Commercial kitchen exhaust air rate optimization method based on oil fume trapping efficiency

A technology of collection efficiency and exhaust air volume, applied in the field of numerical simulation of computational fluid dynamics, can solve problems such as increased energy consumption, increased noise intensity, large indoor negative pressure, etc., to achieve the effect of setting certain and accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

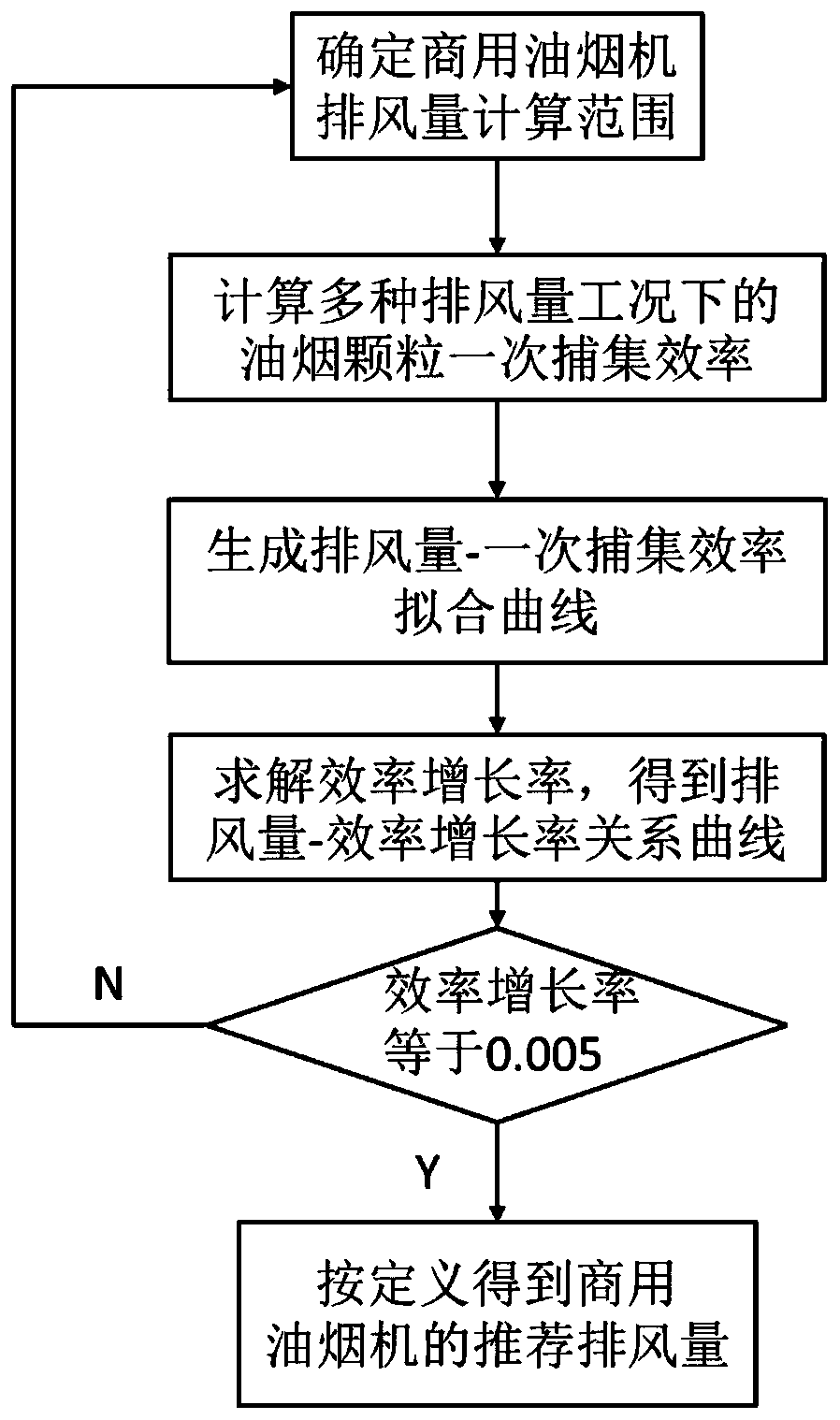

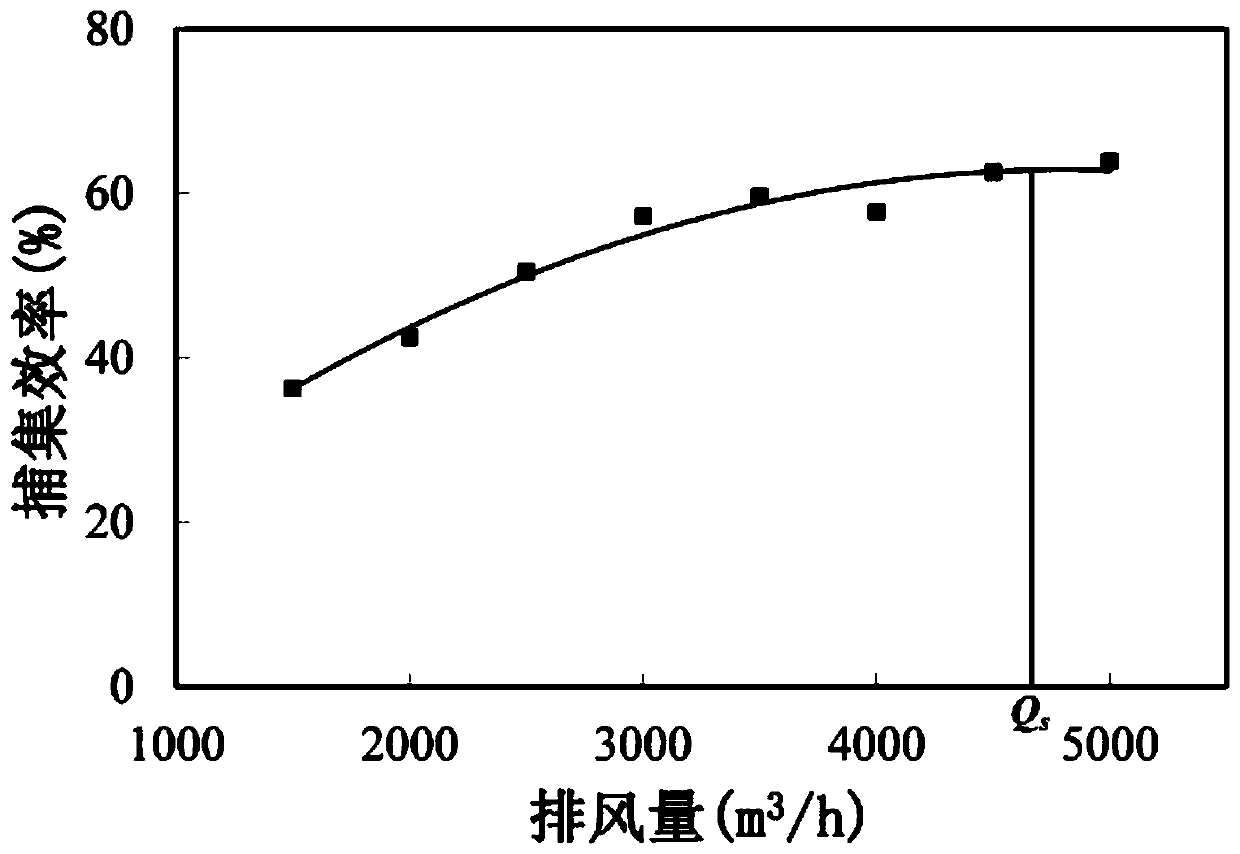

[0017] A method for determining the recommended exhaust volume of a commercial kitchen based on the oil fume capture efficiency of the present invention is applied to the commercial kitchen calculation example of the CFD model schematic diagram, and the specific implementation is described as follows:

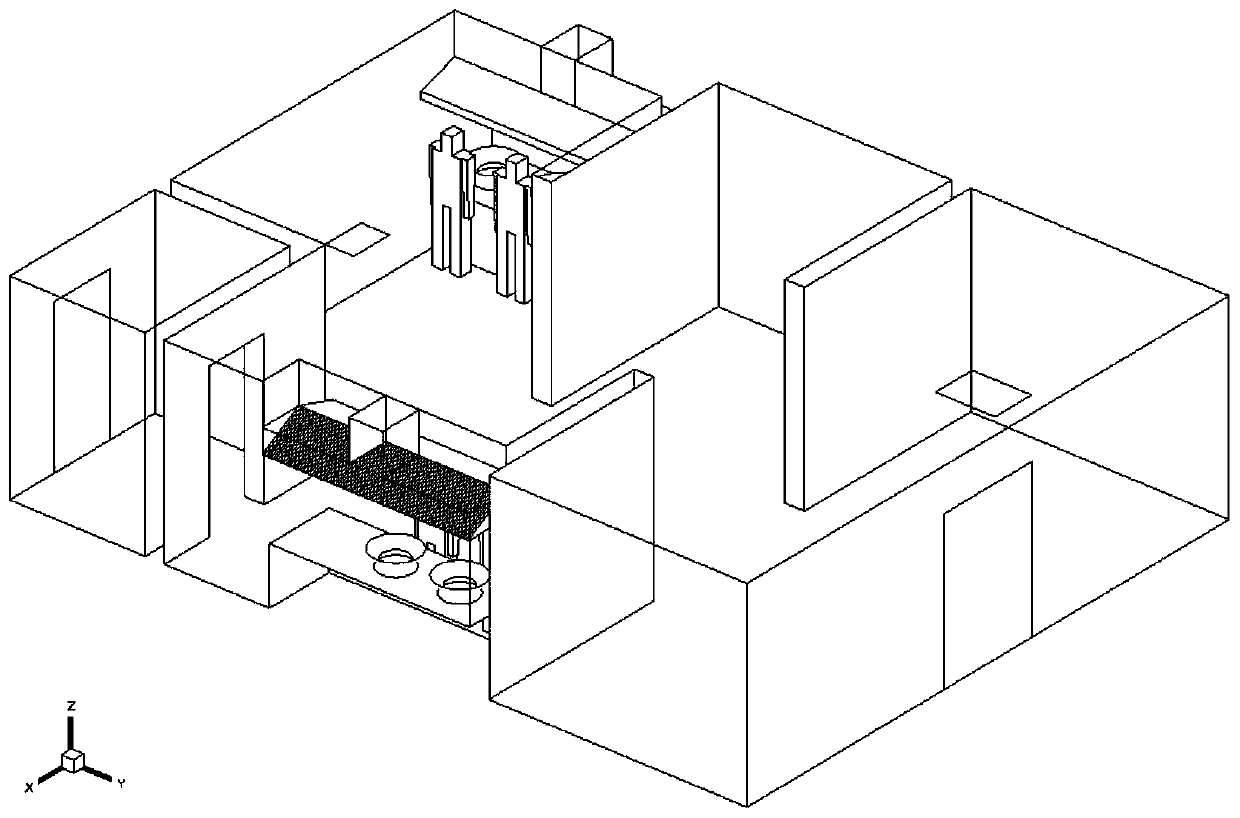

[0018] Step 1. First establish a typical commercial kitchen model, such as figure 2 Shown is a schematic diagram of a CFD model of a specific embodiment of the present invention. In the process of model simulation, the exhaust outlet of the range hood is set as the velocity outlet boundary. Assuming that the flow velocity of each point on the surface of the exhaust outlet is evenly distributed, and in the case of a certain area of the exhaust outlet, different exhaust air volumes can be obtained by changing the veloci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com