Power wrench with angle drive

A power and wrench technology, applied in the field of power wrenches, can solve the problems of undesired working conditions and uncomfortable operator actions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

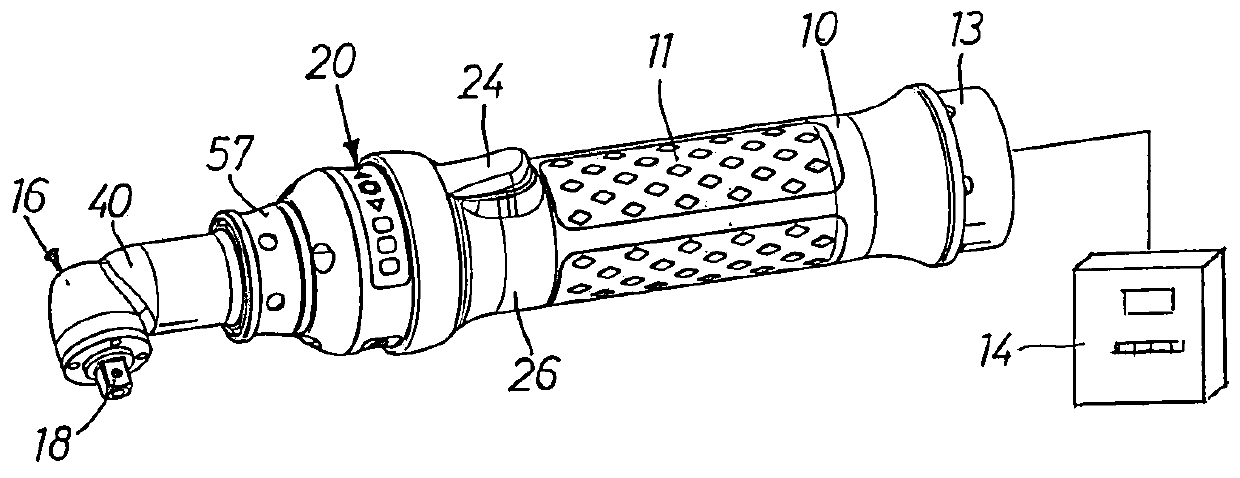

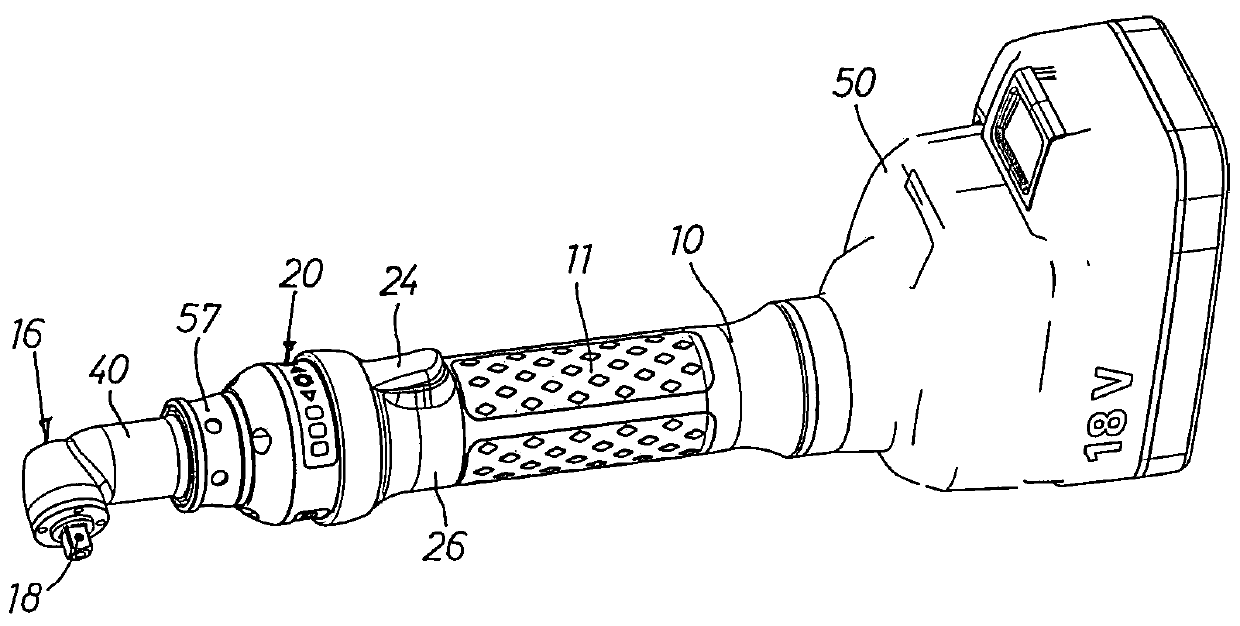

[0021] figure 1 The power wrench shown comprises a cylindrical housing 10 forming a tubular handle 11 and supporting an electric motor, not shown. The housing 10 is provided at its rear end with a connection socket 13 for connecting power and signal transmission cables communicating with a separate programmable operation control unit 14 . The nature and sequence of operations of the control units are of a well-known type and form no part of the present invention. Therefore no further elaboration was given.

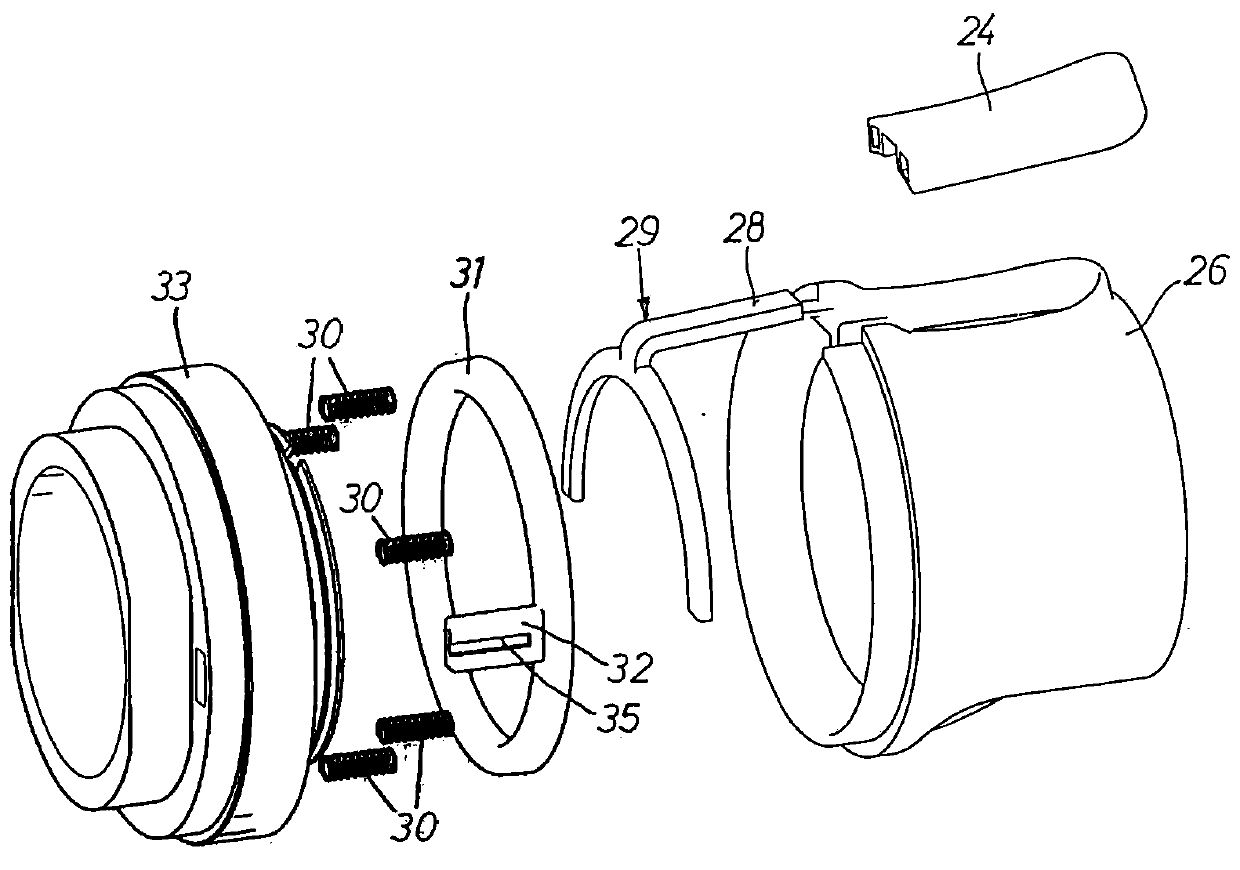

[0022] The housing 10 carries at its front end an elbow 16 having a square ended output shaft 18 adapted to carry a nut socket. The output shaft 18 extends in a transverse direction perpendicular to the cylindrical housing 10 and is connected to the electric motor via an angular transmission. The elbow 16 is connected to the housing 10 by a rotary coupling 20 so that the elbow 16 can be set in a plurality of selectable angular positions relative to the housing 10 so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com