Method for controlling concentration of sulfate radical of pressurized water reactor nuclear power plant unit-loop

A pressurized water reactor nuclear power plant and sulfate technology, which is applied in nuclear power generation, nuclear engineering, reactors, etc., can solve the problems such as failure to remove sulfate, unidentified source, and inability to remove sulfate, so as to optimize water quality control, The effect of eliminating hidden dangers in operation and avoiding economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

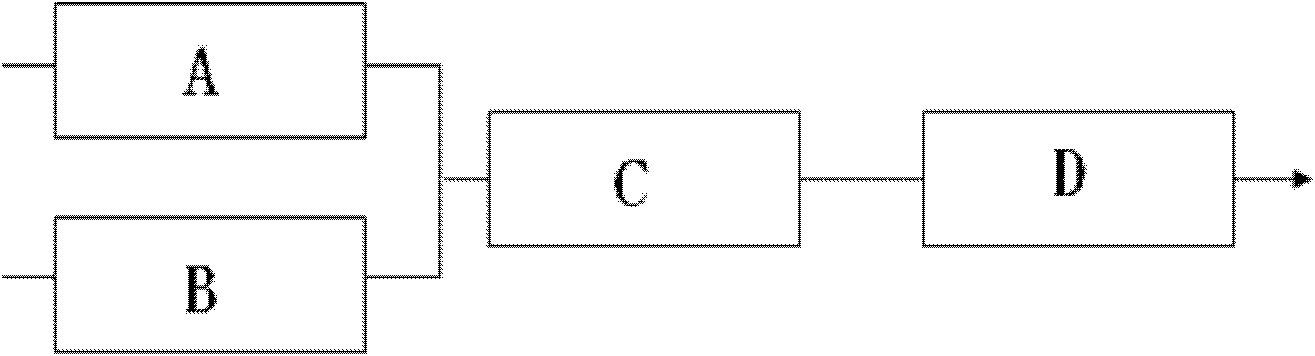

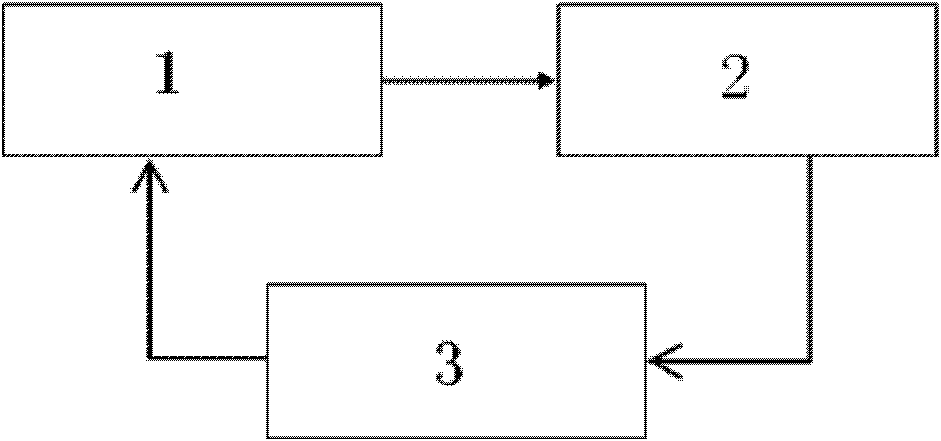

[0020] The present invention adopts the idea of reducing the release of sulfonic acid groups from the cationic resin and removing the sulfonic acid groups in the boron-containing water storage system 2 at the same time, so as to achieve the purpose of reducing the concentration of sulfate radicals by utilizing the operation mode of the existing purification system.

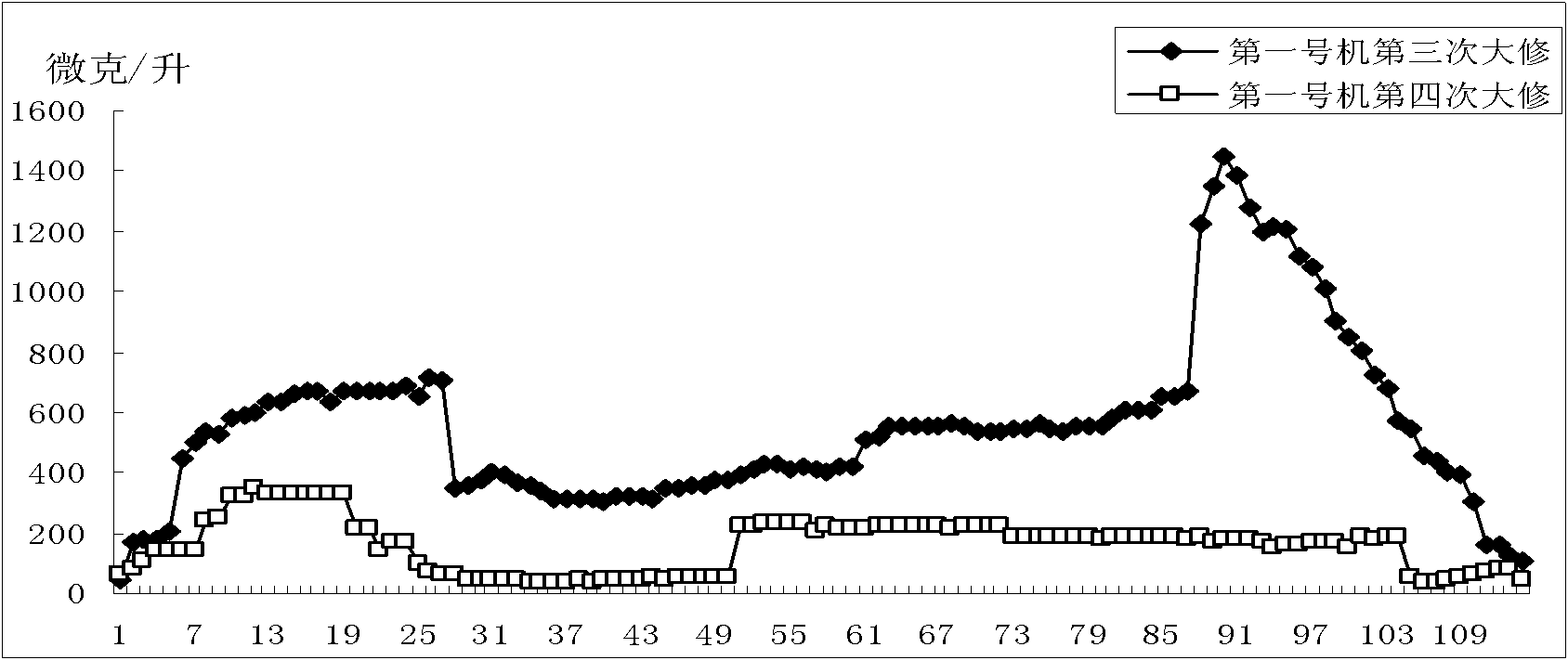

[0021] Reducing the release of sulfonic acid groups from the cation resin: the loss of sulfonic acid groups after the cation resin is oxidized is a common feature of the cation resin. Reducing the oxidation of boric acid in the spent fuel pool 1 requires changing the water quality in the spent fuel pool, which is not allowed by nuclear safety . Only by reducing the amount of cation resin in the purification system, considering that there are two purification units equipped with cation res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com