Metal oxide modified safe porous nickel catalyst

A technology of intermetallic compounds and oxides, which can be used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, preparation of organic compounds, etc. Changes and other problems to achieve the effect of eliminating hidden dangers of operation, improving stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

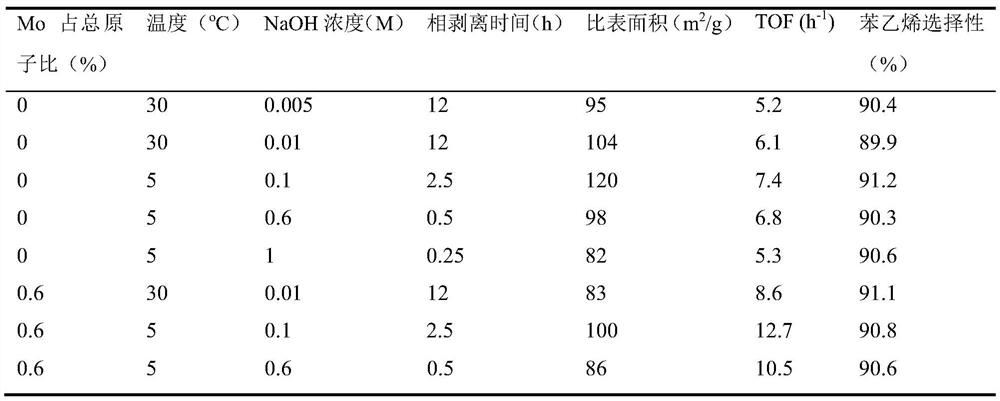

[0022] Using nickel-aluminum atomic ratio of 1:9 as raw material, and adding different contents of Mo metal, refining into composite alloy, and crushing into 200-400 mesh metal powder, after phase stripping under different conditions, the metal oxide modified safe Porous nickel was used in the selective hydrogenation reaction of phenylacetylene, and the test results are listed in Table 1.

[0023]

[0024] It can be seen from Table 1 that during the powder preparation process, temperature, NaOH concentration and phase exfoliation time all have varying degrees of influence on the catalytic conversion and selectivity of safe porous nickel. The powder particles have a high degree of refinement. On the one hand, we hope to increase the surface roughness as much as possible to expose more alloyed surfaces to improve catalytic activity. On the other hand, we need to prevent surface transition oxidation from causing alloy ratio imbalance or surface pore structure collapse. Prelimi...

Embodiment 2

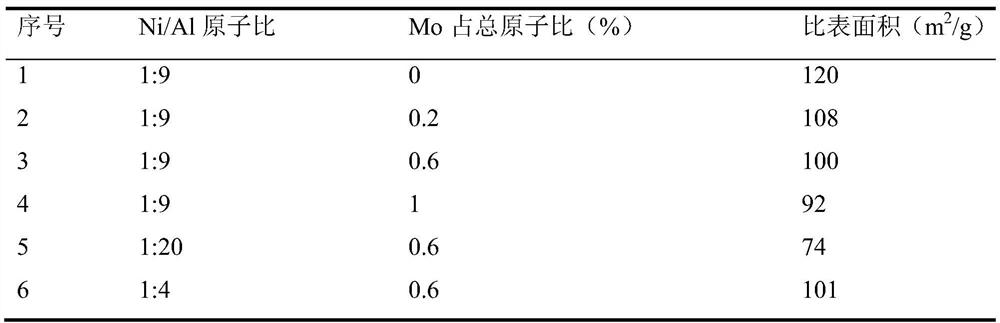

[0026] Using different ratios of nickel and aluminum raw materials (as shown in Table 1), and adding different contents of Mo metal, refining into alloys containing Ni, Al, and Mo, crushing into 200-400 mesh metal powder, and finally performing phase exfoliation ( 0.1M NaOH, 2.5h, 5℃) to remove excess Al, and metal Mo is oxidized in situ on the surface to form MoO 3 The specific surface area of the modified porous nickel catalyst (No. 2-6) is listed in Table 2.

[0027] Table 2

[0028]

Embodiment 3

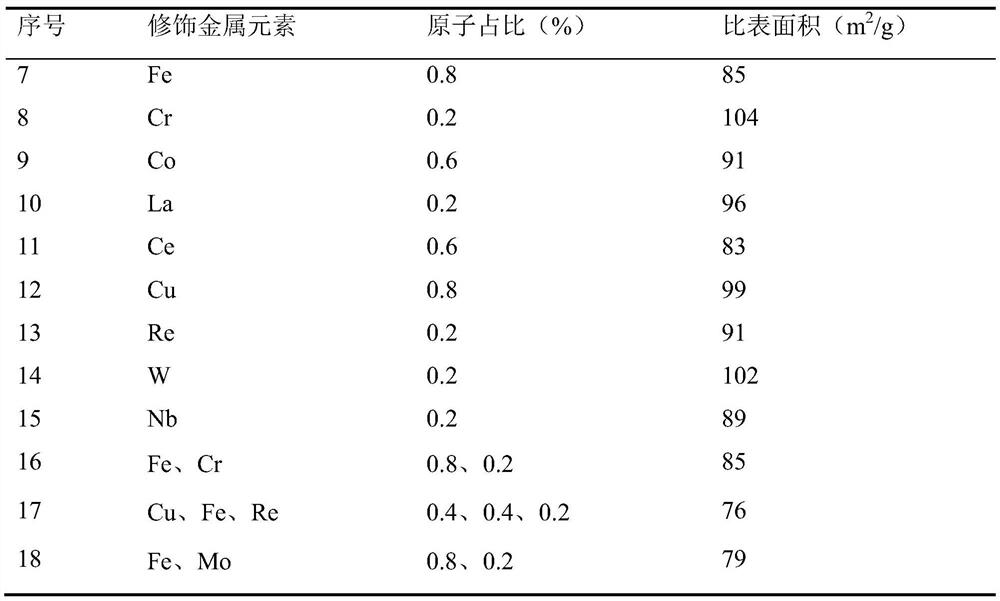

[0030] Based on the Ni / Al atomic ratio of 1:9, and adding different metals (Fe, Cr, Co, La, Ce, Cu, Re, W, Nb), refining it into a composite alloy, crushing it into 200-400 mesh The metal powder was finally phase exfoliated (0.1M NaOH, 2.5h, 5°C) and in-situ oxidized to form a metal oxide-modified porous nickel catalyst (No. 7-18). The specific surface area is listed in Table 3.

[0031] Table 2

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com