Vertical roller mill and operation method therefor

A technology of vertical roller mill and operation method, applied in grain processing and other directions, can solve the problems of difficult drying and pulverizing high-moisture coal, etc., and achieve the effect of economical and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0093] Hereinafter, Experimental Example 1, Comparative Experimental Example 1, and Experimental Example 2 of the present invention will be described. Table 1 below shows the supply start inlet temperature, supply start outlet temperature, and running outlet temperature (all of which are control target values) among the operating conditions of the vertical roller mill 1 in Experimental Example 1 and Comparative Experimental Example 1. Each experiment was carried out on a vertical roller mill for testing which is smaller than the actual machine.

[0094] [Table 1]

[0095] .

experiment example 1

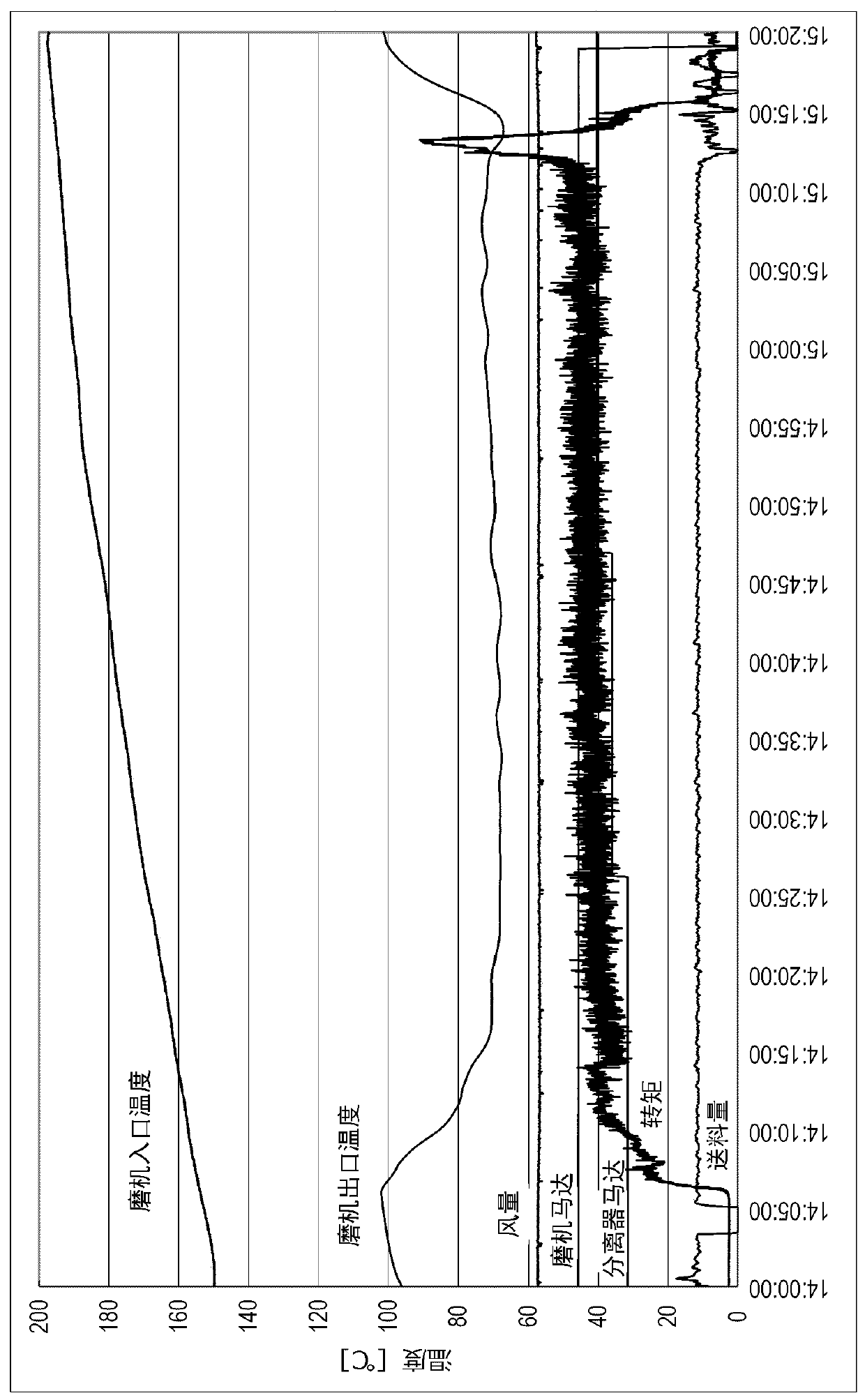

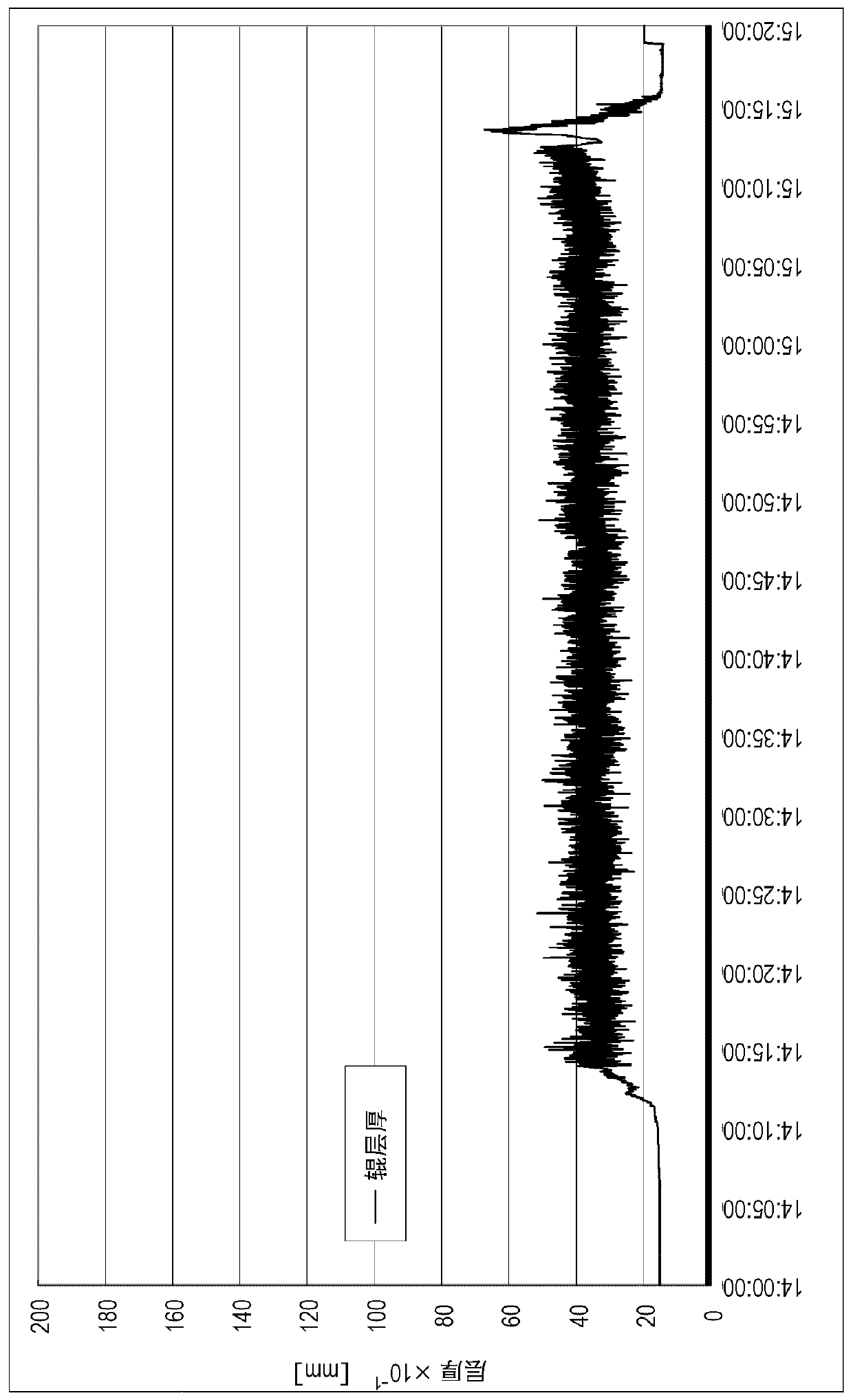

[0097] In Experimental Example 1, hot gas was supplied to the mill inlet 72 of the vertical roller mill for testing at a certain flow rate, and it took one hour of preheating time to preheat the vertical roller mill 1 until the mill inlet temperature was 150°C (controlled target value). The mill outlet temperature was about 100°C when the mill inlet temperature was 150°C, and this mill outlet temperature sufficiently exceeded 65°C as the feed start outlet temperature. After preheating the vertical roller mill 1 in this way, the mill motor 51 and the separator motor 81 are rotated to start supply of lignite with a moisture content of 60 to 64%. After starting the supply of lignite, adjust the temperature of the hot gas supplied to the mill inlet 72 to between 150 and 320°C so that the temperature at the mill outlet is maintained at 70°C (control target value) and adjust the temperature from the mill outlet. 71 The flow rate of the discharged mill exhaust. The flow rate of the...

experiment example 2

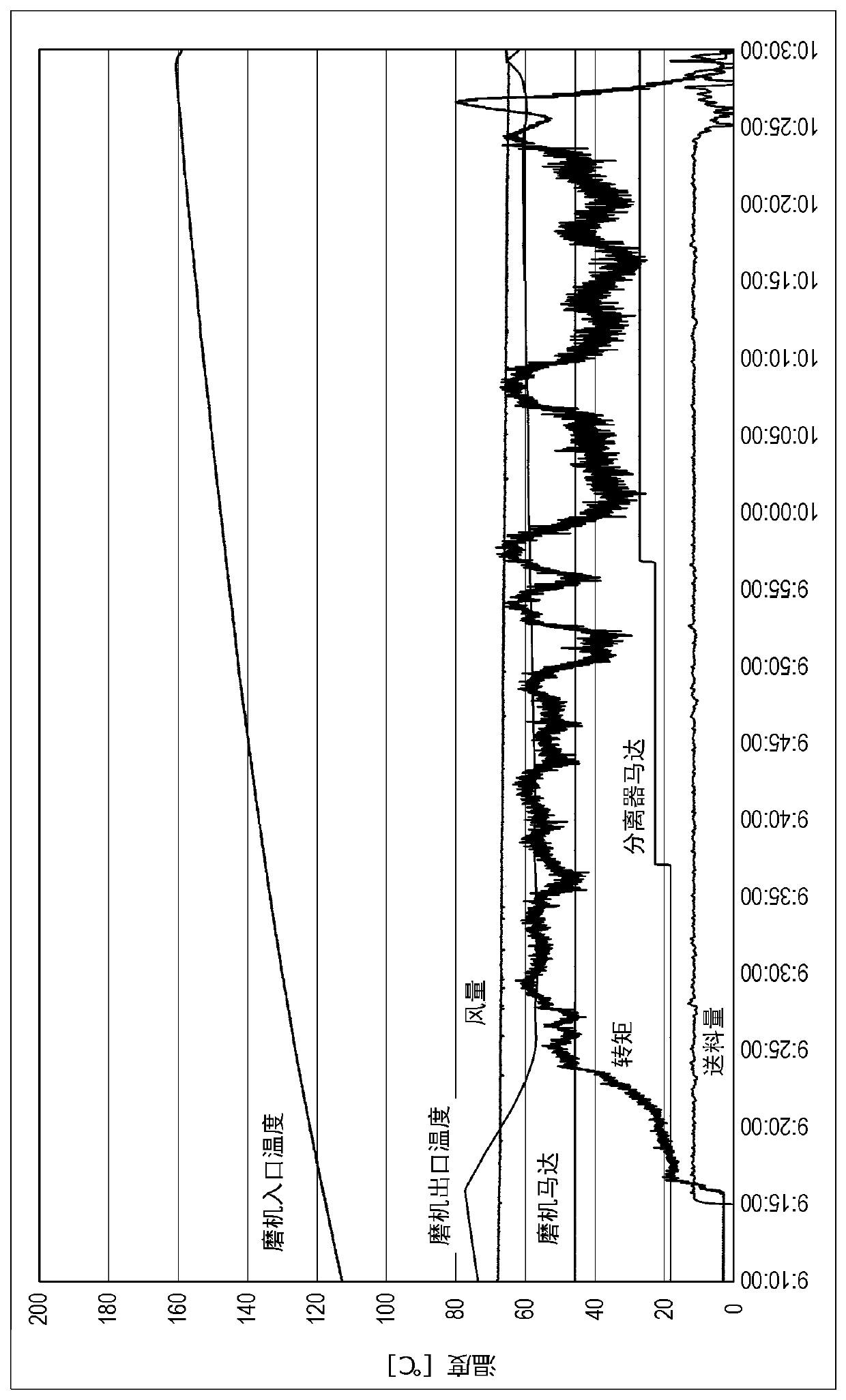

[0109] In Experimental Example 2, in order to find an appropriate range of the inlet temperature at the start of supply, the temperature at the inlet of the mill was changed while the temperature at the outlet of the mill was maintained at 60°C (control target value), and the temperature of the mill motor 51 was measured. torque value. In addition, the operating conditions of the vertical roller mill 1 of Experimental Example 2 are that the supply flow rate of the hot gas is constant, the rotational speed of the mill motor 51 is constant, and the rotational speed of the separator motor 81 is performed within a fluctuation range of about 10% of the rated rotational speed. Adjustment, the supply of lignite is constant.

[0110] Figure 6 The torque value of the mill motor 51 of Experimental Example 2 and the temporal change of the mill inlet temperature are shown. like Figure 6 As shown, the torque value of the mill motor 51 of Experimental Example 2 fluctuates unstably when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com