Patents

Literature

31results about How to "Efficient separation method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

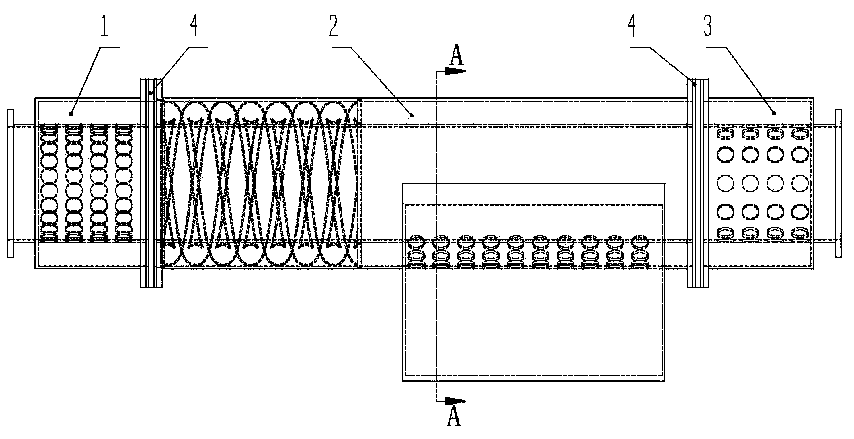

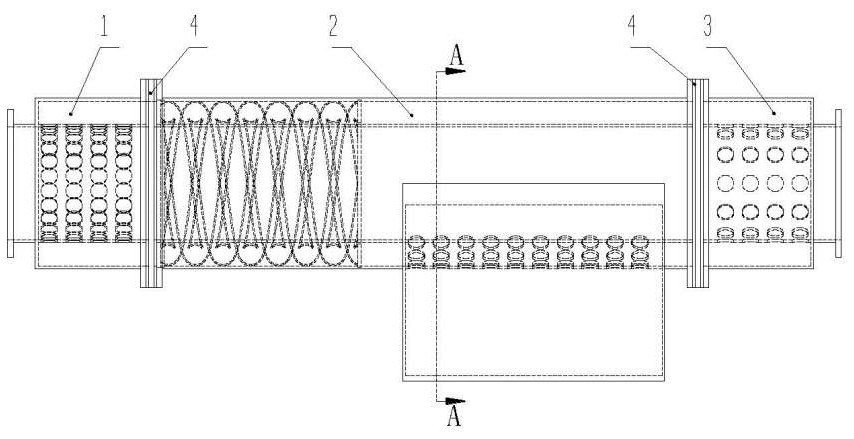

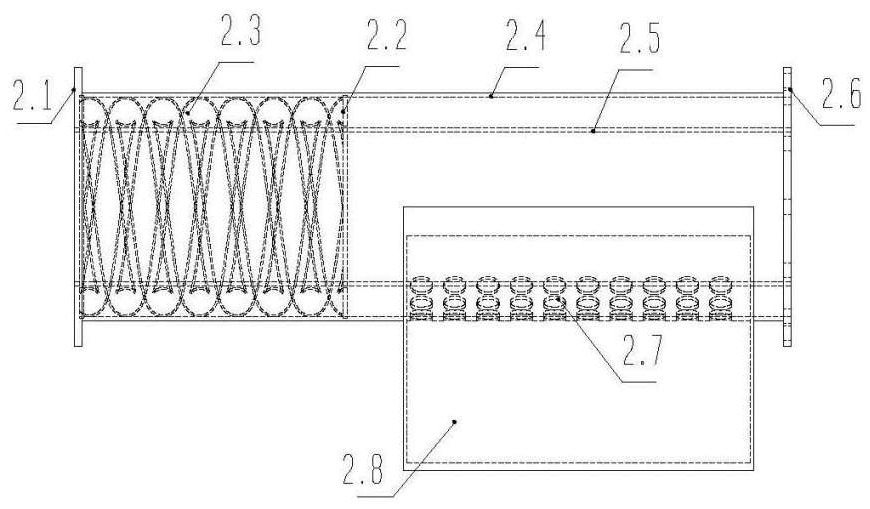

Gravel multi-stage screening device for building construction

InactiveCN108212773AAchieve separationGuaranteed stabilitySievingScreeningReciprocating motionElectric machinery

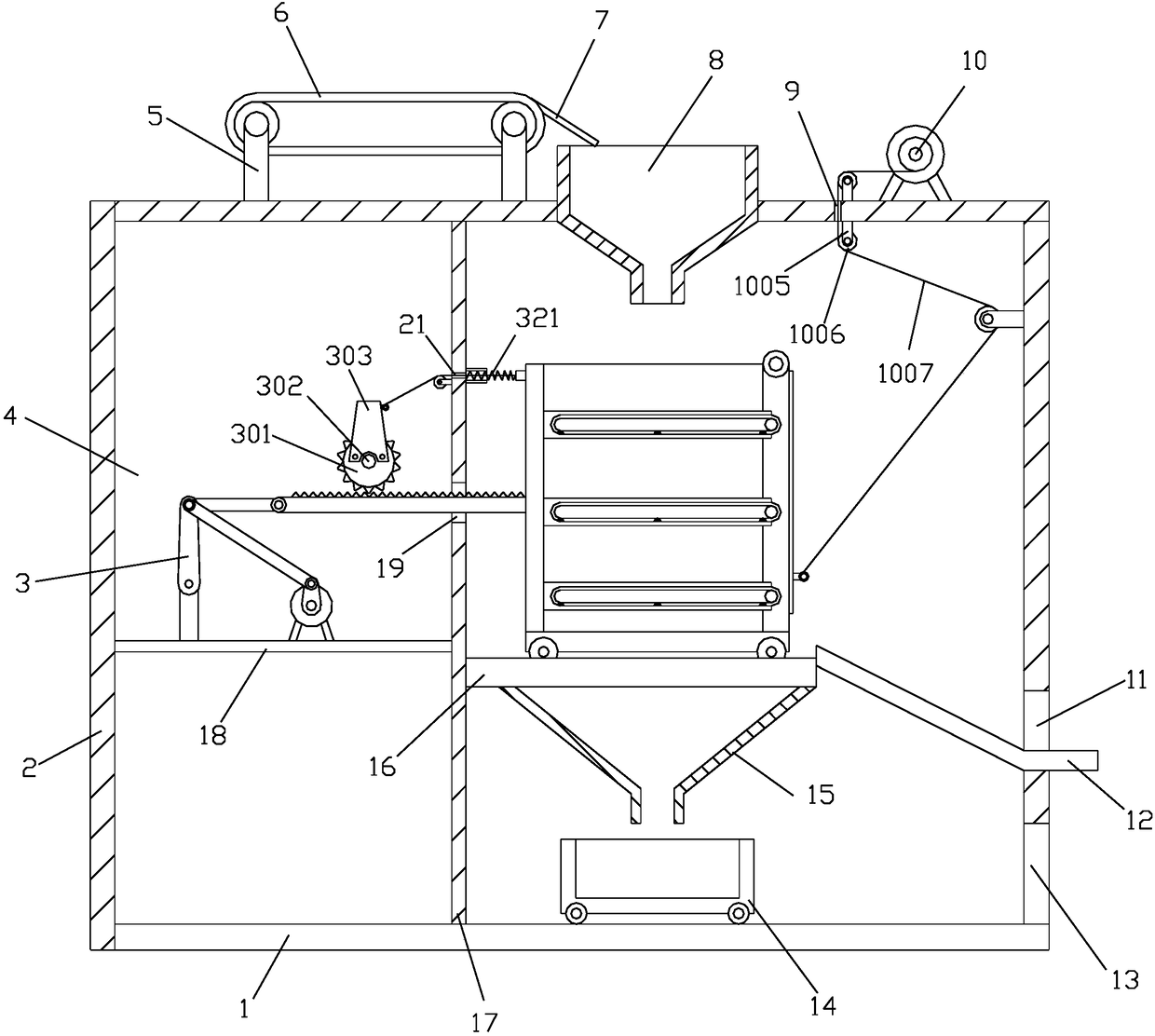

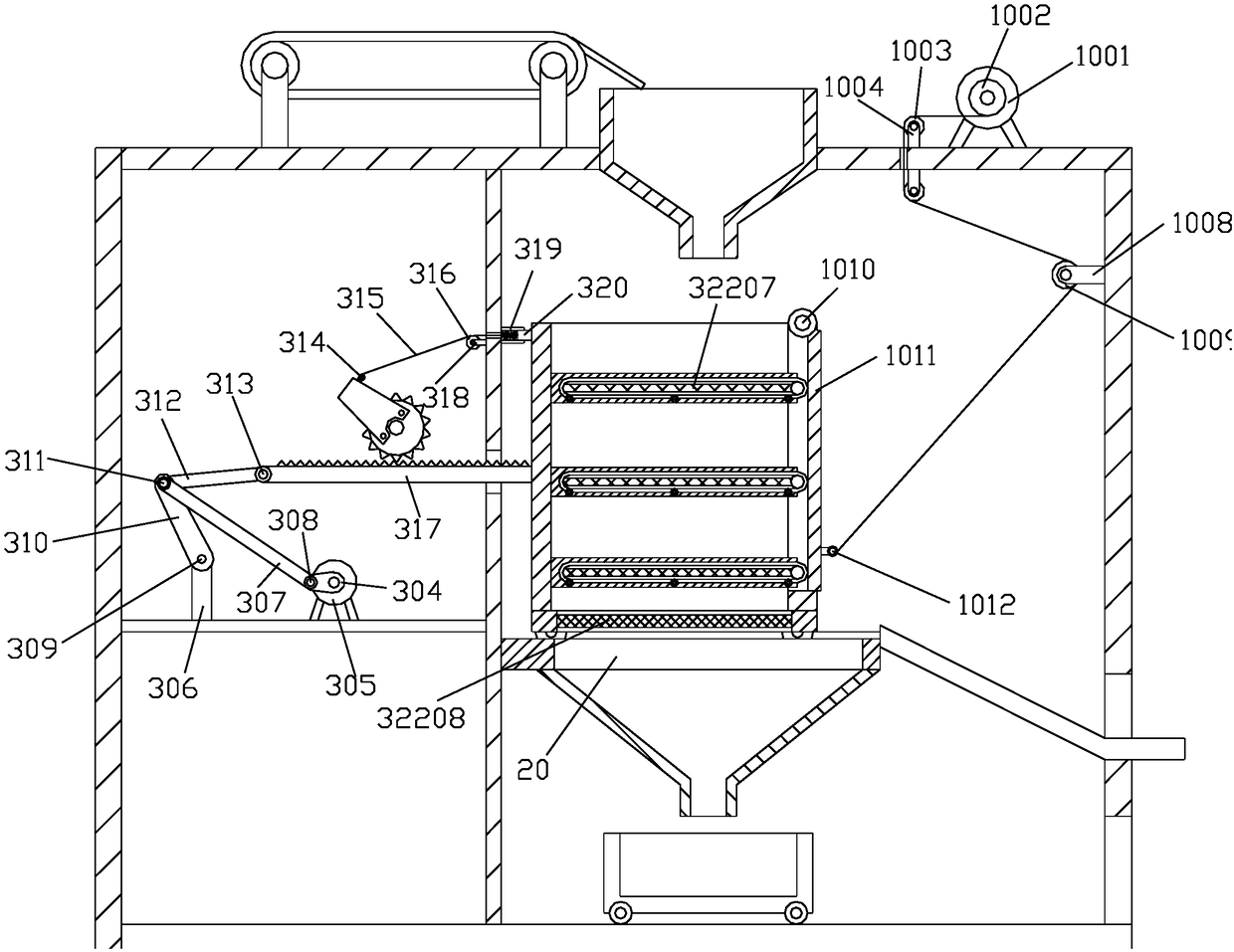

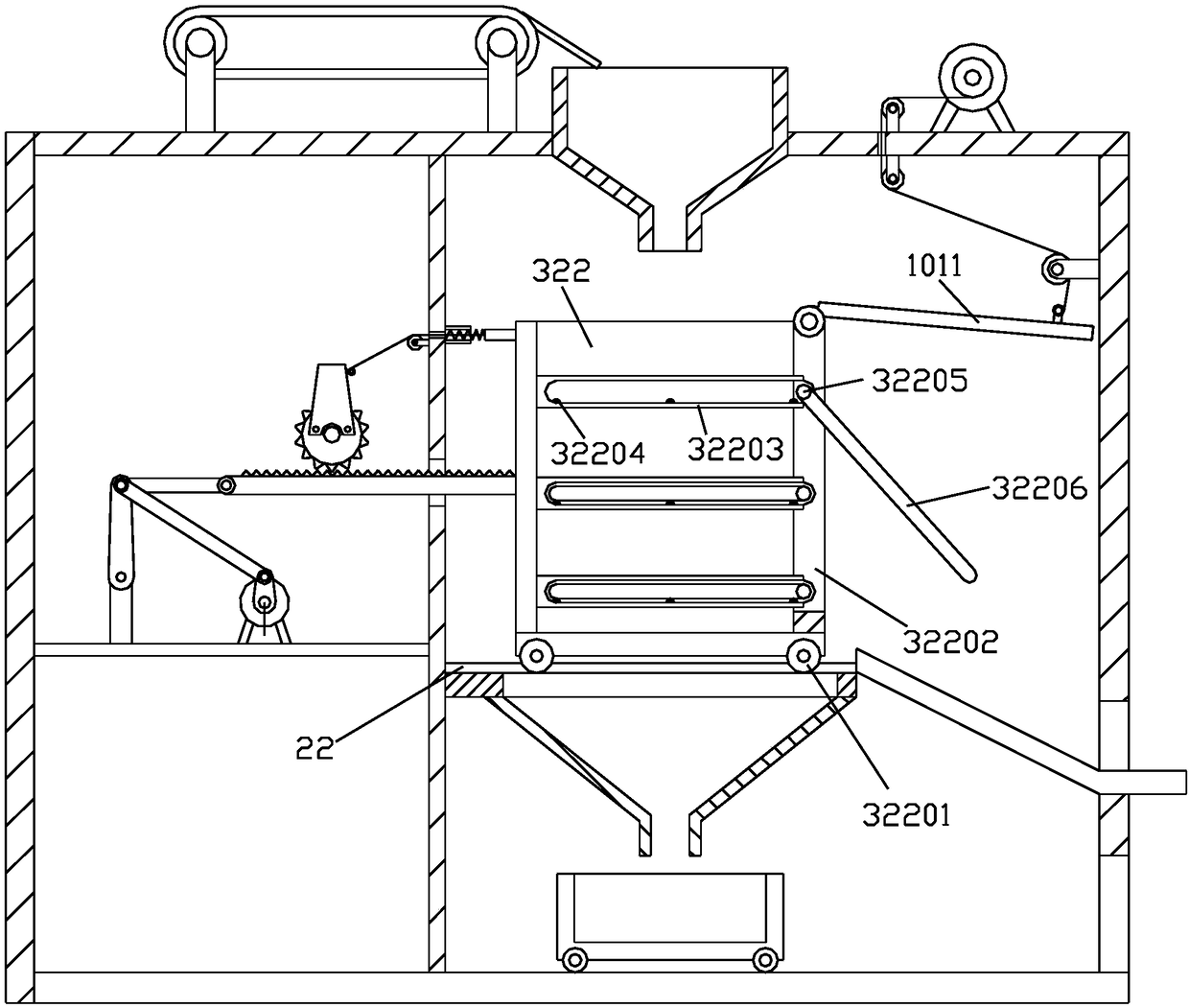

The invention discloses a gravel multi-stage screening device for building construction. The gravel multi-stage screening device for building construction structurally comprises a bottom plate, a shell, a vibration device, a vibration cavity, a supporting column, a conveying belt, a guide plate, a first hopper, a first through hole, an opening and closing device, a stone outlet, a discharging plate, a sand aggregate outlet, a discharging trolley, a second hopper, a first supporting plate, a partition plate, a second supporting plate, a second through hole, a discharging opening, a third through hole and a sliding groove; the bottom plate is vertically mounted at the bottom of the shell through a welding connection manner. According to the gravel multi-stage screening device for building construction, the vibration device is arranged on a left side plate of a screening frame, a motor in the vibration device moves at the high speed, the rack is driven to do reciprocated motion, under theeffect of the rack, the screening frame does the left and right reciprocating motion, shaking between gravel on a screen net can be accelerated, separation between the gravel can be accelerated, stone and sand aggregate are discharged from different outlets, the separation manner is efficient, operation is easy and convenient.

Owner:卢渭彬

Method for removing hyocholic acid from chenodeoxycholic acid

The invention discloses a method for removing hyocholic acid from chenodeoxycholic acid. The method comprises the steps of dissolving, residue removing, complexing, crystallizing, centrifugal separating, emulsifying, acidifying, drying, mother liquor treating and the like; high-boiling-point butyl acetate is utilized as solvent, volatilization of the solvent is reduced, a good separation effect is achieved by utilizing the unique dissolution property of butyl acetate to impurities, and the solvent belongs to a three-level low-toxicity dangerous chemical; the selective complexing characteristic of sec-butylamine to bile acid is utilized, and the hyocholic acid and other impurities can be separated to a higher degree. According to the separation and purification method, impurity removing is qualified in one time, the loss rate of the chenodeoxycholic acid is 5% or below and is greatly lower than the effective ingredient loss of 30% in a conventional crystallization method, the solvent can be recycled, three wastes are not generated, and the method is an environment-friendly, low-cost and efficient separation method.

Owner:CHANGDE YUNGANG BIOTECHNOLOGY CO LTD

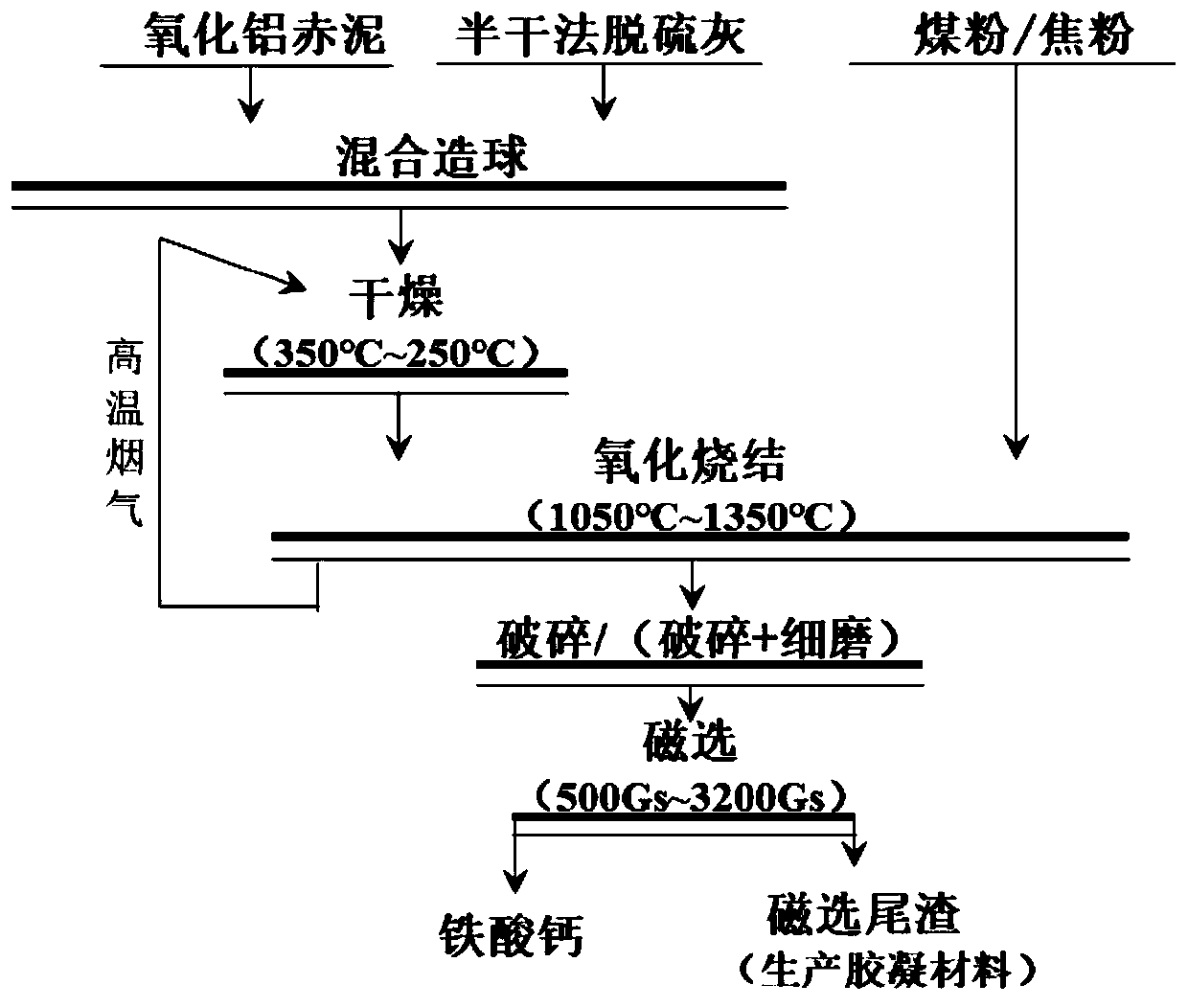

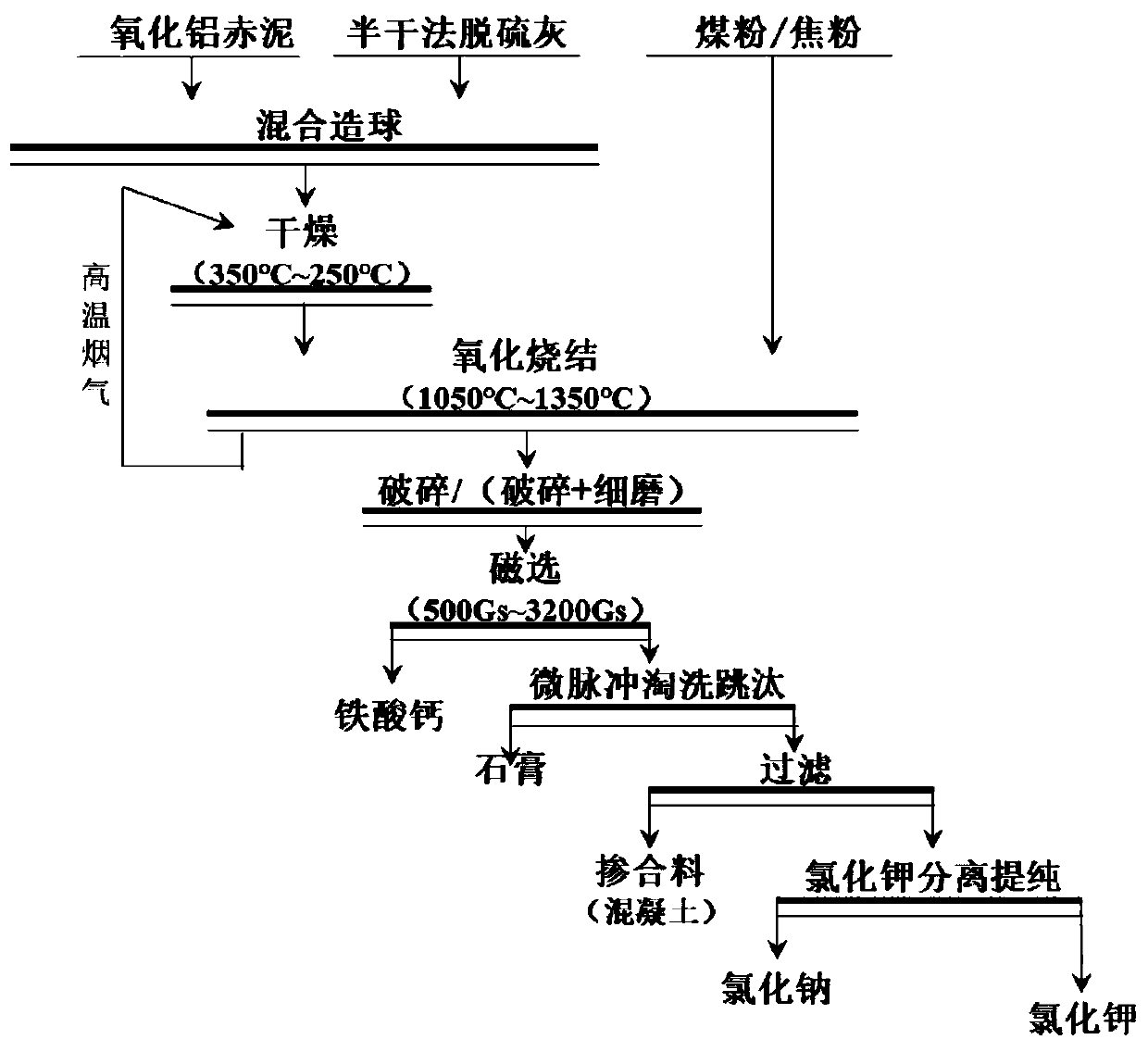

Co-recycling method of aluminum oxide red mud and semi-dry desulfurized fly ash

PendingCN111285406AEfficient separation methodSolid waste managementCalcium/strontium/barium sulfatesRed mudEngineering

The invention belongs to the field of resource regeneration, and particularly relates to a co-recycling method for aluminum oxide red mud and semi-dry desulfurization ash. Compared with desulfurized gypsum, the semi-dry desulfurized fly ash has a high free alkali content, more complex components and unstable properties. First, aluminum oxide red mud and semi-dry desulfurized fly ash are mixed according to a mass ratio of 1: (0.03-1.95), the mixture is pelletized, pellets are dried, the pellets and pulverized coal (or coke powder) are mixed according to a mass ratio of 1: (0.03-0.95), and oxidation sintering is carried out. After cooling, the sintered ore is crushed and finely ground to 0.028mm-13.5mm through roller type crushing equipment and rod milling equipment, and calcium ferrite andgypsum are selectively dissociated. Firstly, magnetic separation is carried out under the conditions that the magnetic separation field intensity is 500 Gs-2100 Gs and the ore pulp concentration is 15%-99.99% to separate out calcium ferrite. The tailings are used for producing a cementing material to replace cement; or a gypsum product is separated from the tailings by using a micro-pulse elutriation jigger, and jigging tailings are filtered. The filter residue is used as a concrete admixture, filtrate is returned to a micro-pulse elutriation jigging process, soluble salt is circularly enriched, and then sodium chloride and potassium chloride are produced by processes such as a cold crystallization direct flotation method.

Owner:UNIV OF SCI & TECH BEIJING

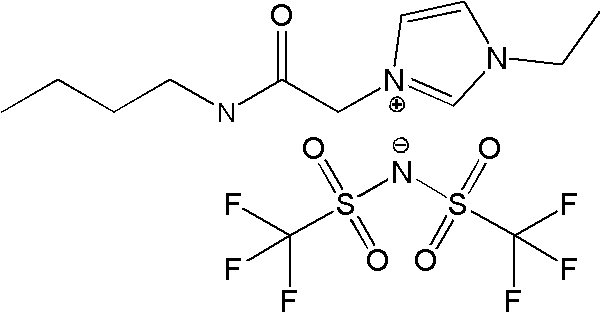

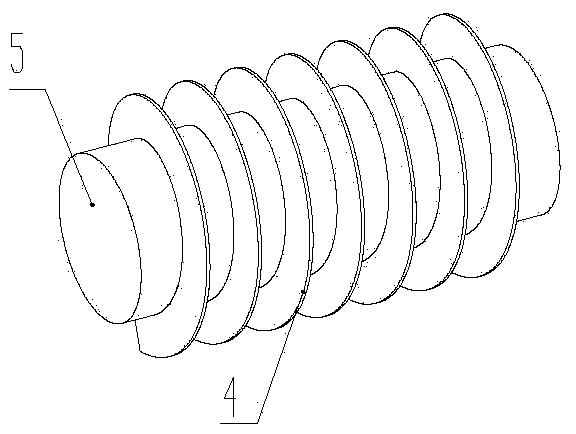

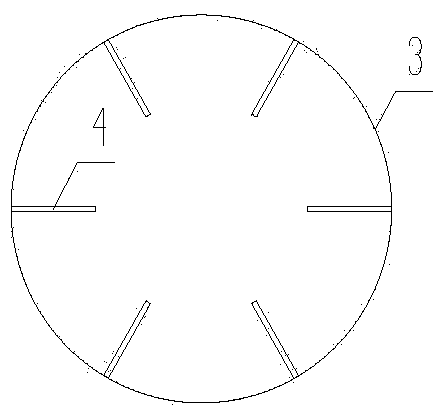

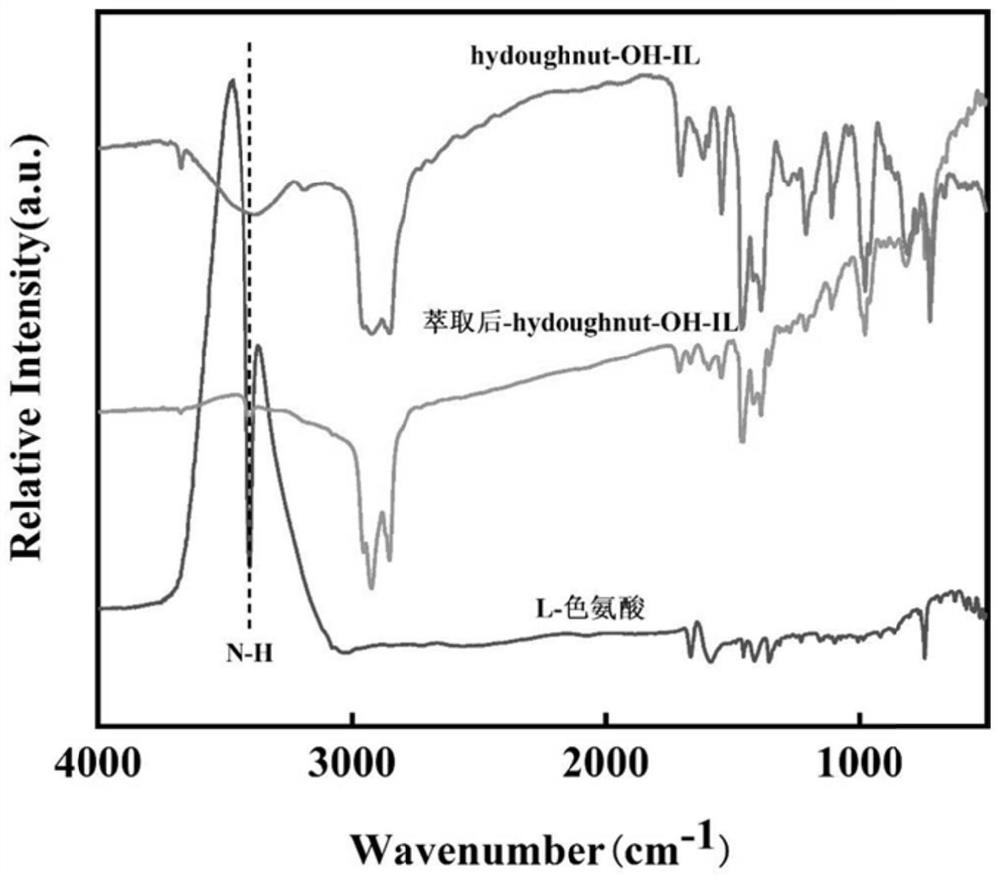

Method for liquid-liquid extraction separation of tryptophan by using hydrophobic amide functionalized ionic liquid

InactiveCN102229559ANo pollution in the processEasy extractionOrganic chemistryTryptophanIonic liquid

The invention relates to a method for liquid-liquid extraction separation of tryptophan by using hydrophobic amide functionalized ionic liquid, which comprises the following steps of: adding an amide functionalized ionic liquid extracting agent and a tryptophan aqueous solution into a processing container under the normal pressure and temperature according to a proportion, stirring and reacting for 20-30min in an acidic condition, wherein the stirring speed is 330 rpm; standing still for layering after reaction is ended; and separating out a water layer and an extracting agent layer. The water layer is an extracted tryptophan aqueous solution; and the detection shows that the content of the amino acid is reduced by 69% to 88%. The method disclosed by the invention is free of pollution to environment and is an efficient and environment-friendly tryptophan separation method.

Owner:DALIAN UNIV

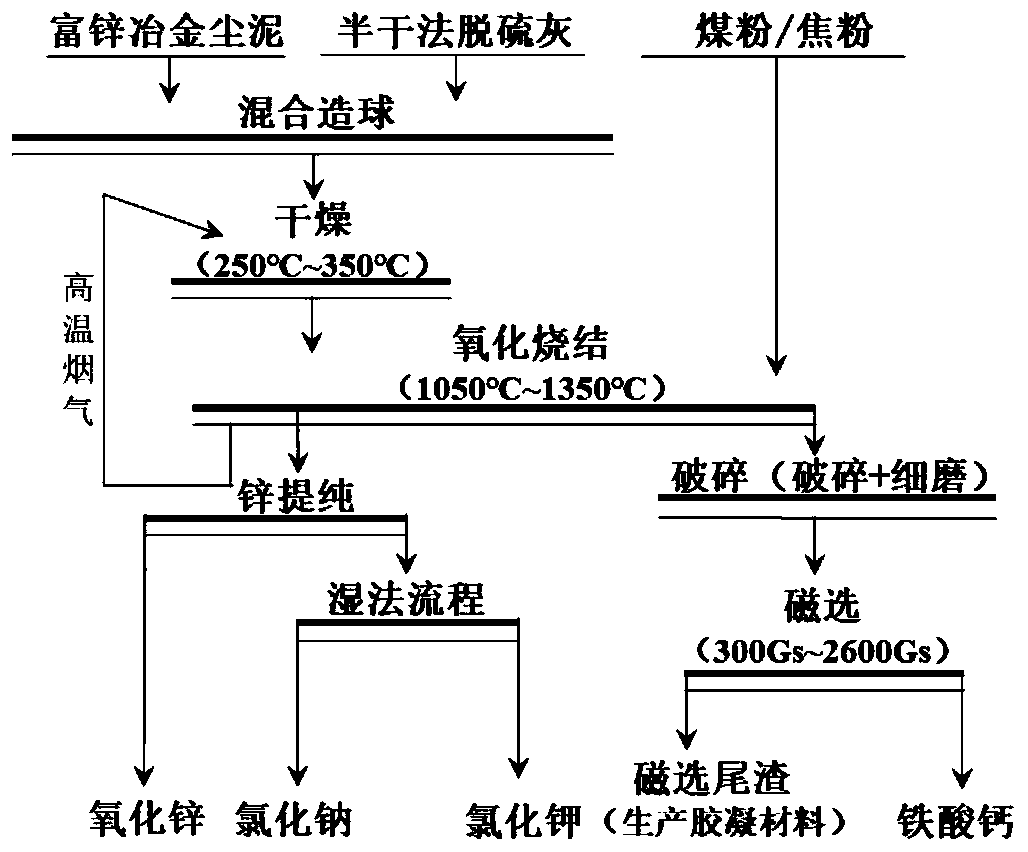

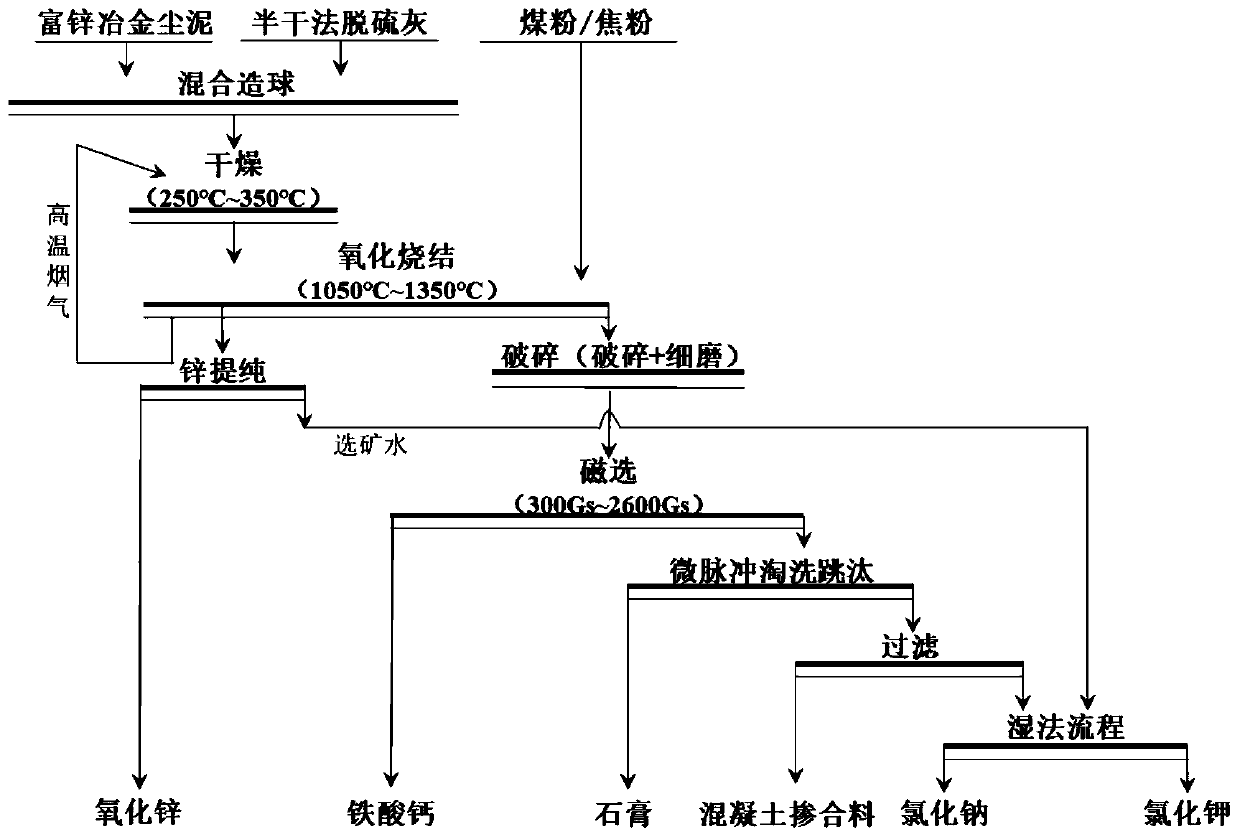

Synergistic recycling method of zinc-rich metallurgical dust sludge and semidry desulfurization ash

PendingCN111302386AHigh in free baseComplex componentsSolid waste managementZinc oxides/hydroxidesCoalCoke

The invention discloses a synergistic recycling method of zinc-rich metallurgical dust sludge and semidry desulfurization ash, and belongs to the field of resource regeneration. The method comprises the following steps: firstly, mixing zinc-rich metallurgical dust sludge and semi-dry desulfurization ash according to a mass ratio of 1: (0.02-1.99), pelletizing, drying, then mixing, oxidizing and sintering according to a mass ratio of small balls to pulverized coal (coke powder) of 1: (0.03-0.89), and enriching sphalerite and an alkali metal chloride salt in the smoke dust, performing reselection and purification to obtain a zinc oxide product, recycling reselected water, circularly enriching a soluble salt, merging into a wet process, producing sodium chloride and potassium chloride by processes such as a cold crystallization direct flotation method and the like, cooling sintered ore obtained by sintering, crushing and finely grinding the sintered ore to 0.028-13.9 mm by using roller type crushing equipment and rod grinding equipment, selectively dissociating calcium ferrite and gypsum, then carrying out magnetic separation to separate calcium ferrite, taking the magnetic separationtailings for producing a cementing material to replace cement, or separating low-density gypsum from the magnetic separation tailings by using a micro-pulse elutriation jigger, filtering the tailings, using the filter residues as a concrete admixture, recycling the filtrate, enriching a soluble salt, and merging the filtrate into the wet process to produce sodium chloride and potassium chloride.

Owner:UNIV OF SCI & TECH BEIJING

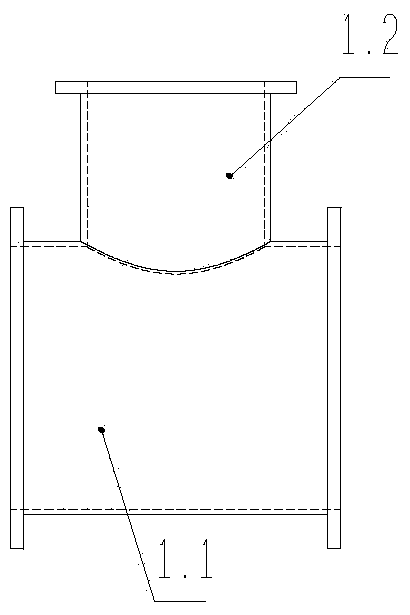

Fungal spore separation device based on microporous filter films, system applying fungal spore separation device, and separation method applied to system

PendingCN110669637ARapid enrichmentEfficient enrichmentBioreactor/fermenter combinationsBiological substance pretreatmentsSporeColloidal silica

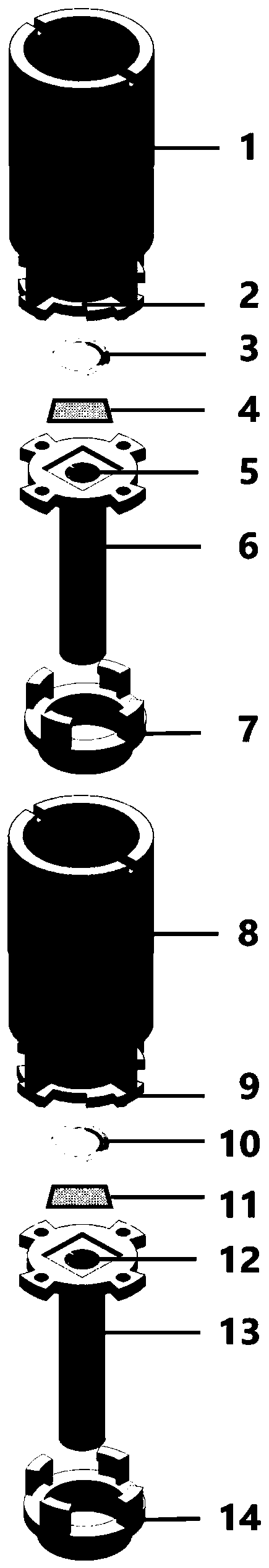

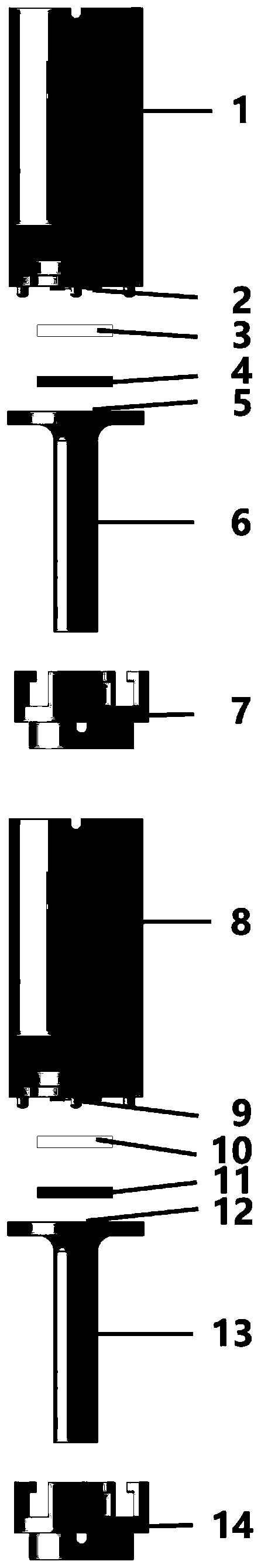

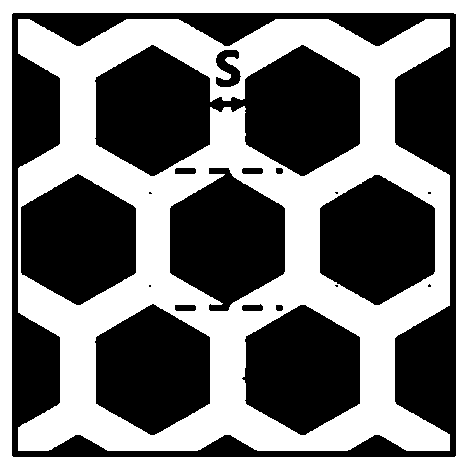

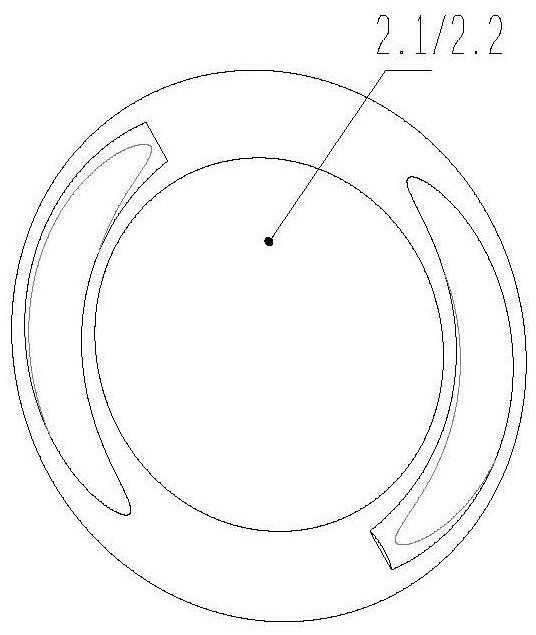

The invention provides a fungal spore separation device based on microporous filter films, a system applying the fungal spore separation device, and a separation method applied to the system. The separation device comprises an upper-layer sample injection pool, an upper-layer silical gel rubber ring, an upper-layer microporous filter film, an upper-layer drainage tube, an upper-layer clamping clamp, a lower-layer sample injection pool, a lower-layer silical gel rubber ring, a lower-layer microporous filter film, a lower-layer drainage tube and a lower-layer clamping clamp which are sequentially connected from top to bottom; the upper-layer sample injection pool and the lower-layer sample injection pool are each a hollow cylinder; an upper-layer sample injection opening and a lower-layer sample injection opening are formed in the bottom of the upper-layer sample injection pool and the bottom of the lower-layer sample injection pool correspondingly; the sample injection pools and the drainage tubes are closely connected through the clamping clamps; and the lower end of the upper-layer drainage tube sequentially penetrates through the middle of the upper-layer clamping clamp and penetrates into the lower-layer sample injection pool. The double layers of microporous filter films have the great flexibility, can be taken down after filtering, are directly folded to be placed into anEP tube for follow-up detection, and are highly compatible with a downstream detection technology. Different targets are selectively separated and enriched mainly through the physical property difference between fungal spore and other cells in body fluid.

Owner:PEKING UNIV

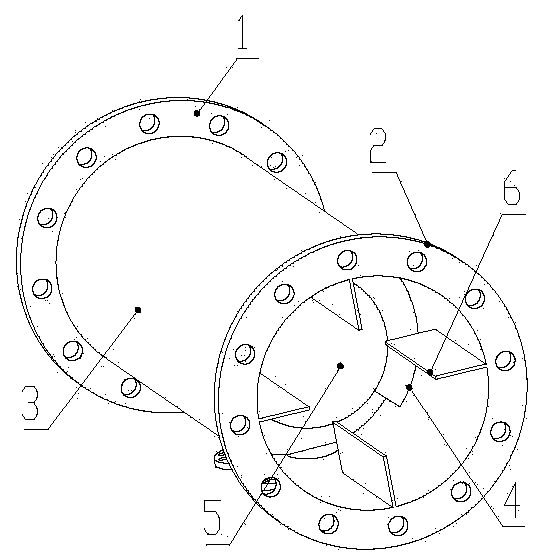

Oil and gas pipeline non-stop transmission on-line desanding device

InactiveCN110735625ARelieves the problem of blockageImprove separation efficiencySettling tanks feed/dischargeCentrifugal force sediment separationHelical bladeVALVE PORT

The invention discloses an oil and gas pipeline non-stop transmission on-line desanding device and aims to overcome the defects that in the prior art, installation is complicated, and the separation effect is poor. The desanding device comprises a desanding device inlet, a desanding device outlet, a desanding device cylinder, a columnar cylinder, a helical blade, rotation-stopping fan-shaped plates, sand discharging outlets and full-bore ball valves, wherein the columnar cylinder is in the desanding device cylinder, the columnar cylinder is coaxial to the desanding device cylinder body, the helical blade is located in an annular space between the desanding device cylinder and the columnar cylinder to form a helical flow channel, the rotation-stopping fan-shaped plates are in the desandingdevice cylinder, the sand discharging outlets are formed in the lower side of the desanding device cylinder in a row, and the sand discharging outlets run through the full-bore ball valves and sand inlets in sequence to be communicated with a sand storage chamber. By means of the oil and gas pipeline non-stop transmission on-line desanding device, the installation way of the desanding device is identical to that of a common valve, the desanding device can be horizontally or vertically installed and occupies little space, auxiliary facilities are not needed, the separation efficiency is high, solid impurities in oil and gas can be efficiently separated out, and normal pipeline transportation is not affected in the sand cleaning process.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

Preparation method of dehydro-harmine

InactiveCN102603732AReduce the number of extractionsReduce dosageOrganic chemistryAcetic acidHarmine

The invention relates to a preparation method of dehydro-harmine, which comprises the steps of smashing harmel seeds which are taken as a material, adding appropriate ammonia water, mixing uniformly, carrying out ammoniation for 10-20 hours, adding a 70-80% carbinol solution with 3-5 times as quantity as that of the material for soaking for 2-3 times, filtering soaking liquid, adding a chloroform solution, collecting a chloroform layer, recycling the chloroform, carrying out separation preparation on solid by a petroleum ether-ethyl acetate-carbinol-hydrosolvent system through using a high-speed counter current chromatograph, collecting dehydro-harmine fluid, recycling reagents, and drying under a low-temperature vacuum condition, so that pure dehydro-harmine is obtained. The method is applicable to the preparation of the dehydro-harmine with high purify.

Owner:苏州宝泽堂医药科技有限公司

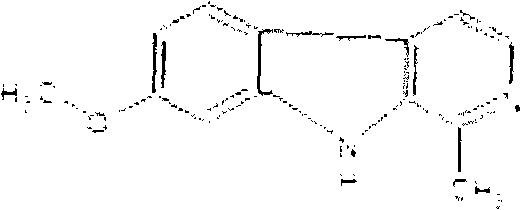

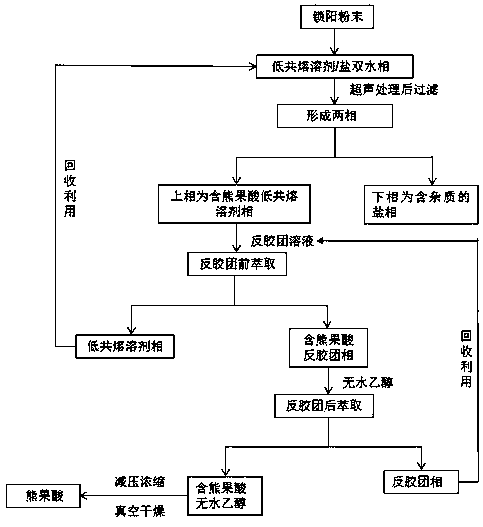

Method for extracting ursolic acid from Cynomorium songaricum by using eutectic solvent/salt aqueous two-phase system

The invention provides a method for extracting ursolic acid from Cynomorium songaricum by using a eutectic solvent / salt aqueous two-phase system. The method comprises the following steps: with the eutectic solvent / salt aqueous two-phase system as an extraction solvent, subjecting the powder of Cynomorium songaricum to ultrasonic extraction at first so as to obtain a eutectic solvent phase containing ursolic acid, then carrying out pre-extraction by using a reversed micelle solution, and carrying out standing for layering, wherein an upper phase is a reversed micelle phase containing ursolic acid; and adding absolute ethyl alcohol into the reversed micelle phase containing ursolic acid for extraction, then carrying out standing and layering, wherein a lower phase is an absolute ethyl alcohol phase containing ursolic acid, and subjecting the absolute ethyl alcohol phase containing ursolic acid to pressure-reduced concentration and vacuum drying so as to obtain ursolic acid powder. According to the invention, the eutectic solvent / salt aqueous two-phase system is employed for extraction of the powder of Cynomorium songaricum, and reversed micelle extraction is employed for separation of ursolic acid in the eutectic solvent, so the method has the characteristics of short phase-splitting time, low viscosity, small possibility of emulsification and the like; the eutectic solvent and the reversed micelle solvent can be cyclically utilized; and the method is low in extraction cost, high in the purity and yield of a ursolic acid product and is a green, highly-efficient and simple separation method.

Owner:NORTHWEST NORMAL UNIVERSITY

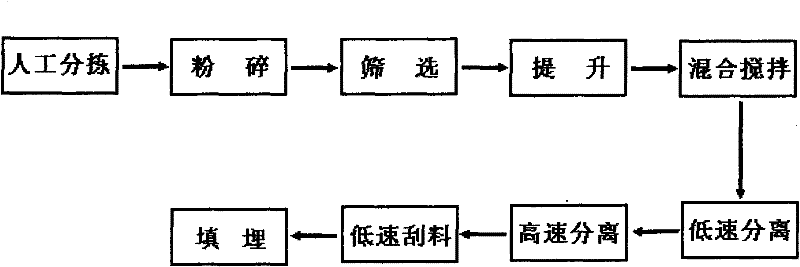

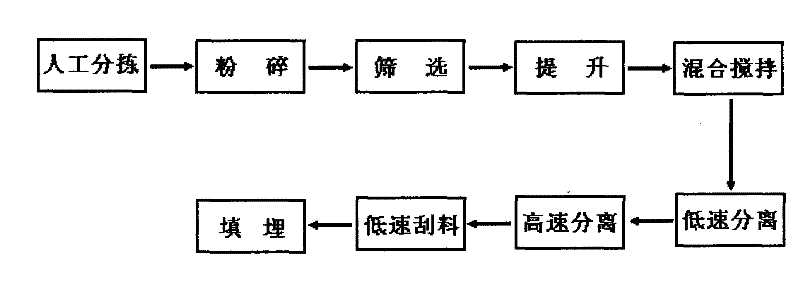

Sharp separation method for housefly larvas

InactiveCN101317559AReduce the cost of trainingFast separation methodAnimal husbandryMicroorganismHousefly

The invention relates to a quick separation method for Musca domestica larva. The method of the invention is characterized in that the Musca domestica larva is under the hypoxia environment; for example, the culture material with the Musca domestica larva is arranged in a closed space without air exchanging; alternatively, the non-oxygen air is pumped into the culture material; or the culture material is mixed with oxygen consumption chemical substance or the oxygen-consumption micro-organism is added into the culture material, so as to force the Musca domestic larva to automatically climb out of the culture material. The quick separation method of the invention has short time in separation process, the separation rate of the larva can achieve more than 96%, manpower is not required, the cultivation cost of the Musca domestica can be effectively reduced; therefore, the invention is a method which is applicable for the automation cultivation of the Musca domestica.

Owner:GUANGDONG INST OF APPLIED BIOLOGICAL RESOURCES

Method for purifying cheliensisin A

InactiveCN102329311AShort extraction timeImprove efficiencyOrganic chemistryChemical recyclingCounter currentChemistry

The invention provides a method for purifying cheliensisin A. The method is characterized by comprising the following steps: taking leaves of goniothalamus cheliensis as raw materials, grinding the leaves to 60-80 meshes, adding the ground leaves to an extraction kettle, extracting the leaves by adopting supercritical CO2, collecting the extracts, adopting a high-speed counter-current chromatography for separation and drying stream under reduced pressure by taking n-hexane-ethyl acetate-methanol-water as a solvent system, thus obtaining cheliensisin A. The method has the advantages of high efficiency, environment friendliness and the like.

Owner:苏州宝泽堂医药科技有限公司

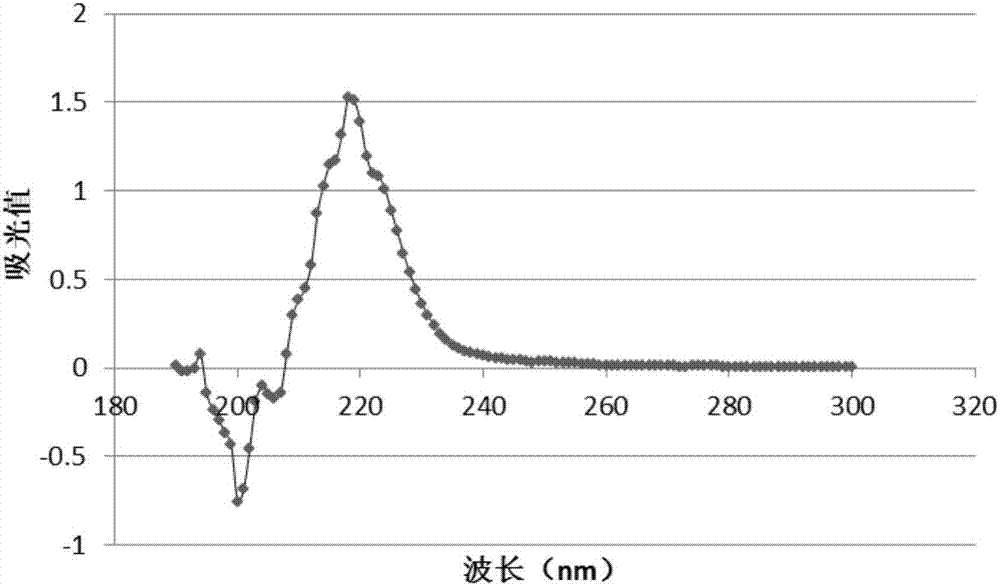

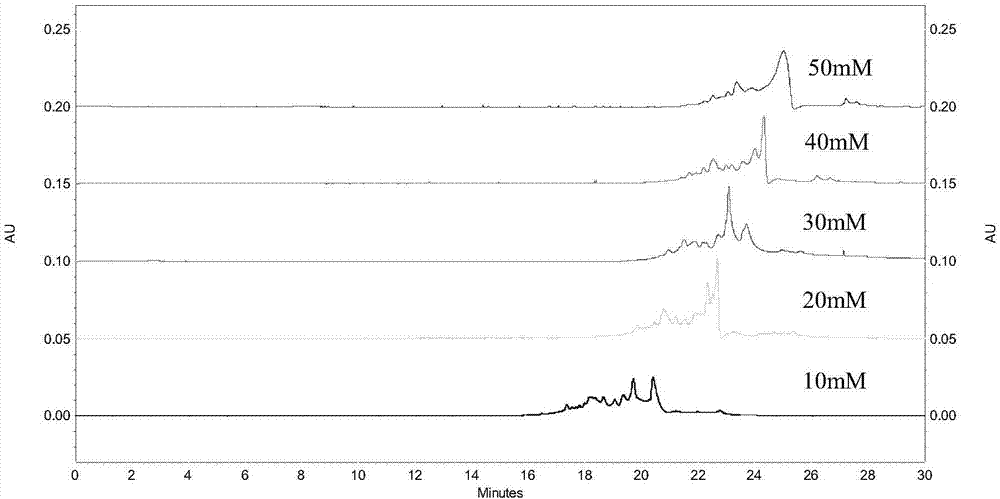

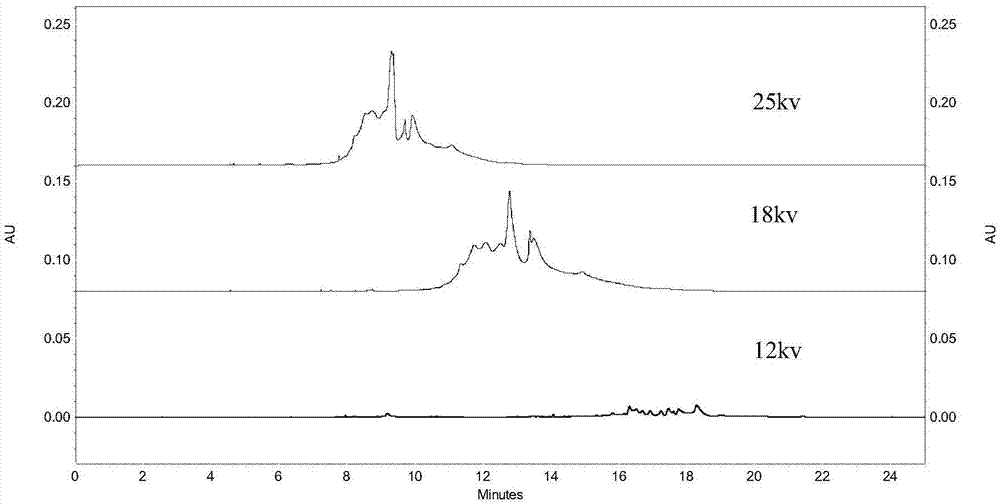

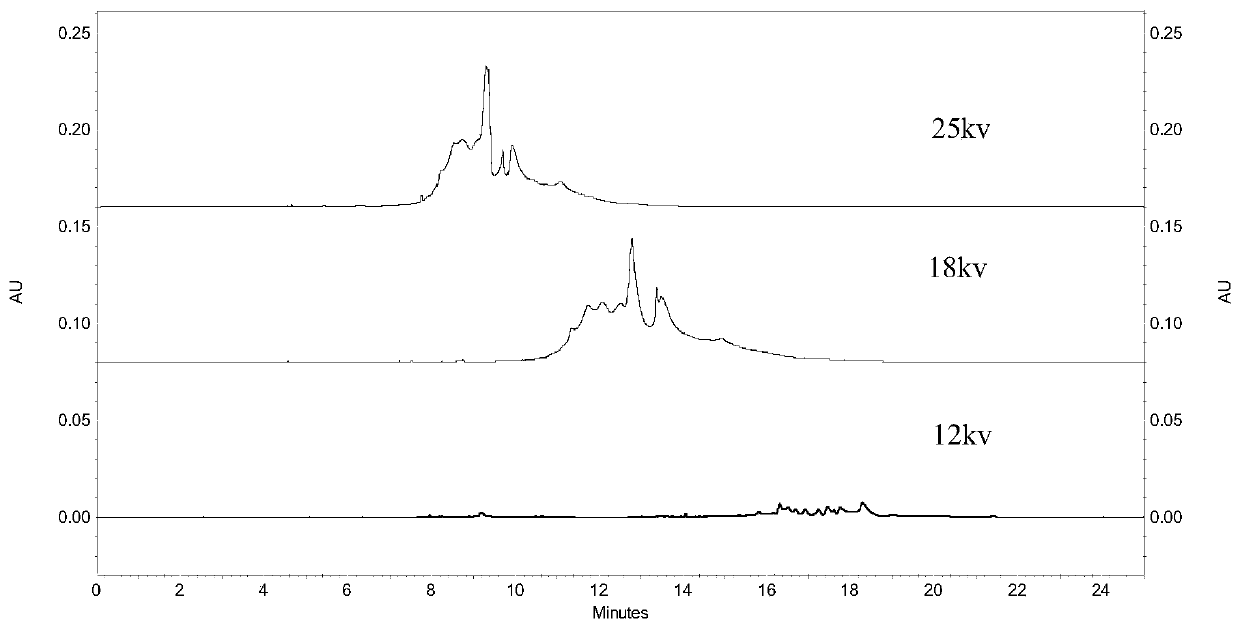

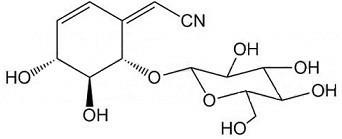

Method for separating wheat gliadin through capillary electrophoresis

ActiveCN107505379ARapid separation methodEfficient separation methodMaterial analysis by electric/magnetic meansSeparation technologyGliadin

Owner:INST OF BOTANY CHINESE ACAD OF SCI

Method for purifying edulinine

InactiveCN102827074AShort extraction timeImprove efficiencyOrganic chemistryChemical recyclingHerbEnvironmental chemistry

The invention provides a method for purifying edulinine. The method comprises the steps that common rue herb is taken as a raw material, ground and soaked with alkaline alcohol for 2-8 hours, the mixture is added into an extraction kettle, supercritical CO2 extraction is adopted, extract is collected and dissolved with acid water, filtration is carried out, the pH of filtrate is regulated to 8-10 through ammonia water, precipitate is subjected to alumina column chromatography to obtain the crude product, a high-speed counter current chromatograph is adopted for separation while taking carbon tetrachloride-methanol-water as a solvent system, and high content of the edulinine is obtained after being dried under reduced pressure. The method is simple, has high yield, can be used for producing products with high purity, and has higher economic value and academic value.

Owner:NANJING ZELANG MEDICAL TECH

Method for fast stripping plastic-aluminum composite material by supercritical CO2 fluid

The invention discloses a method for rapidly separating a aluminum-plastic composite material by supercritical CO2 fluid. The method comprises the following steps: sealing debris of the aluminum-plastic composite material and carbon dioxide in a high pressure vessel, pressurizing or heating so that pressure in the high pressure vessel is greater than 7.39Mpa, or the temperature is more than 31.06 DEG C and less than fusion temperature of plastic in the aluminum-plastic composite material, keeping the pressure and temperature for a period; then allowing depressurizing and desorption so as to totally separate aluminum from plastic, and performing flotation separation and drying to obtain the aluminum and the plastic respectively. The method has the advantages of environmental protection, high efficiency and low cost, and is applicable to industrial production.

Owner:ZHEJIANG UNIV

A method for removing hyocholic acid from chenodeoxycholic acid

Owner:CHANGDE YUNGANG BIOTECHNOLOGY CO LTD

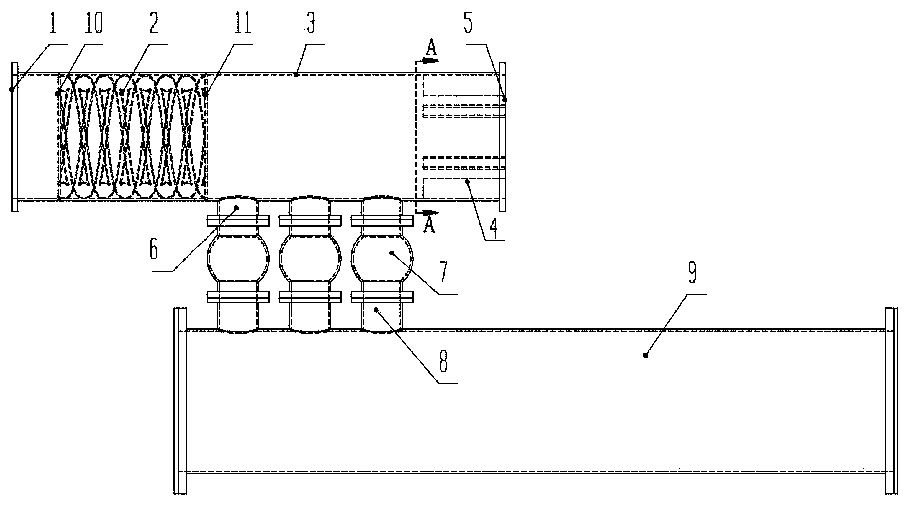

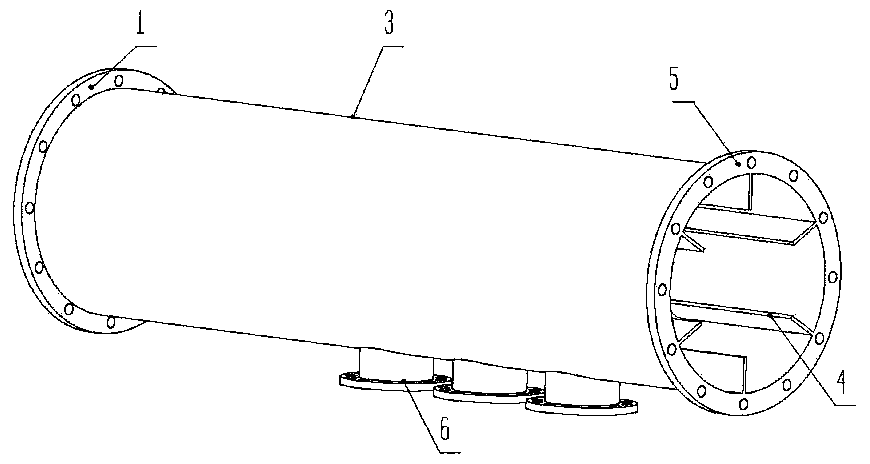

Full-diameter pipeline type sand removing device

ActiveCN110735628ARelieves the problem of blockageEasy to passDispersed particle separationGaseous fuelsEngineeringPipe

The invention discloses a full-diameter pipeline type sand removing device. The device comprises a flow direction adjusting inlet, a cyclone sand removing section and a flow direction adjusting outlet, wherein partition plates are arranged between the flow direction adjusting inlet and the cyclone sand removing section and between the cyclone sand removing section and the flow direction adjustingoutlet, the flow direction adjusting inlet is of a structure formed by mutually nesting a flow direction adjusting inlet inner cylinder and a flow direction adjusting inlet outer cylinder, the cyclonesand removing section is of a structure formed by mutually nesting a cyclone section outer cylinder and a cyclone section inner cylinder, a double spiral pipe is arranged at the inlet end of an annular space formed between the cyclone section outer cylinder and the cyclone section inner cylinder, the bottom, at the the downstream of the double spiral pipe, of the outer cylinder of cyclone sand removing section is provided with sand discharging holes which are uniformly arranged, in the normal sand removing process, the partition boards are isolating blind plates, and in the case of a pipe cleaning, the partition boards are full-diameter backing plates. According to the device, when the sand removing device is used, the installation mode of the sand removing device is the same as a commonvalve, the device can be installed in a horizontal or vertical direction, extra space is not occupied, auxiliary facilities are not needed, the separation efficiency is high, solid impurities in oil and gas can be can effectively separated, and meanwhile, normal conveying of the pipeline in the process of cleaning the sand is not affected.

Owner:SINOPEC GUANGZHOU ENG +1

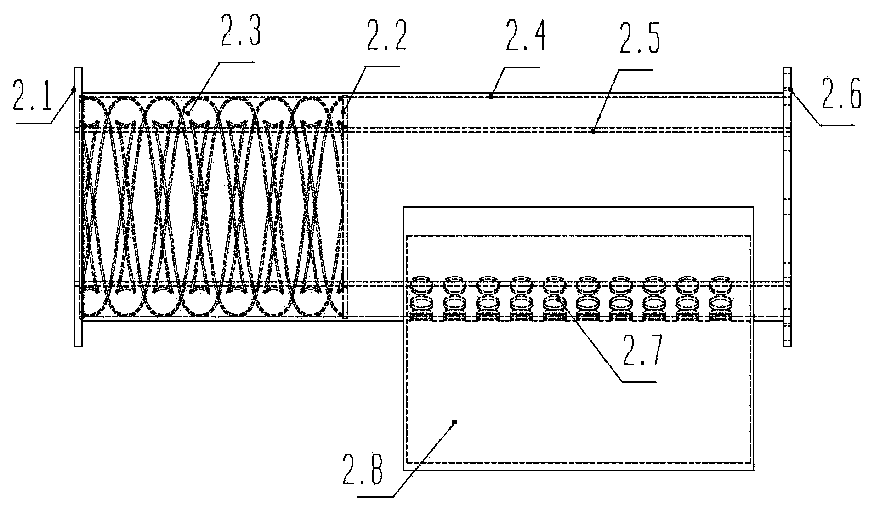

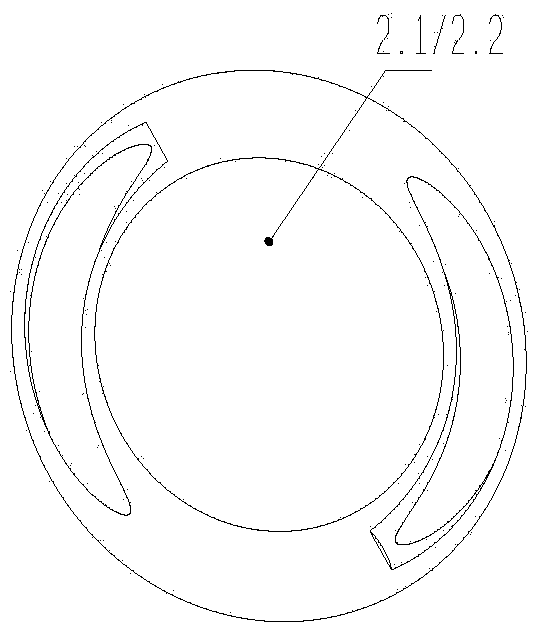

Full-drift-diameter pipeline type sand remover

ActiveCN110735624AEfficient separation methodImprove separation efficiencyDispersed particle separationGaseous fuelsBall valveDesander

The invention discloses a full-drift-diameter pipeline type sand remover. An inlet three-way pipe, a full-drift-diameter pipe cleaning valve, a spiral sand removal section, a flow direction adjustingoutlet, a bypass connecting pipe, a full-drift-diameter ball valve and a sand storage chamber are included. The inlet three-way pipe is composed of a three-way main pipe and a three-way branch pipe. The spiral sand removal section is formed through mutual nesting of a spiral sand removal section inner barrel and a spiral sand removal section outer barrel. The flow direction adjusting outlet is formed through mutual nesting of a flow direction adjusting inner barrel and a flow direction adjusting outer barrel. The three-way main pipe communicates with the spiral sand removal section inner barrel. The spiral sand removal section inner barrel communicates with the flow direction adjusting inner barrel. The spiral sand removal section outer barrel communicates with the flow direction adjustingouter barrel. The bypass connecting pipe communicates with the three-way branch pipe and a branch pipe inlet. A spiral blade is arranged in annular space between the spiral flow sand removal sectionouter barrel and the spiral flow sand removal section inner barrel. The position, below the spiral blade, of the bottom of the spiral flow sand removal section outer barrel is provided with a row of sand discharging ports, and the sand discharging ports serve as openings for solid-liquid impurities to enter the sand storage chamber. By usage of the full-drift-diameter pipeline type sand remover, solid impurities in oil gas can be efficiently separated out, and normal conveying of pipelines is not influenced in the sand cleaning process.

Owner:SINOPEC GUANGZHOU ENG +1

Utilize deep eutectic solvent/salt two-phase system to extract the method for ursolic acid in Cynomorium cynomorium

The invention provides a method for extracting ursolic acid from Cynomorium songaricum by using a eutectic solvent / salt aqueous two-phase system. The method comprises the following steps: with the eutectic solvent / salt aqueous two-phase system as an extraction solvent, subjecting the powder of Cynomorium songaricum to ultrasonic extraction at first so as to obtain a eutectic solvent phase containing ursolic acid, then carrying out pre-extraction by using a reversed micelle solution, and carrying out standing for layering, wherein an upper phase is a reversed micelle phase containing ursolic acid; and adding absolute ethyl alcohol into the reversed micelle phase containing ursolic acid for extraction, then carrying out standing and layering, wherein a lower phase is an absolute ethyl alcohol phase containing ursolic acid, and subjecting the absolute ethyl alcohol phase containing ursolic acid to pressure-reduced concentration and vacuum drying so as to obtain ursolic acid powder. According to the invention, the eutectic solvent / salt aqueous two-phase system is employed for extraction of the powder of Cynomorium songaricum, and reversed micelle extraction is employed for separation of ursolic acid in the eutectic solvent, so the method has the characteristics of short phase-splitting time, low viscosity, small possibility of emulsification and the like; the eutectic solvent and the reversed micelle solvent can be cyclically utilized; and the method is low in extraction cost, high in the purity and yield of a ursolic acid product and is a green, highly-efficient and simple separation method.

Owner:NORTHWEST NORMAL UNIVERSITY

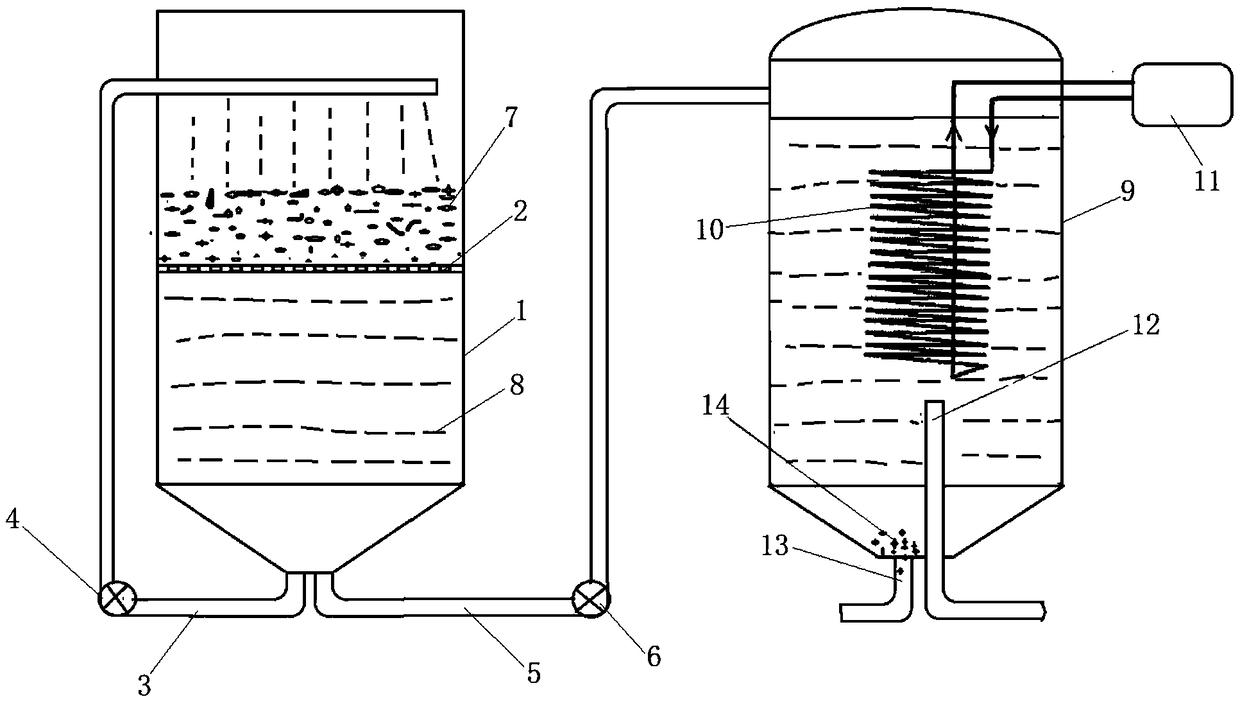

Impurity removal system for extracting medicinal tannin medicine by galla chinensis

InactiveCN109316776ANo impuritiesImprove purityEsterified saccharide compoundsSugar derivativesDistilled waterCooling coil

The invention relates to an impurity removal system for extracting medicinal tannin by galla chinensis. The impurity removal system comprises a soaking tank (1) and a low-temperature cooling tank (9)which are connected by a liquid delivery pipe (5), wherein a horizontal material plate (2) is arranged in the soaking tank, the horizontal material plate (2) is made of a stainless steel mesh and is used for holding a galla chinensis material (7); distilled water (8) is loaded into the soaking tank, a circulating water pipe (3) is arranged at the exterior of the soaking tank, the upper end and lower end of the circulating water pipe (3) are respectively connected into the upper part and lower part of the material plate in a tank body of the soaking tank, a circulating pump (4) is used for continuously and cyclically pumping the distilled water at the lower part of the tank body into the tank body to perform circulating flushing type soaking on the galla chinensis material, and the liquid delivery pipe (5) and a liquid suction pump (6) thereof are arranged at the bottom part of the tank body; a cooling coiled pipe (10) is arranged in the low-temperature cooling tank, a supernatant drainage pipe (12) and an impurity discharge pipe (13) are arranged at the bottom part of the low-temperature cooling tank and are led to the exterior, wherein the supernatant drainage pipe extends up witha certain height in the tank body, and is at least 10 cm higher than the bottom part of the tank body, and an inlet of the impurity discharge pipe is positioned at the bottom part of the tank body. The impurity removal system has the advantages that the impurity removal effect is good, the operation is simple, convenient and rapid, and the safety and reliability are realized.

Owner:云南博泽林化工有限公司

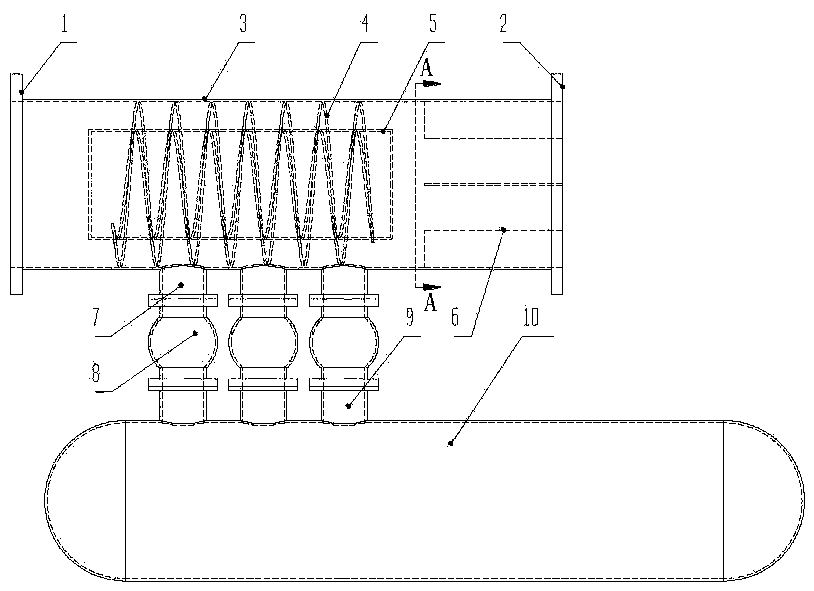

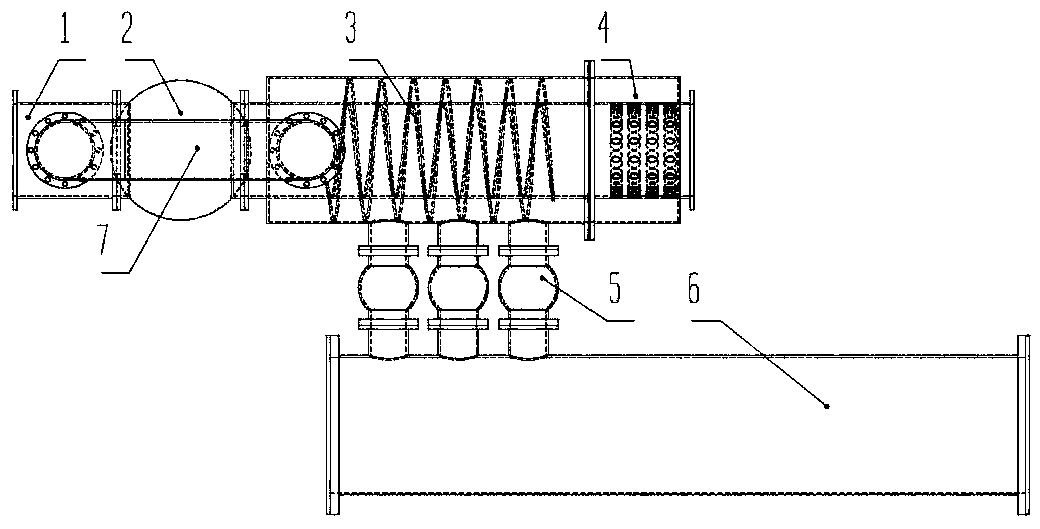

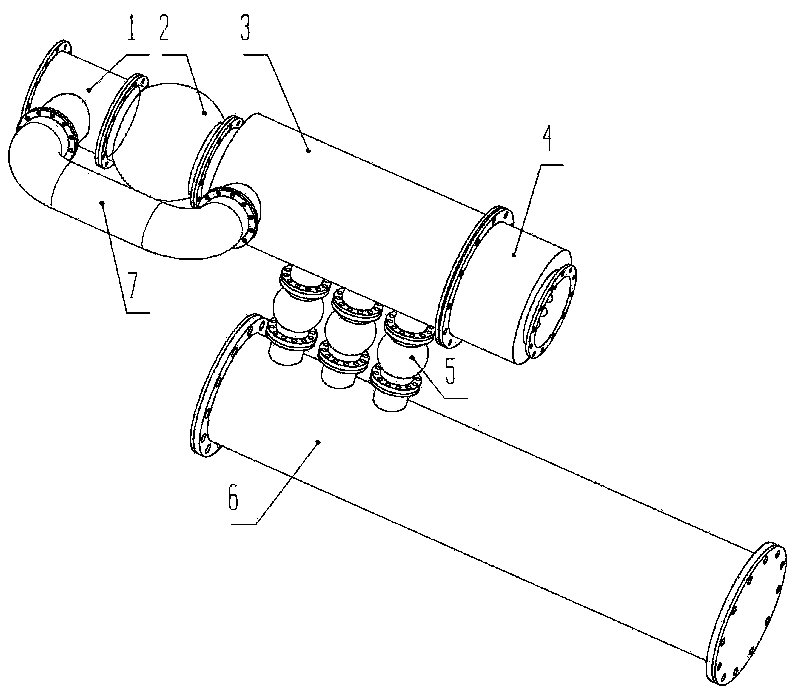

Shutdown-free online grit catcher for oil-gas pipeline

InactiveCN110735627ARelieves the problem of blockageImprove separation efficiencySettling tanks feed/dischargeCentrifugal force sediment separationMarine engineeringGas pipeline

The invention discloses a shutdown-free online grit catcher for an oil-gas pipeline. The shutdown-free online grit catcher for the oil-gas pipeline comprises a grit catcher inlet, a grit catcher outlet, a grit catcher barrel, a double-screw pipe, a double-screw pipe inlet, a double-screw pipe outlet, vortex stopping fan plates, grit discharging openings, full bore ball valves and grit inlets. Thegrit catcher barrel is of a cylinder structure with the two ends provided with flange connectors. One end of the grit catcher barrel is provided with the grit catcher inlet, and the other end of the grit catcher barrel is provided with a grit catcher outlet. The double-screw pipe is installed in the grit catcher barrel and located on the side provided with the grit catcher inlet. The double-screwpipe inlet and the double-screw pipe outlet are located on the head and the tail of the double-screw pipe correspondingly. The vortex stopping fan plates are arranged in the grit catcher barrel and located on the side provided with the grit catcher outlet. The grit discharging openings are located at the bottom of the grit catcher barrel and arranged between the double-screw pipe and the vortex stopping fan plates. The grit discharging openings communicate with a grit storage chamber sequentially via the full bore ball valves and the grit inlets. The shutdown-free online grit catcher for the oil-gas pipeline can permanently solve the trouble of blockage in the grit catcher; and besides, the shutdown-free online grit catcher for the oil-gas pipeline does not occupy extra space during installation and does not need an auxiliary facility.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

A kind of hydrophobic vanadium oxygen-organic molecular cage-based porous liquid for extracting l-tryptophan and its preparation method and application

ActiveCN113292595BAperture adjustableExtraction achievedGroup 5/15 element organic compoundsOrganic chemistry methodsIon exchangeTryptophan

The invention discloses a hydrophobic vanadyl-organic molecular cage-based porous liquid for extracting L-tryptophan and its preparation method and application. By adding vanadyl-carboxyl metal-organic cage powder into the hydrophobic ionic liquid, After ion exchange, the counter cation in the cage and the anion in the ionic liquid form ammonium chloride salt, and by reducing the solubility of the ammonium chloride salt, it enters the crystallization region, removes the counter cation, and obtains pure vanadyl-organic molecular clathrate Porous liquid. The hydrophobic vanadyl-organic molecular cage-based porous liquid has the characteristics of diversified channels and adjustable pore size. The invention realizes the extraction of L-tryptophan in water by adjusting the pore structure of the vanadyl organic molecular cage. The invention is environmentally friendly, has mild operating conditions and simple process, and is an efficient and green method for separating L-tryptophan.

Owner:NANJING TECH UNIV +1

Method for fast stripping plastic-aluminum composite material by supercritical CO2 fluid

The invention discloses a method for rapidly separating a aluminum-plastic composite material by supercritical CO2 fluid. The method comprises the following steps: sealing debris of the aluminum-plastic composite material and carbon dioxide in a high pressure vessel, pressurizing or heating so that pressure in the high pressure vessel is greater than 7.39Mpa, or the temperature is more than 31.06DEG C and less than fusion temperature of plastic in the aluminum-plastic composite material, keeping the pressure and temperature for a period; then allowing depressurizing and desorption so as to totally separate aluminum from plastic, and performing flotation separation and drying to obtain the aluminum and the plastic respectively. The method has the advantages of environmental protection, high efficiency and low cost, and is applicable to industrial production.

Owner:ZHEJIANG UNIV

High-efficiency separation method of caustic lye

ActiveCN101811706BEfficient separation methodSimple processAlkali metal oxides/hydroxidesSodium PhenolateProcess engineering

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Sharp separation method for housefly larvas

InactiveCN101317559BReduce the cost of trainingFast separation methodAnimal husbandryMicroorganismHousefly

The invention relates to a quick separation method for Musca domestica larva. The method of the invention is characterized in that the Musca domestica larva is under the hypoxia environment; for example, the culture material with the Musca domestica larva is arranged in a closed space without air exchanging; alternatively, the non-oxygen air is pumped into the culture material; or the culture material is mixed with oxygen consumption chemical substance or the oxygen-consumption micro-organism is added into the culture material, so as to force the Musca domestic larva to automatically climb out of the culture material. The quick separation method of the invention has short time in separation process, the separation rate of the larva can achieve more than 96%, manpower is not required, the cultivation cost of the Musca domestica can be effectively reduced; therefore, the invention is a method which is applicable for the automation cultivation of the Musca domestica.

Owner:GUANGDONG INST OF APPLIED BIOLOGICAL RESOURCES

Purification method of augustum alkaline

InactiveCN102659799AShort extraction timeImprove efficiencyOrganic chemistryBulk chemical productionCounter currentChemistry

The invention provides a purification method of augustum alkaline. The method comprises enabling complete stool of Amaryllidaceae Crinum augustum Rox. to serve as a raw material and be ground, adding alkaline alcohol into the raw material and soaking for 2-8h, adding the raw material into an extraction kettle, utilizing supercritical CO2 to perform extraction, collecting extract, using acid water to dissolve the extract, filtering, using ammonia water to adjust the pH of filtrate to 8-10, utilizing carbon tetrachloride-methanol-water serving as a solvent system and adopting high-speed counter-current chromatographic instrument to separate sediments, and obtaining the high-purity augustum alkaline by drying under reduced pressure. The method is suitable for preparation of the high-purity augustum alkaline.

Owner:NANJING ZELANG MEDICAL TECH

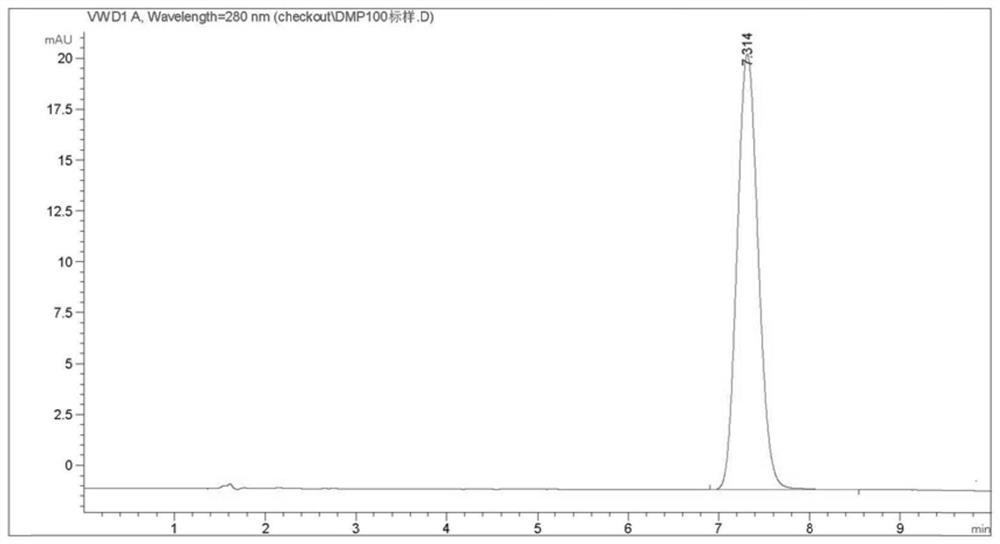

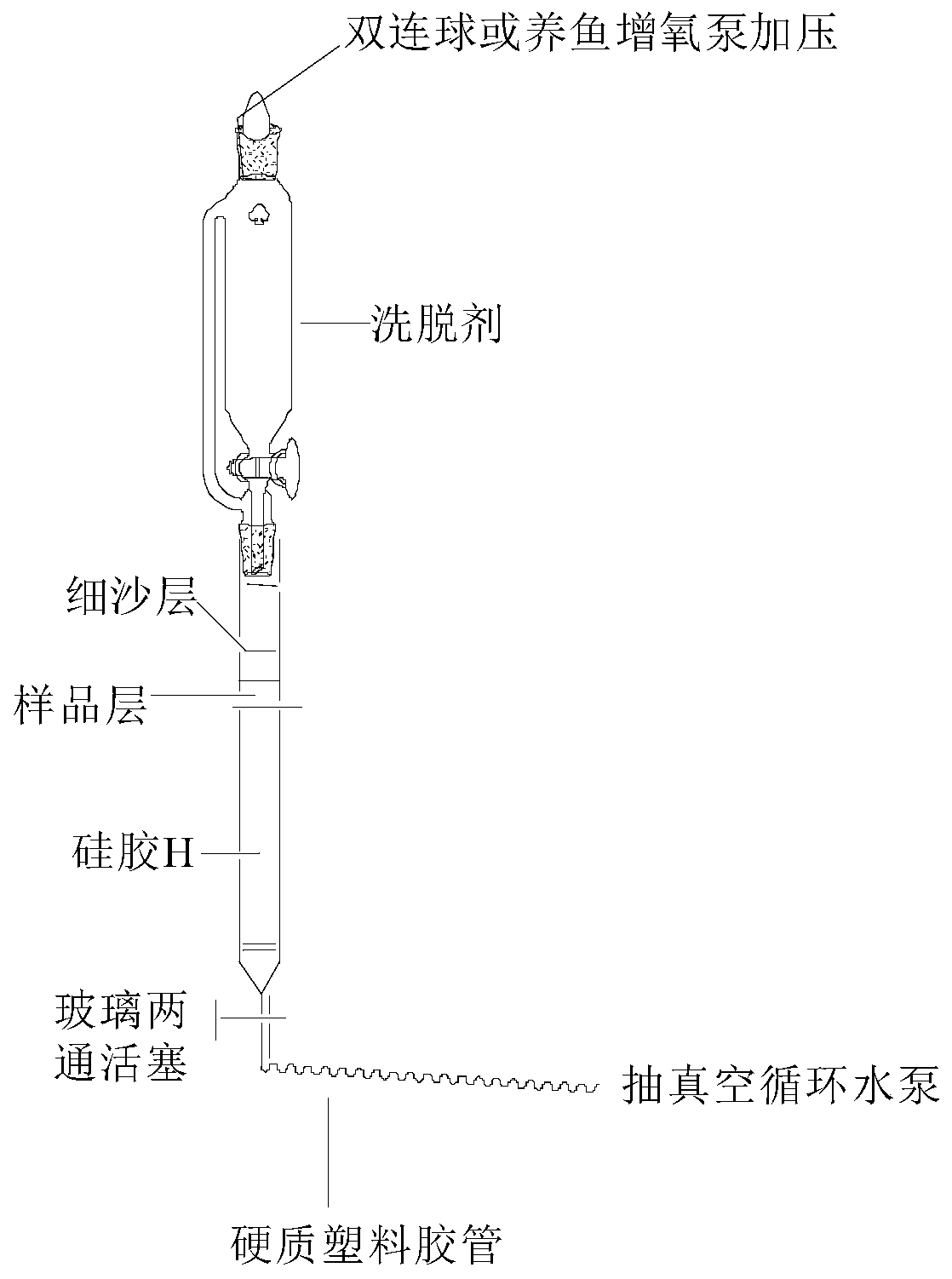

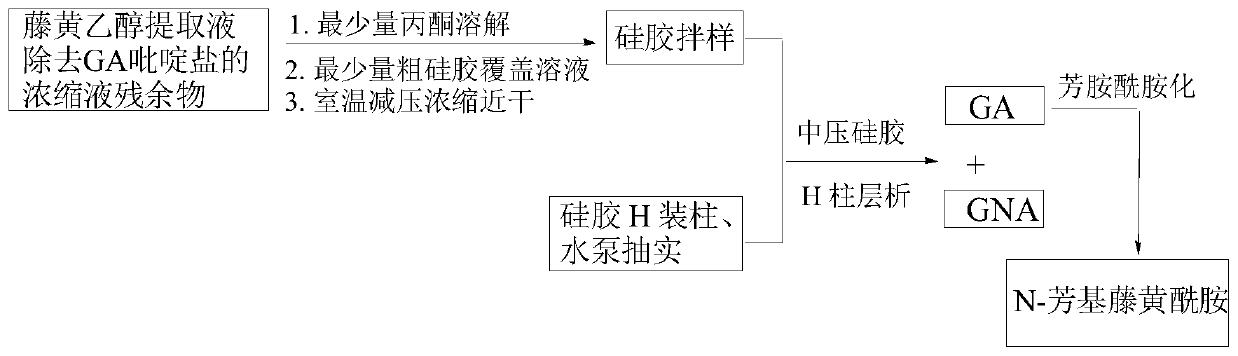

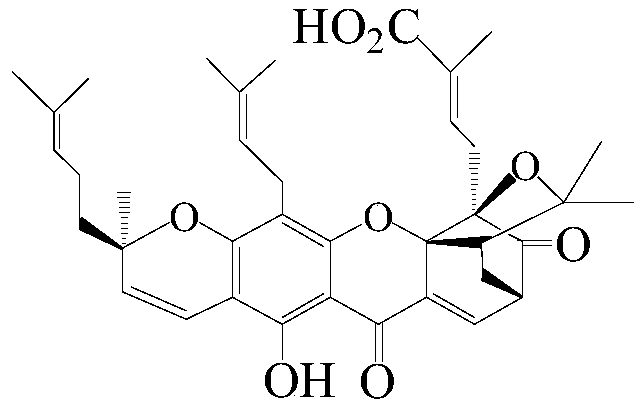

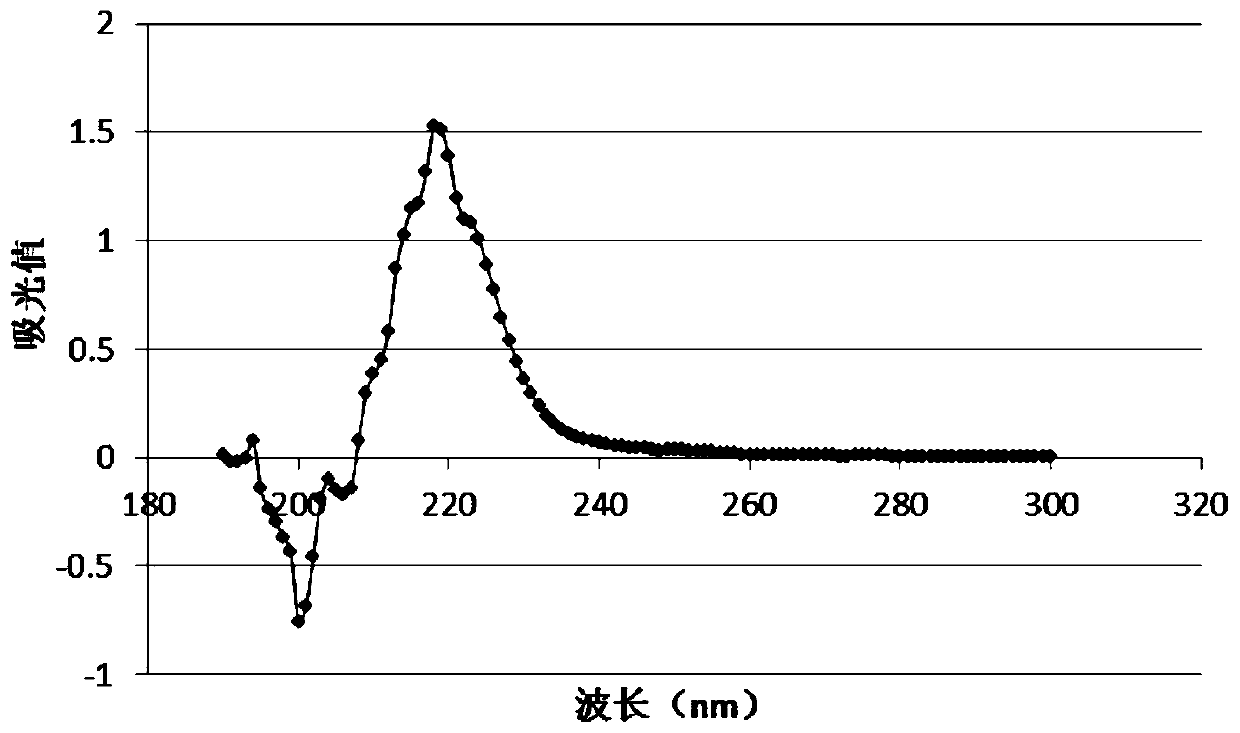

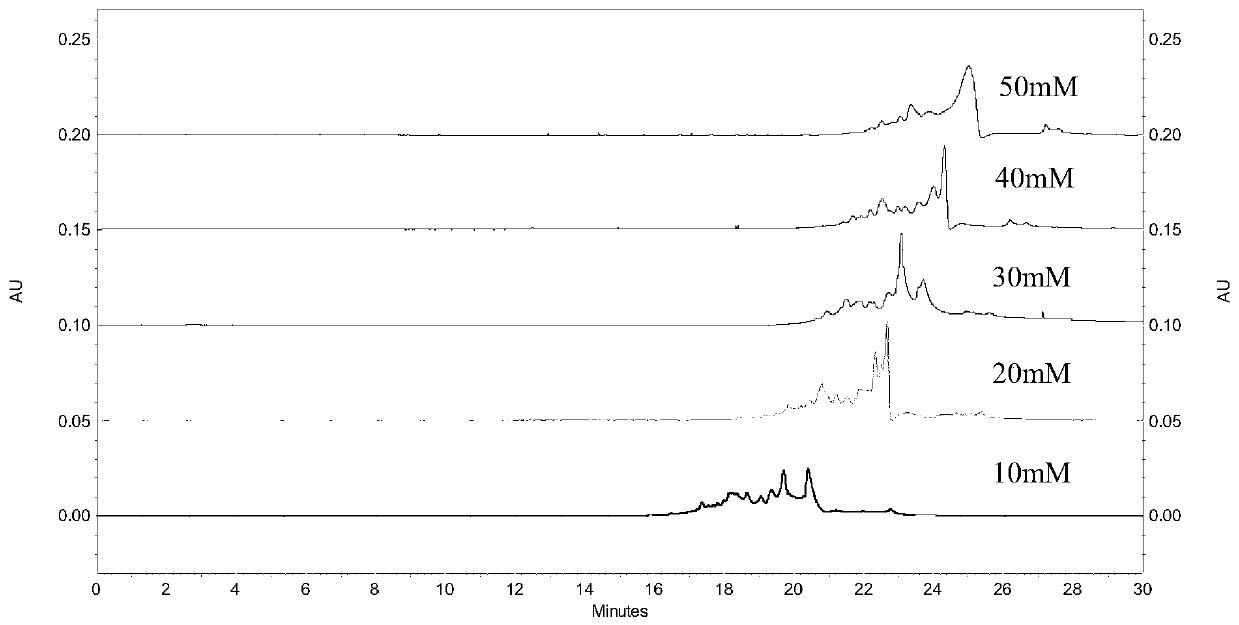

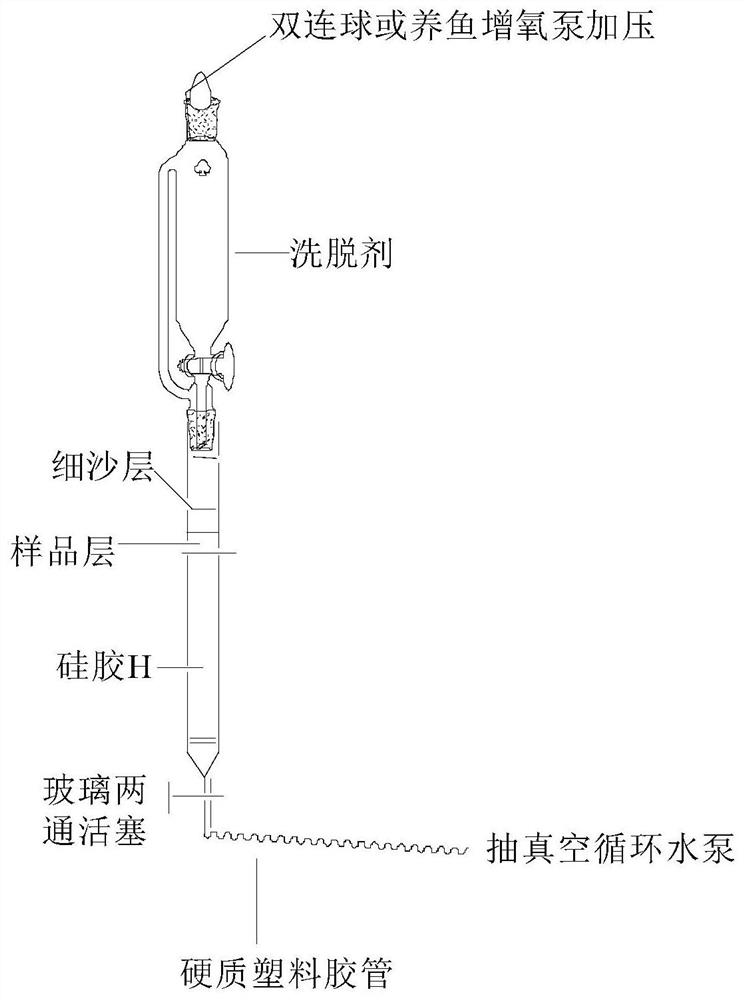

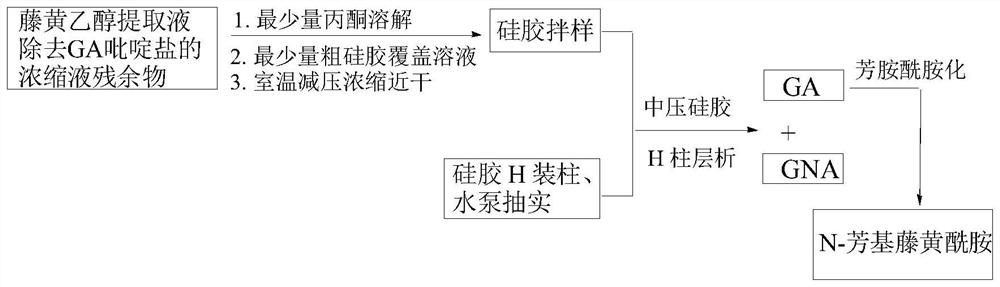

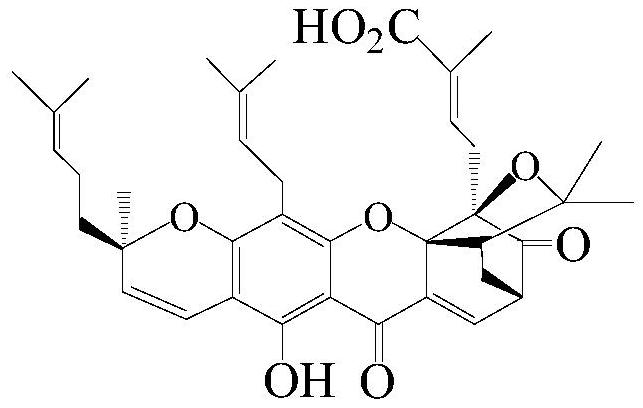

Method for separating neogambogic acid and gambogic acid by medium and low pressure gradient silica gel dry column chromatography and method for preparing N-aryl garcinamide

ActiveCN110437246AImprove protectionGuaranteed stabilityOrganic chemistryChromatographic separationEthyl group

The invention relates to a method for separating neogambogic acid (GNA) and gambogic acid (GA) by medium and low pressure gradient silica gel dry column chromatography and a method for preparing N-aryl garcinamide. The separation method comprises the following steps: silica gel H is used as a stationary phase, a selected eluent is utilized, treatment is performed by the medium and low pressure gradient silica gel dry column chromatography, and therefore the GA sample with purity of 90% and the GNA sample with purity of 93%can be separated in a low-cost, simple, convenient and larger-scale manner. The preparation method comprises the following steps: at room temperature under stirring, 1-ethyl-3-(3-N,N-dimethylaminopropyl)carbodiimide hydrochloride(or dicyclohexylcarbodiimide) and 4-(N,N-dimethylamino)pyridine is used to catalyze an amidation reaction of the gambogic acid and a substituted arylamine; and the crude product is treated by medium-pressure silica gel dry column chromatography using silica gel H as a stationary phase, and therefore the high-purity N-aryl garcinamide sample can be prepared in a low-cost, simple, convenient and larger-scale manner.

Owner:JINING MEDICAL UNIV

A method for separating wheat prolamin by capillary electrophoresis

ActiveCN107505379BRapid separation methodEfficient separation methodMaterial analysis by electric/magnetic meansSeparation technologyGliadin

The invention discloses a method for separating wheat gliadin through capillary electrophoresis. The method comprises the steps as follows: CPVP (cationic polyvinylpyrrolidone) is used as a material, and a coating is prepared on the wall of a capillary; a wheat sample is separated through capillary electrophoresis, and thus, wheat gliadin is separated; the CPVP is cationized polyvinylpyrrolidone with the viscosity average molecular weight of 20,000-25,000; the coating is prepared in the following step: the quartz capillary is washed with an aqueous solution of the CPVP and an operation buffer solution A sequentially. The CPVP is used as the coating material, dynamic modification is performed on a capillary column, the extraction separation condition suitable for wheat gliadin is screened out through optimization, a technological method for stably separating wheat gliadin is established, different varieties of wheat gliadin can be effectively distinguished, and the method becomes a wheat variety fingerprint separation technology.

Owner:INST OF BOTANY CHINESE ACAD OF SCI

A kind of purification method of Grifeng element

InactiveCN102286039ANothing producedReduce extraction timeSugar derivativesSugar derivatives preparationCountercurrent chromatographySolvent free

The invention belongs to the technical field of medicine and relates to a method for purifying Grifengsu. The method is as follows: the method of supercritical CO2 extraction-macroporous resin adsorption-high-speed countercurrent chromatographic purification is used to obtain Grifengsu, the content of which is as high as 95%, and the content is as high as 95%. Compared with the traditional method, the method of the invention has the advantages of simple technological process, convenient operation, safe production, no pollution, no solvent residue in the product, and is suitable for industrial production.

Owner:NANJING ZELANG MEDICAL TECH

A full-bore pipeline type sand removal device

ActiveCN110735628BRelieves the problem of blockageEasy to passGaseous fuelsDispersed particle separationEngineeringMechanics

The invention discloses a full-diameter pipeline type sand removal device. It includes a flow direction adjustment inlet, a swirl sand removal section and a flow direction adjustment outlet. A baffle is set between the flow direction adjustment inlet and the swirl sand removal section and between the swirl sand removal section and the flow direction adjustment outlet, and the flow direction adjustment inlet is the flow direction. The structure in which the inner cylinder of the inlet is adjusted and the outer cylinder of the inlet of the flow direction adjustment is nested with each other. The inlet end of the annular space formed between the inner cylinders is provided with a double helical pipe, and the bottom of the outer cylinder of the swirling sand removal section downstream of the double helical pipe is provided with evenly arranged sand discharge holes. In the case of pipes, the separator is a full-bore backing plate. When the technology of the present invention is used, the installation method of the sand removal device is the same as that of the ordinary valve, which can be installed horizontally or vertically, does not occupy additional space, does not require auxiliary facilities, and has high separation efficiency, which can efficiently separate solid impurities in oil and gas at the same time. , The process of cleaning the sand does not affect the normal transportation of the pipeline.

Owner:SINOPEC GUANGZHOU ENG CO LTD +1

Method for preparing new gambogic acid, gambogic acid and n-aryl gambogic amide by medium and low pressure gradient silica gel dry column chromatography

ActiveCN110437246BImprove protectionGuaranteed stabilityOrganic chemistryChromatographic separationGambogic acid

The invention relates to a method for preparing new gambogic acid, gambogic acid and N-aryl gambogic amide by medium and low pressure gradient silica gel dry column chromatography, using silica gel H as the stationary phase and utilizing a selected eluent to dry through medium and low pressure gradient silica gel Column chromatography can separate GA and GNA samples with purity of 90% and 93% respectively at low cost, simple and large scale; under stirring at room temperature, 1-ethyl-3-(3-N,N-dimethylamino Propyl)carbodiimide hydrochloride (or dicyclohexylcarbodiimide) and 4‑(N,N‑dimethylamino)pyridine catalyze the amidation reaction of gambogic acid with substituted arylamines. The crude product is subjected to medium-pressure silica gel dry column chromatography with silica gel H as the stationary phase, and high-purity N-aryl gambogic amide samples can be prepared in a low-cost, simple and large-scale manner.

Owner:JINING MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com