A linear metal material wire drawing device

A metal material and wire drawing technology, applied in the field of linear metal material wire drawing devices, can solve the problems of reel surface wear, affecting the surface quality of wire-like metal, affecting the internal quality and surface quality of wire-like metal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

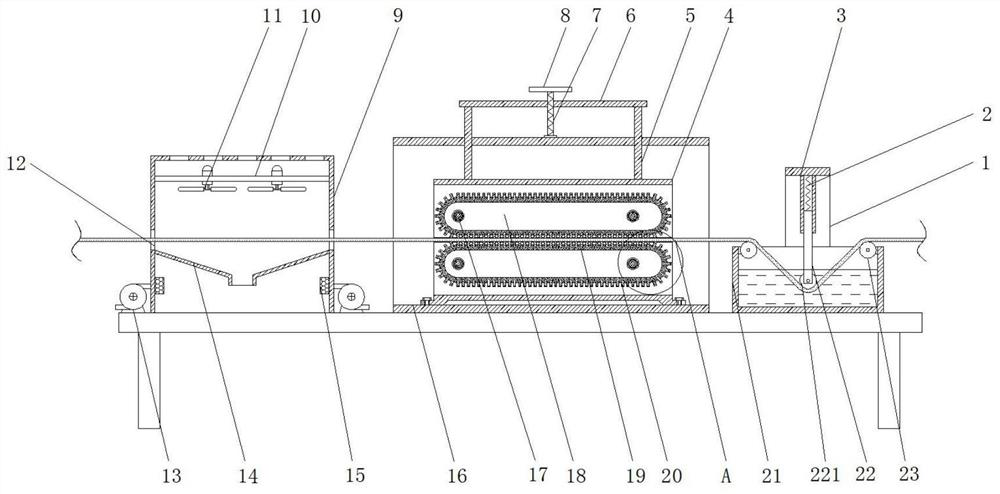

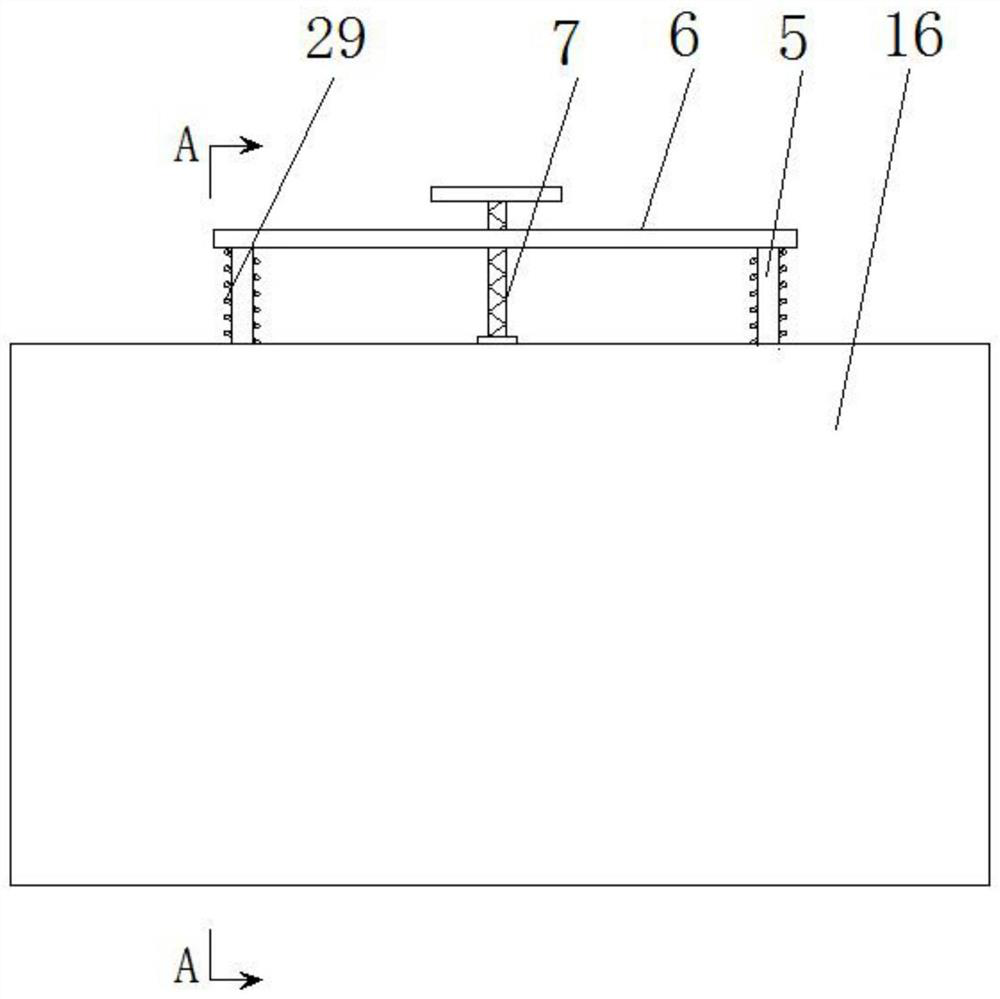

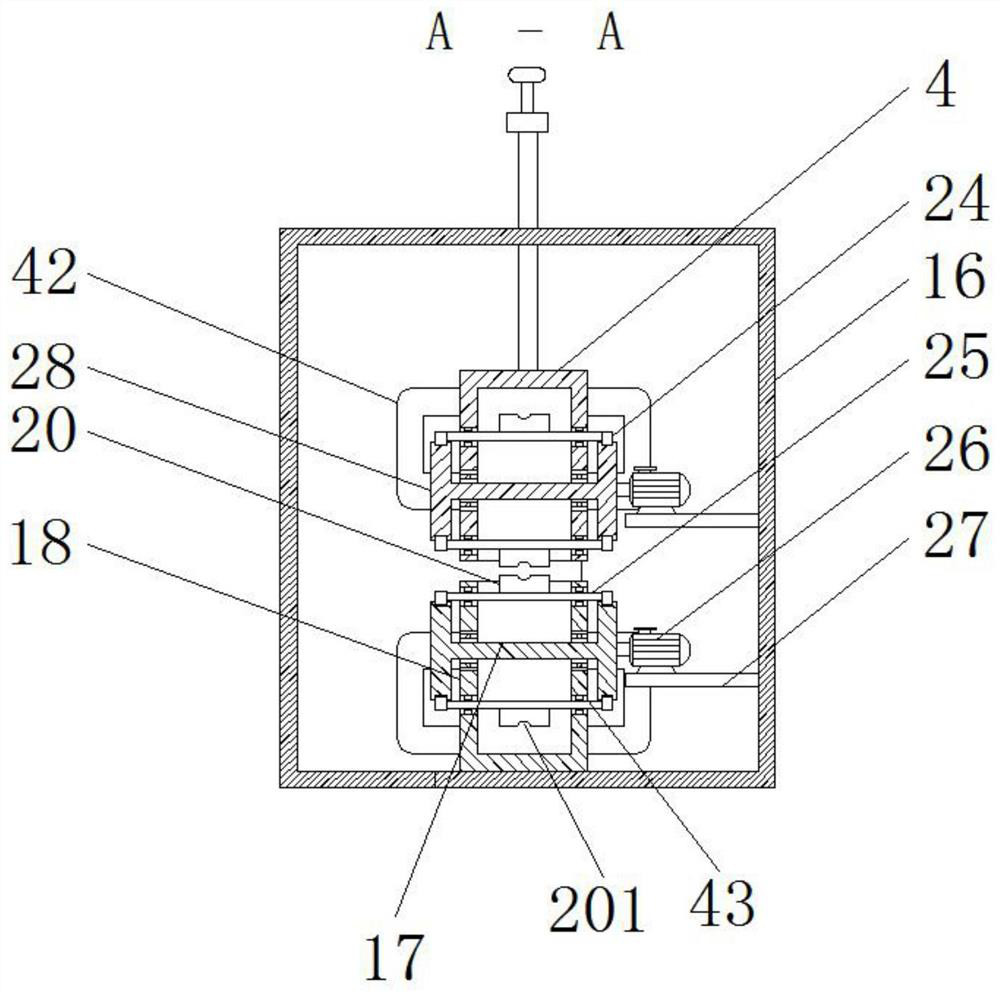

[0030] Such as Figure 1-7The wire drawing device for linear metal materials shown includes a workbench, and also includes a dust removal unit, a wire clamp unit and a water cooling unit arranged on the top of the workbench from left to right. The dust removal unit includes a dust removal housing 9, a funnel cover 14, The fixed rod 10, the fan 11 and the exhaust fan 13, the dust removal housing 9 are fixedly connected to the workbench, the middle part of both ends of the dust removal housing 9 is provided with a wire hole 12, and the dust removal housing 9 below the wire hole 12 is internally set There is a funnel cover 14, and the fixed rod 10 is horizontally arranged on the top of the dust removal housing 9. Two fans 11 are fixed on the fixed rod 10, and an exhaust fan 13 is arranged on the top of the workbench below the thread hole 12, and the output of the exhaust fan 13 The pipe extends to the inside of the dust removal housing 9, the end of the output pipe of the exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com