Drawer assembly with sealing function and air-cooled refrigerator using same

A drawer and component technology, applied in the field of drawer components with sealing function, can solve problems such as inconvenient use, inability to meet consumers' needs for food classification and storage, and easy air drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

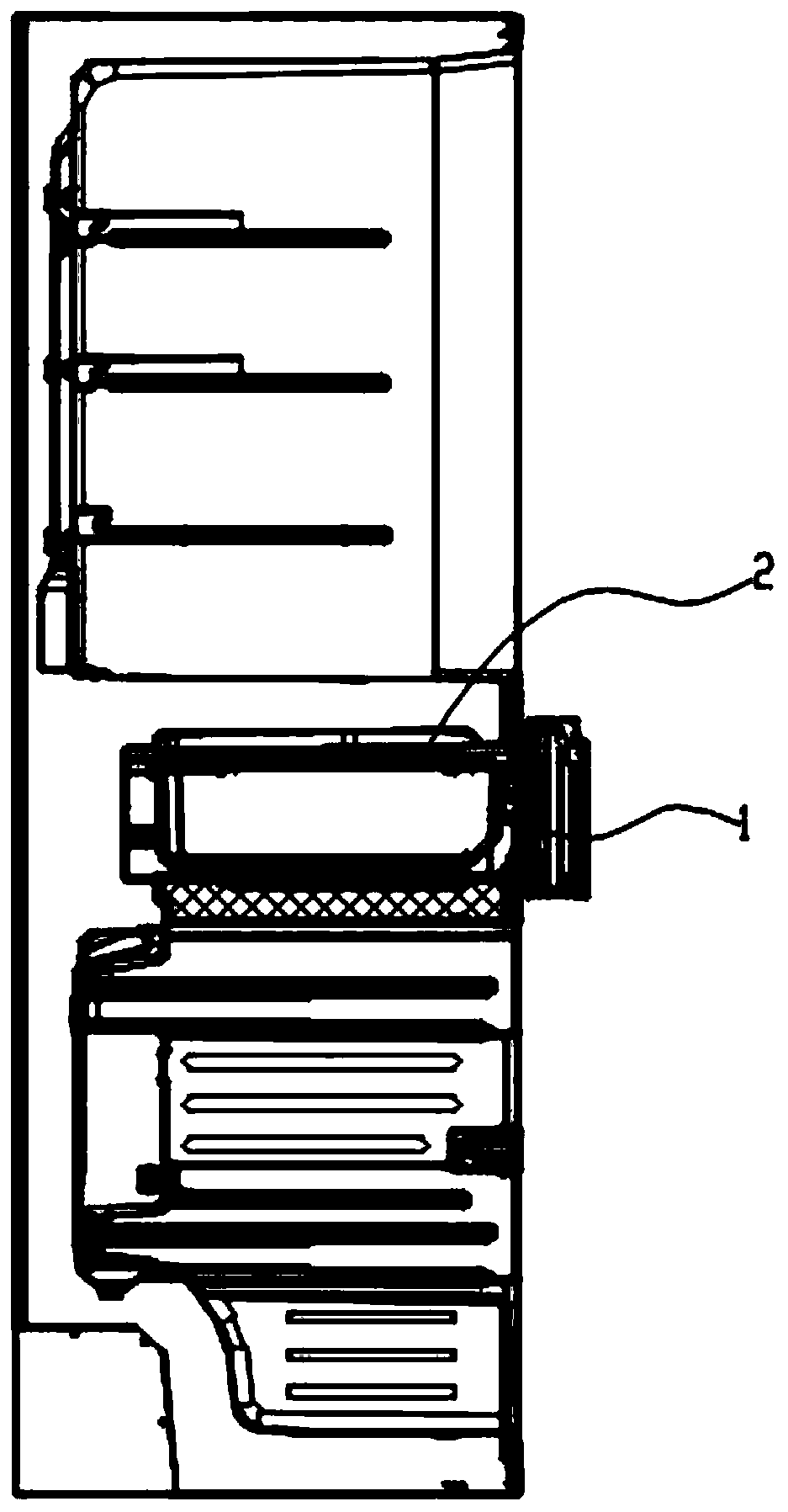

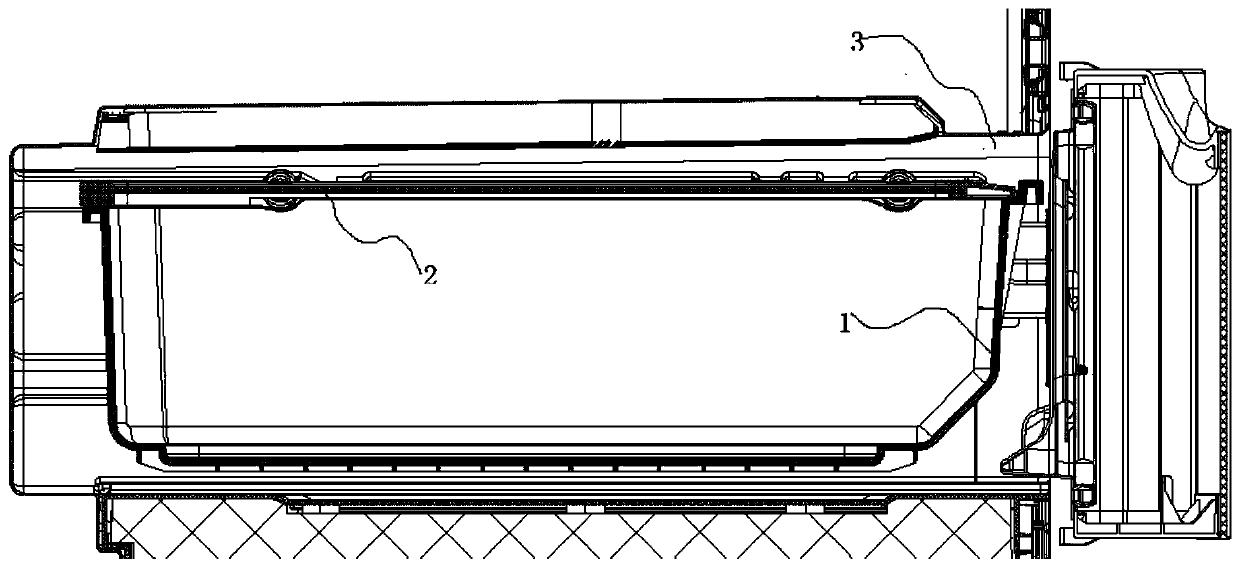

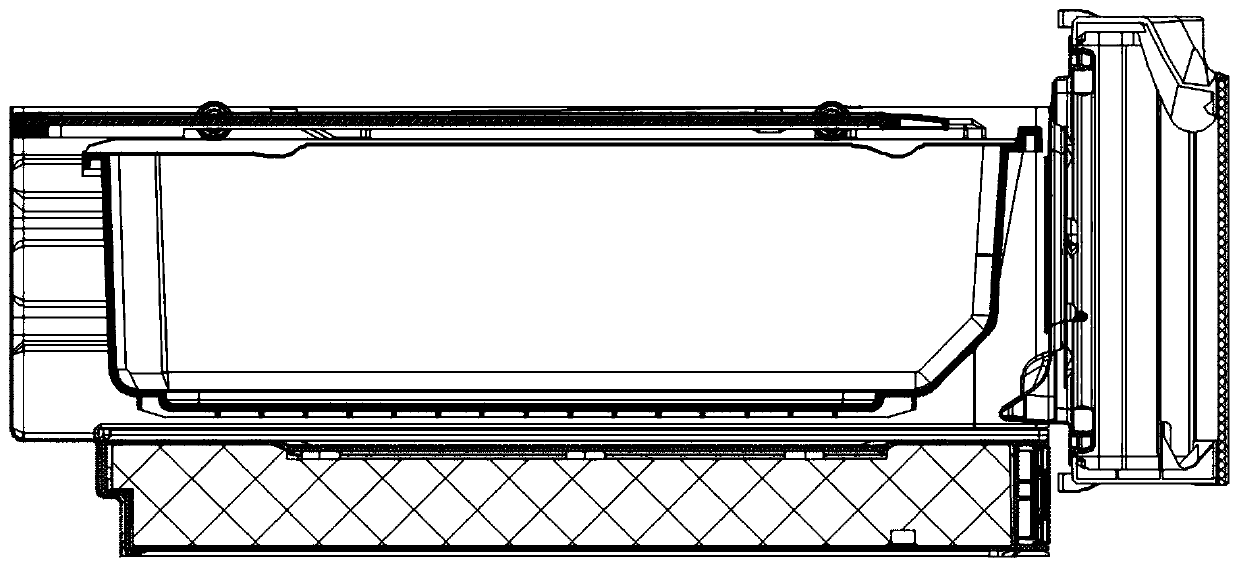

[0031] Such as Figure 1-8 As shown, the present embodiment provides an air-cooled refrigerator, including a temperature-changing room, a refrigerating room, and a freezing room. At least one drawer compartment is provided inside the compartment, and a drawer assembly with a sealing function and a liner 3 are arranged in the compartment. , wherein the drawer assembly includes a drawer bucket 1 and a sealing cover 2 arranged above it, pulleys 21 are respectively provided on both sides of the sealing cover 2, and pulleys 21 are respectively provided on both sides of the drawer bucket 1. The groove rail in the direction, the pulley 21 and the groove rail form a movable cooperation relationship, so that the pulley 21 can move along the groove rails on both sides of the drawer bucket 1 .

[0032] The front and rear ends of each groove rail of the drawer bucket 1 respectively form a downwardly recessed first limiting groove, and the lowest point position of the lower part of the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com