Full-diameter pipeline type sand removing device

A full-bore, pipeline-type technology, applied in wellbore/well components, separation methods, gas fuels, etc., can solve problems such as poor separation effect and complicated installation, achieve high separation efficiency, simplify bypass design, and separate methods. efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

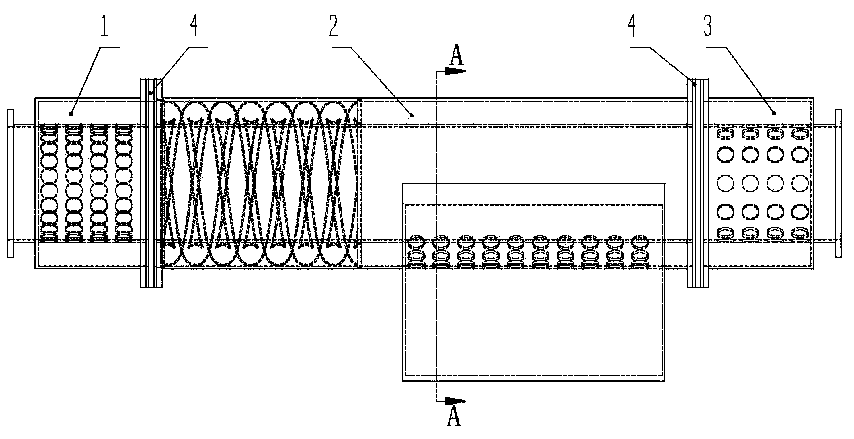

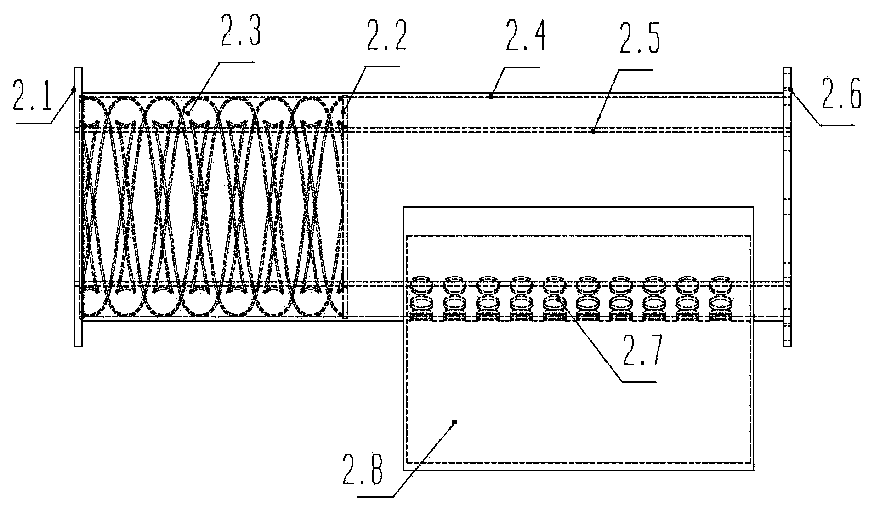

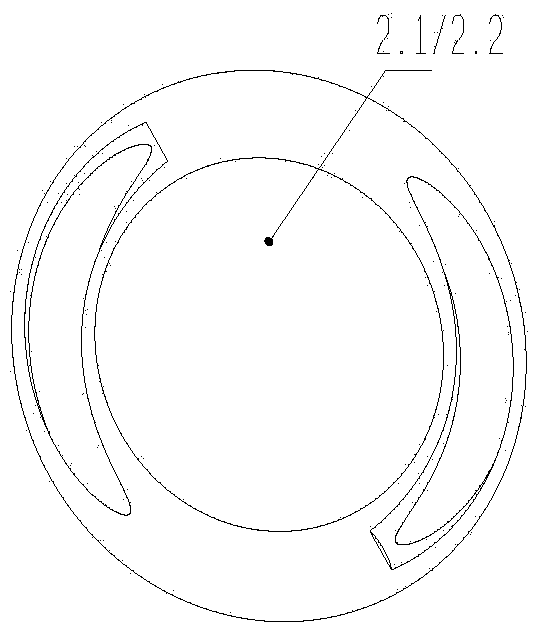

[0033] See attached Figure 1-10, a full-bore pipeline type desanding device of the present invention, comprising a flow direction adjustment inlet 1, a swirl flow sand removal section 2 and a flow direction adjustment outlet 3, the three are connected and formed according to the fluid flow sequence, the flow direction adjustment inlet 1 and the swirl flow Partition plates 4 are set between the desanding section 2 and between the swirl desanding section 2 and the flow direction adjustment outlet 3, and the flow direction adjustment inlet 1 is a structure formed by nesting the flow direction adjustment inlet inner cylinder 1.2 and the flow direction adjustment inlet outer cylinder 1.3 The flow direction adjustment inlet inner cylinder 1.2 is coaxially arranged with the flow direction adjustment inlet outer cylinder 1.3, the inlet end of the flow direction adjustment inlet inner cylinder 1.2 is the natural gas inlet 1.1, and the flow direction adjustment inlet inner cylinder 1.2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com