A two-wheeled electric vehicle gear system composed of graphene lubricated plastic

A gear system and graphene technology, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problem of large size, and achieve the effect of low cost, strong practicability, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

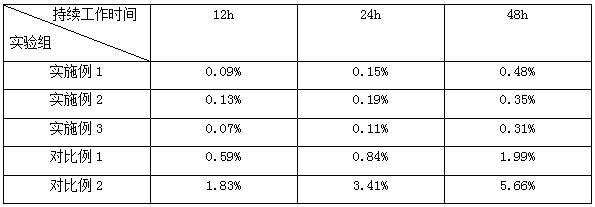

Embodiment 1

[0038] A two-wheeled electric vehicle gear system composed of graphene-lubricated plastics includes a center wheel, a plurality of planetary wheels with the same specifications and respectively meshing with the center wheel, and a ring gear meshing with the planetary wheels. When in use, the center wheel is connected to the drive structure, and after the speed of the drive structure is transmitted to the ring gear through the planetary gear, the speed of the ring gear is reduced relative to the center wheel, and the center wheel, planetary gear and ring gear form a planetary gear reduction structure, which can effectively realize deceleration function.

[0039] Since the center wheel, the planetary gear and the ring gear are meshed by gears, on the one hand, in the long-term use process, it is easy to wear and cause the failure of the reduction gear; In this application, the center wheel, the planetary wheel and the ring gear are respectively an integrated body made of graphen...

Embodiment 2

[0055] This embodiment is basically the same as the above-mentioned embodiment 1, except that the components and preparation methods of the graphene nanosheet self-lubricating plastic are different, and the similarities will not be described in detail.

[0056] The graphene nanosheet self-lubricating plastic, in parts by mass, includes 13 parts of edge graphene oxide nanosheets, 85 parts of engineering plastics, 1 part of dispersant and 0.5 part of modification aid. Among them, polyamide (PA) is selected as the engineering plastic, 1 part of calcium stearate is selected as the dispersant, and quadruple bisphosphonate is selected as the modification additive.

[0057] Wherein, edge graphene oxide nanoplatelets are prepared by the following steps:

[0058] a. Using natural graphite flakes as raw materials, steel needles as grinding bodies, needle-to-material mass ratio 40:1, hydrogen peroxide as grinding media, and grinding for 8 hours at a magnetic field switching frequency of ...

Embodiment 3

[0071] This embodiment is basically the same as the above-mentioned embodiment 1, except that the components and preparation methods of the graphene nanosheet self-lubricating plastic are different, and the similarities will not be described in detail.

[0072] The graphene nanosheet self-lubricating plastic, in parts by mass, includes 16 parts of edge graphene oxide nanosheets, 95 parts of engineering plastics, 4 parts of dispersant and 2 parts of modification aid. Among them, polycarbonate (PC) is selected as the engineering plastic, bis stearic acid amide is selected as the dispersant, 1 part of polyethylene wax and 1 part of tetraerythritol ester are selected as modification additives.

[0073] Wherein, edge graphene oxide nanoplatelets are prepared by the following steps:

[0074] a. Using natural flake graphite as raw material, steel needles as grinding body, needle-to-material mass ratio 60:1, hydrogen peroxide as grinding medium, and grinding for 10 hours at a magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com