Motor flexible PG board

A technology of electric motors and flexible circuit boards, applied in the field of PG boards, can solve problems such as increased manufacturing costs and management difficulties, hidden dangers of PG board quality, etc., achieve flexible three-dimensional space assembly capabilities, reduce quality control difficulties, and reduce manufacturing and management costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

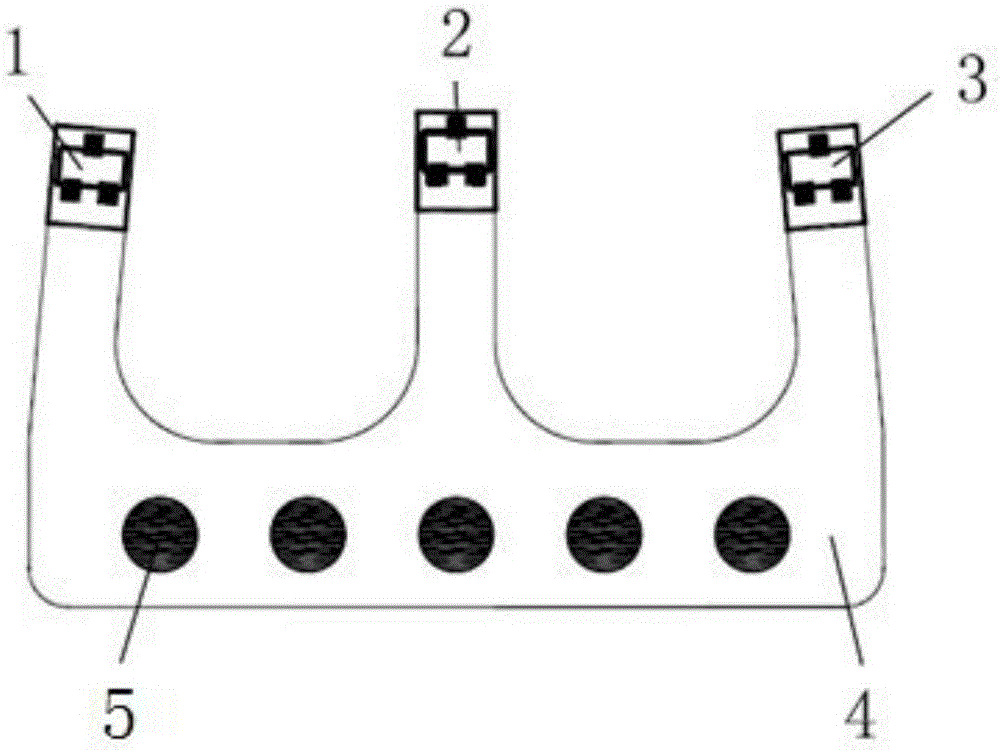

[0029] The structure of a motor flexible PG board according to the present invention is as follows: figure 1 As shown, including the substrate and the Hall circuit arranged on the substrate, the substrate of the PG board adopts a flexible circuit board 4 (FPC), and the Hall circuit arranged on the substrate is a patch type Hall circuit (SOT23).

[0030] After the Hall circuit is assembled, use commercially available conformal paint for surface treatment to achieve the effect of the existing assembled insulating sleeve. The flexible PG board of the motor saves the link of manual assembly of the insulating sleeve. The outer lead wire of the SMD Hall circuit is very short, and the solder joint 5 assembled on the FPC is very small, and the "pull" can be avoided by using ordinary three-proof paint coating. arc phenomenon". The flexible PG board of the motor real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com