Die-casting die for processing small aircraft empennage and using method of die-casting die

A die-casting mold and aircraft technology, which is applied in the field of die-casting molds for processing small aircraft tails, can solve the problems of high cost, harsh processing conditions, and high difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

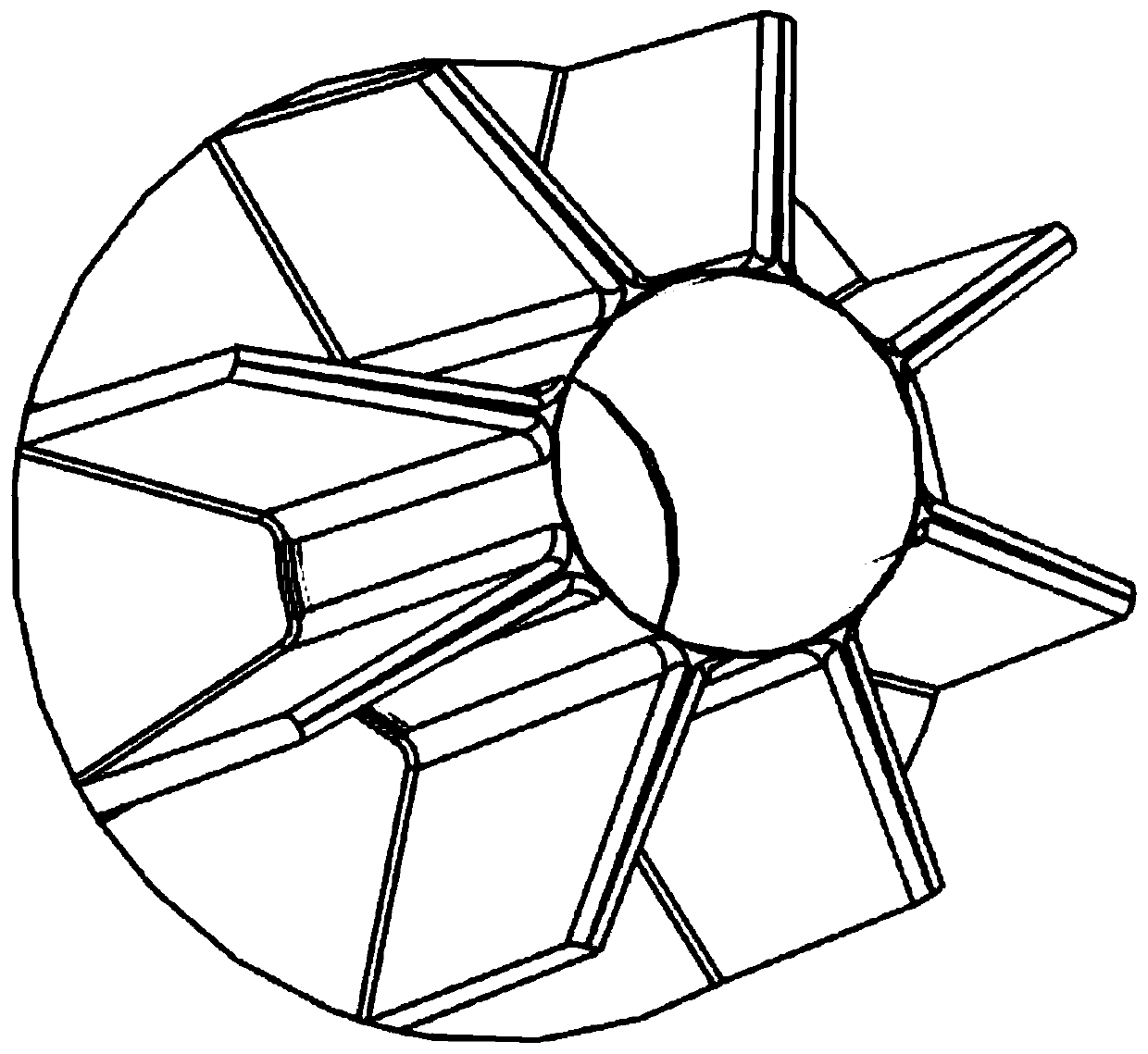

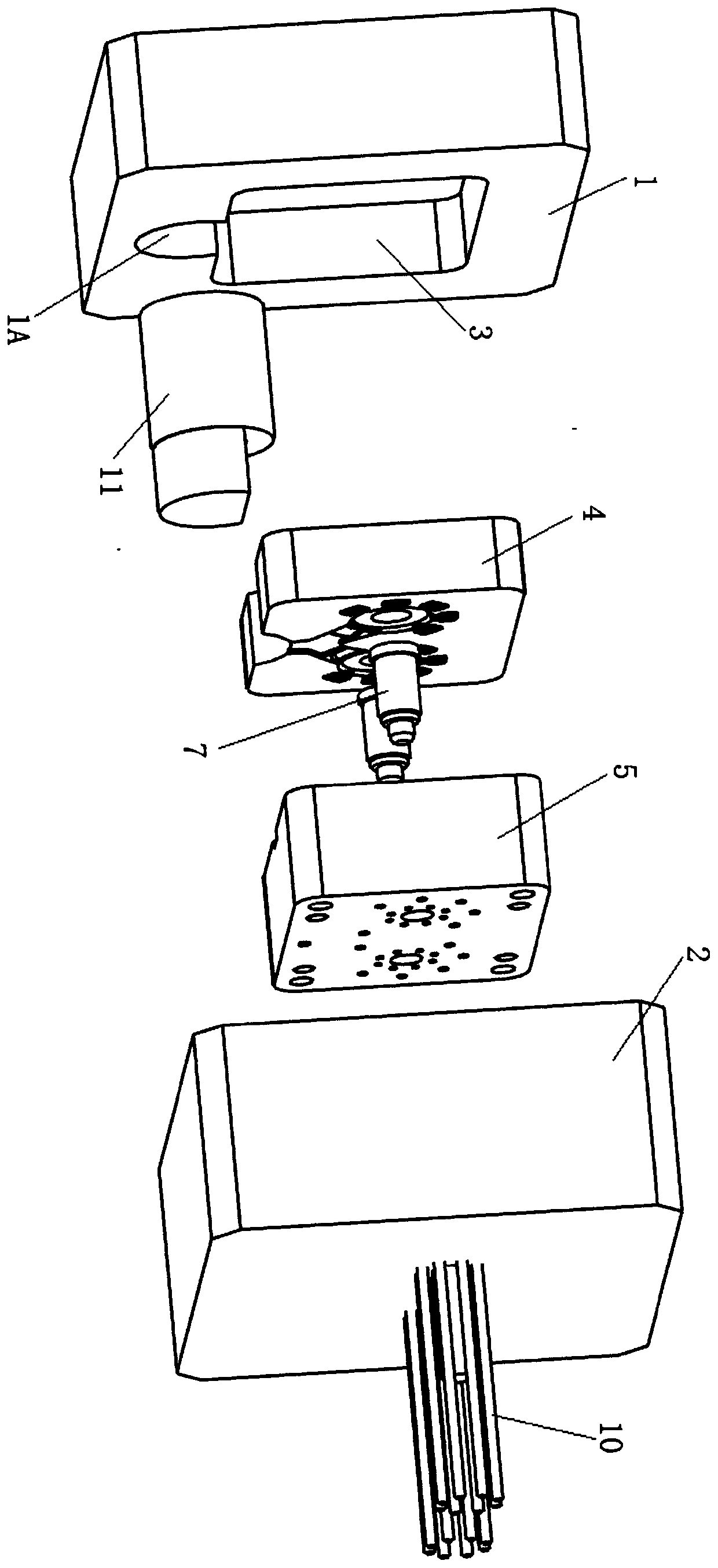

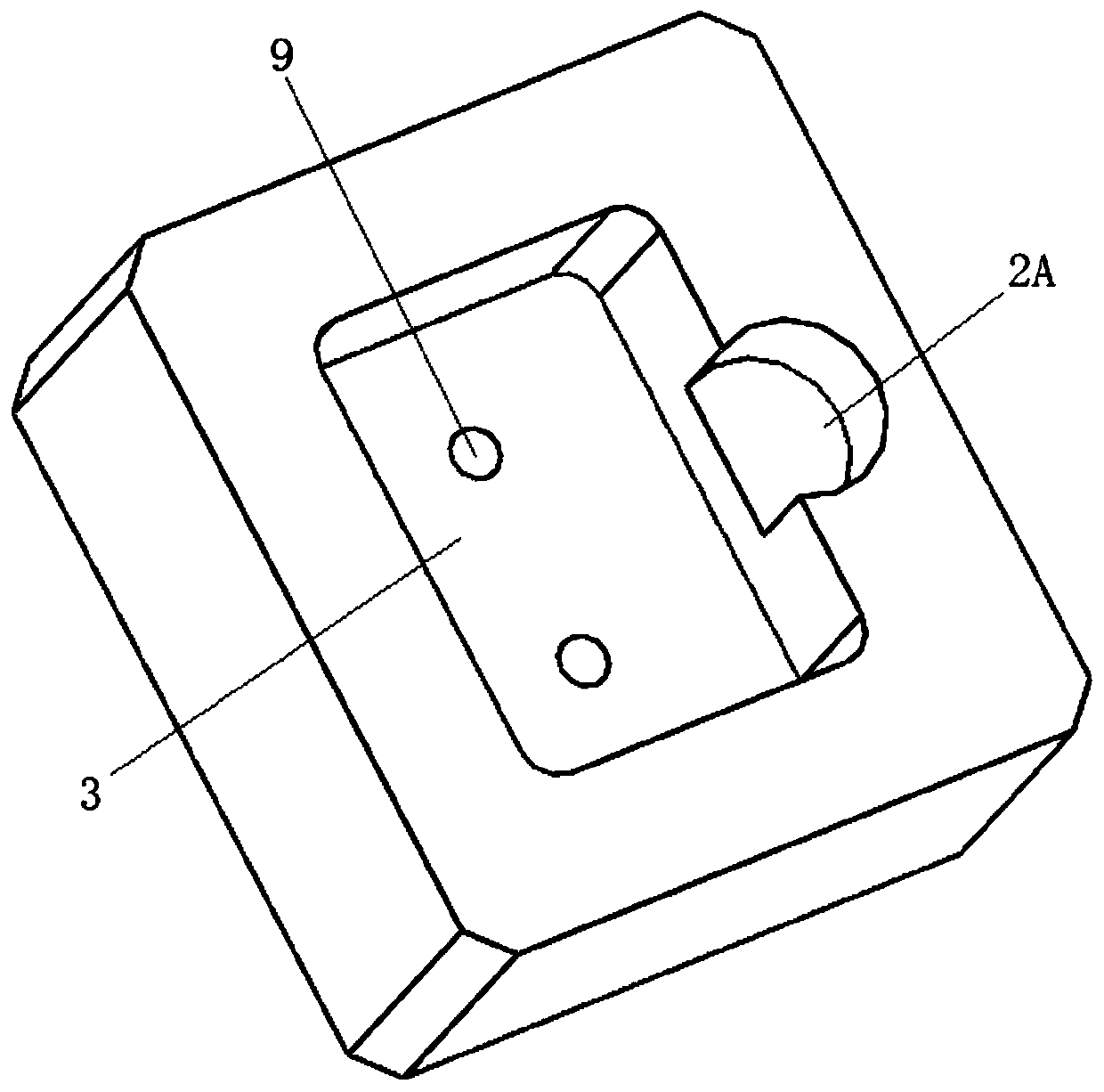

[0033] refer to Figure 2 to Figure 8 , this embodiment provides a die-casting mold for processing the tail of a small aircraft, which includes a matching front template 1 and a rear template 2; Core installation cavity 3; the front template 1 and the rear template 2 are also provided with feed through holes 1A and feed blind holes 2A which are opposite to each other and communicate with the core installation cavity 3; in the core installation cavity 3 The front mold core 4 and the rear mold core 5 are detachably placed; on the side end face of the front mold core 4 opposite to the rear mold core 5, there are two fin bottom plate cavities 4A with the same structure; slag discharge cavity P1 is arranged on the front mold core 4 and the rear mold core 5 at a position close to the peripheral side of the empennage bottom plate cavity 4A, and a feeding groove 6 is provided on both the front mold core 4 and the rear mold core 5; the feeding groove 6 It has a Y-shaped structure, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap