Double-flared-opening plastic part forming mold

A technology for forming molds and bell mouths, which is applied in the field of forming molds for upper and lower bell mouth plastic parts and its output, can solve the problems of one-time injection molding, etc., and achieve the effects of fast efficiency, high precision, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

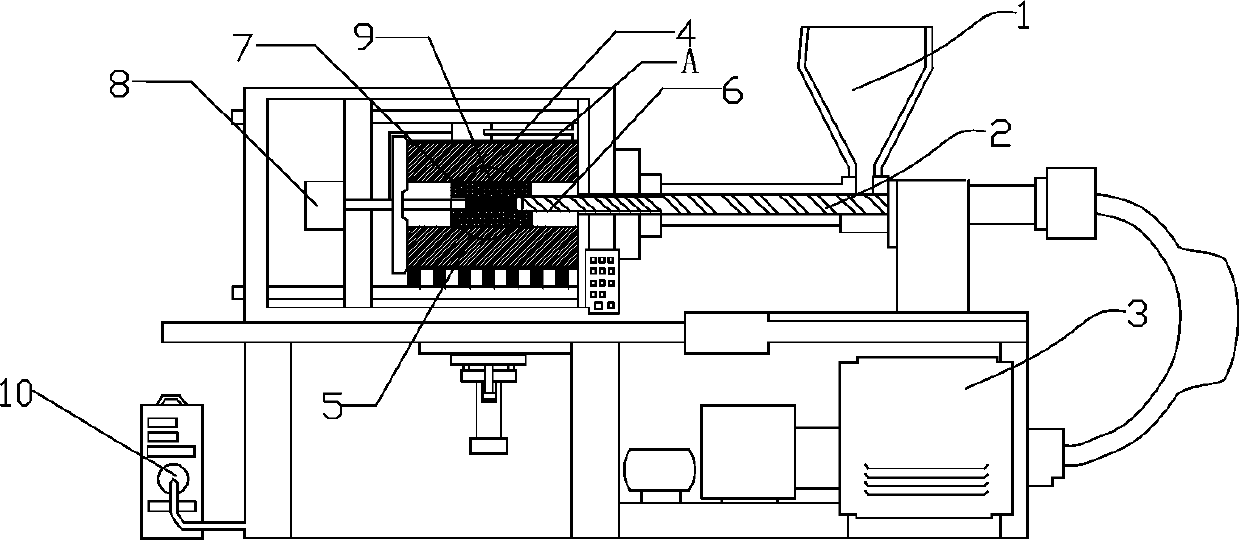

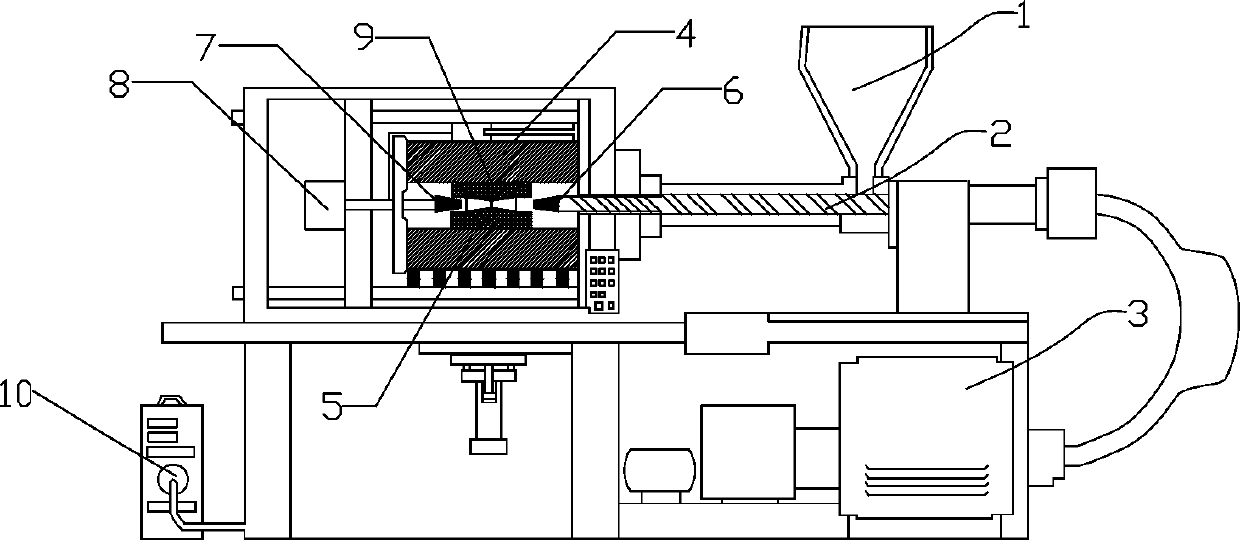

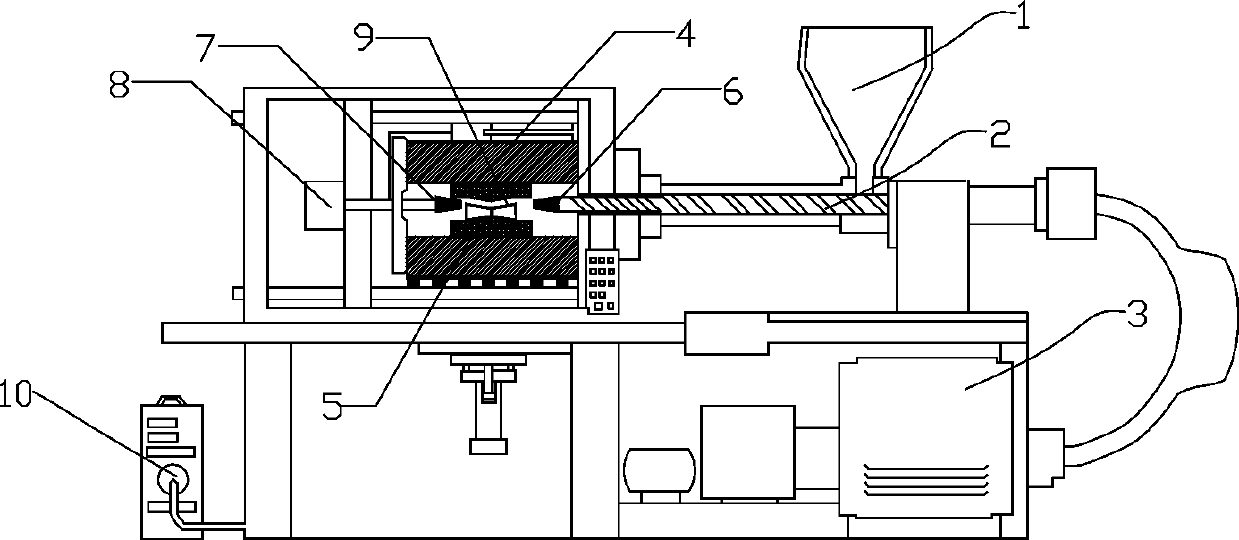

[0019] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0020] A molding die for upper and lower flared plastic parts, comprising a feed port 1, a screw rod 2 is provided below the feed port 1, a pouring head 6 is provided at the front end of the screw rod 2, and the pouring head 6 The end is provided with a main runner 61, and also includes a fixed mold 4 and a movable mold 5 arranged up and down. The pouring head 6 is located on one side of the fixed mold 4 and the movable mold 5. A limit block 7 is also provided on the other side. The fixed mold 4, the movable mold 5, the limit block 7 and the pouring head 6 jointly form a double-flare injection molded part cavity. It is used for injection molding of the double-flare injection molded part 9. The pouring head 6 extends into the cavity of the double-flared injection molded part and keeps a certain distance from the limit block 7 to form a runner 62. 62 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com