Scraping plate mechanism for coating adhesive on plate material

A technology for coating boards and adhesives, which can be used in coatings, devices for coating liquids on surfaces, etc., and can solve problems such as trouble, low efficiency, and large manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

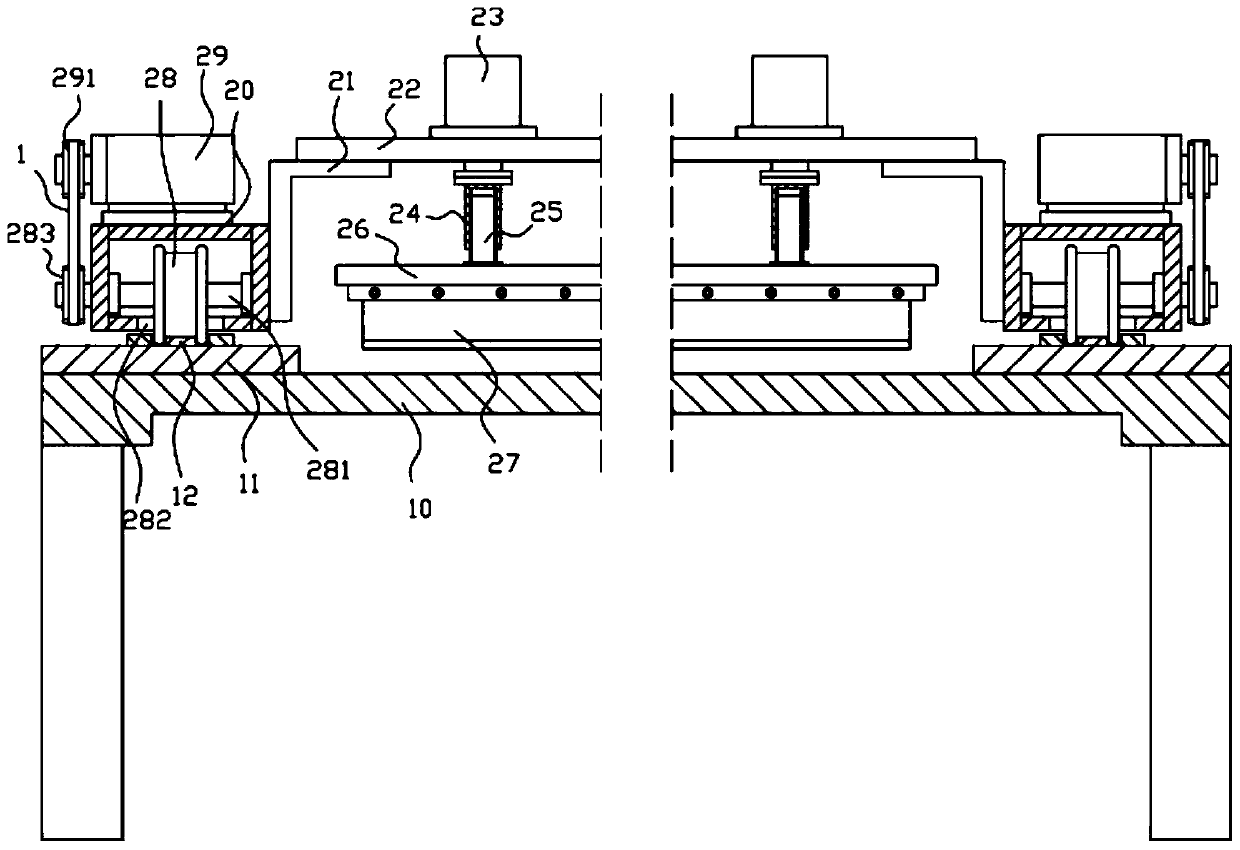

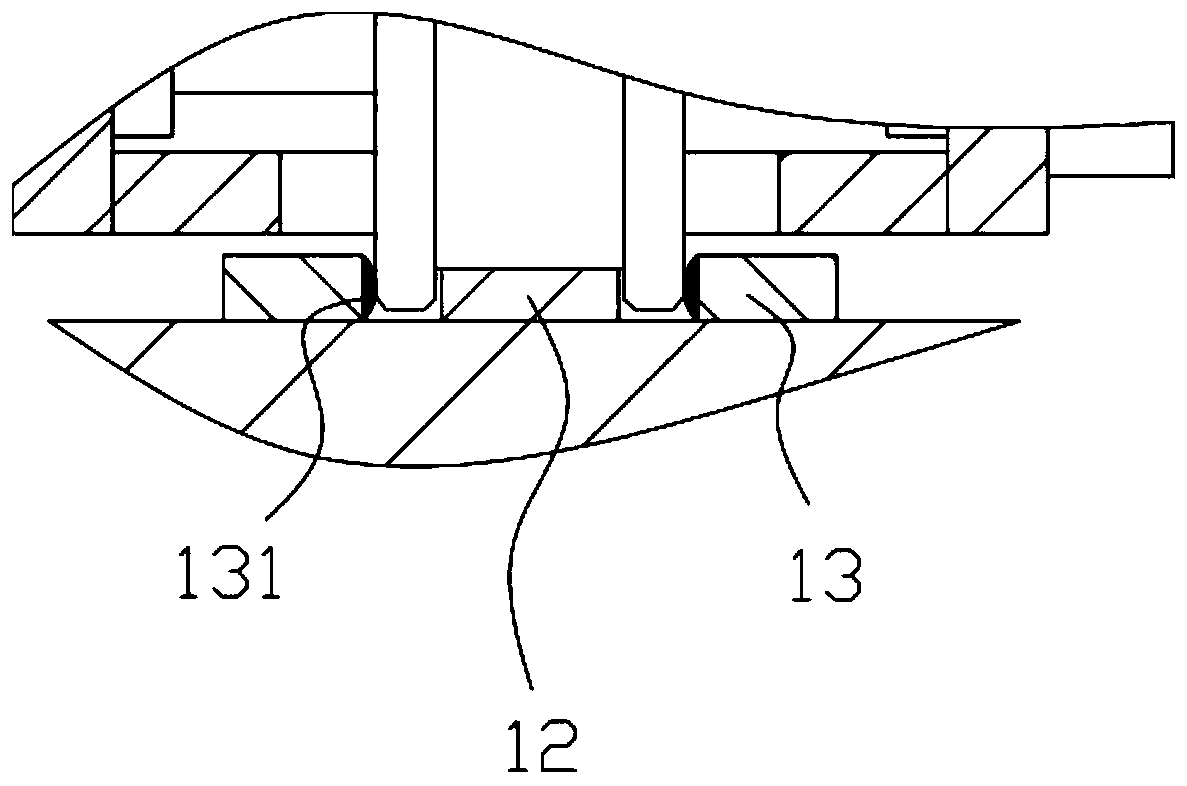

[0023] Example: see Figure 1 to Figure 4 As shown, a scraper mechanism for adhesive coating sheets includes a frame 10, the left and right sides of the top plate of the frame 10 are fixed with crossbeam support plates 11 extending forward and backward, and the top surface of the transverse beam support plate 11 The middle part is fixed with a track 12 extending forward and backward;

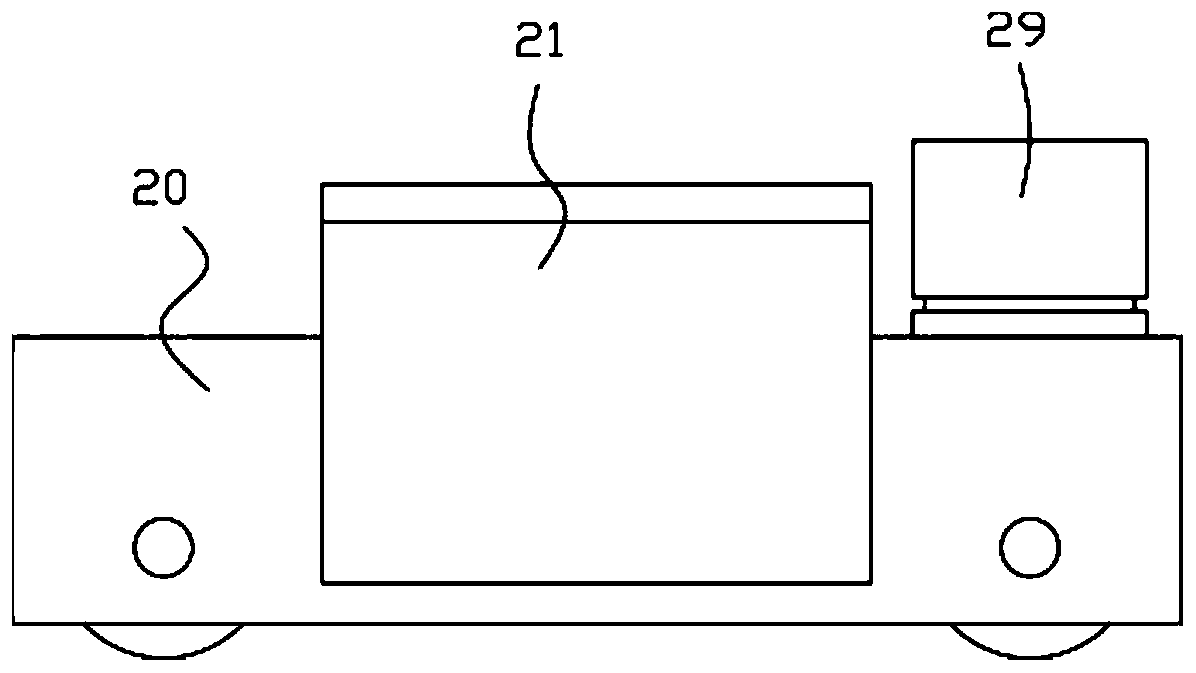

[0024] The transverse beam support plate 11 is provided with a conveying beam mechanism 20, and the middle parts of the beam bodies of the two conveying beam mechanisms 20 are fixed with connecting frames 21, and the main connecting beam 22 is fixed on the two connecting frames 21;

[0025] The left and right parts of the top surface of the main connecting beam 22 are fixed with adjusting motors 23, and the output shafts of the two adjusting motors 23 pass through the bottom surface of the main connecting beam 22 and are connected with a vertical screw sleeve 24 through a coupling , the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com