Full-automatic fish fry sorting machine for aquaculture

A fully automatic technology for aquaculture, applied in the field of sorting machines, can solve problems such as time-consuming, inconsistent standards, and poor grading effects, and achieve the effects of improving work efficiency, increasing survival rate, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

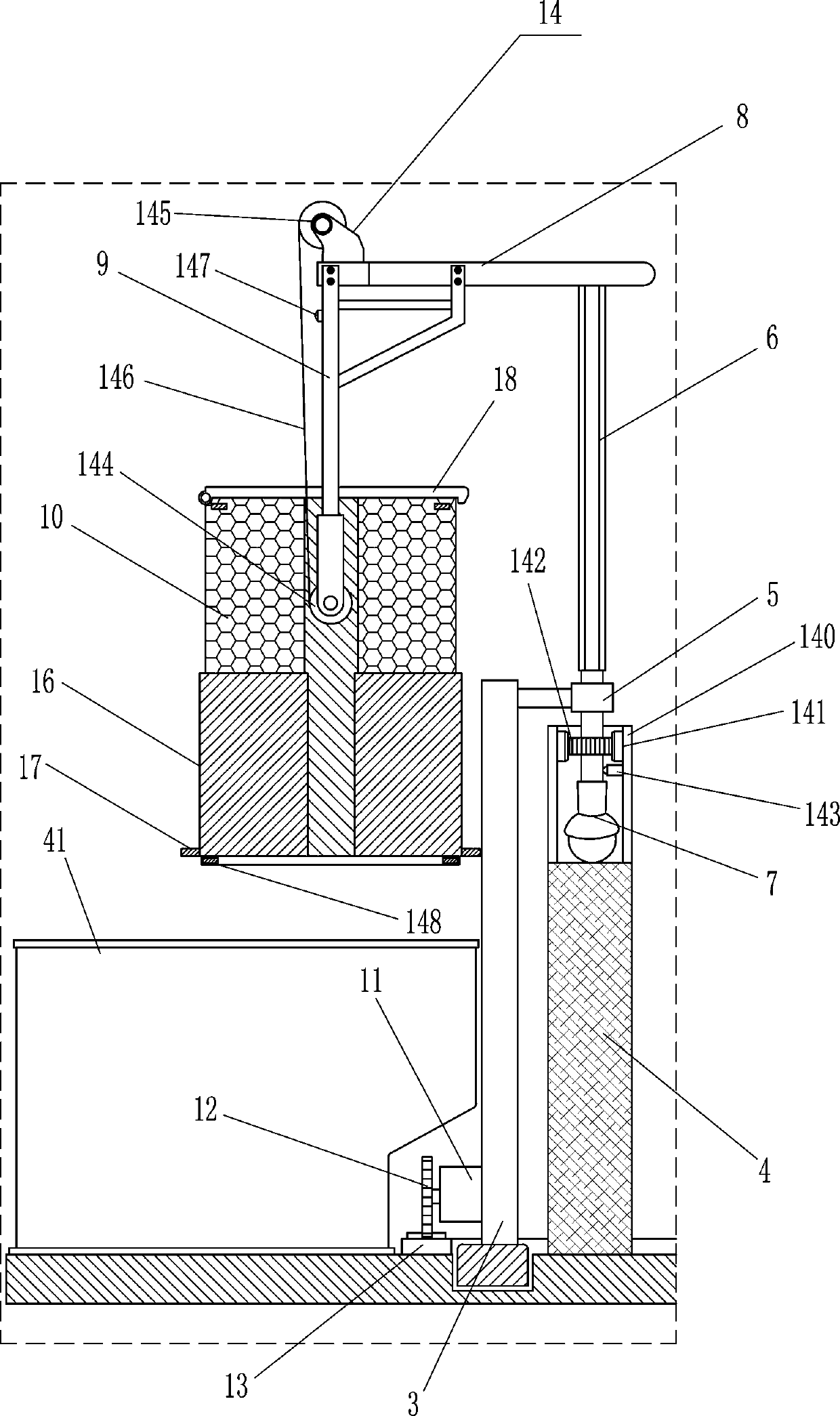

[0020] Such as Figure 1-5 As shown, a fully automatic fry sorting machine for aquaculture includes a base 1, a ring 2, a sliding plate 3, a trapezoidal block 4 and a collection frame 41, and the top of the base 1 is provided with two circles of different sizes Ring 2, the two rings 2 are set at the same center, the base 1 is slidingly provided with a sliding plate 3, the sliding plate 3 can slide along the circumference of the base 1, the sliding plate 3 is located outside the ring 2, and the sliding plates 3 are perpendicular to the base 1. There is a trapezoidal block 4 and a collection frame 41 on the left side of the top of the base 1. The trapezoidal block 4 is located between the sliding plate 3 and the ring 2. The trapezoidal block 4 is connected to the base 1 by bolts, and the collection frame 41 is located in the trapezoidal The left side of block 4 also includes guide sleeve 5, guide rod 6, universal roller 7, connecting plate 8, connecting frame 9, screen frame 10,...

no. 2 Embodiment

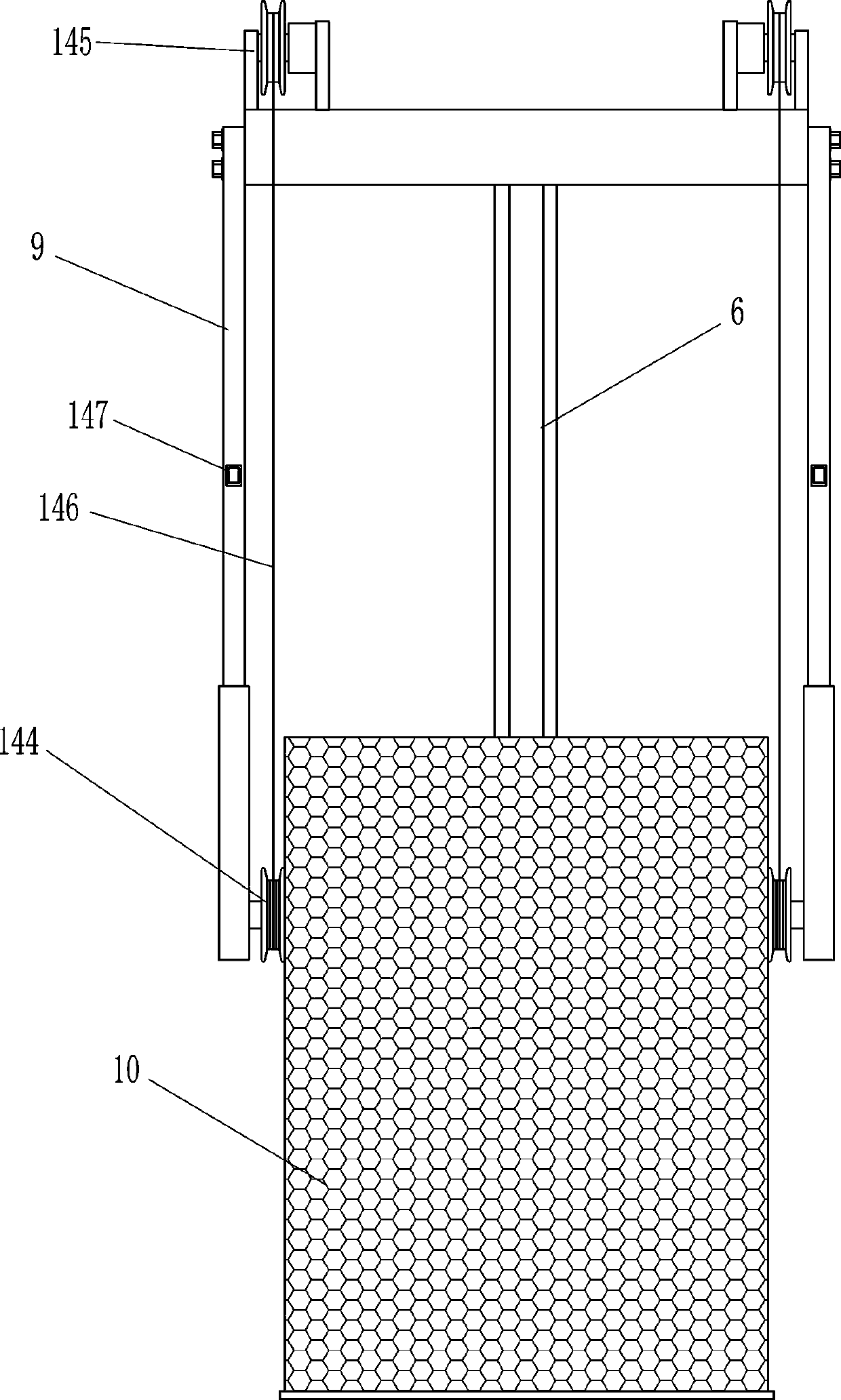

[0023] Such as Figure 2-5 As shown, an automatic unloading device 14 is also included, and the automatic unloading device 14 includes a fixed plate 140, a rack 141, a second gear 142, a first button 143, a reel 144, an electric reel 145, and a pull wire 146 , the second button 147 and the first limit block 148, both sides of the top of the trapezoidal block 4 are provided with a fixed plate 140, and the two fixed plates 140 are symmetrically arranged on the left and right, and the fixed plates 140 on both sides are provided with racks 141, two The rack 141 is staggered front and back, the bottom of the guide bar 6 is provided with a second gear 142, and the second gear 142 is engaged with the rack 141, and the middle part of a fixed plate 140 is provided with a first button 143, and the first button 143 is located on the two racks 141. Between, the front and rear sides of the top of the connection plate 8 are equipped with electric reels 145, the electric reels 145 are connec...

no. 3 Embodiment

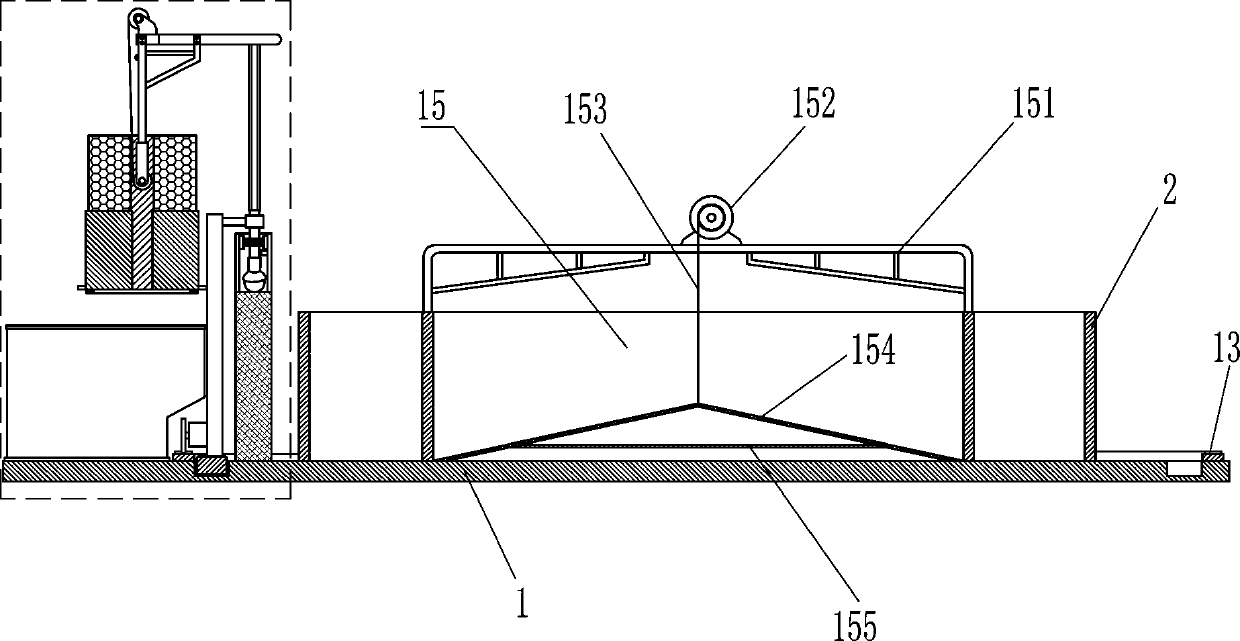

[0026] Such as figure 1 Shown, also comprise elevating device 15, elevating device 15 comprises bracing frame 151, winch 152, stay rope 153, net plate 154 and support plate 155, and inside annulus 2 tops are provided with bracing frame 151, and bracing frame 151 can The way of disassembling and connecting is connected with the ring 2 on the inner side. There is a hoist 152 in the middle of the top of the support frame 151. The hoist 152 is connected with the support frame 151 by means of bolt connection. End is connected with net plate 154, and net plate 154 is positioned at inner side ring 2, and net plate 154 and inner side ring 2 are slidably matched, and net plate 154 bottom is provided with support plate 155, and support plate 155 is netted.

[0027] When the fry between the two rings 2 was less, start the winch 152 to drive the net plate 154 to move upwards through the stay rope 153, and the net plate 154 moves upwards to drive the fry in the inner circle 2 to move upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com