Metallurgy speed reducer

A reducer and box technology, which is applied in the direction of mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of increased production costs, easy splashing of lubricating oil, unfavorable streamlining of structures, etc., to reduce production and production costs Cost, prevention of spatter injection, effect of streamlining machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0010] Further description will be given below with reference to the drawings and embodiments.

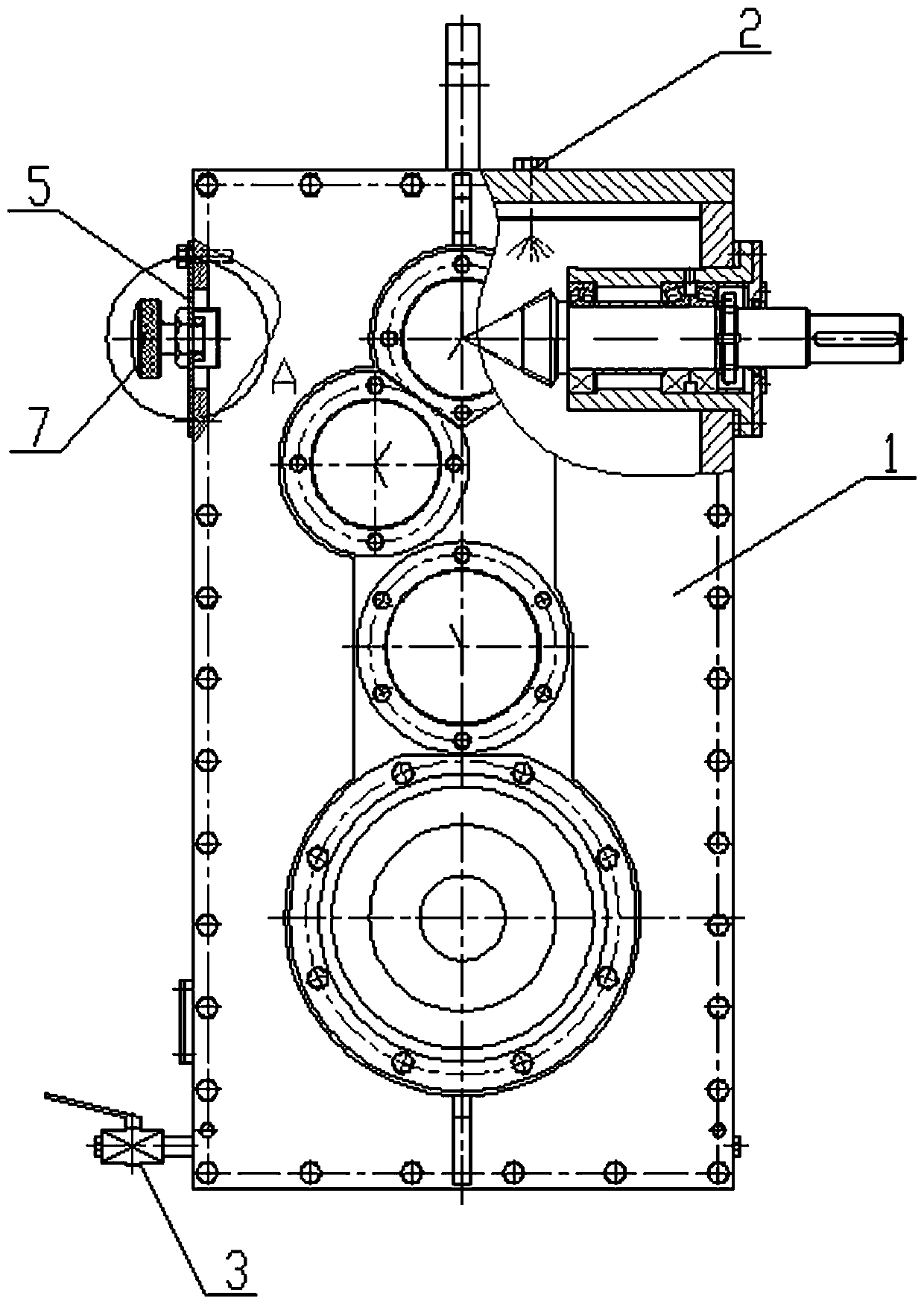

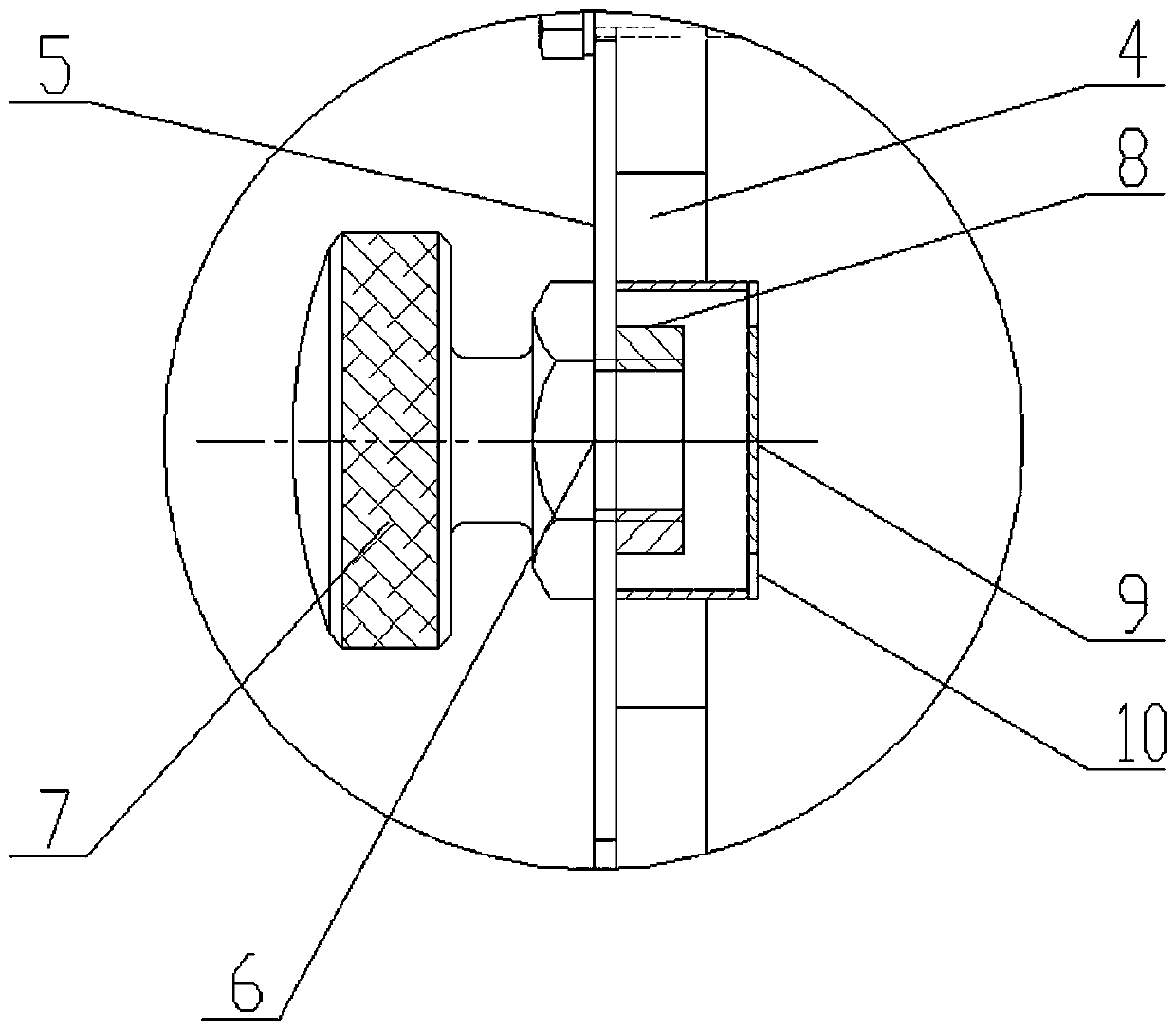

[0011] figure 1 , 2 Shown: a metallurgical reducer includes a box body 1, an oil injection hole 2, an oil discharge port 3, a sight hole cover 5, a breather cap 7, a mounting nut 8, and a shield 9. The top of the box body 1 is provided with a plurality of oil injection holes 2 corresponding to the internal transmission engagement structure for oil injection lubrication. The lower part of the side wall of the box body is provided with an oil discharge port 3, and the upper part of the side wall of the box body is provided with a viewing hole 4 and the viewing hole 4 The viewing hole cover 5 is fixedly installed by bolts. The viewing hole cover 5 is provided with a vent 6 and a mounting nut 8 is installed on the venting hole. The mounting nut 8 can be located outside or inside the viewing hole cover. This embodiment is installed inside the vent cap 7 is screwed to the mounting nut 8. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com