Method for judging whether abrasion of bearing retainer of locomotive traction motor fails or not

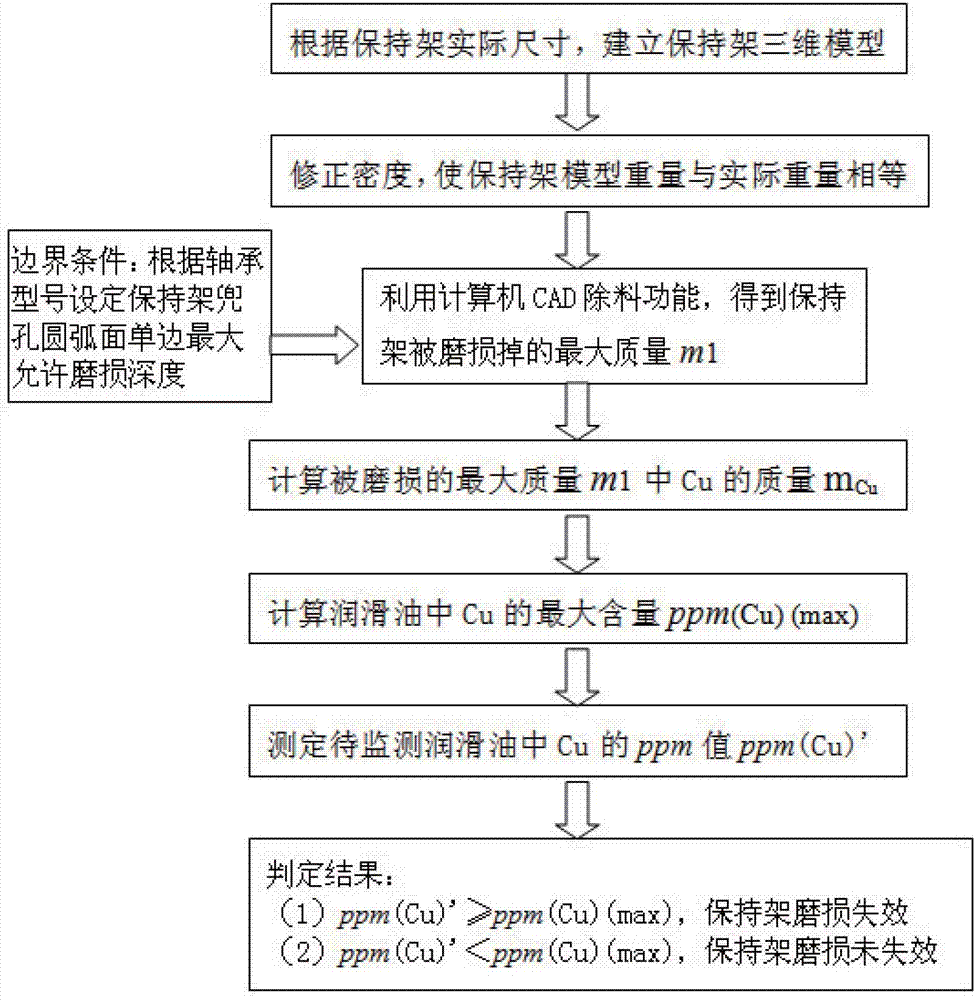

A bearing cage and traction motor technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of rough judgment method, bearing load failure, and difficulty in monitoring whether the bearing is running normally, so as to eliminate hidden dangers in operation and reduce misjudgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

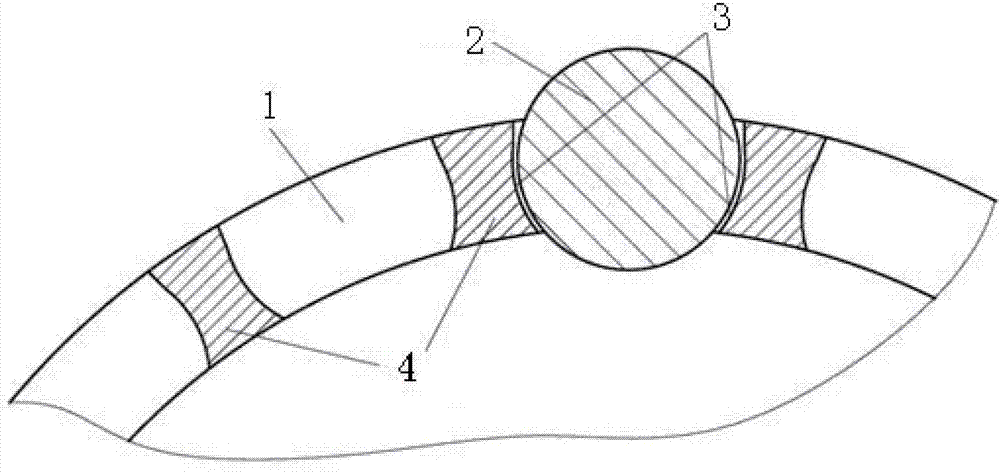

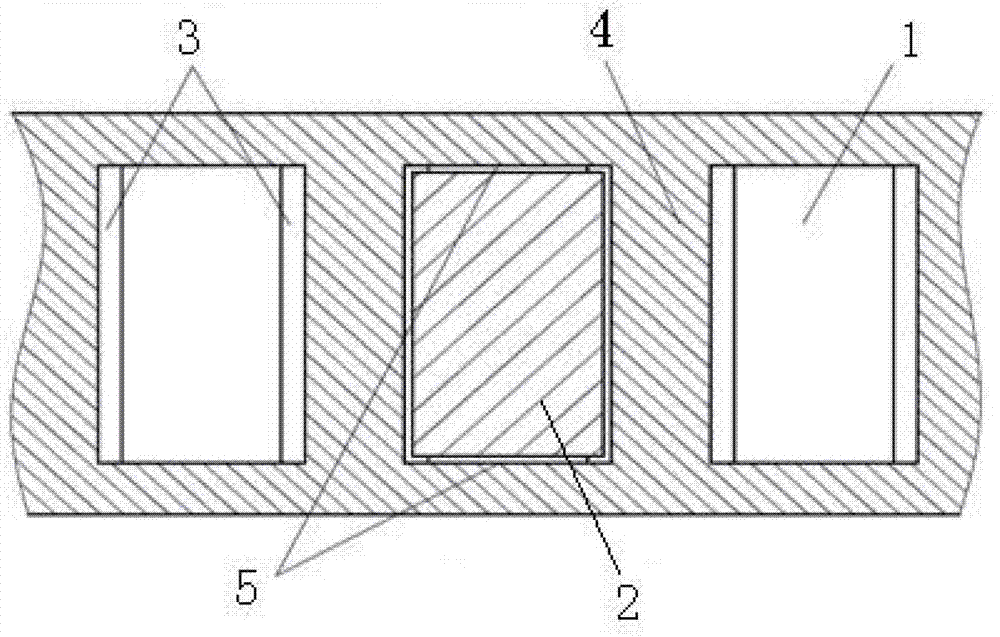

[0033] like figure 1 , figure 2 As shown, the bearing cage of the traction motor of a locomotive mainly includes a cage pocket 1, a cylindrical roller 2 and a cage cross rib 4, wherein the cage pocket arc surface 3 is between the cylindrical roller 2 and the cage cross rib 4 , the cage pocket arc surface 3 is the main worn surface of the cage; between the upper and lower axial ends of the cylindrical roller 2 and the cage transverse rib 4 is the cage pocket side wall 5, because the cage The two side walls of the cylinder will be worn due to the axial movement of the cylindrical roller 2, but th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com