A kind of production system and production method of microfiber glass wool

A production system and glass wool technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of poor stability of glass wool knocking degree, unstable glass wool quality, unstable flame airflow, etc., and achieve temperature maintenance. Stable and uniform, easy to achieve, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

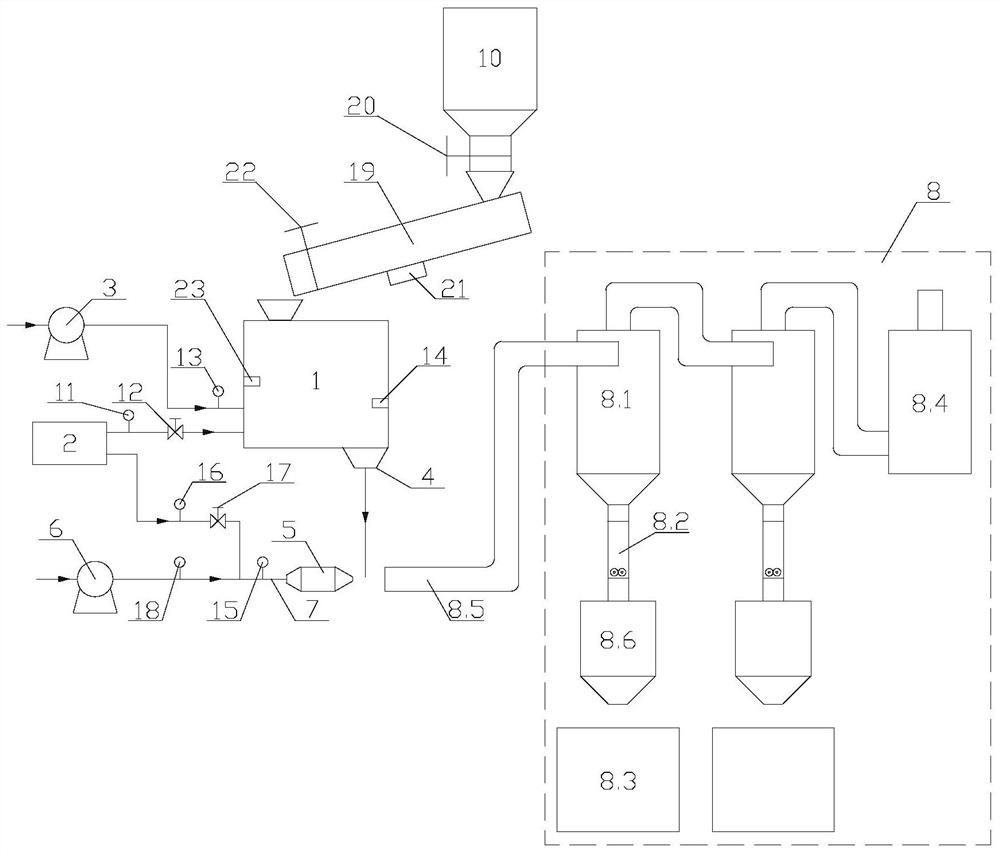

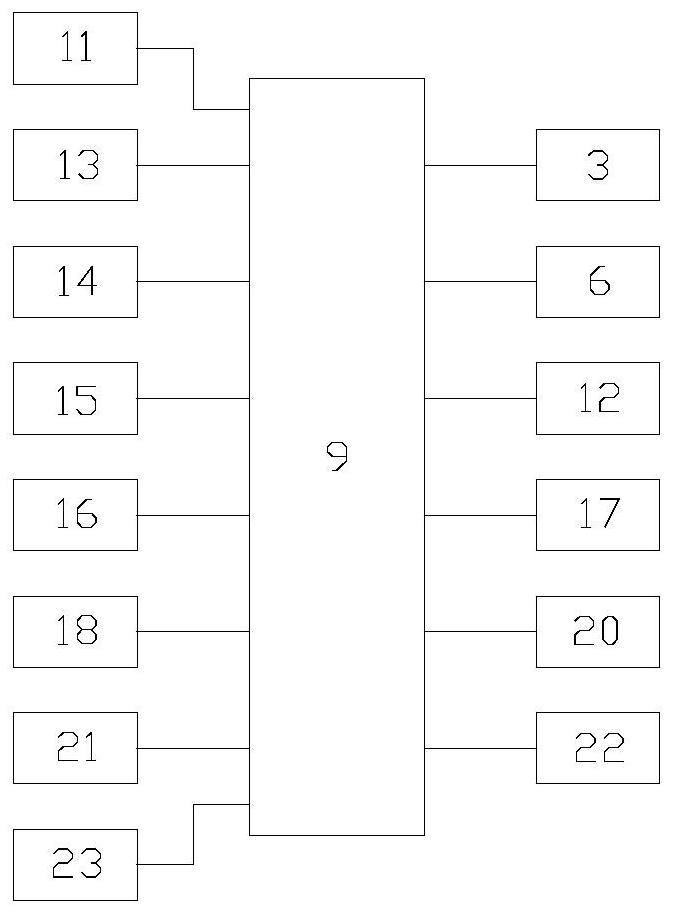

[0022] Embodiment 1: as Figure 1-2As shown, a production system of microfiber glass wool, which includes a melting furnace 1, a fuel gas source 2, a first blower 3, a wire drawing bushing 4, a cotton blowing device 5, a second blower 6, and a gas mixing main pipe 7 , cotton receiving device 8, controller 9 and feed bin 10, the gas outlet of fuel gas source 2 and the first blower 3 all communicate with the air inlet of the combustion chamber of melting kiln 1 by pipeline, in fuel gas source 2 A first flow sensor 11 and a first electromagnetic valve 12 are arranged on the pipeline between the melting furnace 1 and a second flow sensor 13 and a second electromagnetic valve are arranged on the pipeline between the first blower 3 and the melting furnace 1 A temperature sensor 14 is provided in the melting furnace 1; a drawing bushing 4 is provided at the liquid outlet of the melting furnace 1, and the drawing bushing 4 has been disclosed by the "glass fiber bushing" with the appli...

Embodiment 2

[0027] Embodiment 2: utilize the method for the production system of embodiment 1 to produce microfiber glass wool, it comprises the following steps: (1) heating and melting; (2) drawing; (3) blowing cotton;

[0028] (1) Heating and melting: a certain amount of glass frit is added to the melting furnace 1, and fuel gas and supporting gas are introduced into the combustion chamber of the melting furnace 1, and the glass frit in the melting furnace 1 is ignited and heated. The block melts into a liquid;

[0029] (2) Wire drawing: the liquid obtained in step (1) is drawn through the drawing bushing 4 to obtain fine glass filaments.

[0030] (3) Cotton blowing: the mixed gas of fuel gas and combustion-supporting gas is passed into the cotton blowing device 5, ignited to form a flame, and the formed flame blows the glass filament obtained in step (2), and the glass filament is blown into glass wool.

[0031] Add glass gobs to the melting furnace 1 in the step (1): the liquid leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com