Heavy anti-collision buffer vehicle

A buffer vehicle and anti-collision technology, which is applied to vehicle components, shock absorbers, mechanical equipment, etc., can solve the problems of hidden dangers of workers and equipment, and achieve the effect of good anti-collision effect and long buffer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

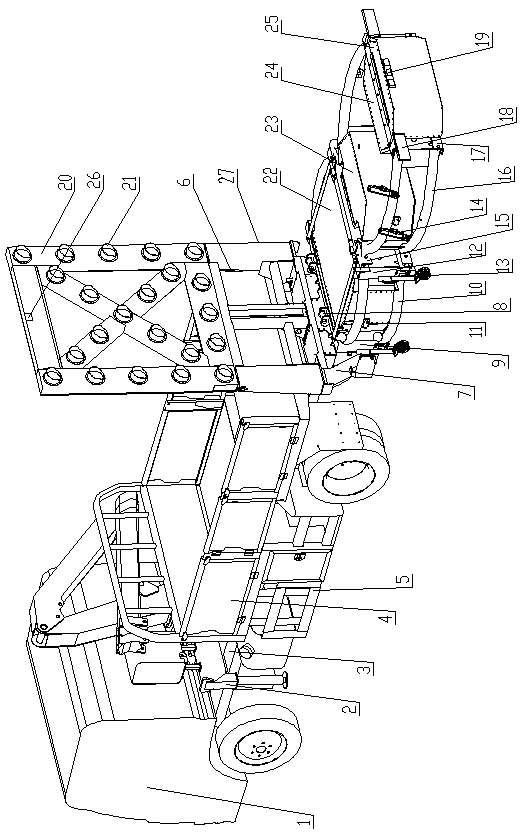

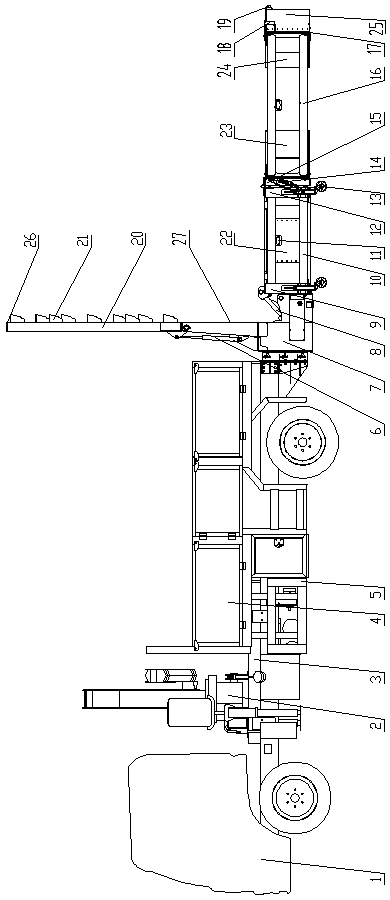

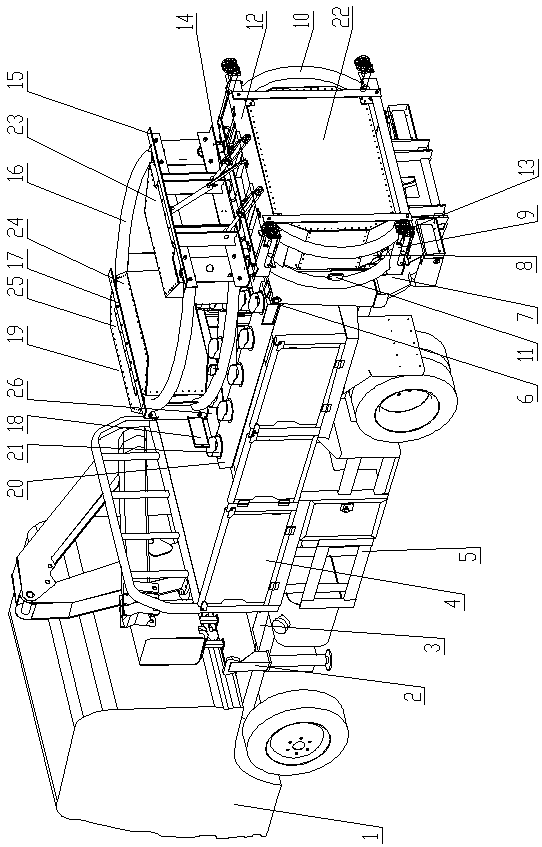

[0028] Such as Figure 1-Figure 4 As shown, a heavy-duty anti-collision buffer vehicle of the present invention includes a load truck 1, a truck-mounted crane 2, a sub-frame assembly 3, side protection 5, a turning drive mechanism, a folding light frame assembly and a folding buffer block Assemblies, the lorry-mounted crane 2 is arranged behind the cab of the truck 1 and on the sub-frame assembly 3 in front of the carriage 4, the folding light frame assembly is arranged at the rearmost side of the carriage 4 of the truck 1, and the foldable buffer block The assembly is located on the rear side of the foldable light frame assembly, and the lower end of the foldable light frame assembly is set on the sub-frame assembly 3 through the connecting base 7;

[0029] The folding buffer block assembly includes a primary buffer block assembly and a secondary buffer block assembly located on the front side of the primary buffer block assembly. The overturning drive mechanism includes a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com