Easy-to-mount prefabricated wall body and mounting method thereof

A prefabricated and wall technology, applied in walls, building components, buildings, etc., can solve the problems of complex installation and low efficiency, and achieve the effects of high wall strength, reduced garbage pollution, and good sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present application clearer, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

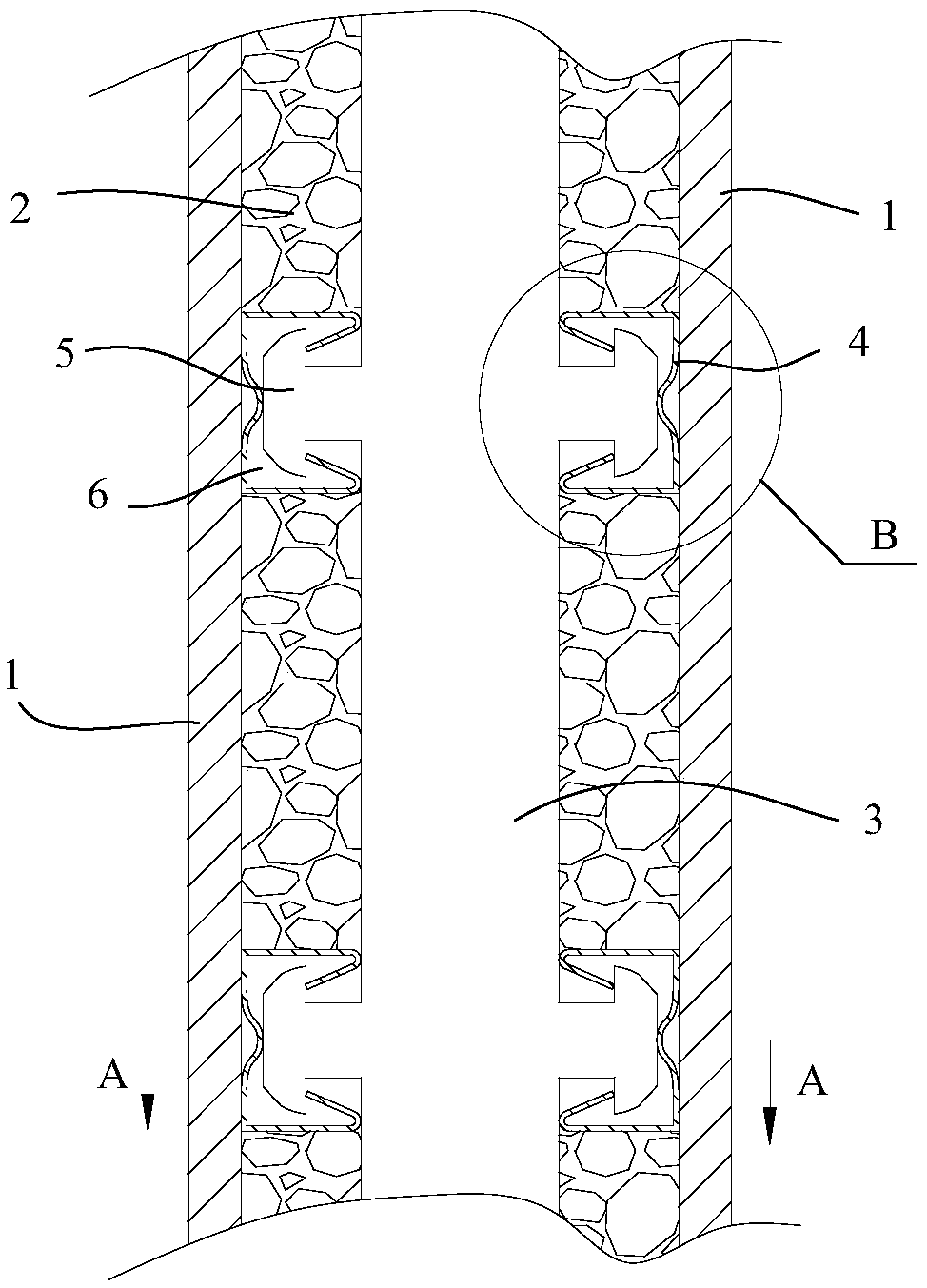

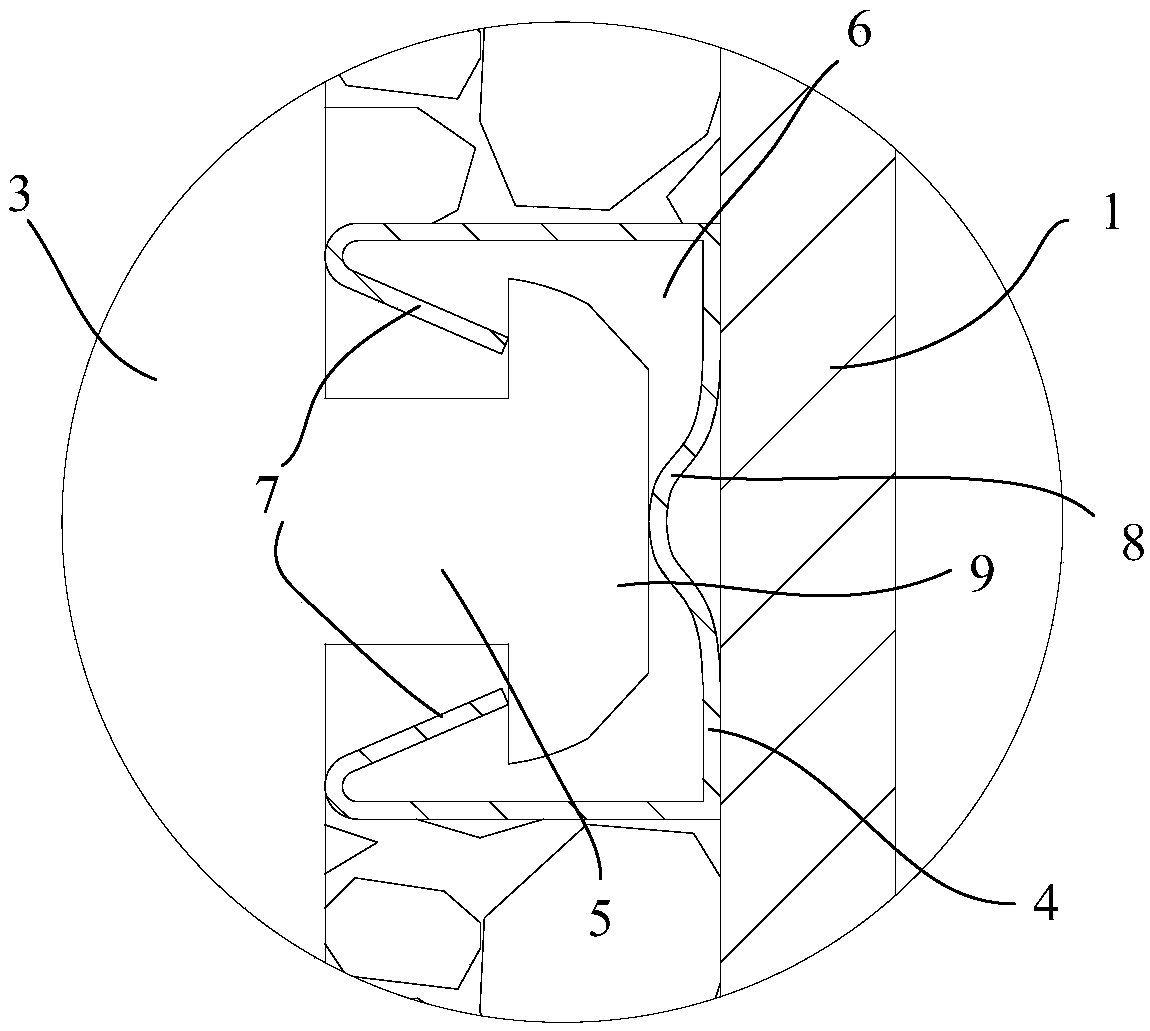

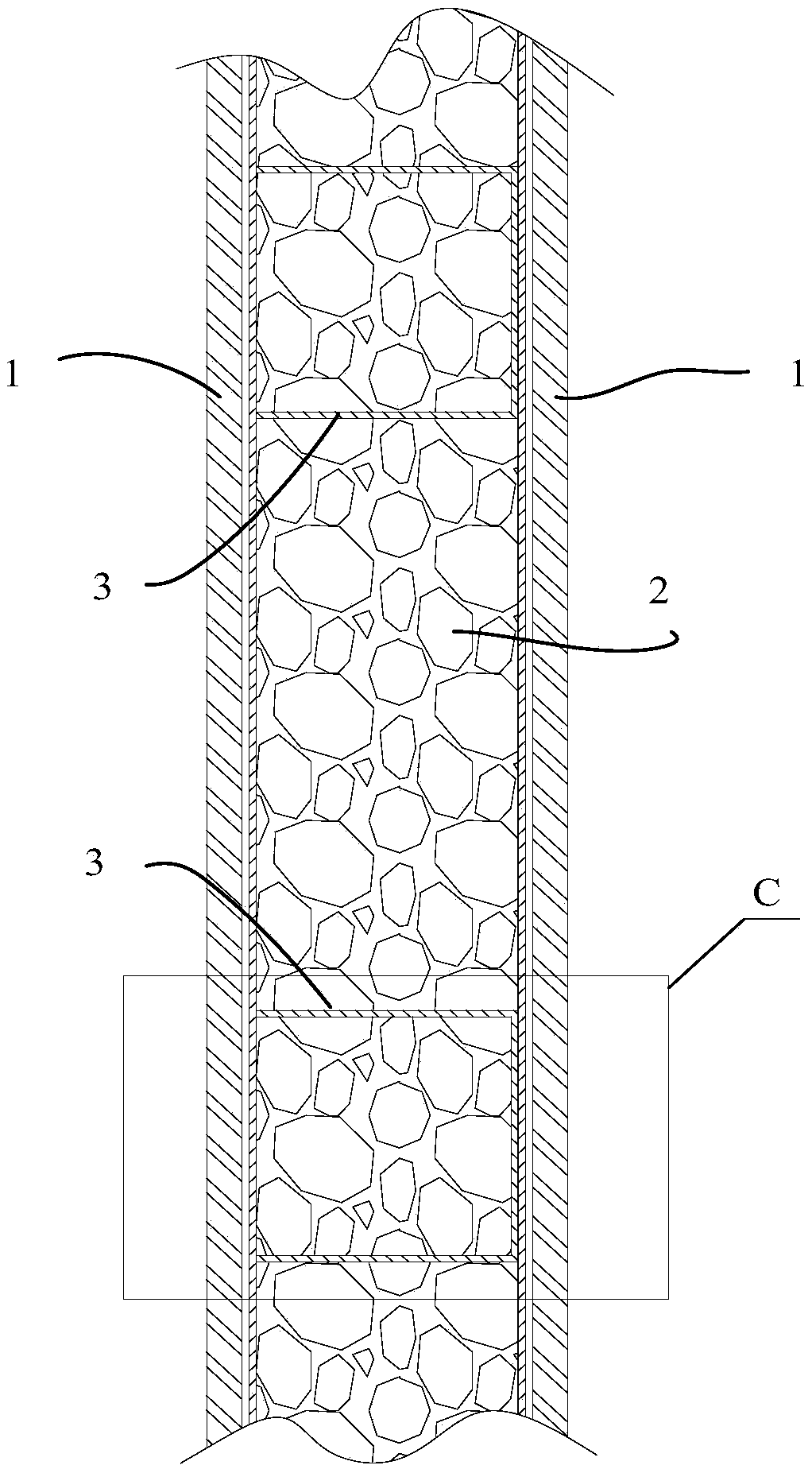

[0035] see Figure 1 to Figure 9 Embodiment of the assembled wall body of the present invention. like Figure 1 to Figure 4 As shown, the prefabricated wall includes a wall panel 1 as a decorative surface, a supporting keel 3 as a main support, and an insulating material 5 for sound insulation and heat insulation. Among them, the supporting keels 3 are vertically fixed between the upper and lower floors, a plurality of supporting keels 3 are spaced from each other and arranged in a straight line along the length direction of the assembled wall, and two wall panels 1 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com