A Combined Sealing System of Reactor Stirring Shaft and Its Application

A combined sealing and reaction kettle technology, applied in the direction of engine sealing, separation method, filtration separation, etc., can solve the problems of unexpected stop of stirring, sealing failure, etc., and achieve the effect of improving stability, ensuring cleanliness, and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

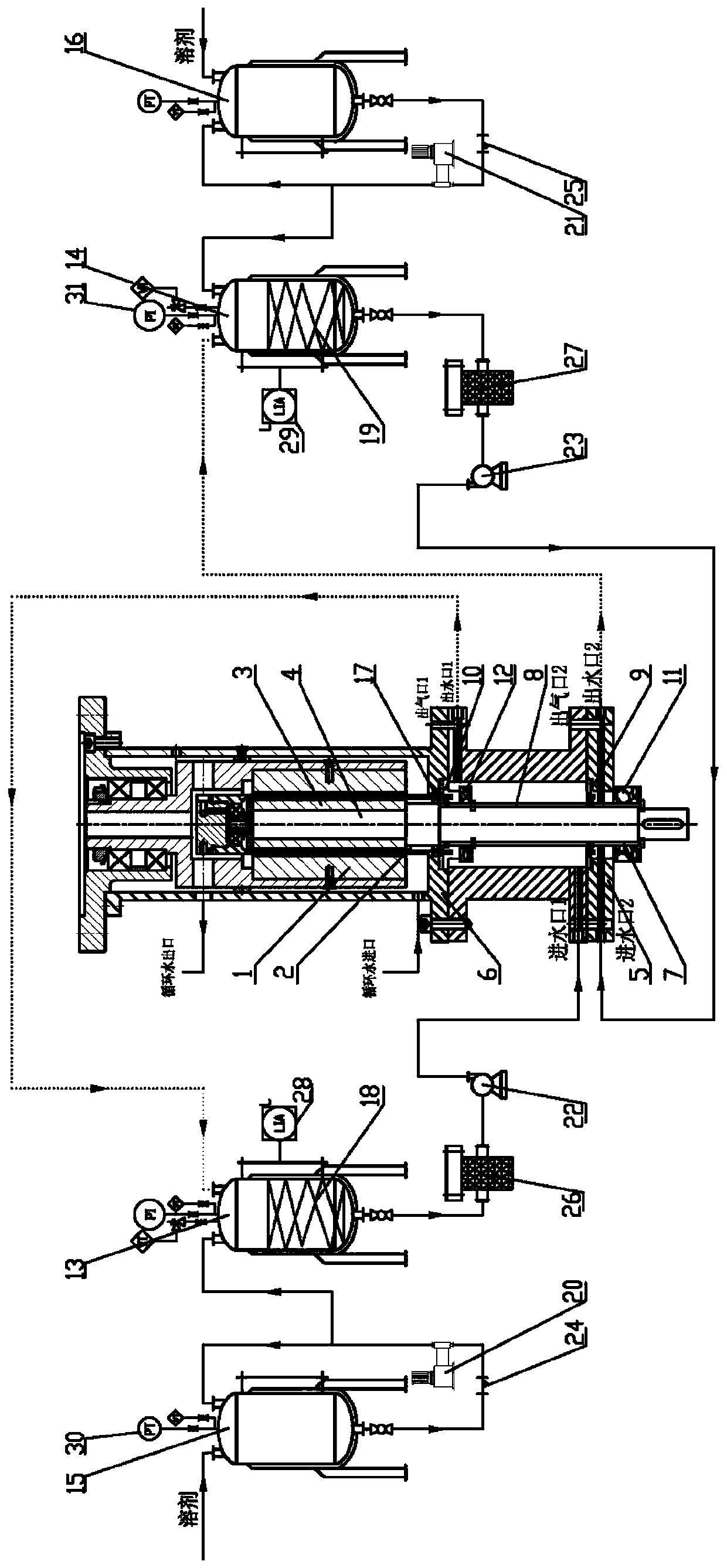

[0041] This embodiment provides a combined sealing system for the stirring shaft of the reactor, which is especially suitable for medium and high pressure suspension polymerization reactors. figure 1 Provided schematically the structural representation of the combined sealing system of the reactor stirring shaft provided by the present invention, as figure 1 As shown, the combined sealing system of the stirring shaft of the reactor includes:

[0042] Outer magnetic drive part 1, atmospheric side magnetic seal cavity 2, inner magnetic drive part 3, stirring shaft 4, first flange 5, second flange 6, first medium side mechanical seal cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com