Machining device for saw cutting and milling grinding

A processing device and sawing technology, which is applied in the field of mechanical processing, can solve the problems of not smooth and smooth surface, high price, easy to scratch hands, etc., achieve the effect of convenient operation, simple structure, and reduce the risk of burr scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

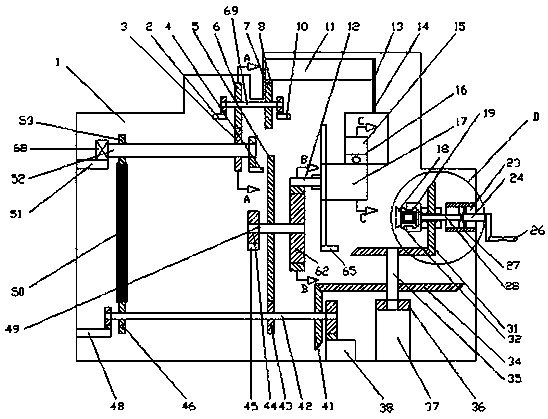

[0019] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

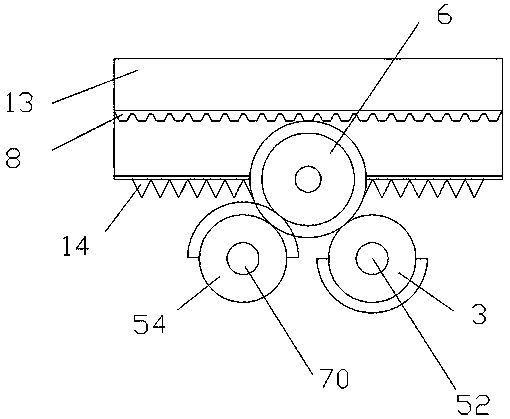

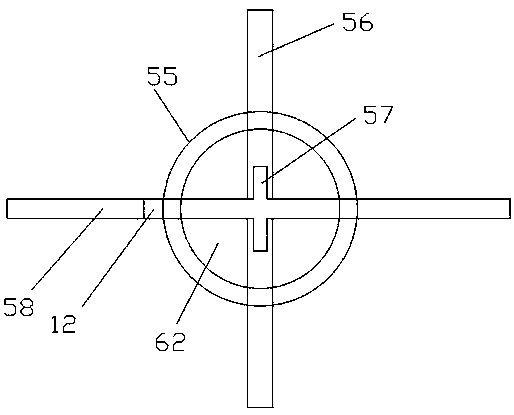

[0020] combined with Figure 1-5 The described processing device for sawing and milling includes a support box 1, the left side of the support box 1 is provided with a first beam 51, and the first beam 51 is equipped with a front motor 68, The right side of the front motor 68 is connected to the front rotating shaft 52, and the right side of the front rotating shaft 52 is installed on the second crossbeam 4 through the bearing seat, and the second crossbeam 4 is laterally installed on the support box 1. Upper belt pulley 53 and front semicircular gear 3 are installed respectively on the left and right ends of rotating shaft 52, and the rear motor that is positioned at front motor 68 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com