Sofa iron frame structure, sofa and sofa production method

A sofa and iron frame technology, applied in the field of smart home production, can solve the problems of low production efficiency, high cost, large amount of wood, etc., and achieve the effects of improving the yield rate, easy disassembly, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

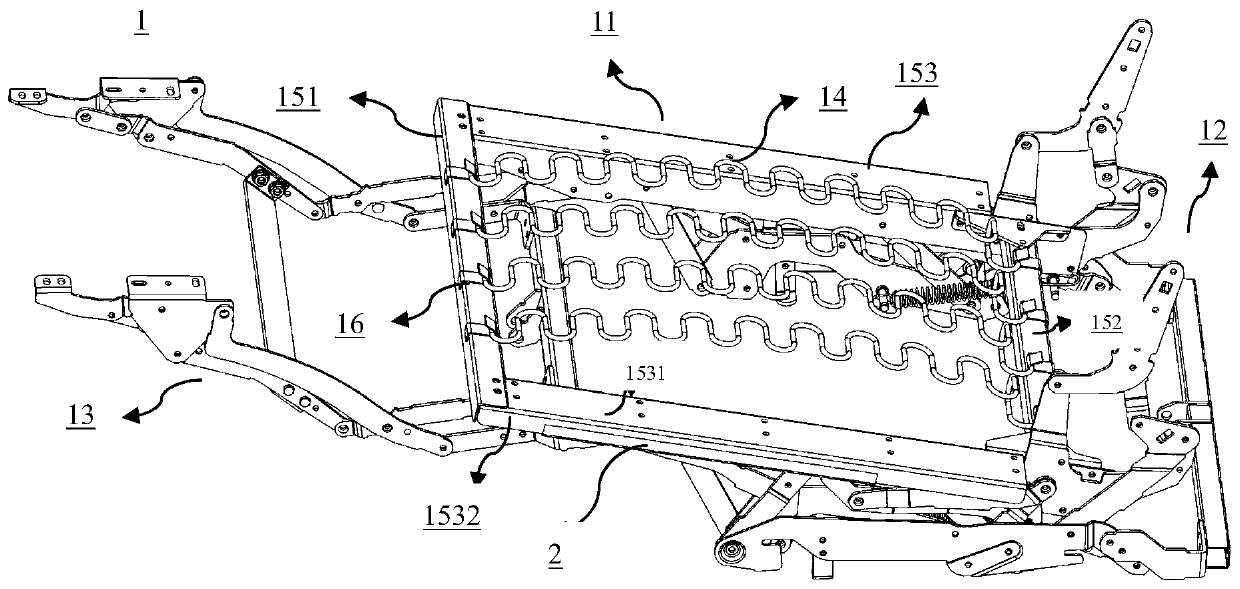

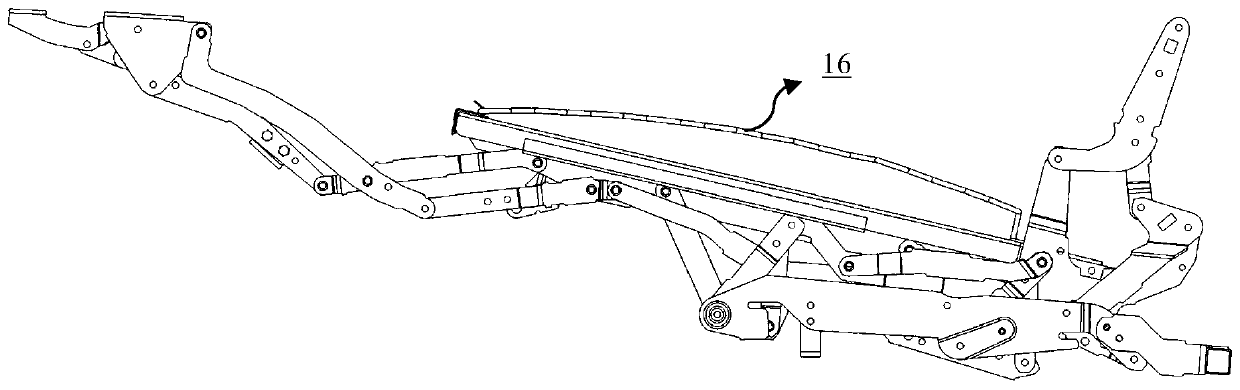

[0033] Such as figure 1 and figure 2 As shown, the sofa iron frame structure 1 of this embodiment includes a seat frame 11, two symmetrically arranged backrest assemblies 12 and two symmetrically arranged leg telescopic assemblies 13, and the seat frame of this embodiment does not introduce additional wood frame to support the structure of the soft bag. In this embodiment, the function of supporting the soft bag is integrated on the seat frame 11. Specifically, the seat frame 11 of this embodiment includes a support assembly for supporting the soft bag. The support assembly includes a support assembly frame, A plurality of serpentine springs 14 and a fixing mechanism 16 for detachably fixing the serpentine springs 14 on the support assembly frame, in detail, the support assembly frame of this embodiment consists of a front rod 151, a rear rod 152 and two end support plates 153 are connected in pairs. The support plate of this embodiment should play the role of supporting the...

Embodiment 2

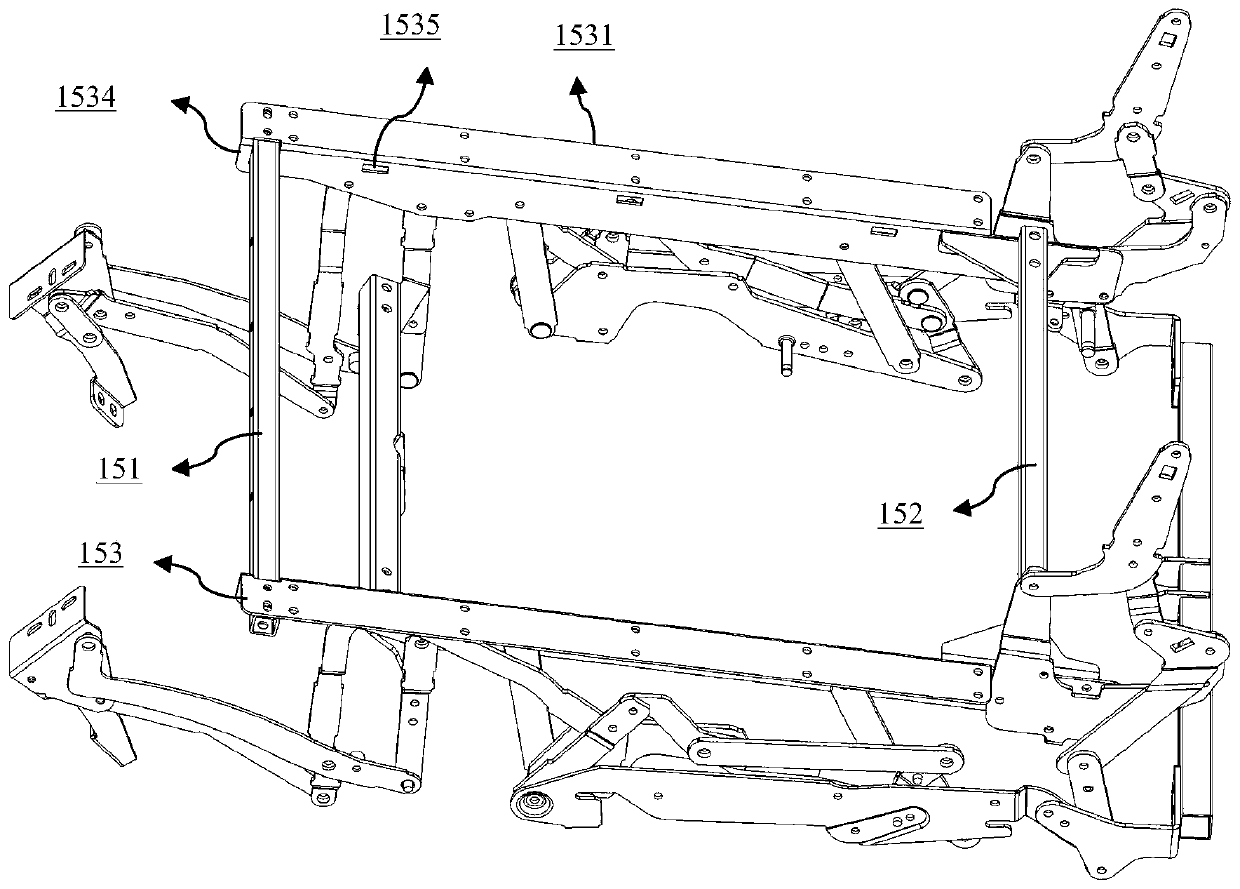

[0038] Such as image 3 As shown, the difference between the iron frame structure of the sofa in this embodiment and the structure of Embodiment 1 is that the structure of the supporting plate is different, and the specific description is as follows:

[0039] The support plate 153 of this embodiment is used to support the panel 1531 of the soft bag and the inner side plate 1534 vertically fixed on the inner side of the lower surface of the panel, and a plurality of buckle holes 1535 are arranged on the inner side plate, and the inner side plate 1534 and the buckle holes 1535 constitute the main body. In the actual manufacturing process of the fittings of the embodiment, square holes are used, and a plurality of square holes are distributed on the inner side plate 1534 at equal intervals.

[0040] In order to realize that the connecting parts of the soft bag can be detachable with the matching parts, when the iron frame structure of this embodiment is used, it is necessary to s...

Embodiment 3

[0043] This embodiment is a sofa made by adopting the iron frame structure disclosed in Embodiment 1, and also includes a soft bag arranged on the iron frame and a sofa fabric covered on the surface of the soft bag. In this embodiment, connectors are sewn on the sofa fabric The connection between the iron frame and the soft bag is completed through the detachable connection between the connecting piece and the matching piece of the support assembly. The soft bag in this embodiment generally uses sponge, and leather or cloth is used as the sofa fabric.

[0044] In order to cooperate with the iron frame structure of Embodiment 1, the connector of this embodiment adopts a U-shaped clip 2, which is made of hard materials such as metal and added with magnetic materials, and can be automatically adsorbed in place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com