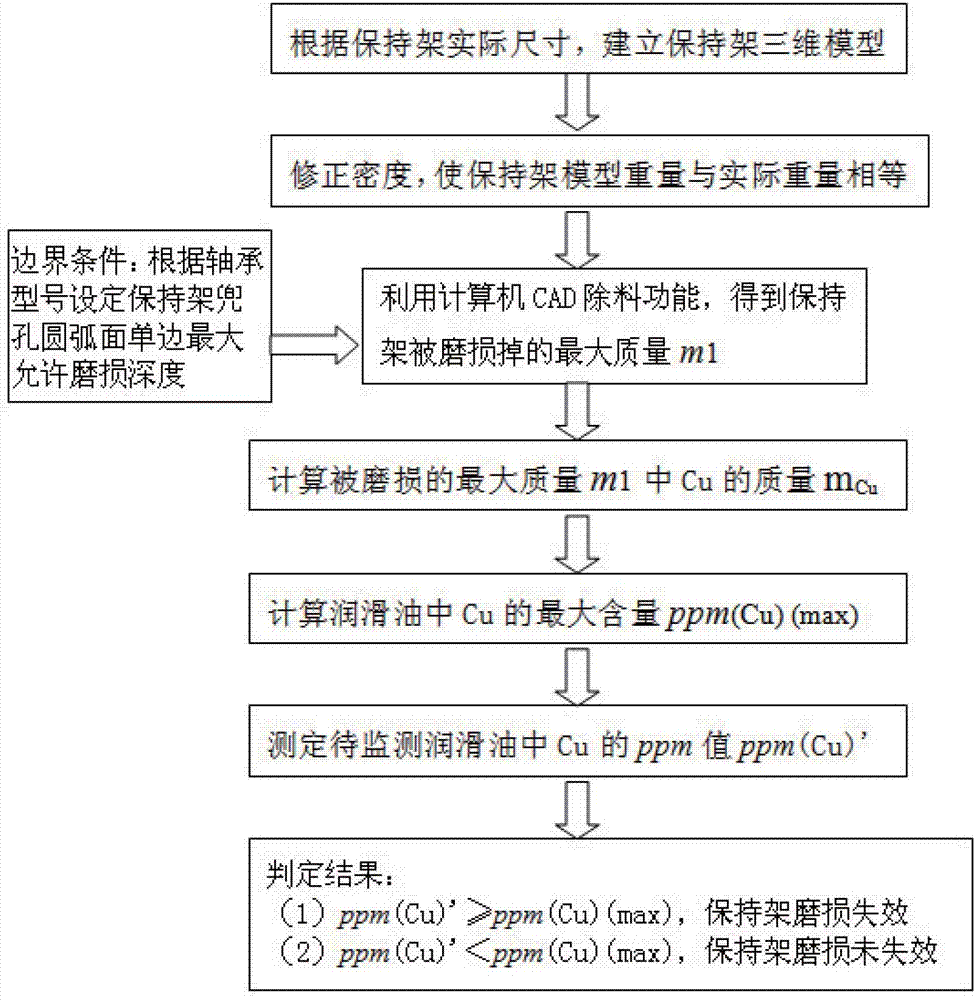

Method for judging whether abrasion of bearing retainer of locomotive traction motor fails or not

ActiveCN103292997BEliminate operational hazardsReduce misjudgmentMachine bearings testingComputer Aided DesignCu element

The invention provides a method for judging whether an abrasion of a bearing retainer of a locomotive traction motor fails or not. The method comprises the steps of S1, establishing a copper alloy retainer three-dimensional model through computer-aided design (CAD); S2, correcting the calculated weight of the three-dimensional model in the CAD to be equal to the actual weight; S3, according to a selected bearing model, setting the unilateral maximum permissible abrasion depth of an arc surface of a pocket of the copper alloy retainer, and obtaining the maximum mass m1 of the copper alloy retainer, which is abraded, through the CAD; S4, calculating the mass mCu of Cu elements in the maximum mass m1; S5, calculating the maximum content ppm(Cu)(max) of the Cu elements in lubricating oil; and S6, measuring a ppm value ppm(Cu)' of the Cu elements contained in the lubricating oil to be monitored in a locomotive, and comparing the ppm(Cu)' with the ppm(Cu)(max), wherein if the ppm(Cu)' >= the ppm(Cu)(max), the abrasion of the retainer fails and can not be used any longer, and if the ppm(Cu)' < the ppm(Cu)(max), the abrasion of the retainer does not fail. By the aid of the judging method, a scientific and reliable judgment foundation is provided to monitor whether the abrasion of the retainer fails or not, so that erroneous judgments are reduced.

Owner:CSR CHENGDU

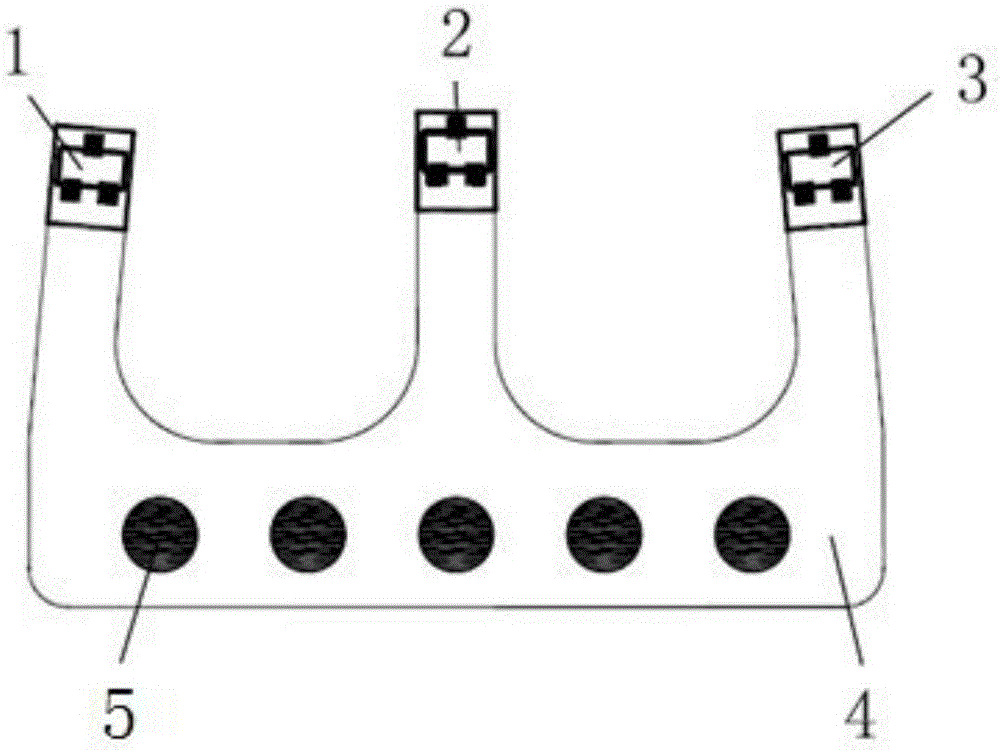

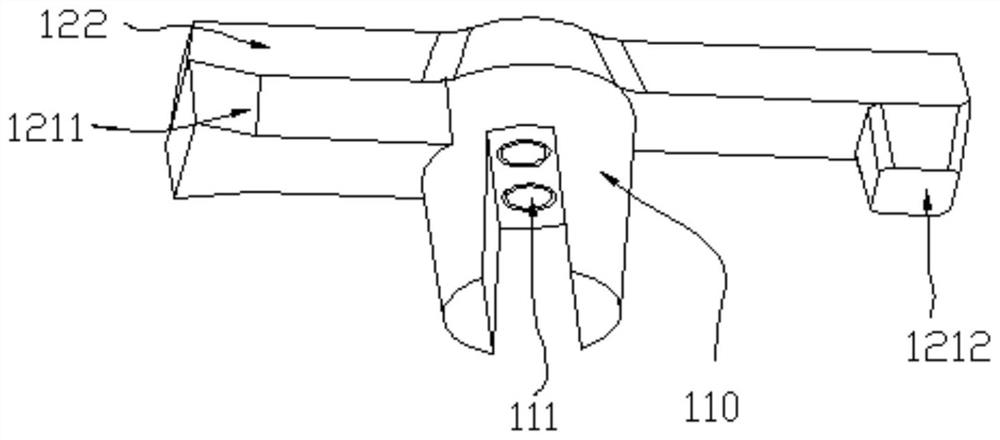

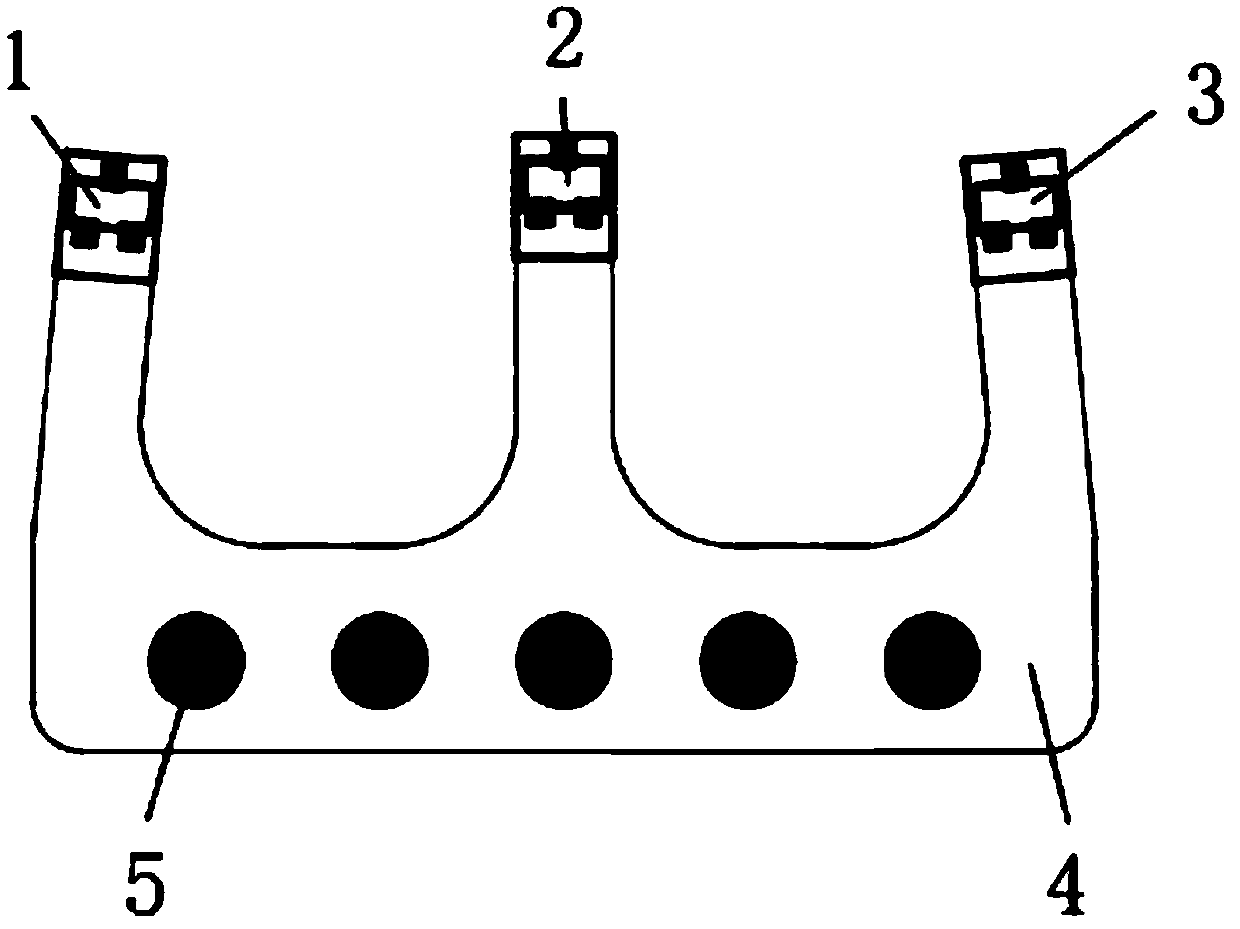

Motor flexible PG board

ActiveCN105576902AReduce manual assemblyReduce solder jointsElectric machinesStructural associationThree-dimensional spaceFlexible circuits

The invention discloses a motor flexible PG board, which comprises a substrate and Hall circuits arranged on the substrate. The substrate of the PG board adopts a flexible circuit board. The flexible circuit board is in an E-shaped structure comprising three branches. The Hall circuits are arranged on the top ends of the three branches respectively. The three branches are mutually nonparallel; the branches at the two sides converge to the middle and form acute-angle included angles with the middle branch respectively. The motor flexible PG board is in an axisymmetric distribution structure with the branch in the middle as a symmetry axis. The step of manual assembly of an insulating bush is saved; full-automatic SMD process is realized; the flexible PG board has flexible three-dimensional space assembly capability, and the PG boards of the same type can be fit to more motors; the flexibility of the PG board helps to reduce assembly labour intensity of workers effectively; and the motor flexible PG board is compatible with the PG boards of all hub motors, including a 60-degree motor and a 120-degree motor, and hub motors of different wheel diameters.

Owner:南京艾驰电子科技有限公司

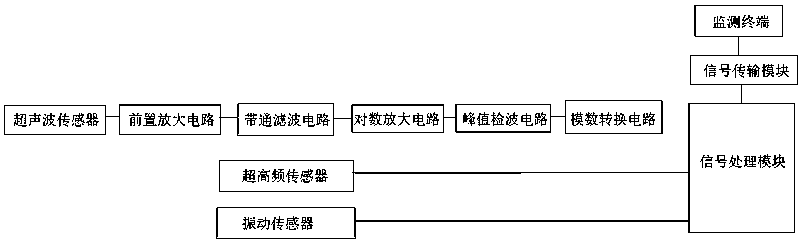

System for monitoring ring network cabinet online

InactiveCN108802579AEffectively find discharge defectsDiscover partial discharge defectsTesting using acoustic measurementsDielectricUltrasonic sensor

The invention discloses a system for monitoring a ring network cabinet online, which comprises an ultra-high frequency sensor, a vibration sensor, a sound measurement module, a signal processing module, a signal transmission module and a monitoring terminal, wherein the sound measurement module includes an ultrasonic sensor, a pre-amplification circuit, a band-pass filtering circuit, a logarithmicamplifying circuit, a peak detection circuit and an analog-to-digital conversion circuit which are sequentially connected, the ultra-high frequency sensor, the vibration sensor and the sound measurement module are arranged in the cabinet body, the ultra-high frequency sensor, the vibration sensor and the analog-to-digital conversion circuit are connected with the signal processing module, the signal processing module is connected with the signal transmission module, and the signal transmission module is connected with the monitoring terminal. The system can effectively discover equipment surface corona and partial discharge defects inside a dielectric in the cabinet, thereby effectively eliminating hidden dangers of the equipment operation.

Owner:苏州树云网络科技有限公司

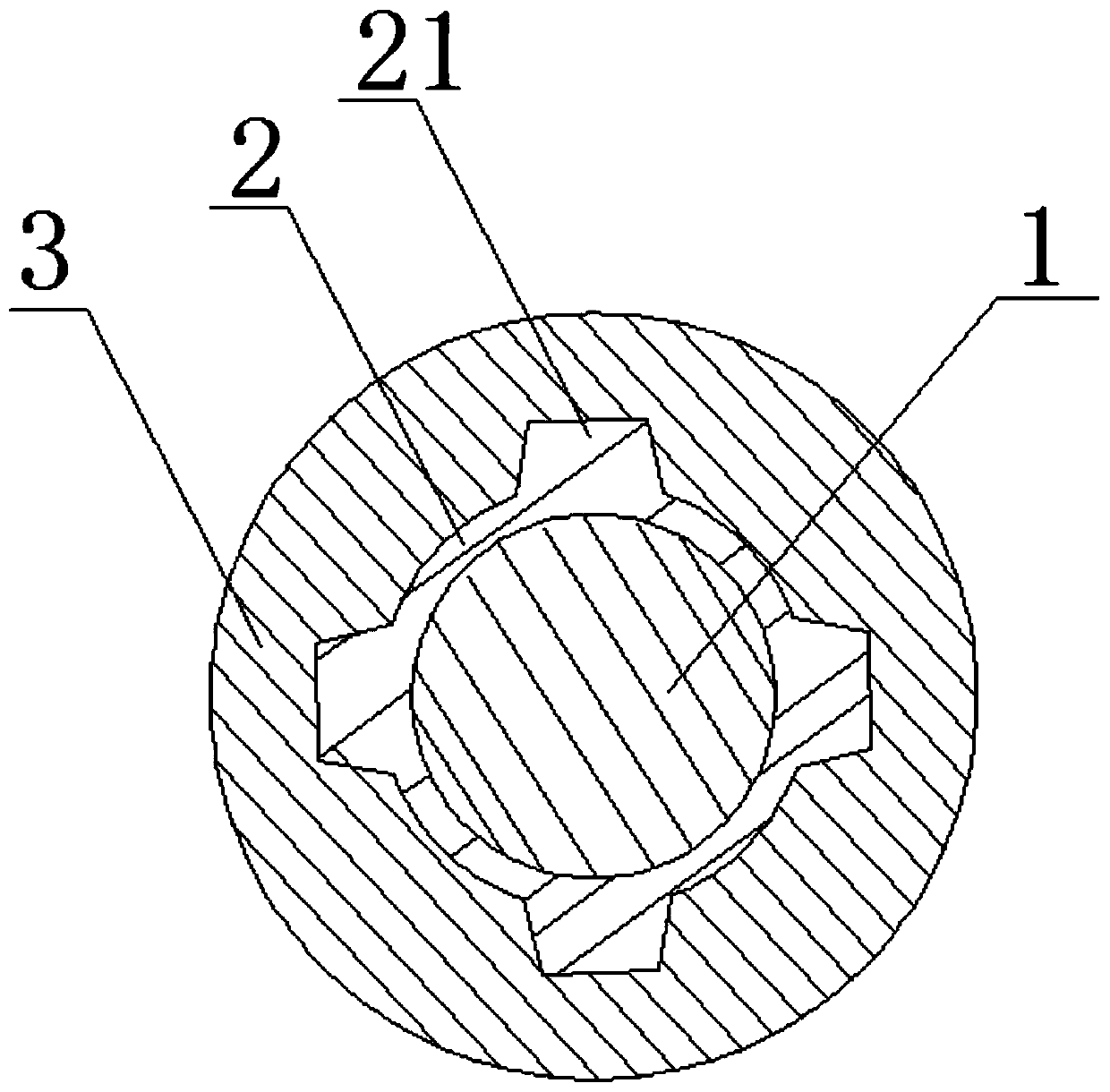

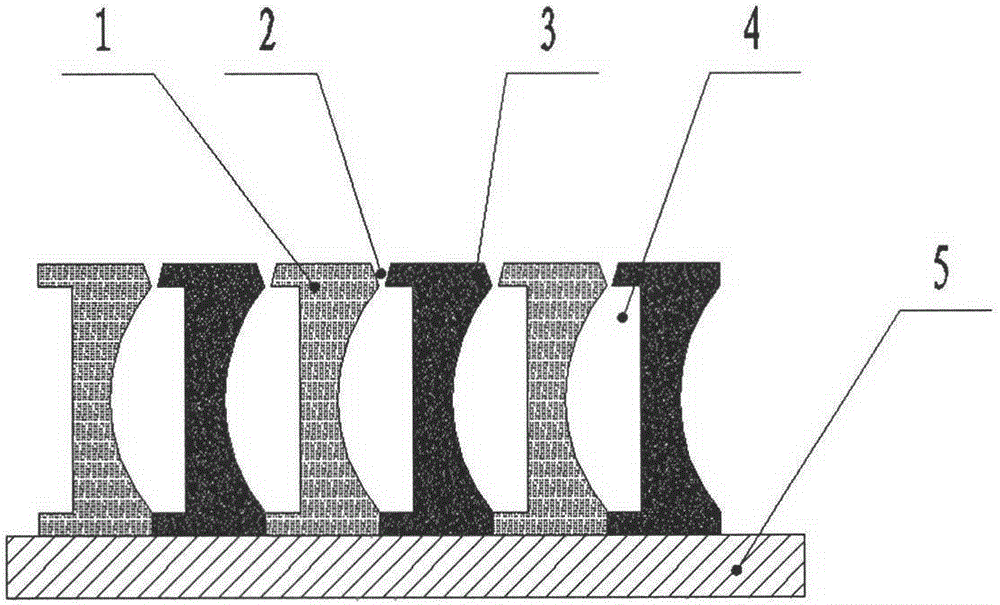

Novel composite insulator and production process thereof

InactiveCN109698049AAvoid corrosionGood adhesionSuspension/strain insulatorsComposite insulatorsEngineering

The invention relates to the technical field of composite insulators, in particular to a novel composite insulator and a production process thereof. The novel composite insulator includes a mandrel, asilicone rubber sheath and an umbrella skirt. The silicone rubber sheath fixedly sleeves the outer surface of the mandrel by extrusion. The silicone rubber sheath includes a sheath body, and four raised strips extend from the outer surface of the sheath body in the form of a cross. The umbrella skirt is formed on the outer surface of the silicone rubber sheath by injection. Compared with the prior art, the silicone rubber sheath is fixed on the outer surface of the mandrel by extrusion, and the umbrella skirt is fixed on the outer surface of the silicone rubber sheath by injection, so that the bonding between the silicone rubber sheath and the mandrel is firmer and more aging-resistant; and multiple interface generation points are reduced, so that moisture, acid and alkali are prevented from infiltrating into the mandrel, and the use and operation risk of the product is greatly reduced. The application also provides a production process of the composite insulator.

Owner:DONGGUAN GAONENG IND CO LTD

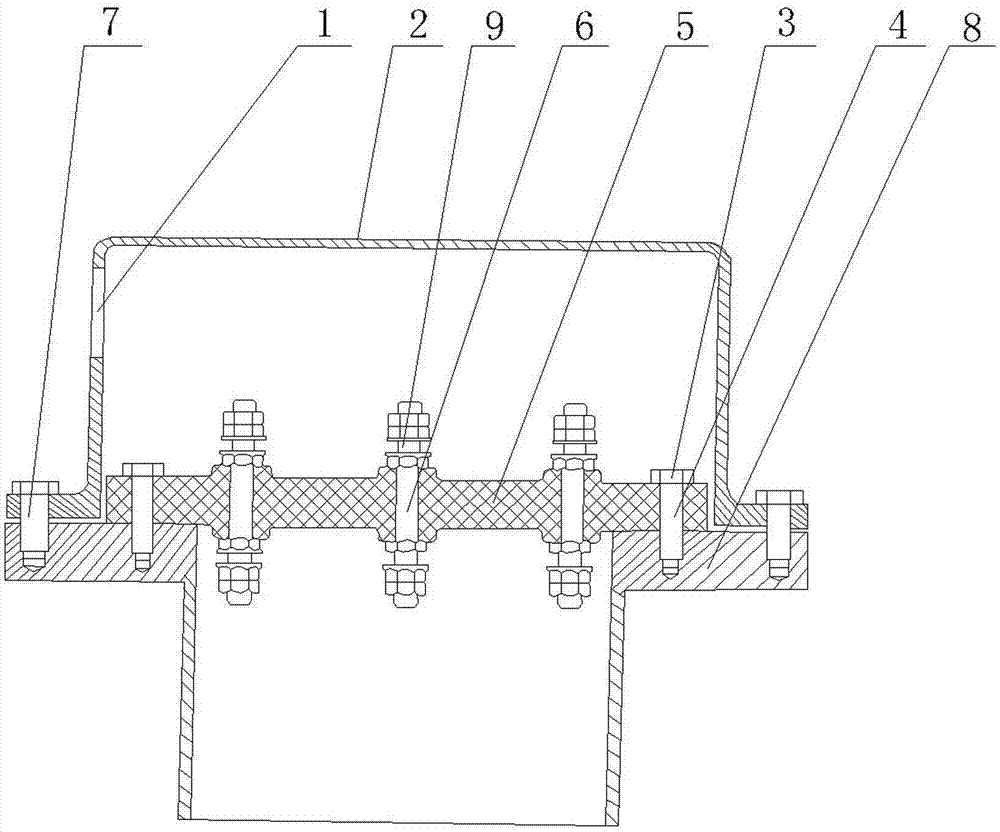

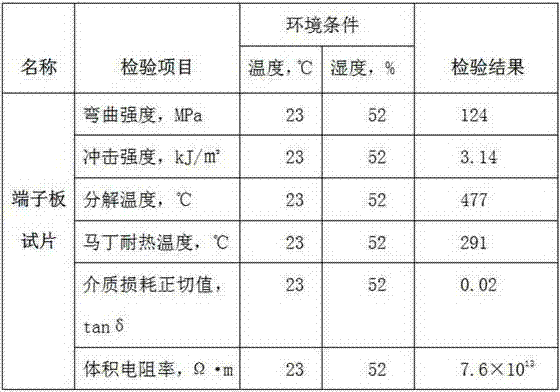

High-tenacity terminal board used for transformer and mutual inductor

InactiveCN106856143AMeet the use requirementsEasy to useTransformers/inductances coils/windings/connectionsEpoxyNitrile rubber

The high-toughness terminal board for transformers and transformers of the present invention has higher toughness and impact resistance, and completely solves the problem that the existing terminal boards for transformers and transformers are brittle and prone to fracture; and the structure of the present invention is compatible with The technical indicators can fully meet the current requirements for the use of transformers and transformers. The present invention comprises the lifting base of the transformer and the transformer, the housing arranged on the upper part of the lifting base, and the housing and the lifting base are fixedly connected by external installation bolts; the upper part of the lifting base and the inside of the housing are provided with a terminal board; the terminal board is composed of Carboxyl-terminated nitrile rubber and epoxy resin are mixed by vacuum casting. Mounting holes are evenly distributed around the terminal board, and internal mounting bolts are provided through the mounting holes, and are fixedly connected to the rising seat through the internal mounting bolts; A casing opening is provided; connecting terminals are evenly arranged and distributed on the terminal board, and the upper and lower ends of the connecting terminals are connecting terminals.

Owner:SHENYANG HONGDA RUBBER & PLASTIC CO LTD

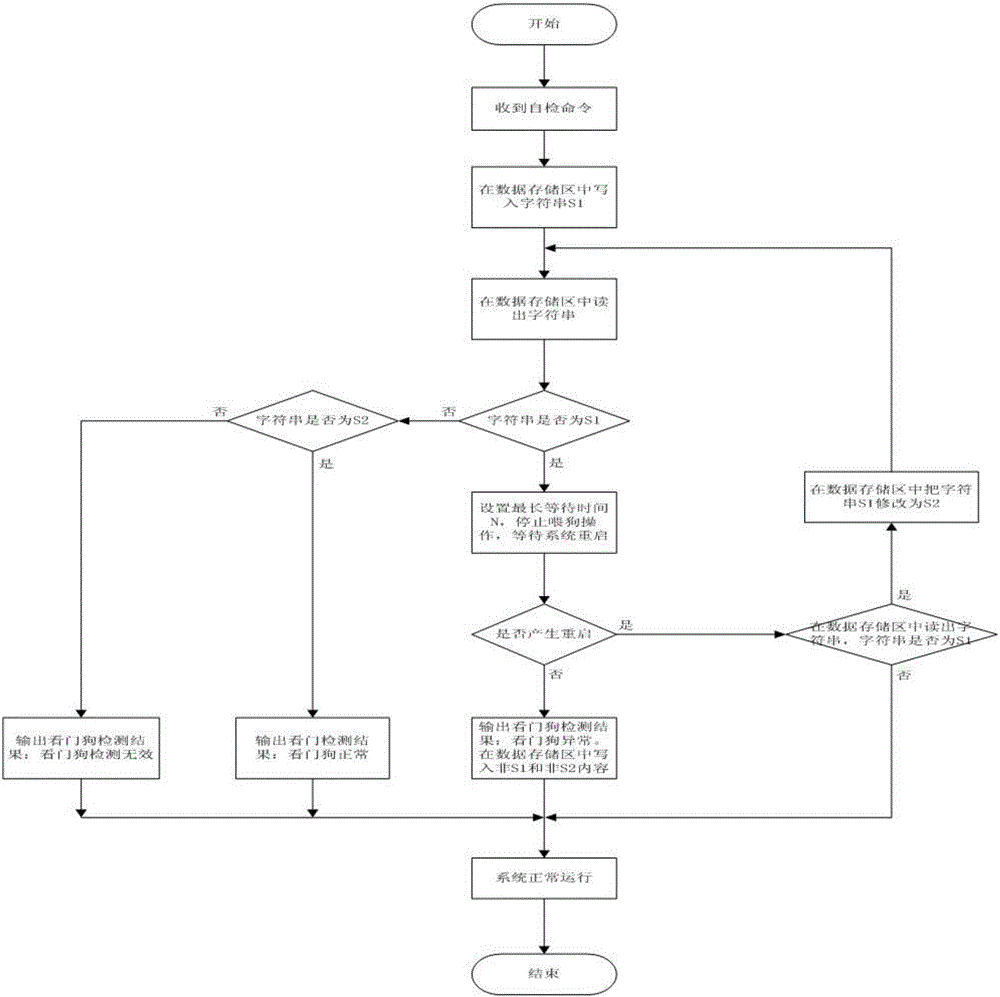

Method for checking whether external watchdog chip works normally

PendingCN106354596APrevent inflowEliminate operational hazardsFault responseFaulty hardware testing methodsComputer terminalEmbedded system

A method for checking whether an external watchdog chip works normally comprises initiation of a self-check instruction, system resetting, entering of a self-check state, result output and normal operation of the system. Through detection of the watchdog chip, a collector terminal, which cannot work normally, of the chip can be found timely, a fault terminal is prevented from coming into the market, and the potential operation risk of an on-site terminal is eliminated timely.

Owner:INTEGRATED ELECTRONICS SYST LAB

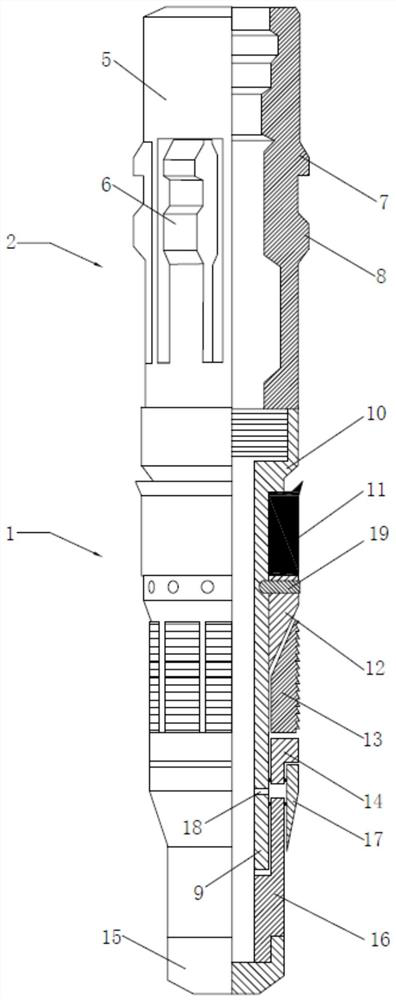

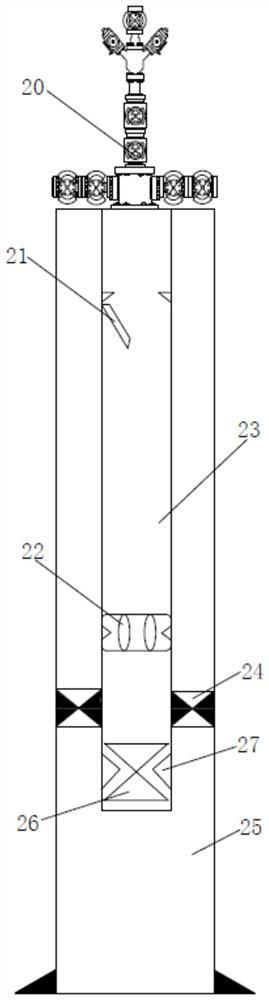

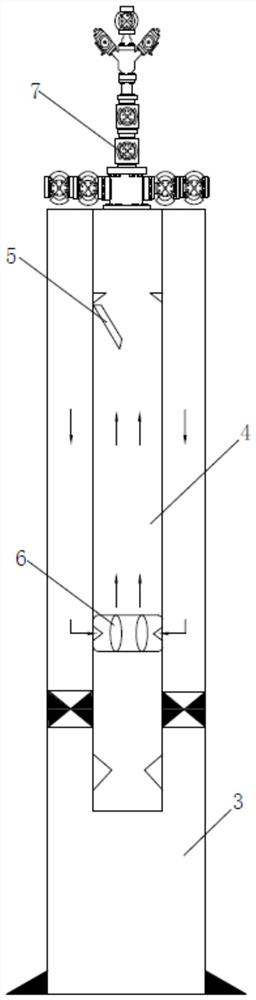

Pumping soluble plug

The invention discloses a pumping soluble plug, and relates to the technical field of oil and gas well tools. The pumping soluble plug comprises a soluble bridge plug and a soluble locking device, thesoluble bridge plug can be located on the preset locating short section in an oil pipe under the hydraulic pressure effect in the oil pipe, the soluble locking device is assembled on the soluble bridge plug, is located on the upper end of the soluble bridge plug during use, and carries the soluble bridge plug under the effect of pressurizing or self gravity to arrive at and be locked on the preset locating short section, multiple steps are mounted on the preset locating short section, the soluble locking device comprises a shaft body assembled at one end of the soluble bridge plug and multiple elastic buckling parts mounted on the outer side of the shaft body and used for being buckled on the steps, and through the technical scheme, the advantages of removing work hidden dangers of steelwire work, saving work time, reducing work cost and being wide in application range are achieved.

Owner:深圳百途石油技术服务有限公司

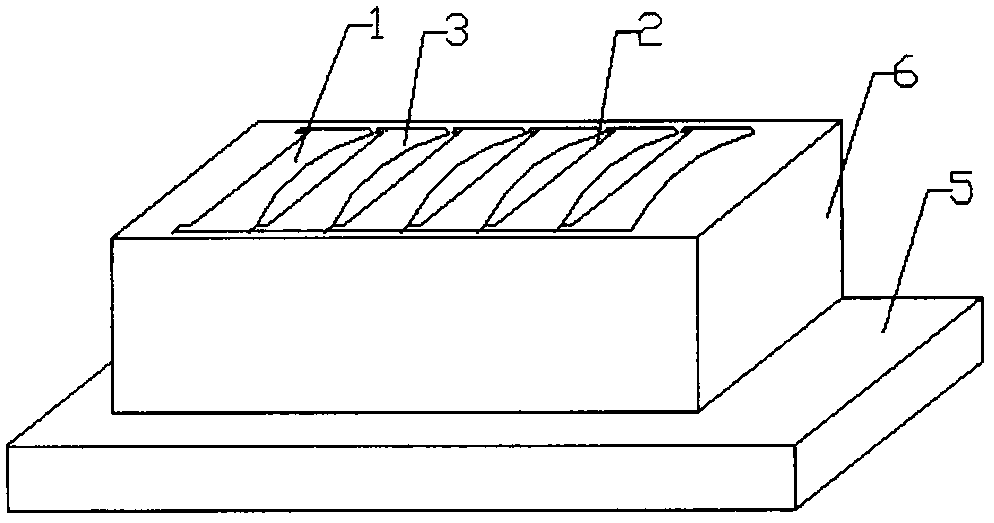

Vertical pouring structure for mass production of well lids

ActiveCN106825405AOvercome the disadvantages of poor air permeabilityImprove appearance qualityFoundry mouldsFoundry coresMaterials science

The invention discloses a vertical pouring structure for mass production of well lids. The vertical pouring structure comprises a plurality of clay sand molds, a plurality of film covering sand molds and a platform. The dimension of the clay sand molds and the dimension of the film covering sand molds are both 1200 mm*1200 mm. The clay sand molds and the film covering sand molds are arranged on the platform alternately and orderly. After the clay sand molds and the film covering sand molds are combined, cavities are formed, and the upper portion of each cavity is provided with a pouring gate. After the clay sand molds and the film covering sand molds are combined, the two sides and the vertical surfaces of the sand molds are additionally provided with iron plates for fixing. According to the vertical pouring structure, through mixing usage of the clay sand molds and the film covering sand molds, the defect that existing clay sand molds are poor in air permeability is overcome, and the appearance quality of the well lids can be remarkably improved; and by the adoption of the vertical pouring structure, the forming speed of the well lids is increased, operation hidden danger is eliminated, and mass production of the well lids is achieved.

Owner:CANGZHOU JIUNAI METAL PROD CO LTD

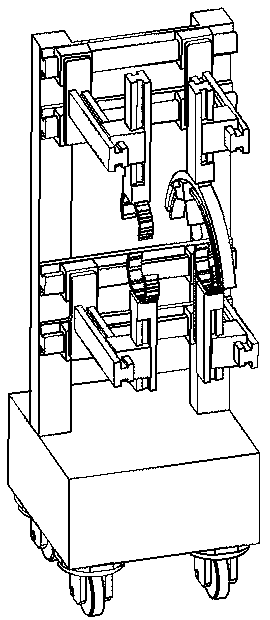

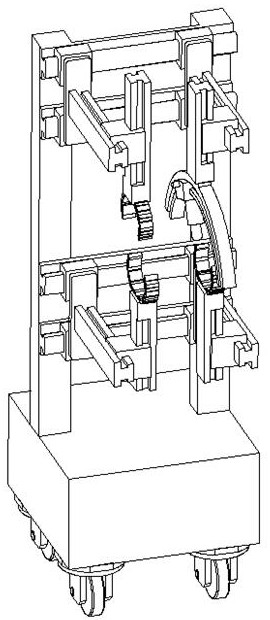

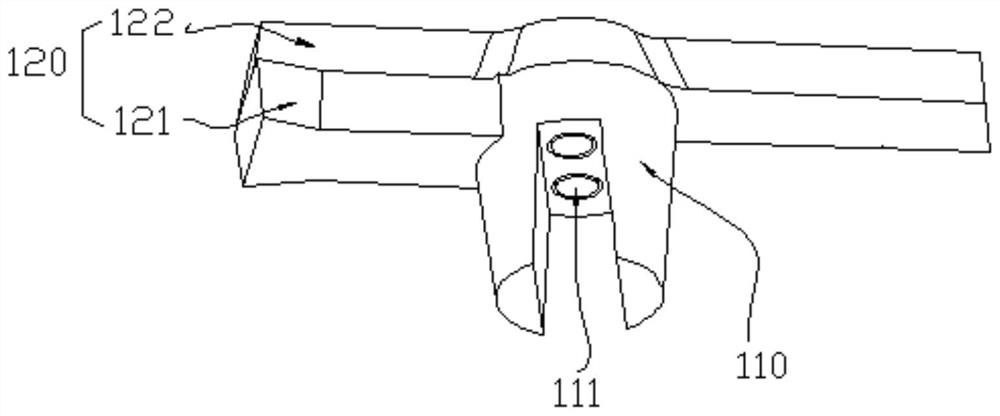

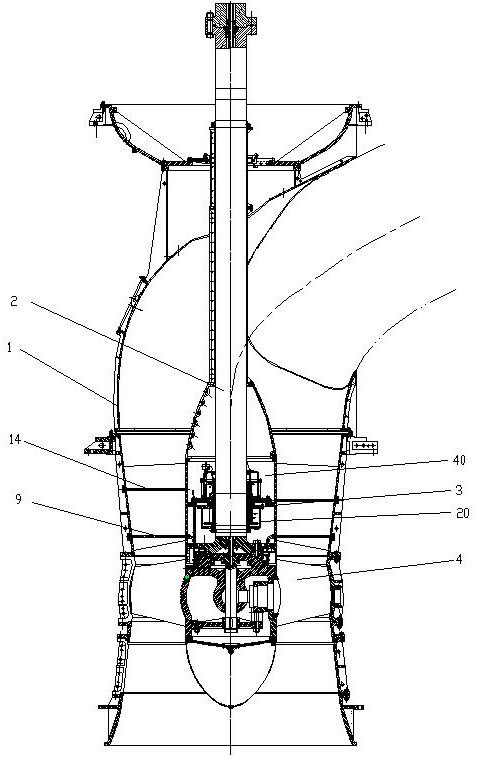

Disassembling and assembling robot for high-temperature connecting pipe

ActiveCN111515653AReduce the risk of injuryEliminate operational hazardsGripping headsHollow article cleaningEngineeringMechanical engineering

The invention relates to a disassembling and assembling robot for a high-temperature connecting pipe. The disassembling and assembling robot comprises a support mechanism (12) and a base mechanism (13). The support mechanism (12) is arranged on the upper portion of the base mechanism (13). A plurality of movable stations are arranged on the support mechanism (12). Mechanical claws (14) or mechanical hammers (30) are arranged on the multiple movable stations correspondingly. The multiple mechanical claws (14) are positioned and grab all disassembling and assembling parts of the high-temperatureconnecting pipe correspondingly. Assembling and disassembling of all the disassembling and assembling parts of the high-temperature connecting pipe are completed through space movement of the mechanical claws. Each mechanical hammer (30) comprises an arc-shaped guide rail (22) and a hammer head (26) arranged on the arc-shaped guide rail (22). The hammer heads (26) slide along the arc-shaped guiderails (22) so that the high-temperature connecting pipe can be knocked in different radial directions. According to the disassembling and assembling robot, condensed ice residues on the pipeline areautomatically knocked and removed before the connecting pipe is disassembled and assembled, and complete mechanical operation of disassembling and assembling of the high-temperature pipeline can be achieved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

A disassembly and assembly robot for high-temperature connecting pipes

ActiveCN111515653BReduce the risk of injuryEliminate operational hazardsGripping headsHollow article cleaningMechanical engineeringTotal/mechanical

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Testing method of digital protection tester with fault data model base for protection testing

ActiveCN102175940BEliminate operational hazardsPerfect debugging projectElectrical testingSpecial data processing applicationsTester deviceParallel I/O

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

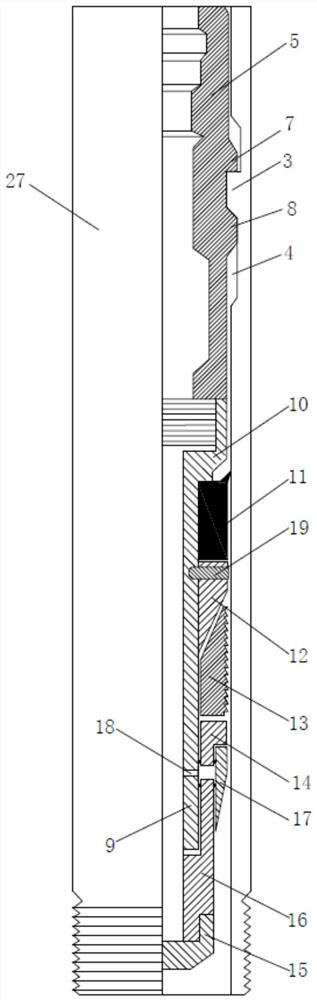

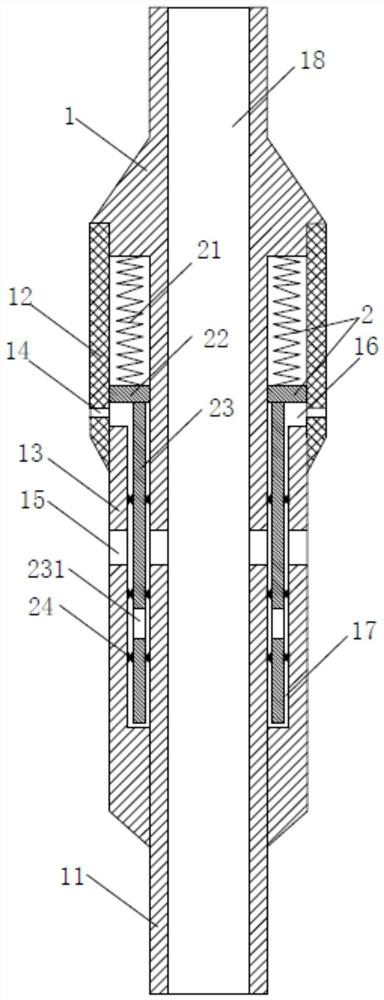

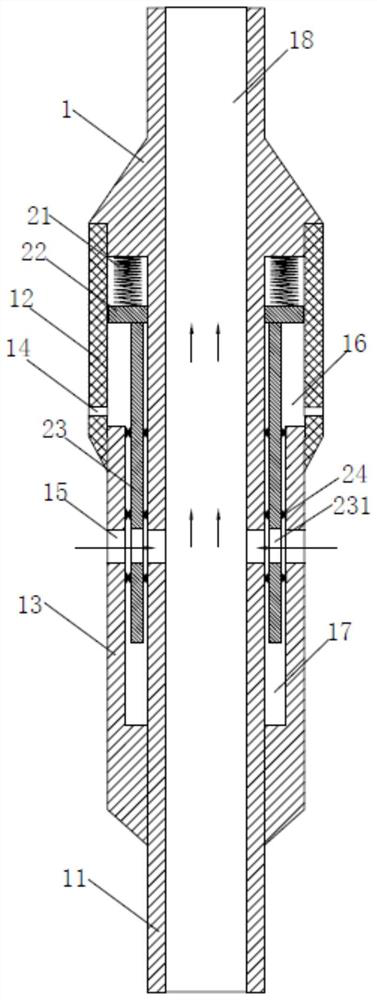

Pressure control sliding sleeve

PendingCN111734348AEliminate operational hazardsShorten working timeWell/borehole valve arrangementsSealing/packingReciprocating motionControl switch

The invention provides a pressure control sliding sleeve, and relates to the technical field of well completion operation. The pressure control sliding sleeve comprises a sliding sleeve body and a hydraulic control switch, wherein a hydraulic hole and a liquid inlet hole which communicate with an annulus are formed in the sliding sleeve body; and the hydraulic control switch is movably assembled in the sliding sleeve body, communicates with the hydraulic hole and is used for opening or closing the liquid inlet hole according to change of external hydraulic pressure. A cavity and a subspace which communicate with the hydraulic hole and the liquid inlet hole and are used for assembling the hydraulic control switch are arranged in the sliding sleeve body, and the hydraulic control switch comprises an elastic piece assembled in the cavity, a piston which is movably assembled in the cavity and does linear reciprocating motion in the cavity under the action of the external hydraulic pressureand the elastic piece, and a piston gate plate which is movably assembled in the subspace, is fixedly connected with the piston and is used for moving along with the piston to open or close the liquid inlet hole. By the technical scheme, the pressure control sliding sleeve has the advantages that the operation time is saved, the operation cost is reduced, the operation difficulty is reduced, andthe operation hidden danger of steel wire operation is eliminated.

Owner:深圳百途石油技术服务有限公司

Checking method to prevent failure of thermal protection system for thermal power generating units

ActiveCN105332744BVerification steps are concise and clearEasy to operateMachines/enginesSafety/regulatory devicesAutomatic controlEngineering

Owner:STATE GRID CORP OF CHINA +1

Sand core hanging nose fixing structure and its application method

The invention belongs to the field of the foundry industry, and particularly relates to a sand core hanging nose fixing structure and a use method thereof. The sand core hanging nose fixing structurecomprises a fixing base and a positioning structure. The fixing base is used for fixing a hanging nose. The positioning structure is connected with the fixing base in a lap joint manner or a fixed manner. The positioning structure is installed on a sand core mold. A groove is formed in the end face, opposite to the end face connected with the positioning structure, of the fixing base in a concavemanner. At least one installation hole is formed in the inner wall of the bottom of the groove. A magnet is installed in each installation hole. The sand core hanging nose fixing structure is easy tooperate, easy to take out and high in universality.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

Apparatus and method for preparing metal nitride catalytic material

InactiveCN100457270CIncrease surface areaLarge specific surface areaCatalyst activation/preparationPtru catalystFluidized bed

The invention relates to a device for preparing metal nitride catalyst, wherein the mixer via tube is connected to the fluidize bend reactor whose outlet via tube is connected to the heat exchanger; the heat exchanger via tube is connected to the mixer, while said tube via six-way valve is connected to the gas spectrum device, and the heat exchanger via tube is connected to the water cooler; the separator via tube and drying part is connected to the compressor whose outlet via tube is connected to the heat exchanger; the cooler is connected to the inlet and outlet tubes of compressor; MoO3 / TiO2, MoO3 / NiO-TiO2, MoO3 / Al2O-TiO2 or MoO3 / Al2O3 is put into fluidize bed reactor, to process N2-H2 reduction to replace MoO3, to prepare the Mo2N / TiO2, Mo2N / NiO-TiO2, Mo2N / Al2O3-TiO2, or Mo2N / Al2O3 carried metal nitride catalyst; the volume ration between N2 and H2 is 3-5:1, and the reaction temperature is 933K+-10K, the temperature kept time is 0.5-1h. The invention can improve the product quality and prepare the gamma-Mo2N with high specific surface area.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

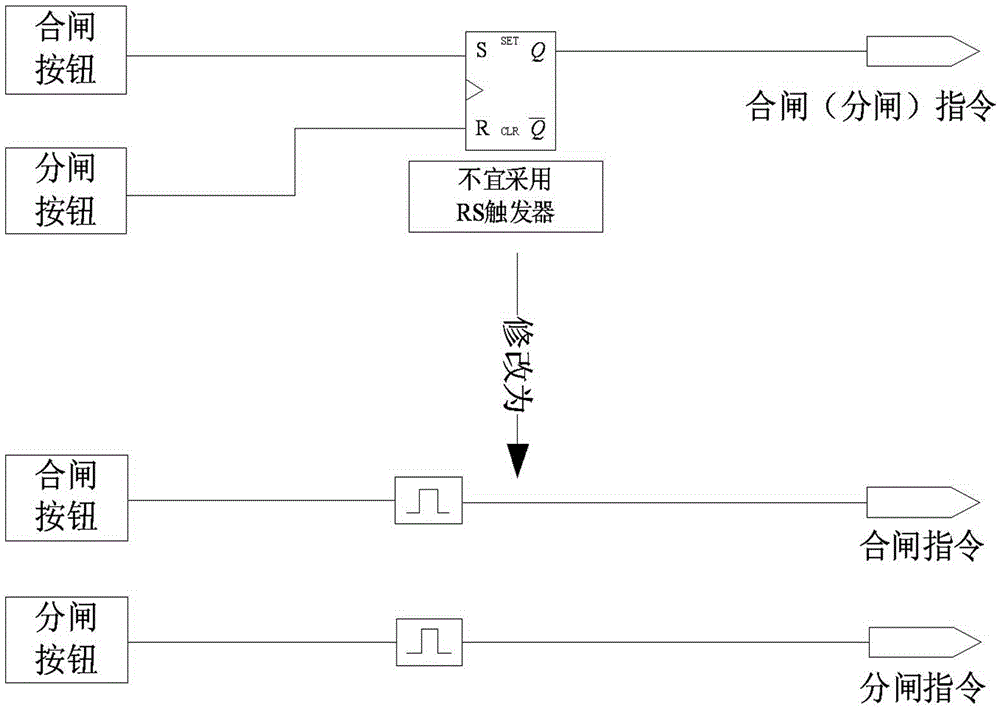

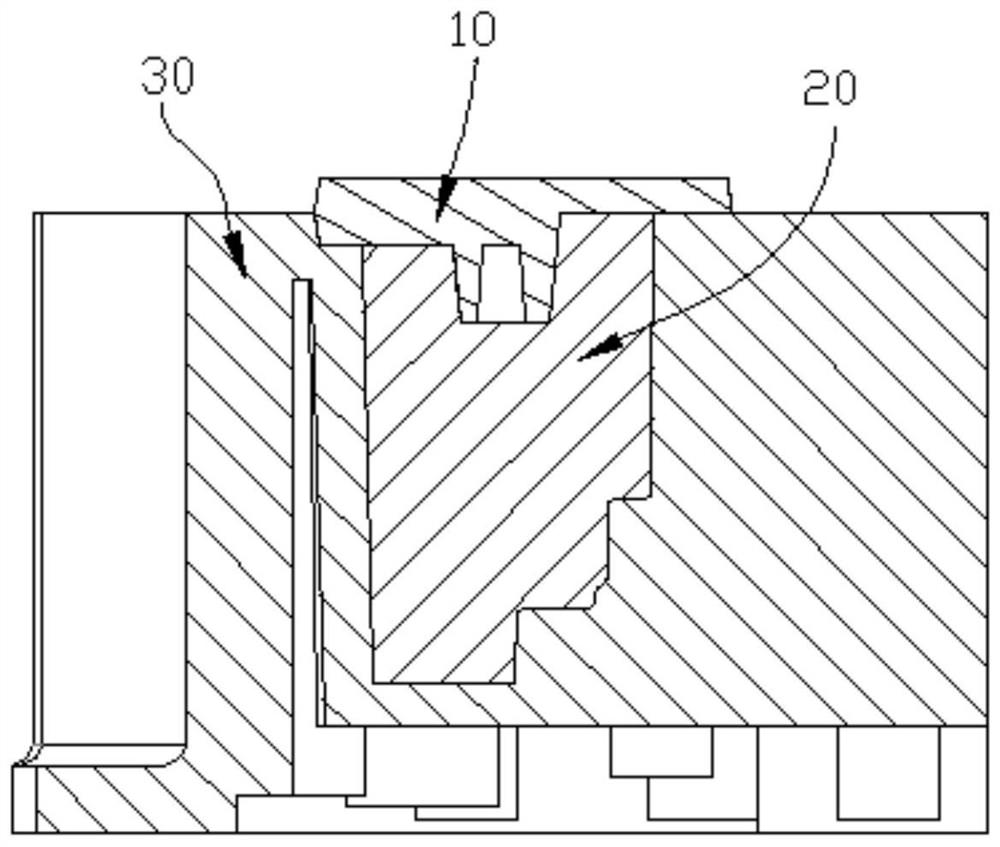

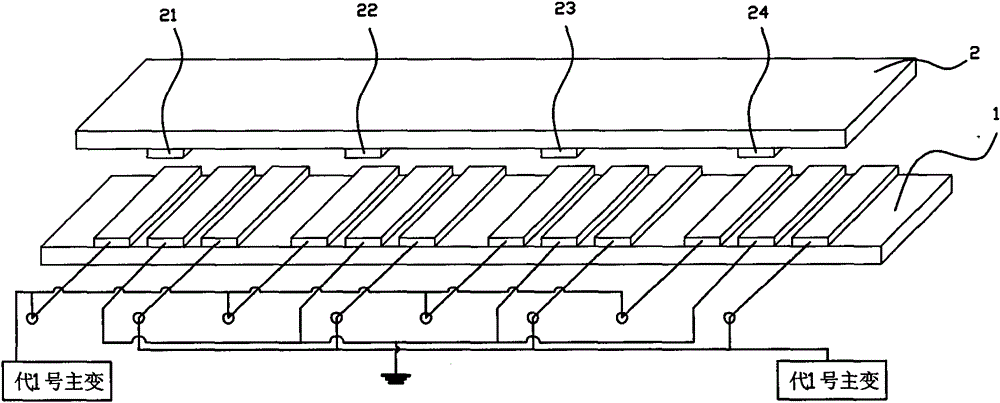

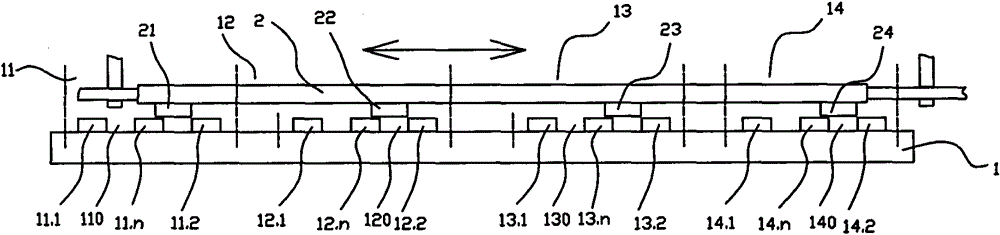

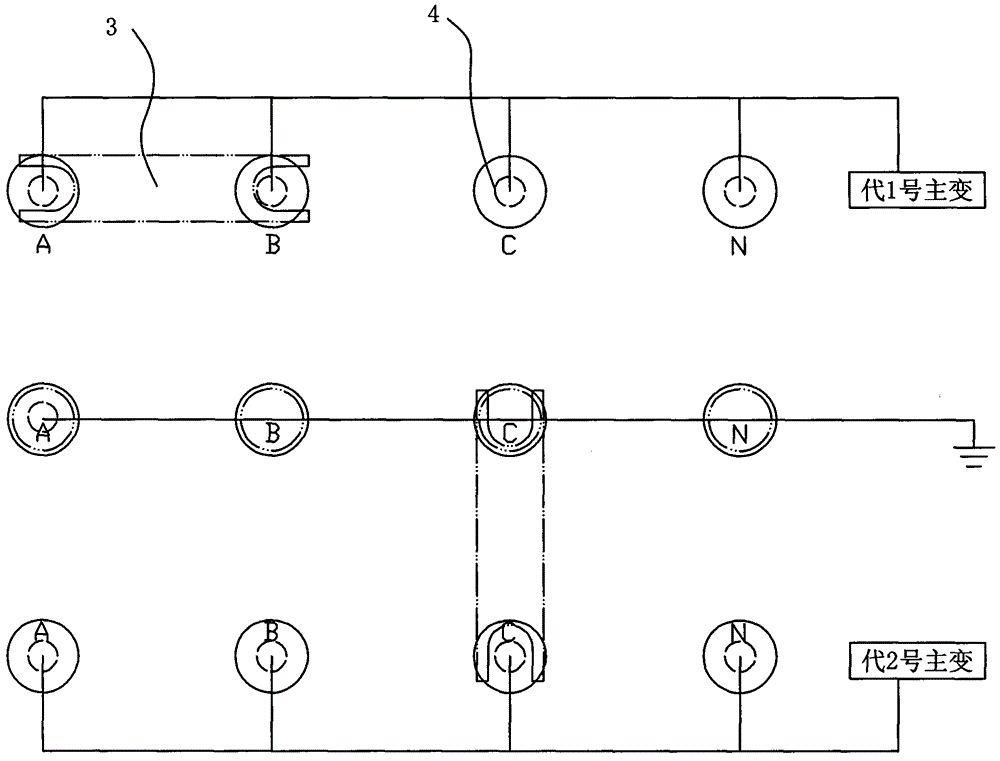

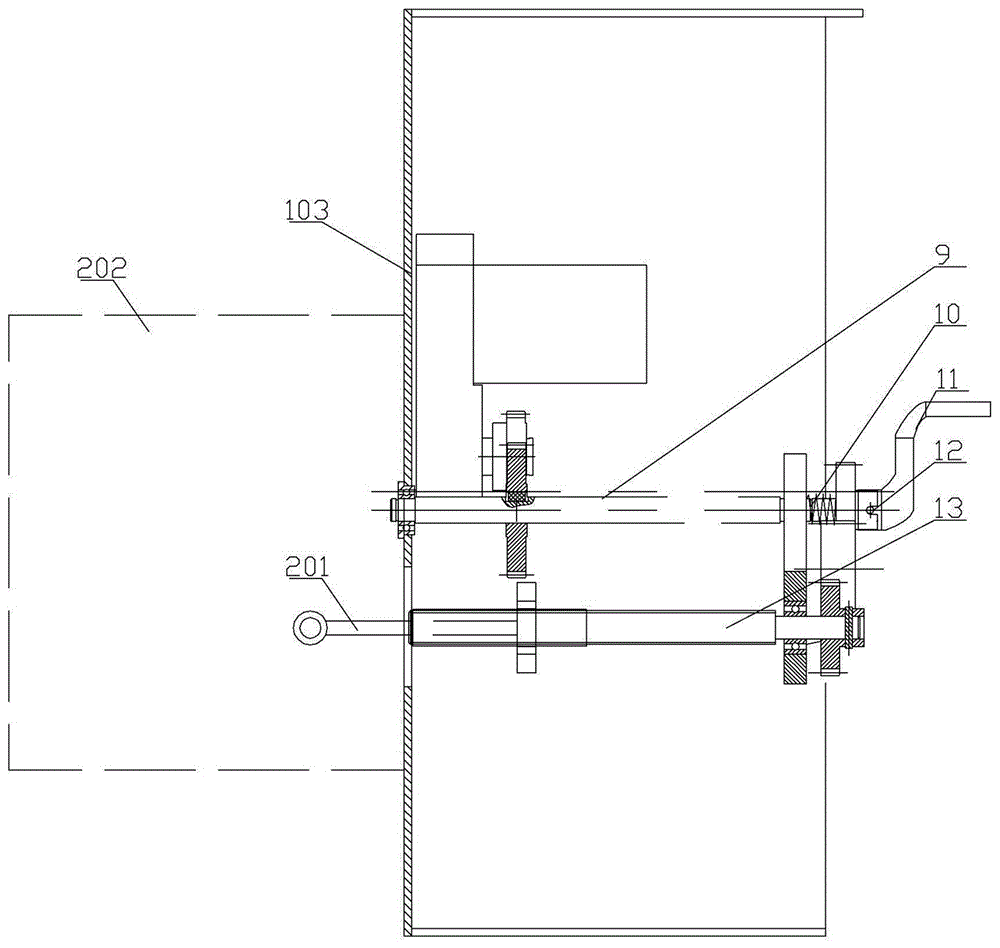

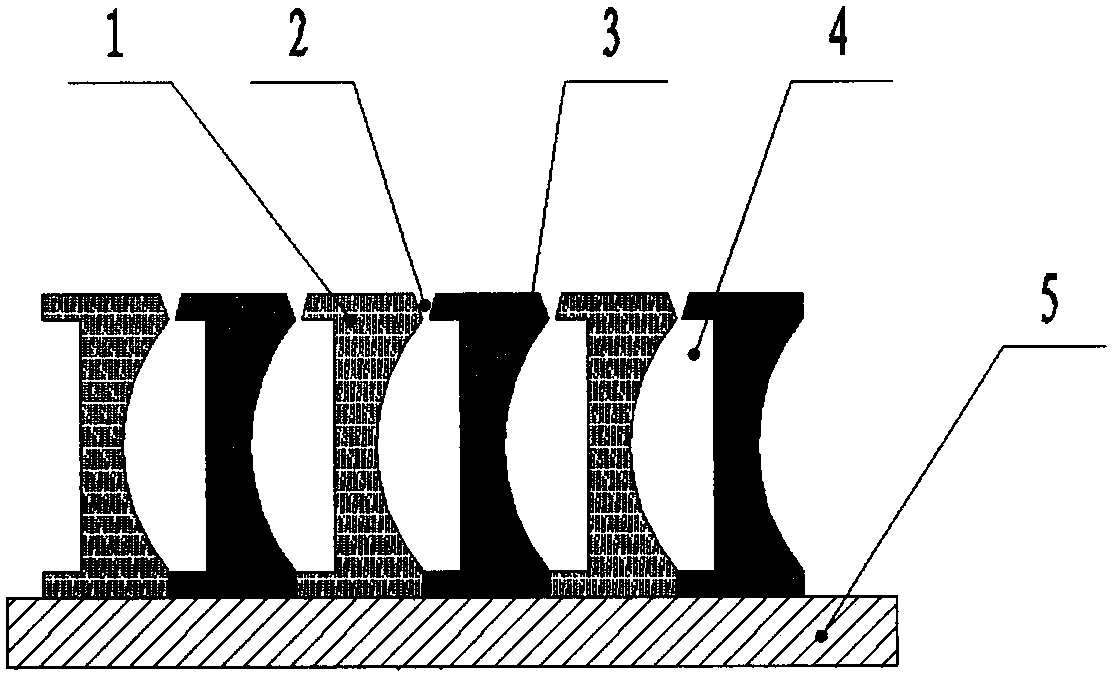

A current three-phase linkage switching device

ActiveCN102214519BImprove the quality of operationAvoid misuse accidentsEmergency protective circuit arrangementsMake-before-break contact arrangementPower flowTransformer

The invention discloses a current three-phase linked switching device, and relates to an improvement on a current switching device. The switching device can meet the current application situation in China, greatly reduce operating strength, improve operating safety and convenience and avoid misoperation, is used for connecting and switching bypass current between a No.1 main transformer and a No.2 main transformer, and comprises a rectangular insulating movable plate and a rectangular insulating fixed plate, wherein conducting bar groups A, B, C and N are uniformly distributed in the transverse direction of the fixed plate at equal intervals; three conducting bars are arranged in each conducting bar group; lapping bars A, B, C and N are arranged in the transverse direction of the movable plate; the initial positions of the four lapping bars in the transverse direction of the movable plate are respectively consistent with those of 0# conducting bars in the conducting bar groups on the fixed plate in the transverse direction of the fixed plate; and the width of the lapping bars is L3 which is less than L2+2*L1 and more than L1. By the switching device, short circuit, withdrawal, investment and short circuit removing operation which is performed stepwise originally is changed into one-step operation, so that misoperation accidents are avoided.

Owner:JIANGSU ELECTRIC POWER COMPANY YANGZHOU POWER +1

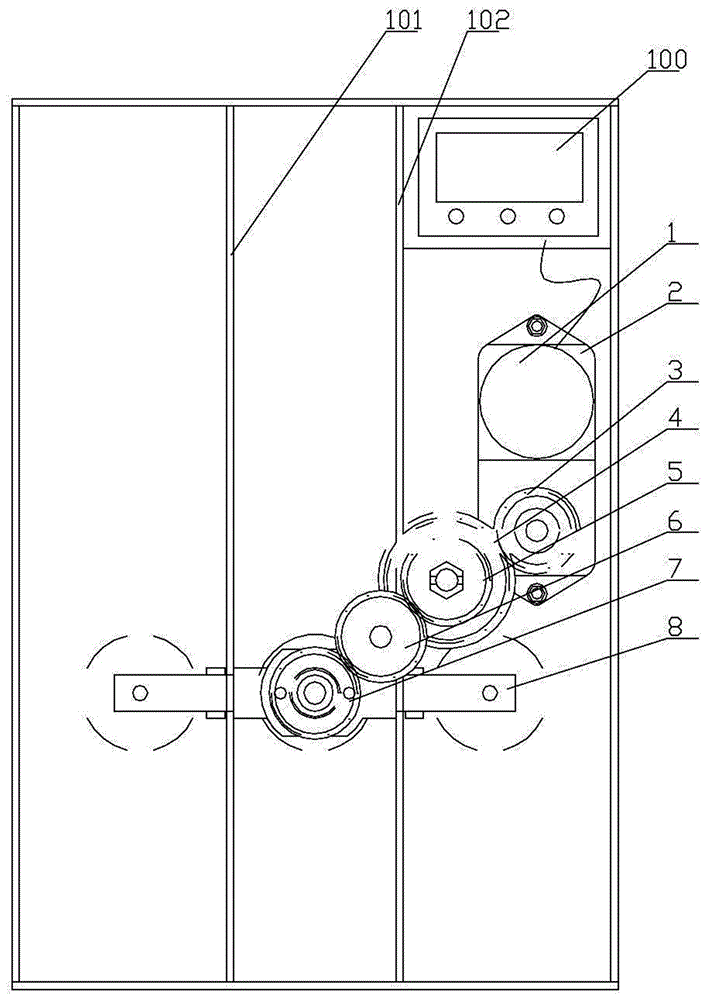

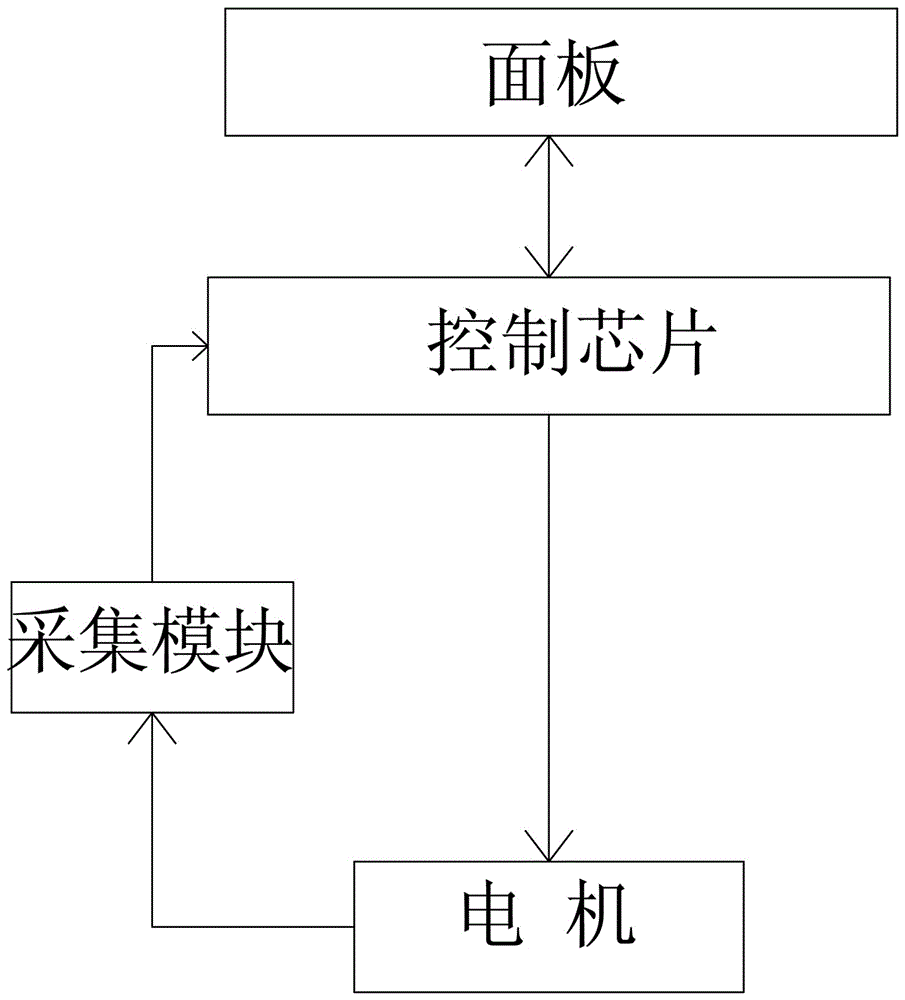

A manual and automatic integrated intelligent electric operating mechanism for medium voltage isolating switch

ActiveCN103065825BRealize intelligent requirementsAccurate separation and closingContact driving mechanismsSwitch power arrangementsIntelligent controlMedium pressure

The invention relates to a medium-voltage disconnecting switch manual-automatic intelligent electric operating mechanism. The medium-voltage disconnecting switch manual-automatic intelligent electric operating mechanism comprises an operating handle, a leave-joint gear, a transmission gear, a third gear, a screw rod, a slider, a transmission rod and disconnecting switch operating rods. The operating handle is sleeved on a hexagonal shaft of the leave-joint gear, the leave-joint gear is sleeved on the transmission rod, the third gear is connected with the screw rod into a whole, the slider is provided with threads in the middle and sleeved with the screw rod, and the three disconnecting switch operating rods are arranged on the slider. The operating mechanism further comprises an intelligent control module, a motor, a transmission case, a first gear and a second gear. According to the medium-voltage disconnecting switch manual-automatic intelligent electric operating mechanism, manual and automatic free switching of a disconnecting switch can be achieved, the whole structure is small and exquisite, structure assembly is simple and flexible, the medium-voltage disconnecting switch manual-automatic intelligent electric operating mechanism can be conveniently matched with various types of medium-voltage disconnecting switches, and the whole configuration is flexible.

Owner:福建森达电气股份有限公司

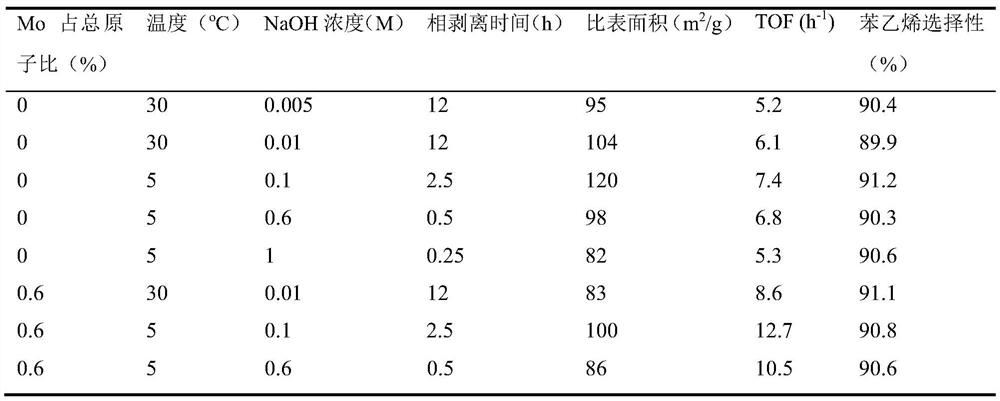

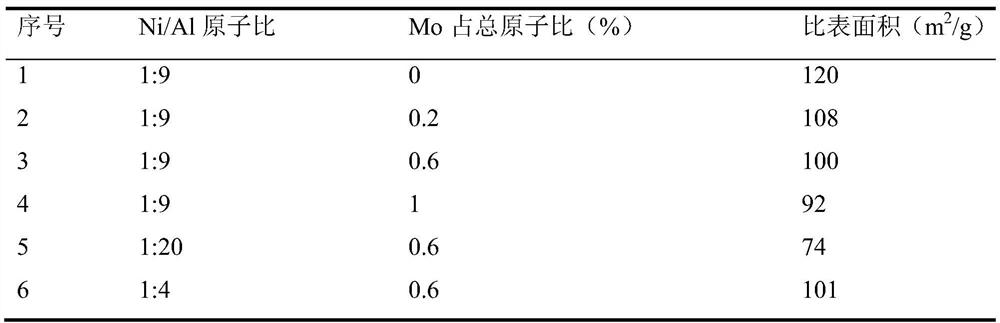

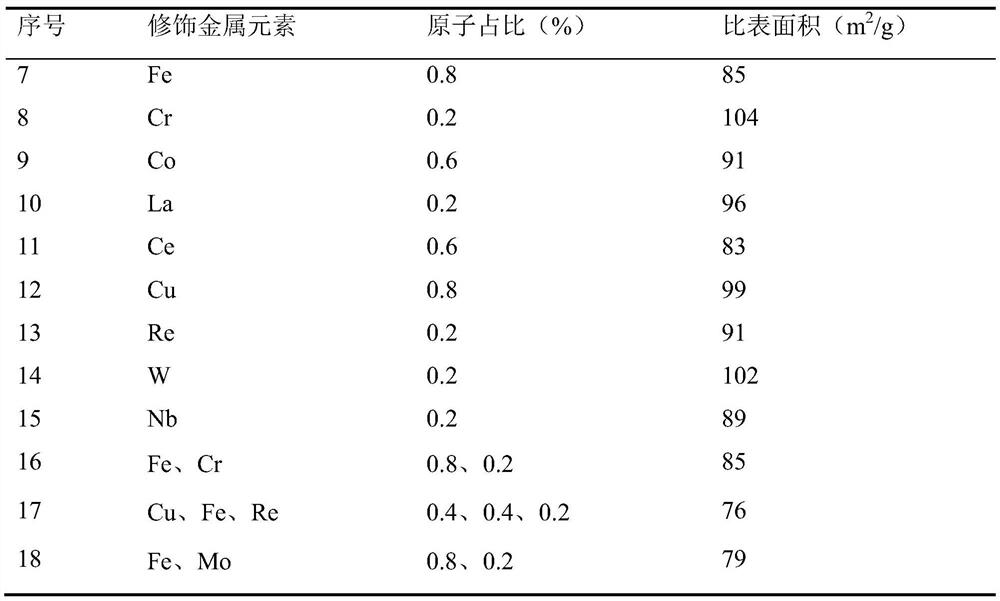

Metal oxide modified safe porous nickel catalyst

PendingCN113786836AImprove stabilityAvoid security issuesPreparation by hydrogenationHydrocarbon by hydrogenationNickel catalystPtru catalyst

The invention provides a metal oxide modified safe porous nickel catalyst and a preparation method thereof, and the catalytic activity, stability and selectivity of the porous nickel catalyst are improved through surface modification of a transition metal oxide. The transition metal oxide is subjected to in-situ oxidation through the phase stripping process of the composite alloy powder and covers the surface of the porous structure framework with the specific Ni / Al atomic ratio, and the oxide of the transition metal oxide comprises one or more of FeOx, Cr2O3, MoO3, CoOx, La2O3, CeOx, CuOx, ReOx, WO3 and Nb2O5. The catalyst provided by the invention has the advantages of simple preparation process, high activity and good stability, and can be widely applied to hydrogenation, dehydrogenation, isomerization, hydrodehalogenation and other reactions.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

A Vertical Casting Structure for Mass Production of Manhole Covers

ActiveCN106825405BOvercome the disadvantages of poor air permeabilityImprove appearance qualityFoundry mouldsFoundry coresMaterials scienceCasting

The invention discloses a vertical pouring structure for mass production of well lids. The vertical pouring structure comprises a plurality of clay sand molds, a plurality of film covering sand molds and a platform. The dimension of the clay sand molds and the dimension of the film covering sand molds are both 1200 mm*1200 mm. The clay sand molds and the film covering sand molds are arranged on the platform alternately and orderly. After the clay sand molds and the film covering sand molds are combined, cavities are formed, and the upper portion of each cavity is provided with a pouring gate. After the clay sand molds and the film covering sand molds are combined, the two sides and the vertical surfaces of the sand molds are additionally provided with iron plates for fixing. According to the vertical pouring structure, through mixing usage of the clay sand molds and the film covering sand molds, the defect that existing clay sand molds are poor in air permeability is overcome, and the appearance quality of the well lids can be remarkably improved; and by the adoption of the vertical pouring structure, the forming speed of the well lids is increased, operation hidden danger is eliminated, and mass production of the well lids is achieved.

Owner:CANGZHOU JIUNAI METAL PROD CO LTD

Visual guide vane body device for automatic dredging of vertical axial flow pump

PendingCN114576206AEasy dischargePromote softeningGeneral water supply conservationPump componentsAxial-flow pumpMarine engineering

The invention discloses an automatic dredging visible guide vane body device of a vertical axial flow pump. The automatic dredging visual guide vane body device of the vertical axial flow pump is simple in structure, convenient to clean and capable of improving efficiency. Comprising a pump body, a vertical pump shaft is arranged in the pump body, and a water guide bearing is arranged at the bottom of the pump shaft and located in a bearing socket of a guide vane body; the drainage assembly comprises a first calandria, a second calandria and a plurality of pipeline dredging machines, the first calandria is annular, the second calandria is a vertically-arranged vertical pipe, the pump body is located in an annular opening of the first calandria, the second calandria is communicated with the first calandria, and the pipeline dredging machines are annularly and evenly distributed on the outer side of the pump body; the pipeline dredging machine is arranged above the first rack pipe through a support, a main pipe of the pipeline dredging machine penetrates through the pump body and extends into the bottom of the bearing socket of the guide vane body, and a branch pipe is arranged on the main pipe, located outside the pump body and communicated with the first rack pipe. The device is convenient to control, stable in operation, free of manual disassembly and cleaning, time-saving, labor-saving and capable of eliminating unit operation hidden dangers.

Owner:江苏省江都水利工程管理处

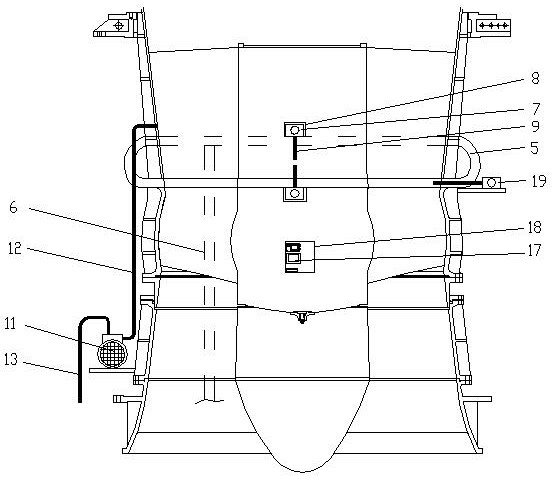

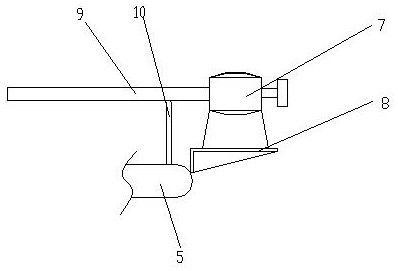

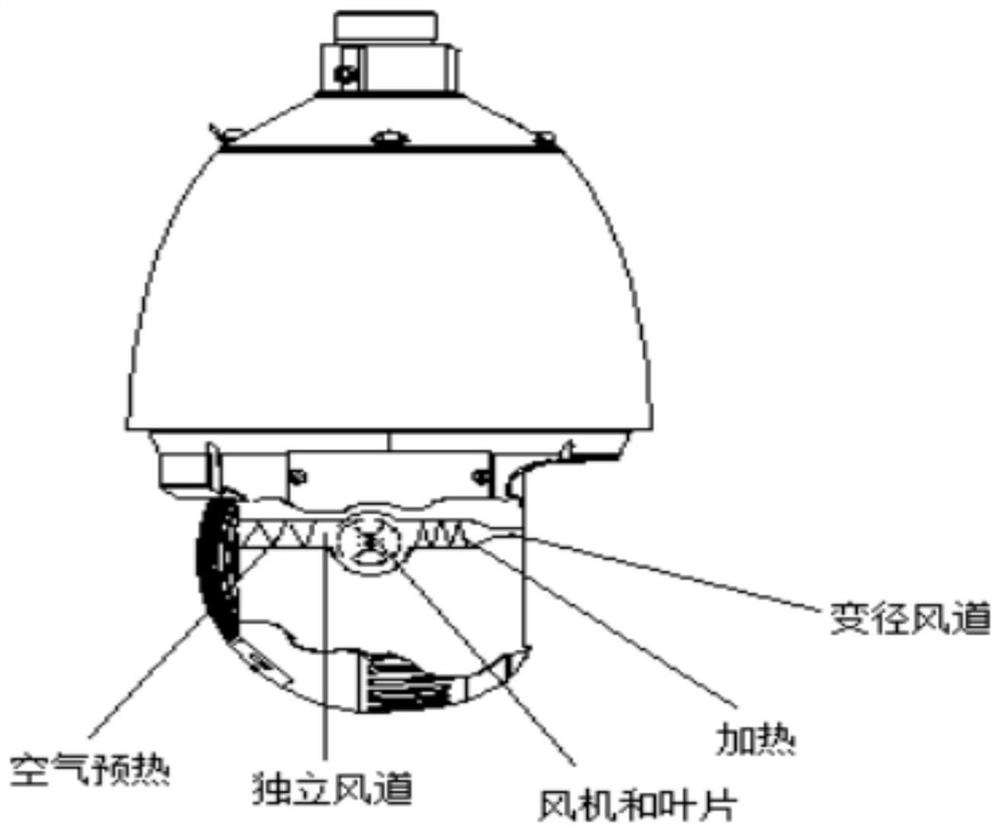

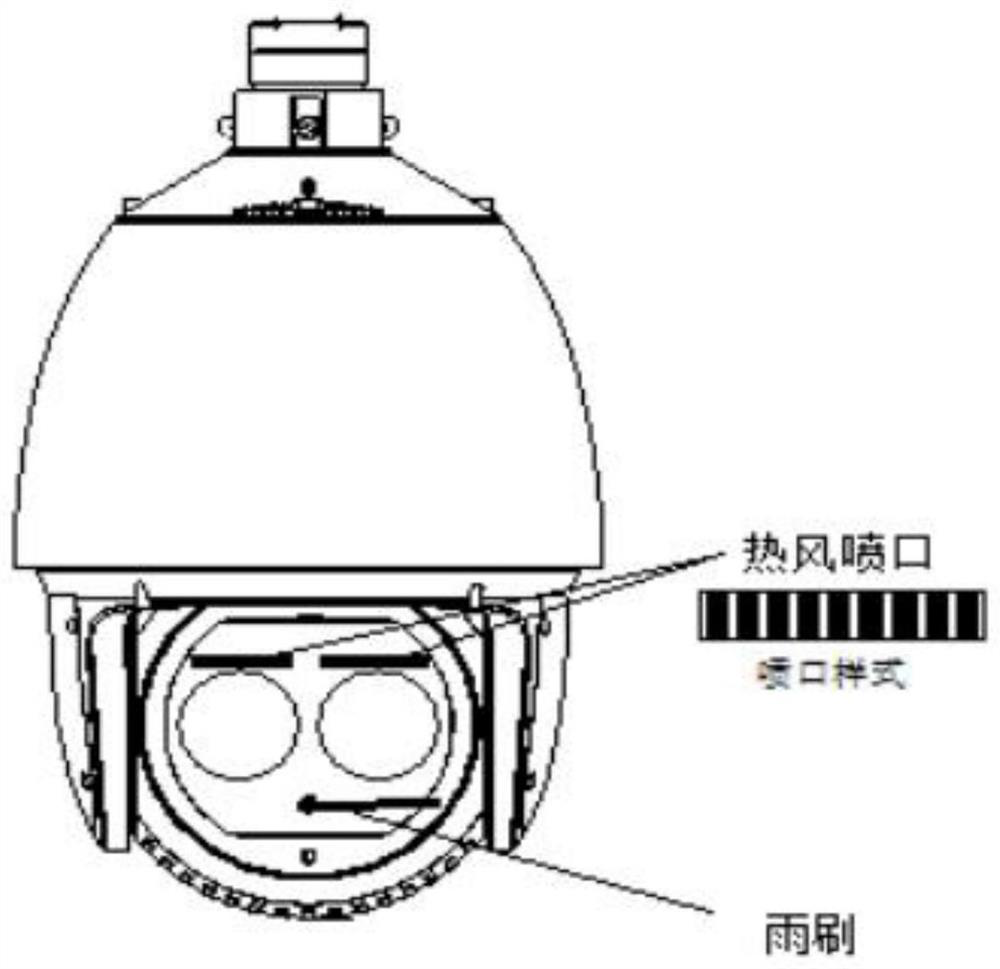

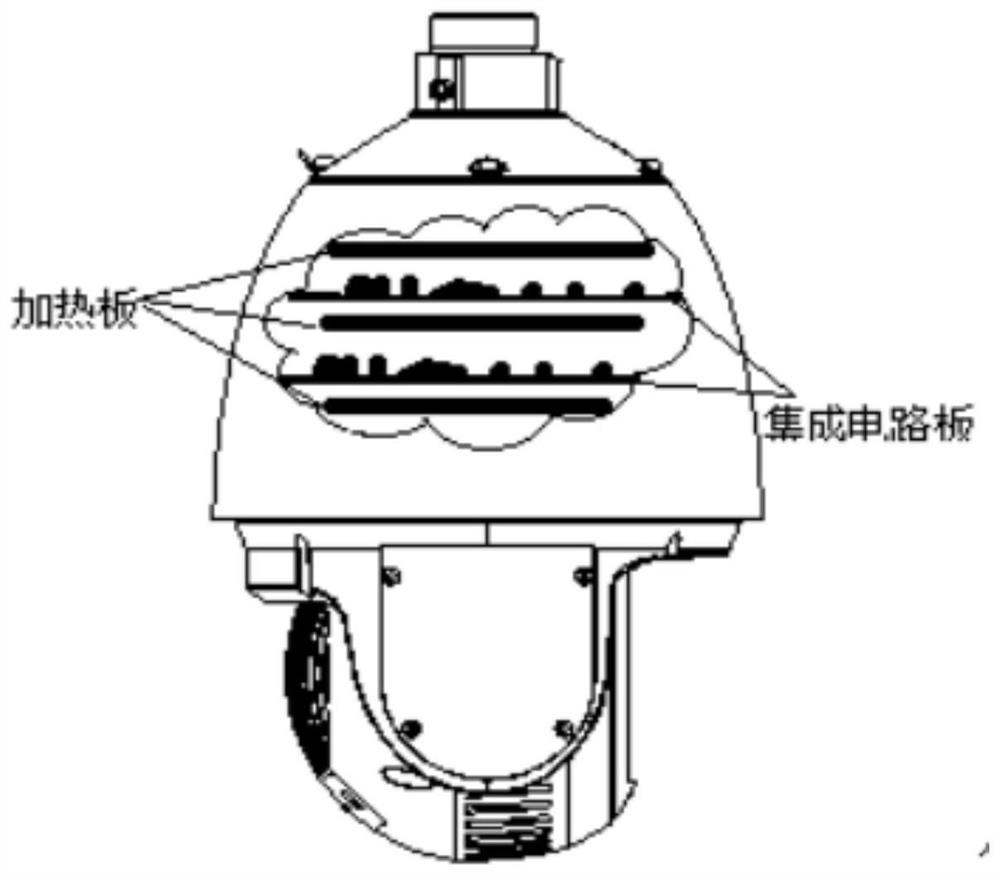

A Dual Spectrum Camera Applied in Alpine Region

ActiveCN110536061BSolve the problem that it cannot be used in winter in alpine regionsEliminate operational hazardsTelevision system detailsColor television detailsCarbon fibersControl cell

Owner:国网黑龙江省电力有限公司鹤岗供电公司 +2

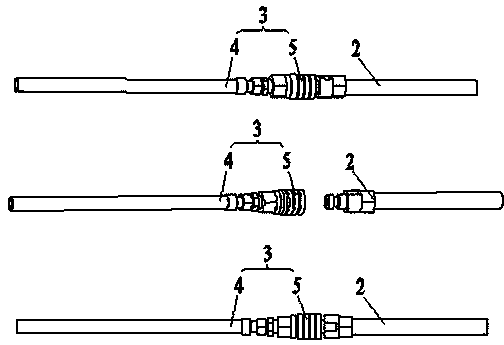

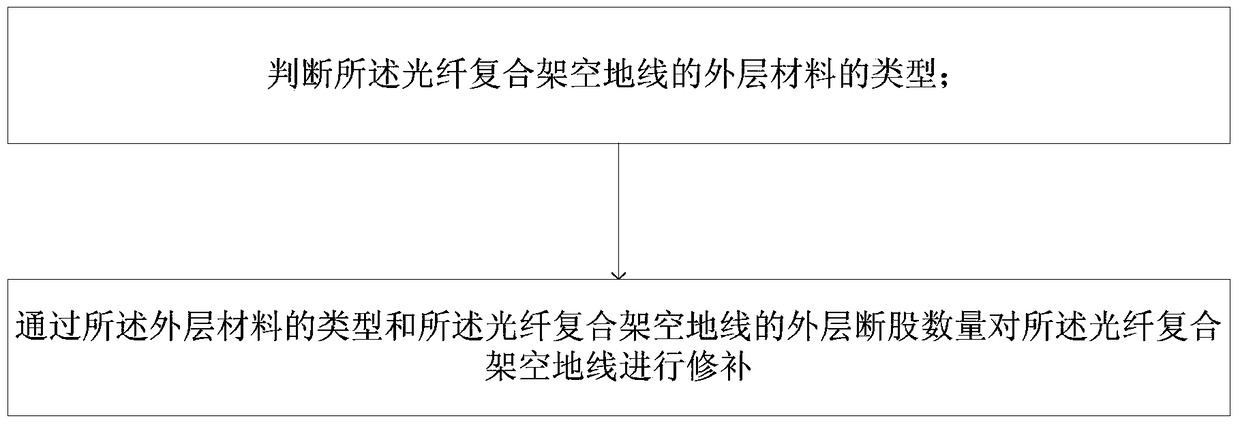

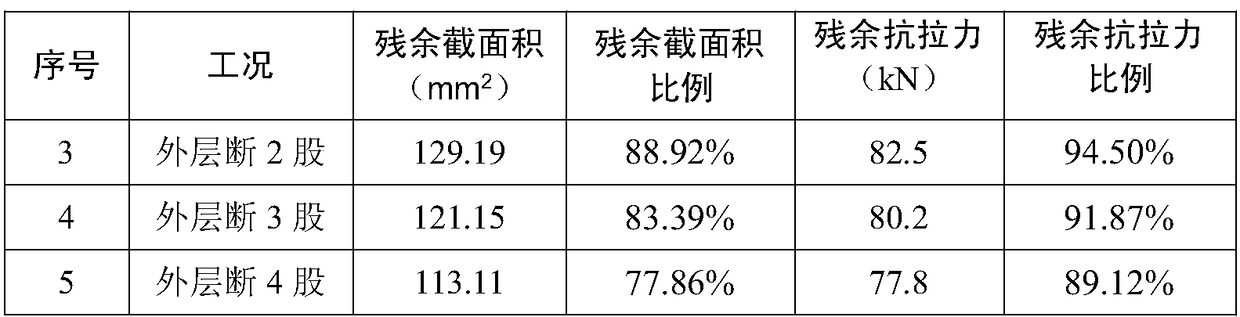

A permanent repair method for broken strands of optical fiber composite overhead ground wire

ActiveCN105720514BLess investmentShorten the timeApparatus for overhead lines/cablesMaterial typeBlack out

The invention discloses a permanent restoration method for a broken strand of an optical fiber composite overhead ground wire, comprising steps of determining the type of the outer layer material of the optical fiber composite overhead ground wire, performing mending on the optical composite overhead ground wire through the external layer material type and the broken strand quantity of the external layer of the optical fiber composite overhead ground wire, wherein the mending comprises mending through an aluminum-coated steel mending strip or replacement of the optical fiber composite overhead ground wire after the aluminum-coated steel mending strip performs temporary mending and the circuit is blacked out. The method of the invention utilizes a pre-stranded mending strip and adopts the different mending methods according to the OPGWs of different conductivities on the external layer, which enables the mended OPGW to satisfy the mechanical performance, the electric performance and light transmission performance, and guarantees the safety reliability of the mended OPGW. The technical scheme of the invention eliminates the fault and the operation hidden dangers with the minimum investment and time and the most reliable method, and has an important meaning to the reliability of guaranteeing the power grid power supply and information transmission.

Owner:STATE GRID CORP OF CHINA +2

A kind of motor flexible pg board

ActiveCN105576902BReduce manual assemblyReduce solder jointsElectric machinesStructural associationFlexible circuitsThree-dimensional space

The invention discloses a motor flexible PG board, which comprises a substrate and Hall circuits arranged on the substrate. The substrate of the PG board adopts a flexible circuit board. The flexible circuit board is in an E-shaped structure comprising three branches. The Hall circuits are arranged on the top ends of the three branches respectively. The three branches are mutually nonparallel; the branches at the two sides converge to the middle and form acute-angle included angles with the middle branch respectively. The motor flexible PG board is in an axisymmetric distribution structure with the branch in the middle as a symmetry axis. The step of manual assembly of an insulating bush is saved; full-automatic SMD process is realized; the flexible PG board has flexible three-dimensional space assembly capability, and the PG boards of the same type can be fit to more motors; the flexibility of the PG board helps to reduce assembly labour intensity of workers effectively; and the motor flexible PG board is compatible with the PG boards of all hub motors, including a 60-degree motor and a 120-degree motor, and hub motors of different wheel diameters.

Owner:南京艾驰电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com