Fastening unit for fastening a clamping element to a unit

A technology for fixing units and components, applied in the direction of threaded fasteners, transmission components or ropes or cables for pulleys, connecting components, etc., to achieve the effect of simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Preferred embodiments of the present invention will be described below with reference to the drawings.

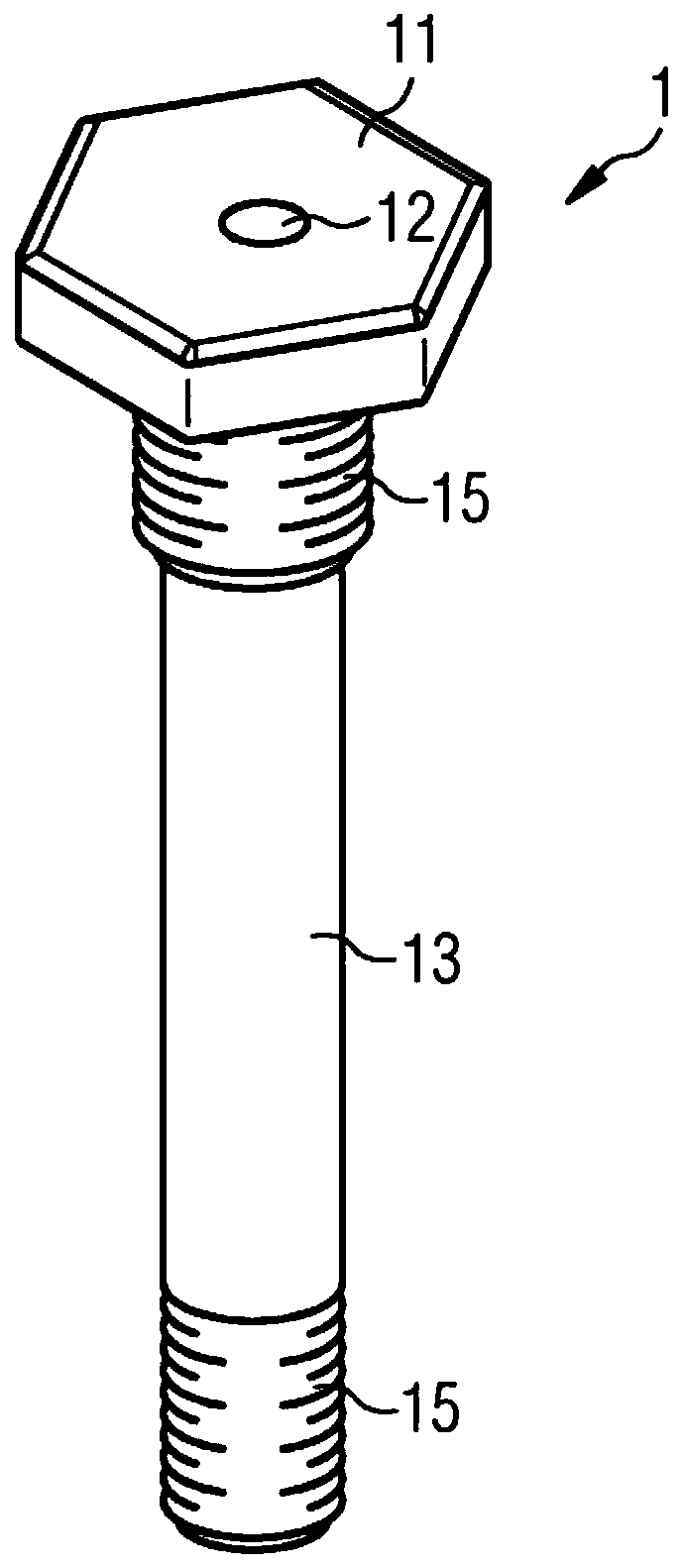

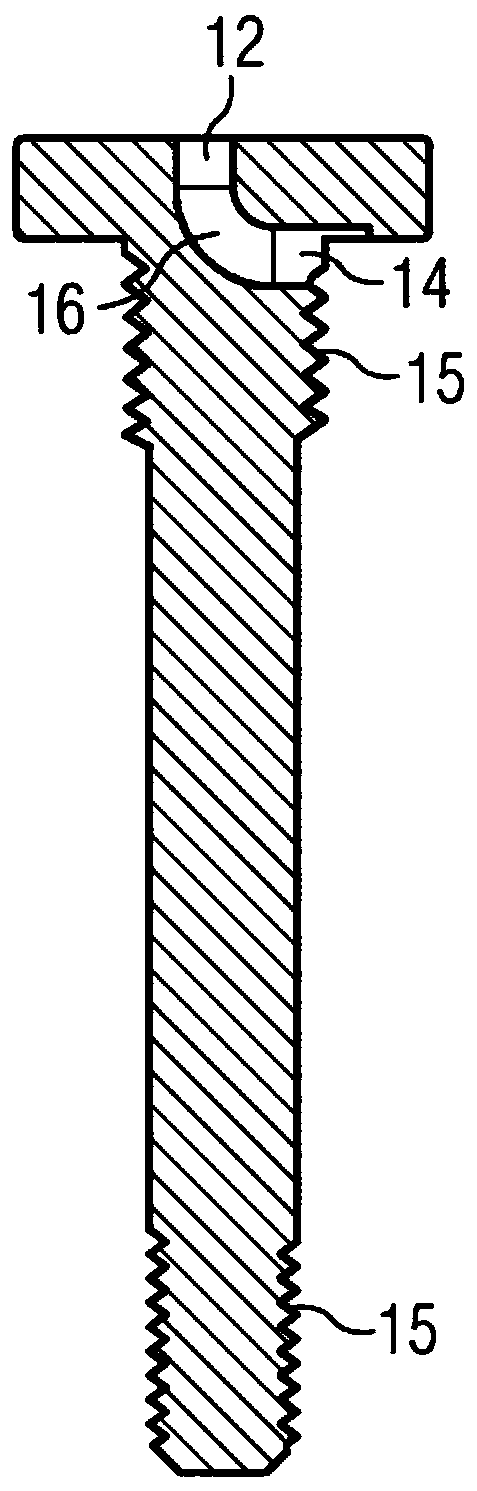

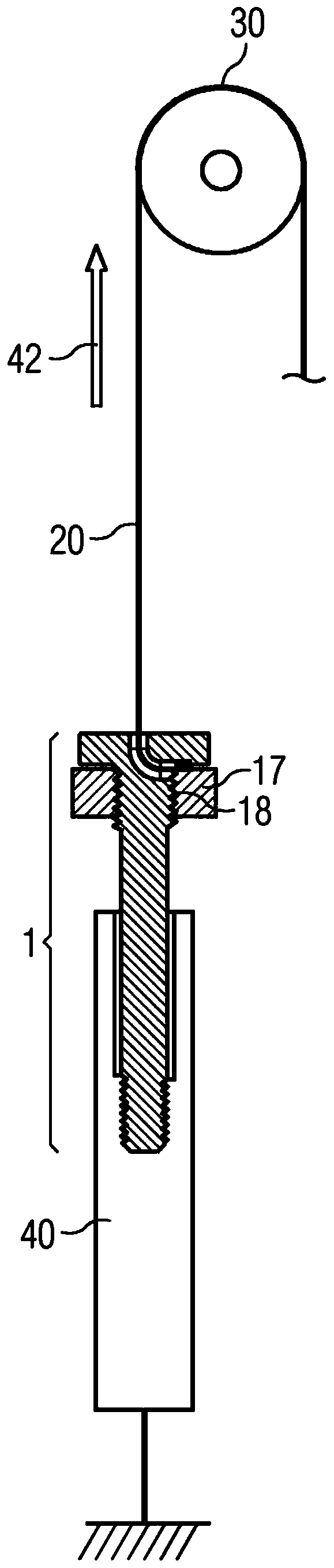

[0046] figure 1A fastening unit 1 is shown, which consists of two subunits 11 , 13 . The upper subunit 11 may be called a head, and the lower subunit 13 may be called a stem. The fixing unit can be produced by means of a 3D printing process or other manufacturing processes. The subunits 11, 13 have openings 12, 14, respectively.

[0047] For example, the head 11 has several edges and is designed flat. The shaft 13 is arranged below the head 11 and is designed in the shape of a thin stick. Furthermore, the shank 13 has a threaded section 15 . For example, the external thread 15 is arranged on the end region of the shank 13 . The shank 13 can correspondingly be inserted into the internal thread 18 of the counter piece 17 . The fastening unit 1 can be, for example, a bolt.

[0048] Between the two openings 12 , 14 , a channel 16 extends continuously from the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com