A lock clip pressing tool

A press-fitting tool and press-fitting technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as the inability to ensure the alignment of the locking rib and the ring groove of the valve stem at the same time, low production efficiency, and high labor intensity. problems, to achieve the effect of reducing manual assembly links, reducing labor intensity, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

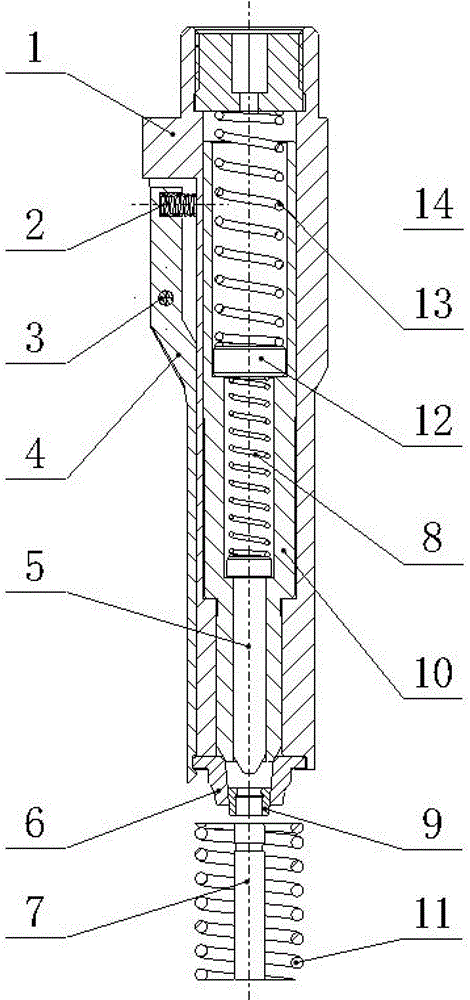

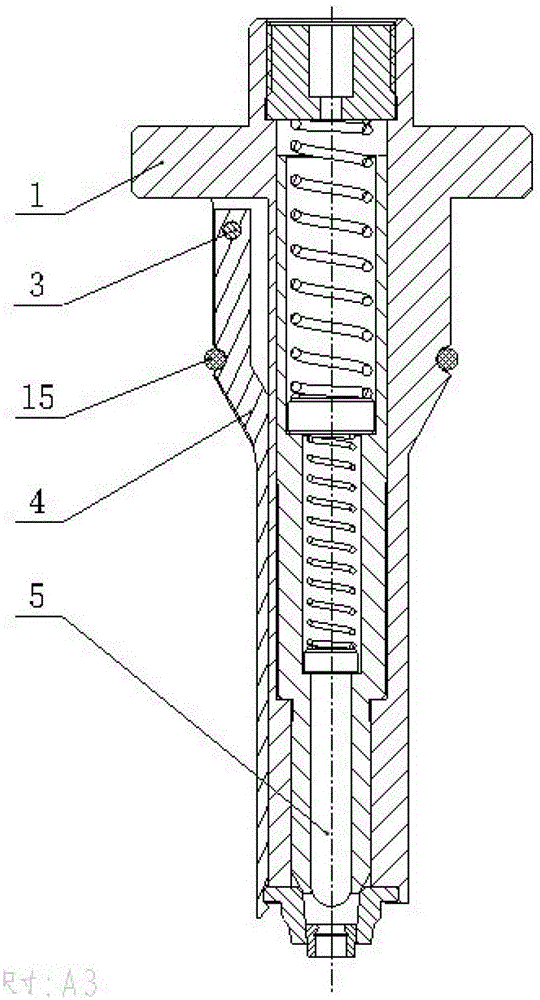

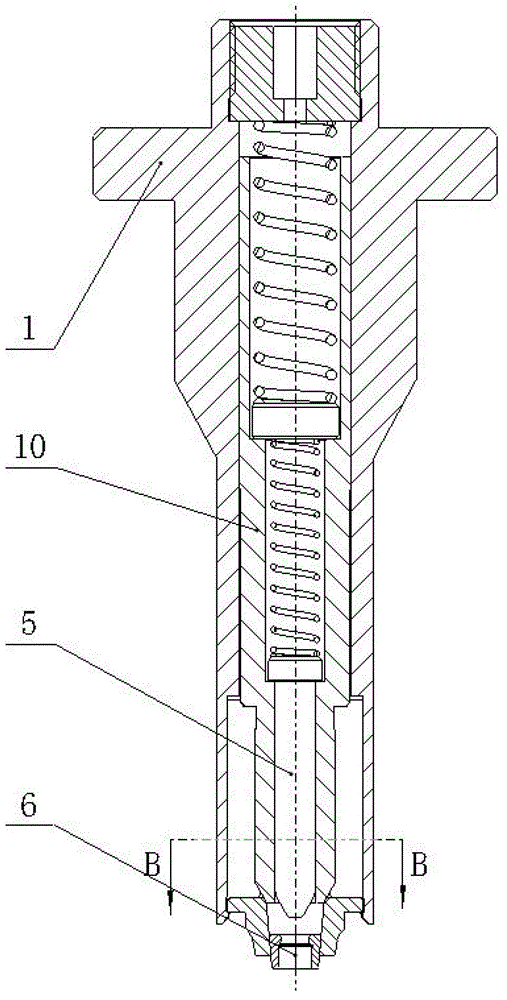

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing: figure 1 , the outer circumference of the pressing body 1 of the present invention is provided with three grooves in the axial direction, and the three grooves are evenly distributed along the axis. The spring 2 is respectively press-fitted between the blind hole on the upper part of the jaw 4 and the press-fit body; the mandrel 5 is assembled in the inner hole of the lower part of the pressure sleeve 10, and the mandrel spring 8 is press-fitted between the mandrel 5 and the spring washer 12 between the spring washer 12 and the inner hole of the upper part of the pressure sleeve 10, the pressure sleeve spring 13 is pressed between the spring washer 12 and the limit screw 14, and the lower part of the pressure sleeve 10 is smoothly fitted in the inner hole of the lower part of the pressing body 1 Among them, the limit screw 14 is threadedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com