Drum type compensator for main pipe of coke oven gas and manufacturing method thereof

A technology for coke oven gas and main pipelines, which is applied to expansion compensation devices, manufacturing tools, and pipe components for pipelines, can solve problems such as interruption of normal gas supply to civil gas users, ignition, economic losses, etc., and reduce labor costs for employees. Strength, process safety and reliability, and the effect of extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

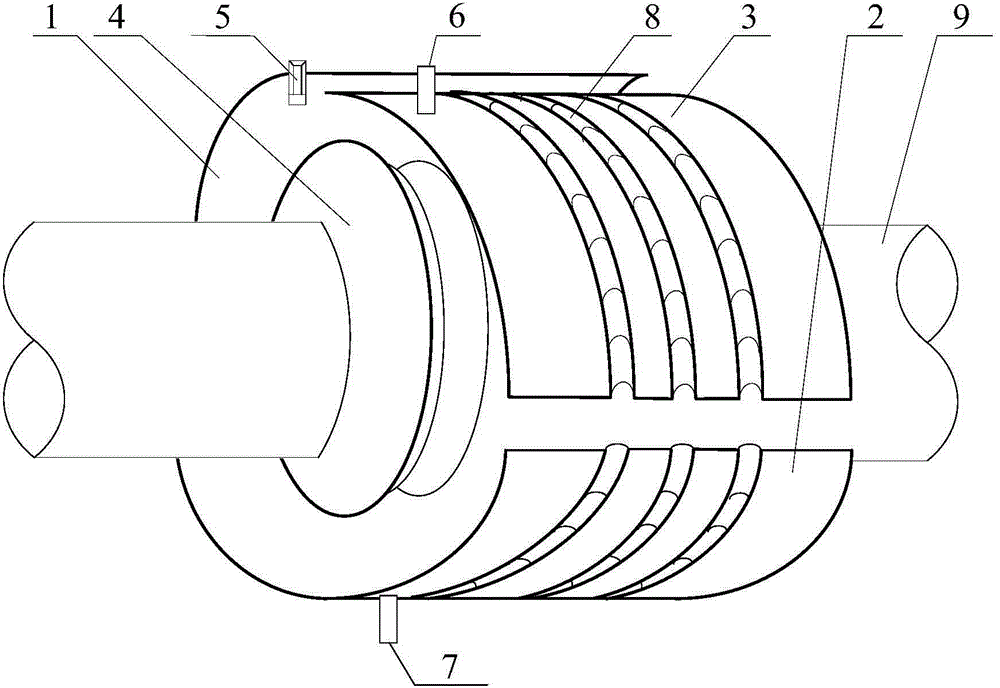

[0038] Coke oven gas main pipeline drum compensator, including: 1 # Arc plate 1, 2 # Arc plate 2, 3 # Arc plate 3, annular vertical plate 4, are characterized in that: 1 # Arc plate 1, 2 # Arc plate 2, 3 # Arc plate 3 The three arc plates have the same shape, and the arcs are all 120 degrees. The middle part of each arc plate is provided with interval corrugations 8 in the direction parallel to its arc edge, and the straight edges of adjacent arc plates are combined and welded to form A cylinder, the middle section of the side wall of the cylinder forms annular corrugations at intervals, and the two end faces of the cylindrical shell are respectively welded with an annular vertical plate 4, the inner diameter of the annular vertical plate 4 is the same as the outer diameter of the coke oven gas main pipe 9 For matching, a release pipe head 5 and a reserved release pipe head 6 are respectively arranged on the side wall of the cylindrical shell, and a reserved nitrogen gas f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com