Connecting wire assembly

A technology for connecting wires and connecting parts, which is applied in the direction of connections, parts of connecting devices, devices for reducing the stress at the connection of wires, etc., which can solve problems such as bending, damage to data wires, and wire deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

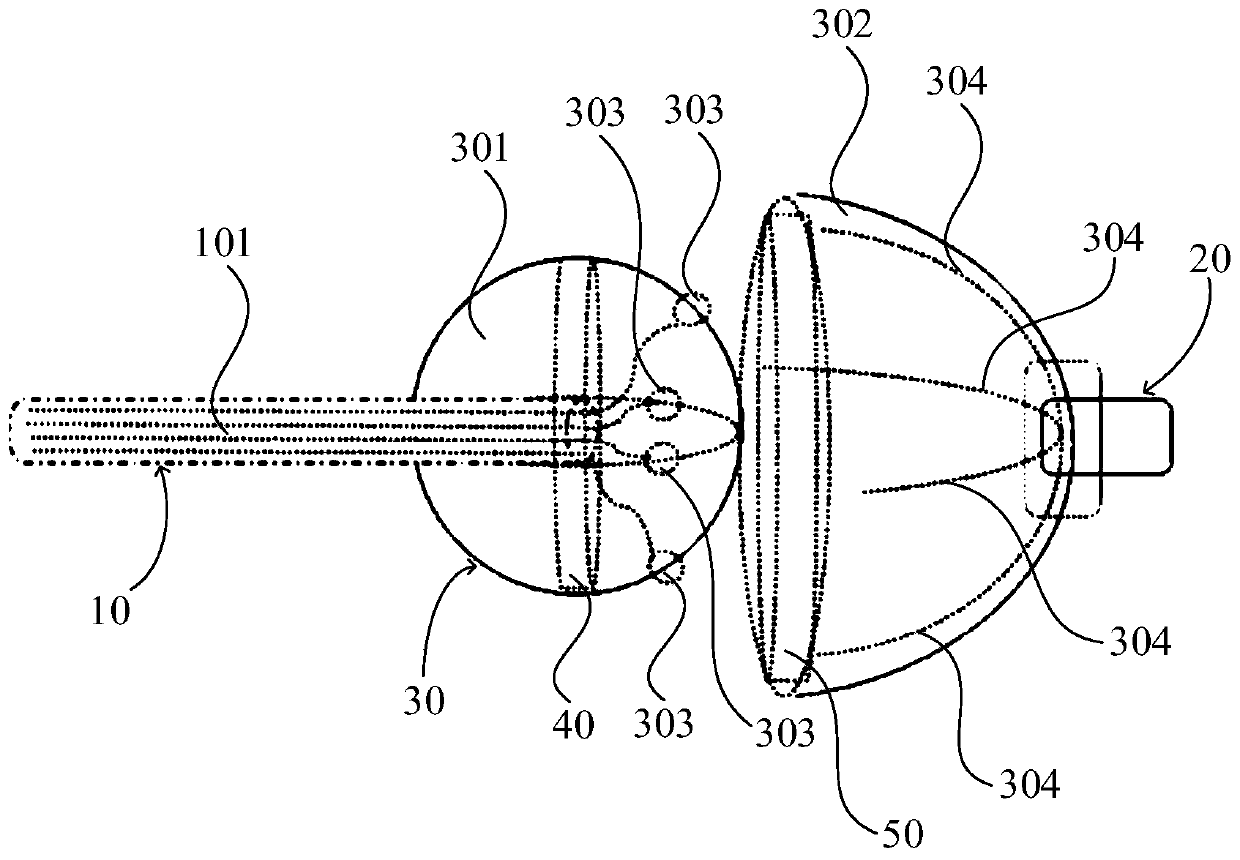

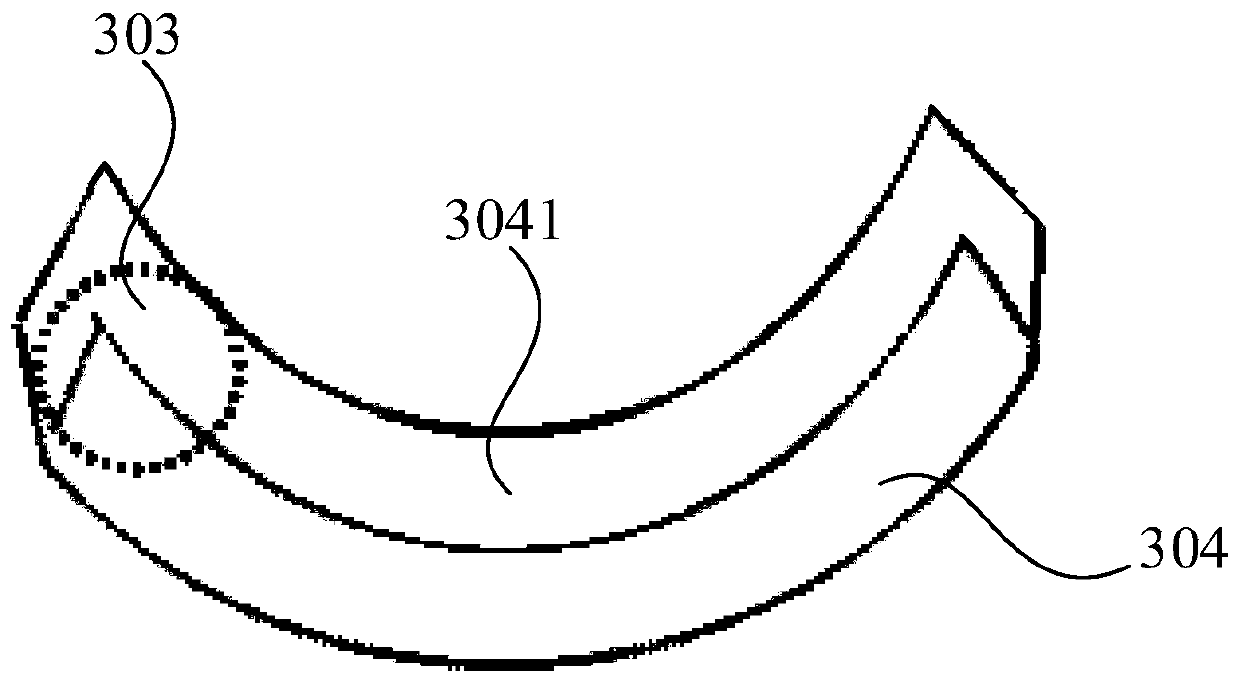

[0048] This embodiment discloses a connecting wire 101 assembly, such as Figure 1-2 As shown, the connecting line 101 assembly includes a line body end 10, an interface end 20 and a connector 30 connected between the line body end 10 and the interface end 20, and the connector 30 includes a first connecting body 301, a conductor 303, a second connecting body 302 and connecting rail 304. Wherein, the first connecting body 301 has a first end and a second end along the extending direction of the line body in the line body end 10, the first end is connected to the line body end 10, and one end of the line body end 10 is connected to the first connecting body 301 Extend into the inside of the first connecting body 301 . The conductor 303 is embedded on the outer wall of the second end, and the conductor 303 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com