Co-recycling method of aluminum oxide red mud and semi-dry desulfurized fly ash

A semi-dry desulfurization and alumina technology, applied in chemical instruments and methods, inorganic chemistry, wet separation, etc., can solve problems such as unstable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

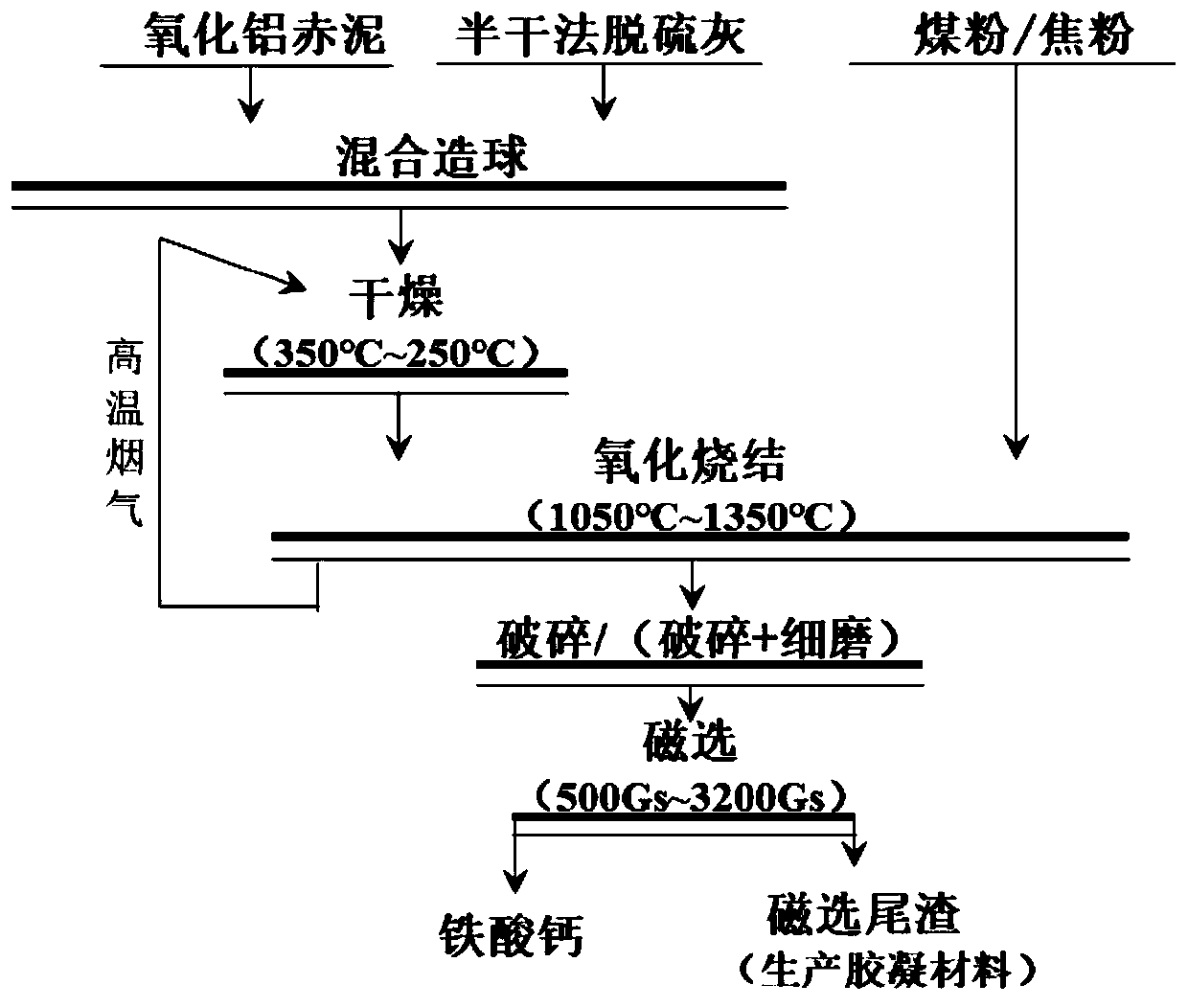

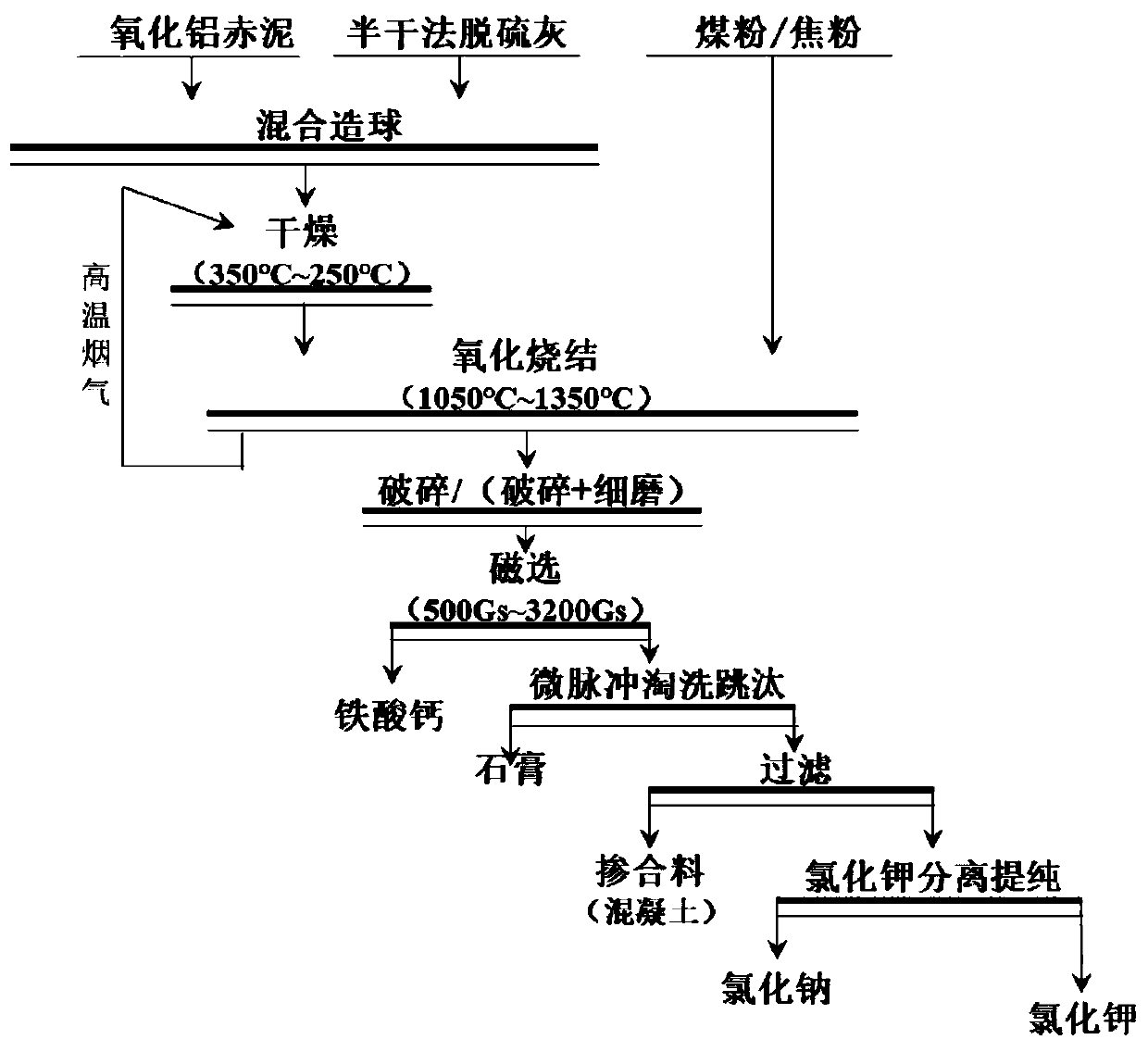

Method used

Image

Examples

example 1

[0037] Semi-dry desulfurization ash from a steel plant in Shandong, alumina red mud from an aluminum plant in Shandong, the main components (the range listed in the example is the range of multiple tests, the same below): alumina red mud TFe 48.32%~49.61% , SiO 2 10.59%~11.20%, Al 2 O 3 7.93%~8.24%, CaO 0.80%~0.98%, MgO 0.22%~0.53%; semi-dry desulfurization ash TFe5.56%~5.61%, SiO 2 10.59%~11.20%, Al 2 O 3 0.81% to 1.19%, CaO 32.21% to 39.96%, MgO 0.35% to 1.09%.

[0038] Use process:

[0039] (1) Mixed ingredients. Alumina red mud and semi-dry desulfurization ash are mixed and pelletized according to the mass ratio of 1:0.55~0.93. After drying, the pellets and coal powder are mixed according to the mass ratio of 1:0.15~0.22 and then oxidized and sintered at 1200℃~1250℃. Production of sinter.

[0040] (2) Selective crushing. After the sinter is cooled, the sinter is crushed to 0.8mm~1.5mm with a pair-roll crusher to selectively dissociate calcium ferrite and gypsum.

[0041] (3)...

example 2

[0045] Semi-dry desulfurization ash from a steel plant in Inner Mongolia, and alumina red mud from an aluminum plant in Inner Mongolia. The main components are: alumina red mud TFe 26.11%-32.37%, SiO 2 14.54%~15.20%, Al 2 O 3 9.93%~10.24%, CaO1.66%~1.73%, MgO 0.38%~0.69%; Semi-dry desulfurization ash TFe 3.55%~4.21%, SiO 2 11.22%~11.37%, Al 2 O 3 0.71%~1.37%, CaO 35.42%~38.59%, MgO 0.22%~1.17%.

[0046] Use process:

[0047] (1) Mixed ingredients. Alumina red mud and semi-dry desulfurization ash are mixed and pelletized according to the mass ratio of 1:0.36~1.01. After drying, the pellets and coal powder (or coke powder) are mixed according to the mass ratio of 1:0.25~0.3 and then mixed at 1250℃~1280 Oxidize and sinter at ℃ to produce sintered ore.

[0048] (2) Selective crushing. After the sinter is cooled, the sinter is crushed to 0.5mm~0.6mm with a pair of roller crusher, and calcium ferrite and gypsum are selectively dissociated.

[0049] (3) Magnetic separation of calcium fe...

example 3

[0053] Semi-dry desulfurization ash from a steel plant in Guangxi and alumina red mud from an aluminum plant in Guangxi. The main components are: alumina red mud TFe 47.77% ~ 49.21%, SiO 2 12.24%~12.98%, Al 2 O 3 8.22%~8.23%, CaO1.83%~1.87%, MgO 0.92%~1.63%; Semi-dry desulfurization ash TFe 5.53%~6.07%, SiO 2 10.73%~10.81%, Al 2 O 3 0.97% to 1.49%, CaO 36.42% to 39.01%, MgO 0.39% to 0.79%.

[0054] Use process:

[0055] (1) Mixed ingredients. Alumina red mud and semi-dry desulfurization ash are mixed and pelletized at a mass ratio of 1:0.36~0.53. After drying, the pellets and coal powder (or coke powder) are mixed at a mass ratio of 1:0.28~0.31 and then mixed at 1230℃~1260. Oxidize and sinter at ℃ to produce sintered ore.

[0056] (2) Selective crushing. After the sinter is cooled, the sinter is crushed to 2.5mm~3mm with a pair-roll crusher to selectively dissociate calcium ferrite and gypsum.

[0057] (3) Magnetic separation of calcium ferrite. The magnetic separation is carried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com