Shutdown-free online grit catcher for oil-gas pipeline

A technology for oil and gas pipelines and desanders, which is applied to chemical instruments and methods, production fluids, and feeding/discharging devices of sedimentation tanks. It can solve the problems of complicated installation and poor separation effect, and achieve high separation efficiency and separation. efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

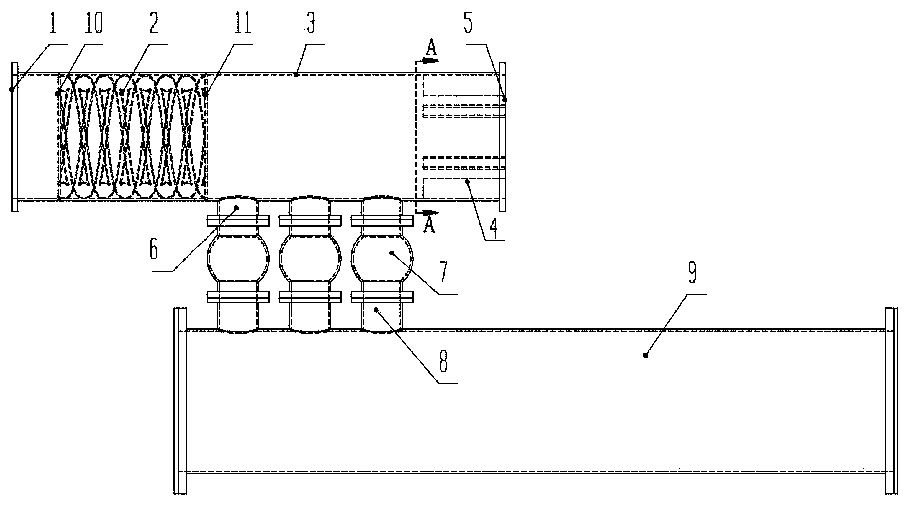

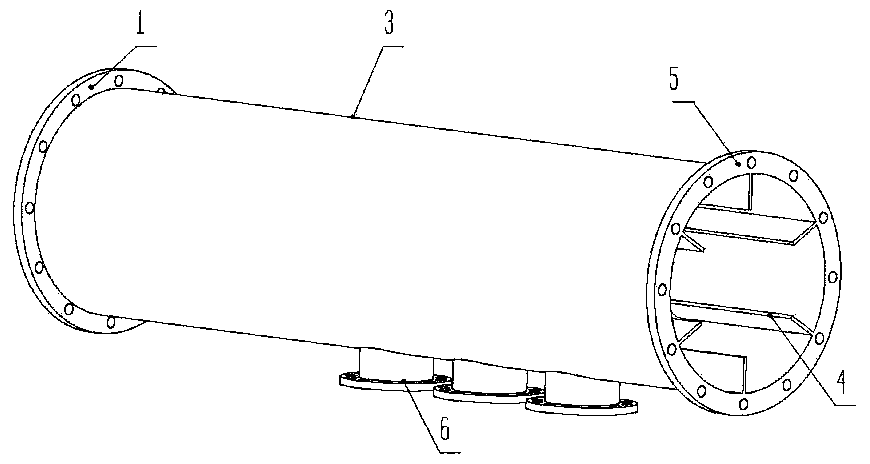

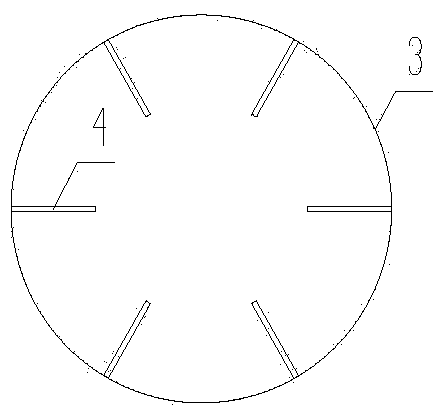

[0024] see Figure 1-Figure 5 , an oil and gas pipeline non-stop online desander of the present invention, comprising a desander inlet 1, a desander outlet 5 and a sand storage chamber 9, and also includes a desander cylinder 3, a double helical pipe 2, a double helical pipe Inlet 10, double spiral pipe outlet 11, anti-rotation fan plate 4, sand discharge port 6, full-bore ball valve 7 and sand inlet 8, the desander cylinder 3 is a cylinder with flange joints at both ends Structure: one end of the desander cylinder 3 is the desander inlet 1, the other end is the desander outlet 5, and the desander cylinder 3 is installed with a double helical tube 2 on the side of the desander inlet 1, and the double helical tube 2 A spiral flow channel is formed inside the cylinder body 3 of the desander, and the double helix inlet 10 and the double helix outlet 11 are respectively located at the head and tail of the double helix 2; the double helix inlet 10 and the double helix outlet 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com