Pumping soluble plug

A pumping and bridge plug technology, which is applied in the field of pumping soluble plugs, can solve the problems of unsuitable inclined well operation, high operating cost, and long operating time, so as to eliminate operating hidden dangers, save operating time, and reduce operating time. The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

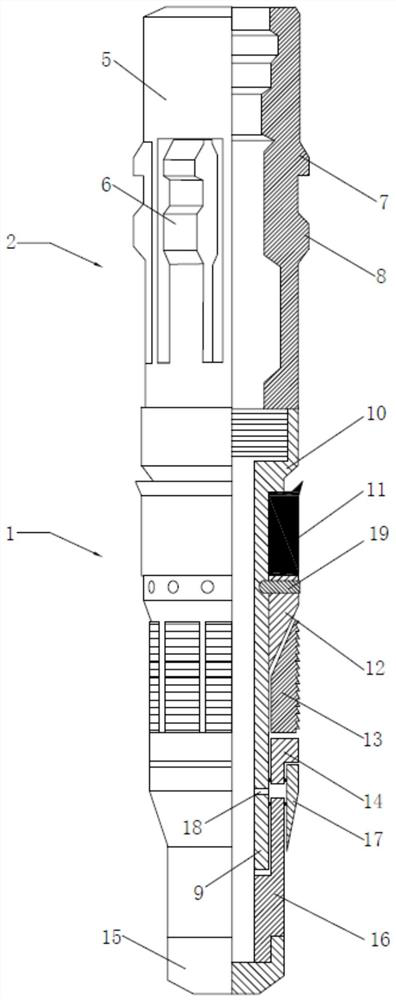

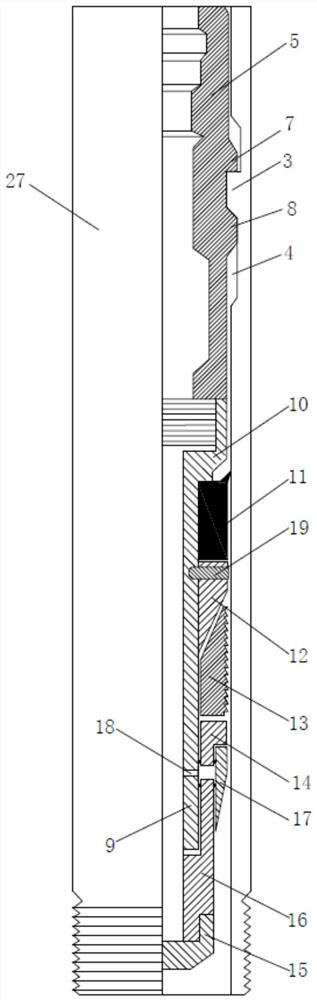

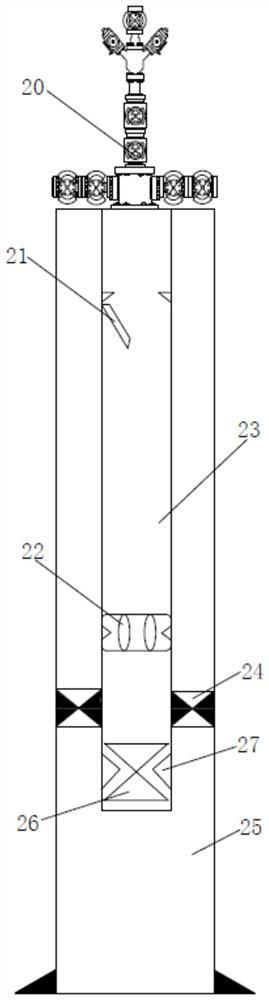

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

[0020] This embodiment relates to a pumping soluble plug, such as figure 1 As shown, it includes: a soluble bridge plug 1 and a soluble locking device 2 . The soluble locking device 2 is assembled on the soluble bridge plug 1, and under the action of pressure or its own gravity, it carries the soluble bridge plug 1 to reach and lock it at the preset short joint 27. Under the action of the hydraulic pressure in the oil pipe 23 , the soluble bridge plug 1 is located in the oil pipe 23 at the preset nipple 27 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com