Non-pneumatic tire of elliptical overall bearing body structure

A non-pneumatic tire, ellipse technology, used in non-pneumatic tires, tire parts, transportation and packaging, etc., can solve the problems of large driving resistance, easy bumps, large longitudinal deformation, etc., to increase stability, avoid tire blowout, Integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] According to the accompanying drawings, the present invention is described in detail.

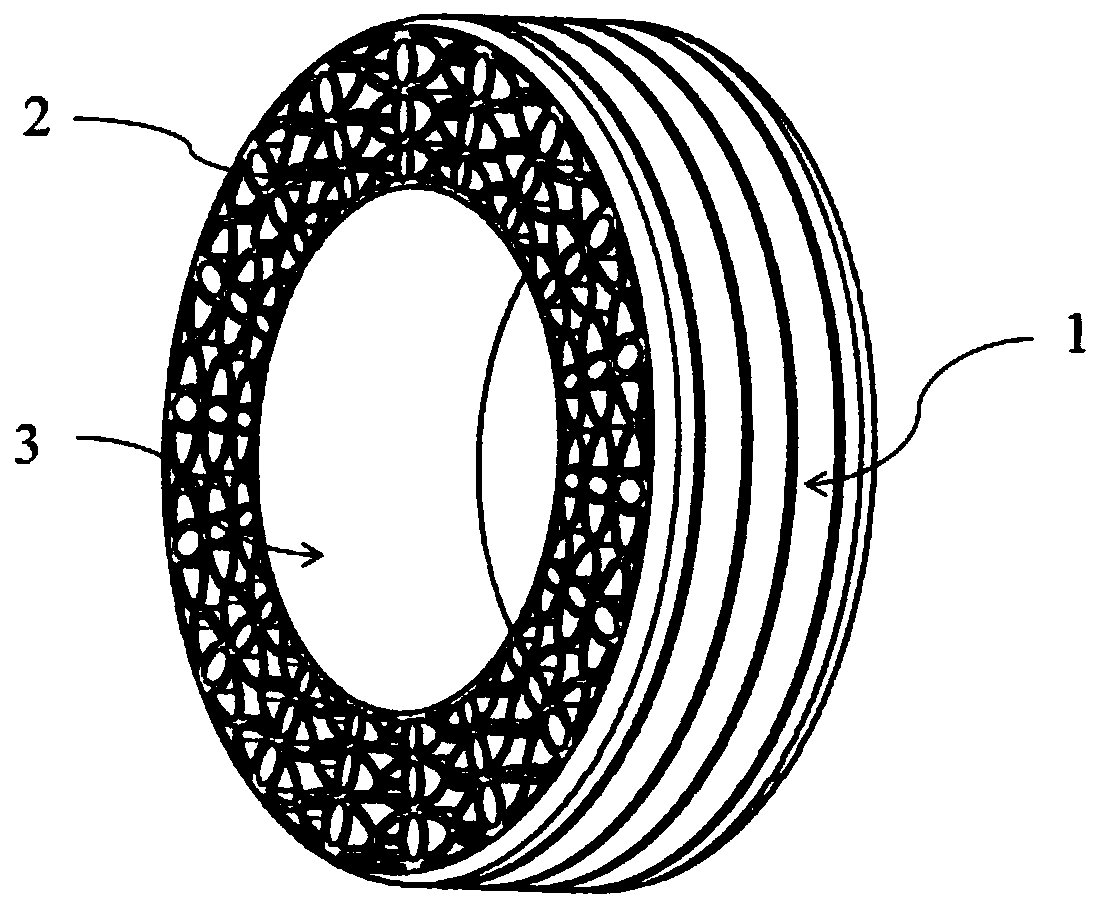

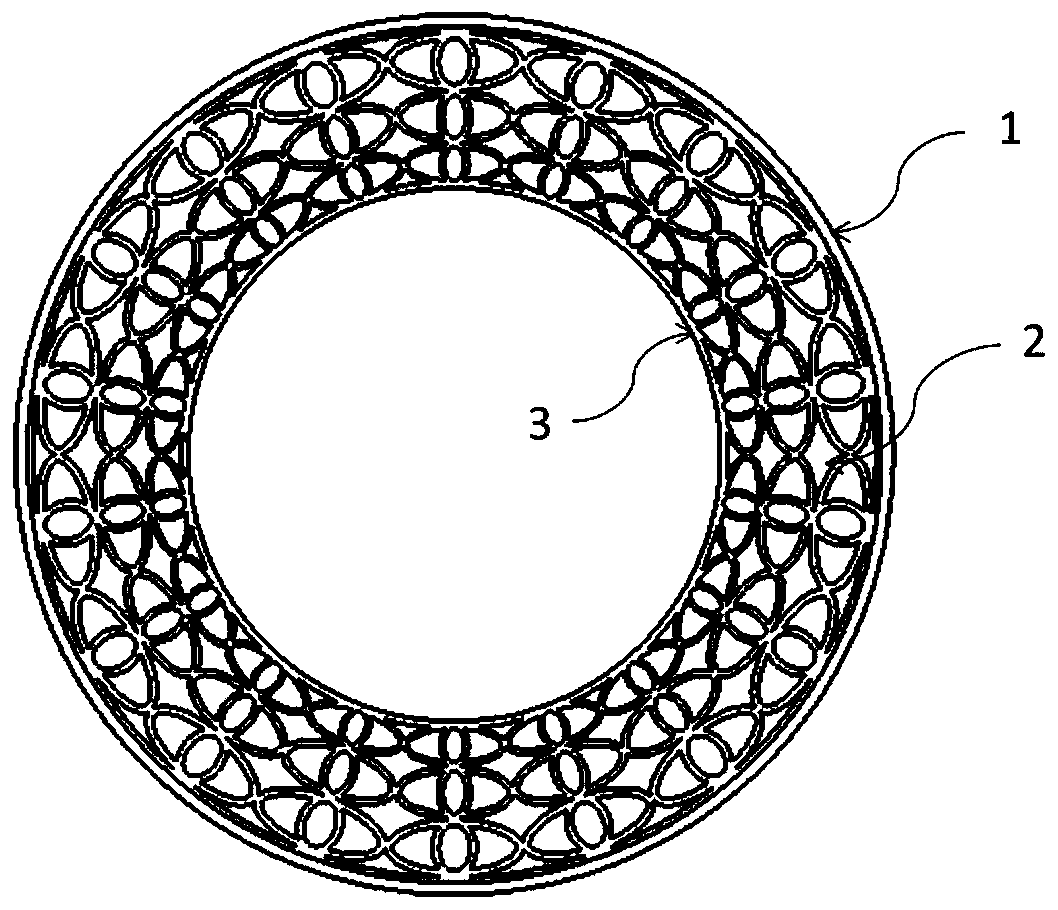

[0025] Such as figure 1 with figure 2 As shown, a non-pneumatic tire with an elliptical overall bearing structure according to the present invention includes a crown portion 1 , an elliptical overall bearing 2 and a rim joint ring 3 from outside to inside in the radial direction.

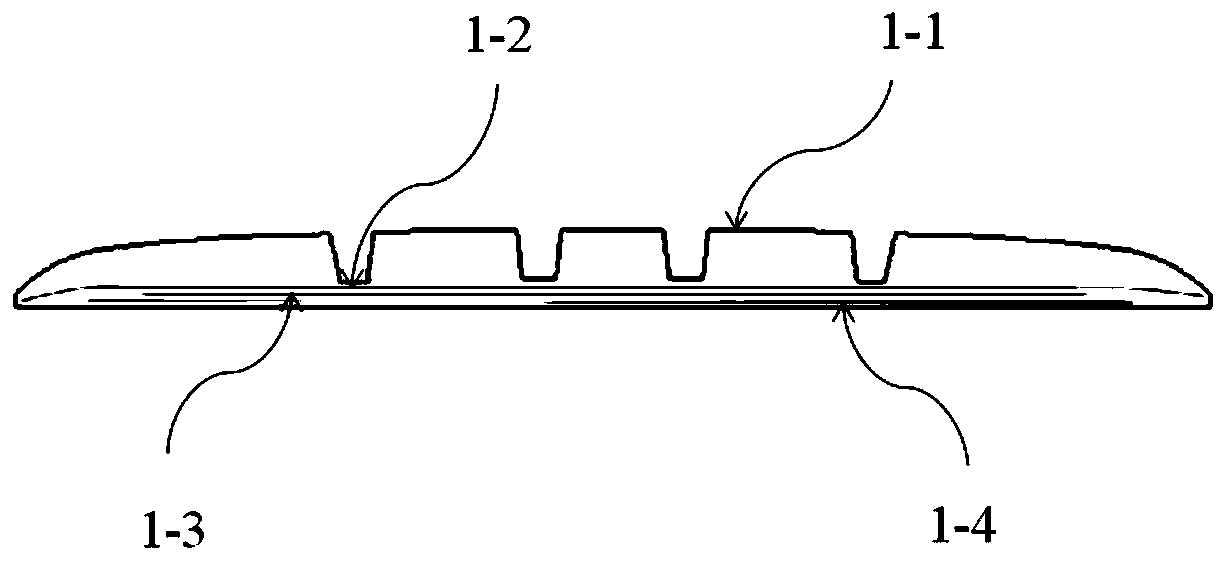

[0026] image 3 The crown part 1 includes the tread 1-1, tread rubber 1-2, cushioning layer 1-3 and carcass ply 1-4 with patterns from outside to inside in sequence along the tire radial direction; The pattern of the tread 1-1 design can increase the drainage capacity and the friction between the tire and the ground, and enhance the grip of the tire; the tread rubber 1-2 can make the tread 1-1 and the tread The parts below 1-1 are combined together; the buffer layer 1-3 can alleviate the impact from the outside, and the ply layer 1-4 can bear internal tension and impact load, increasing the tear resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com