Fire hose connector

A technology for fire hoses and connectors, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve the problem of uneven circumferential force on the parts connected by fire hoses and the impact of fire hoses on fire protection Rescue effectiveness, joint leakage and other issues, to avoid leakage or even breakage, improve stability, and increase frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

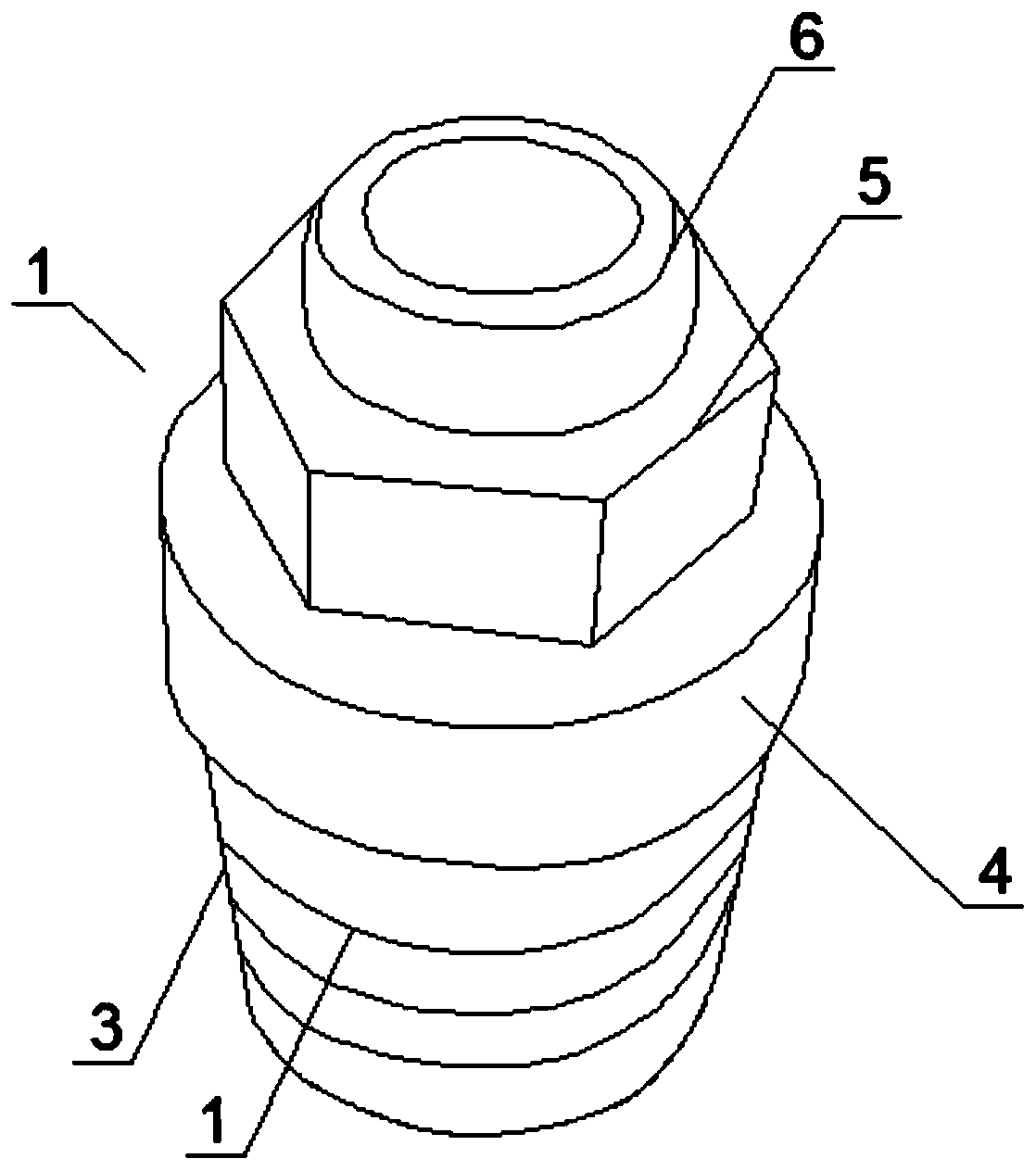

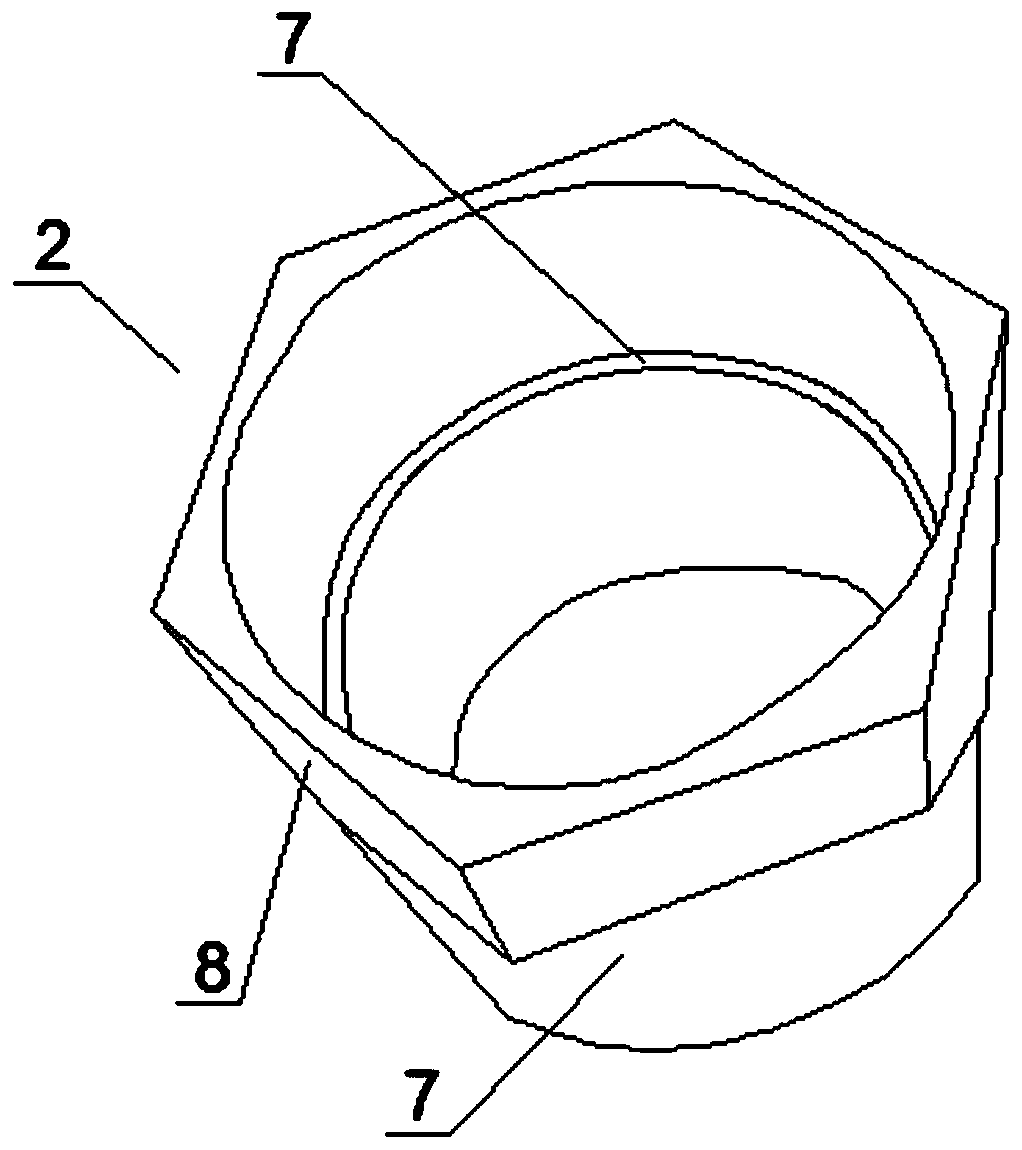

[0021] Such as Figure 1~2 Shown:

[0022] A connector for a fire hose, consisting of an inner connector 1 and an outer connector 2, the outer connector is screwed to the inner connector; specifically, the inner connector 1 includes an inner plug inserted into the fire hose 3. The inner plug 3 is a hollow tubular structure. After the inner plug 3 is inserted into the fire hose, the inner wall of the fire hose is tightly attached to the outer wall of the inner plug, and the pressure of the liquid in the fire hose is realized through the inner plug. Transfer, in order to increase the tight friction between the outer wall of the inner plug and the inner wall of the fire hose, a plurality of printing grooves distributed at intervals can be set on the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com