Patents

Literature

68results about How to "Block sputtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

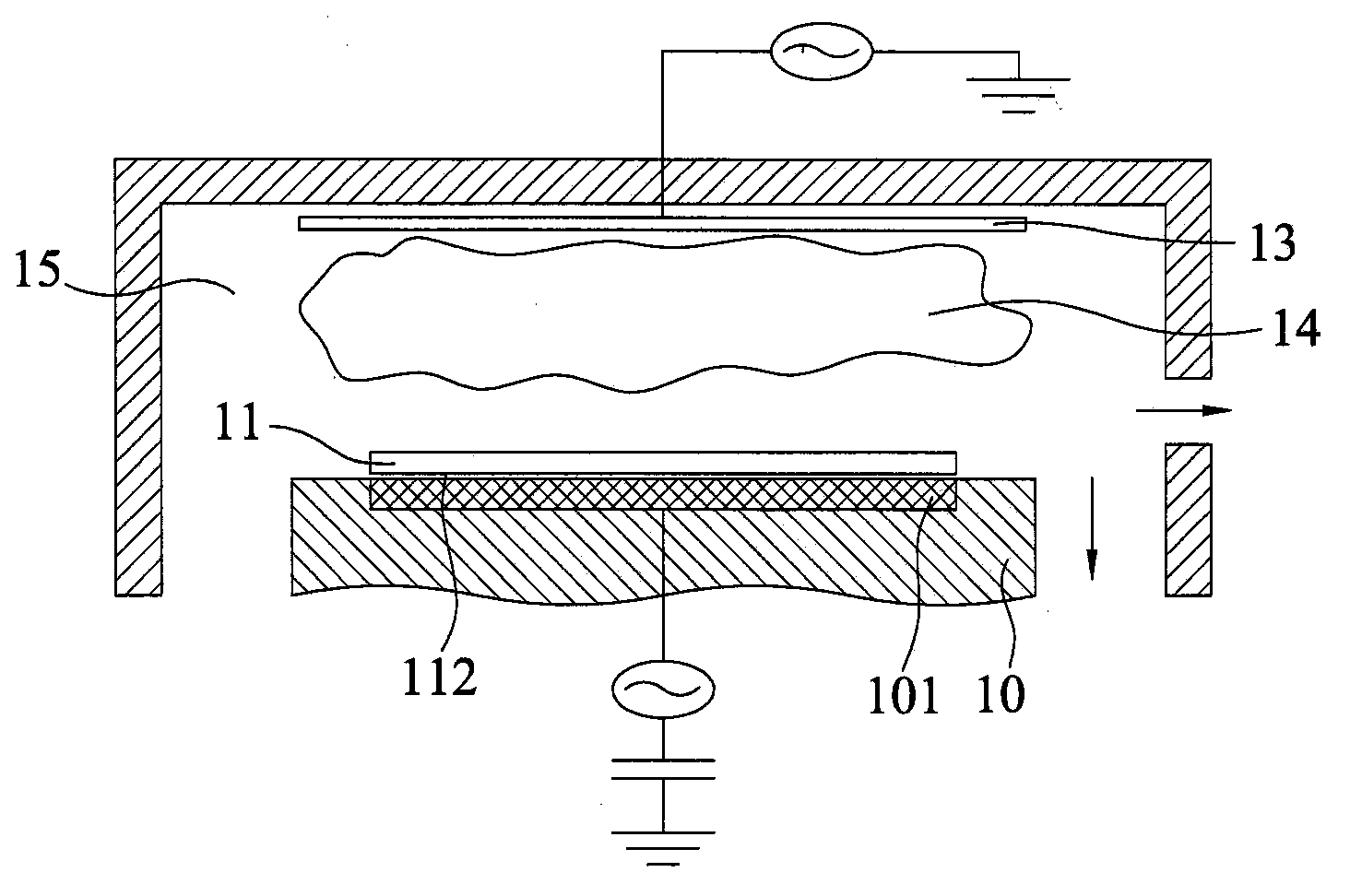

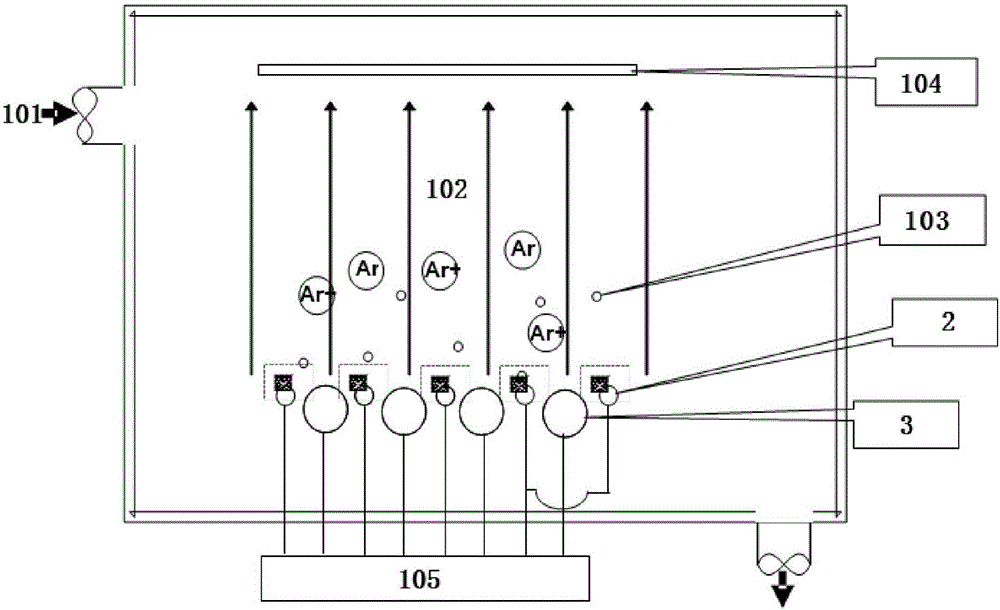

Surface preparation for thin film growth by enhanced nucleation

ActiveUS7943527B2Promote growthEnhanced nucleationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaOptoelectronics

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

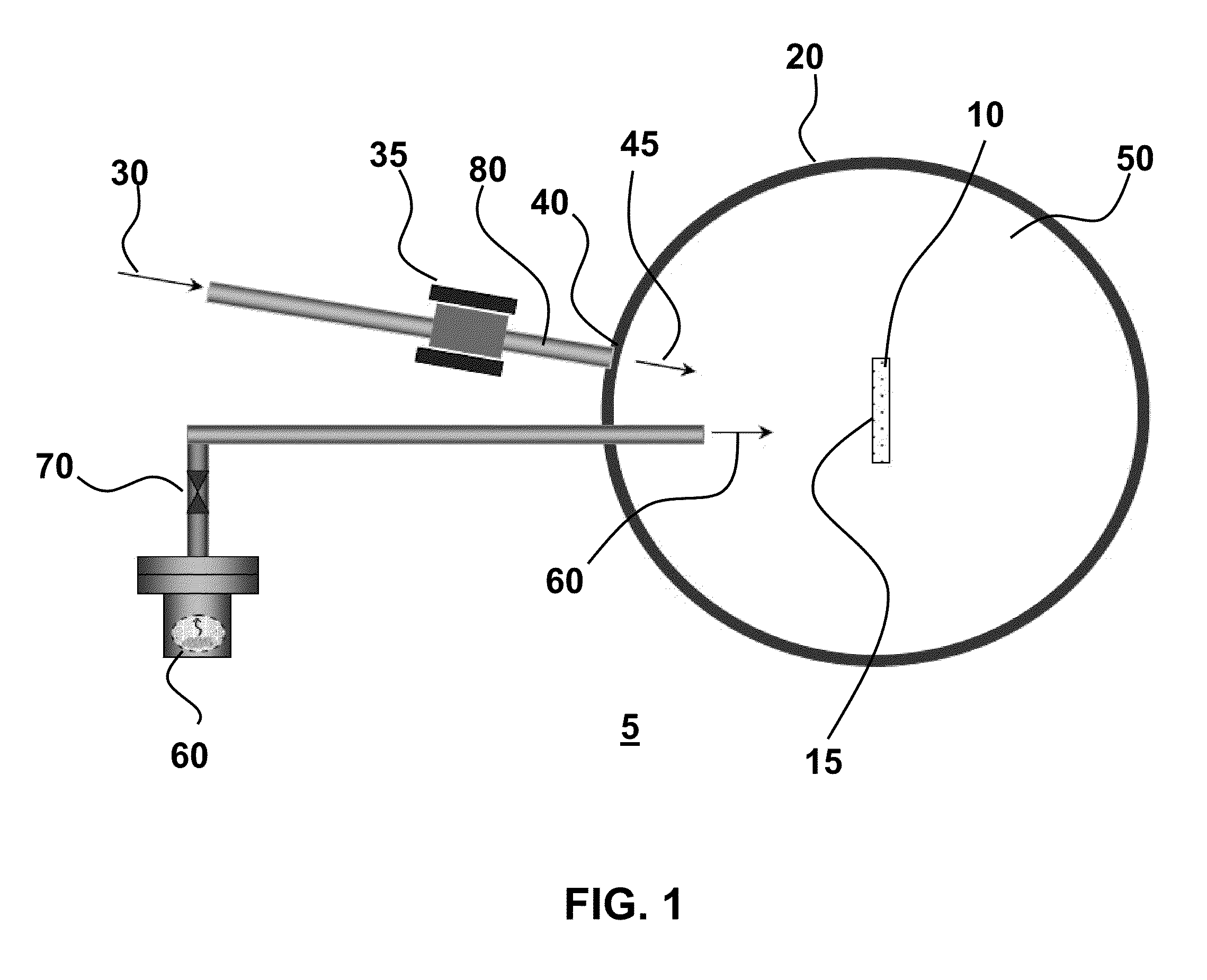

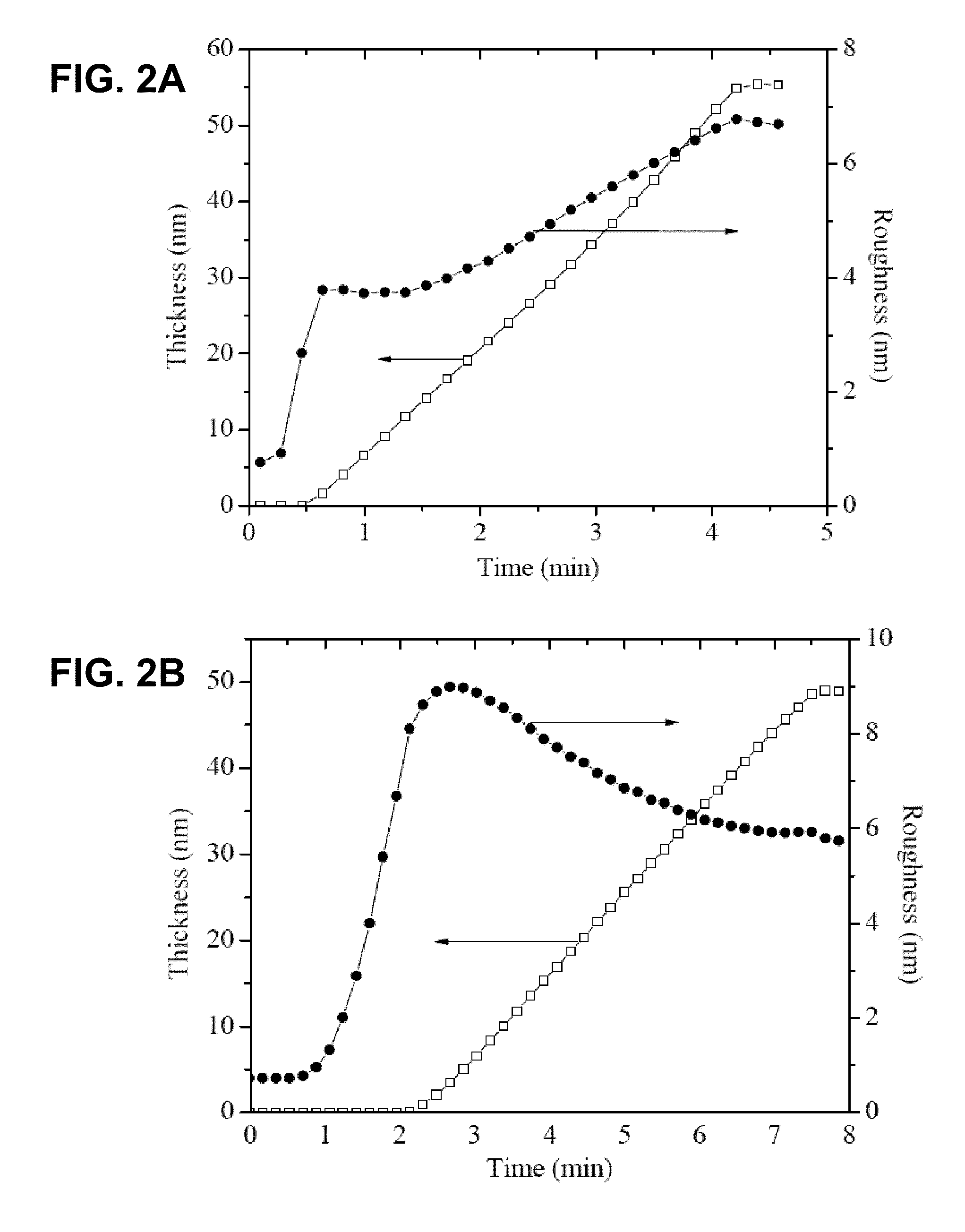

Surface Preparation for Thin Film Growth by Enhanced Nucleation

ActiveUS20100048029A1Superior film growthEnhanced nucleationVacuum evaporation coatingPretreated surfacesRemote plasmaProduct gas

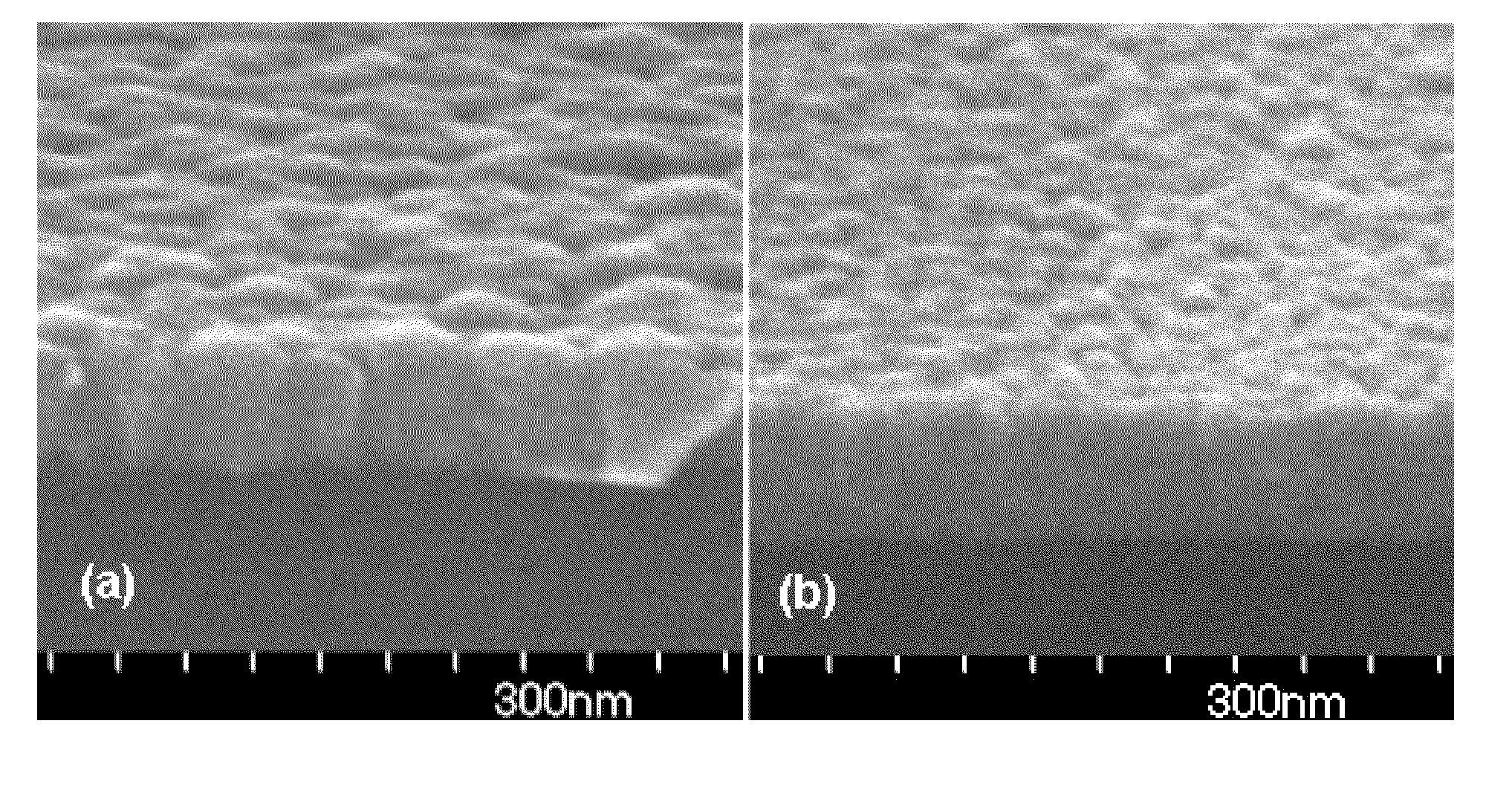

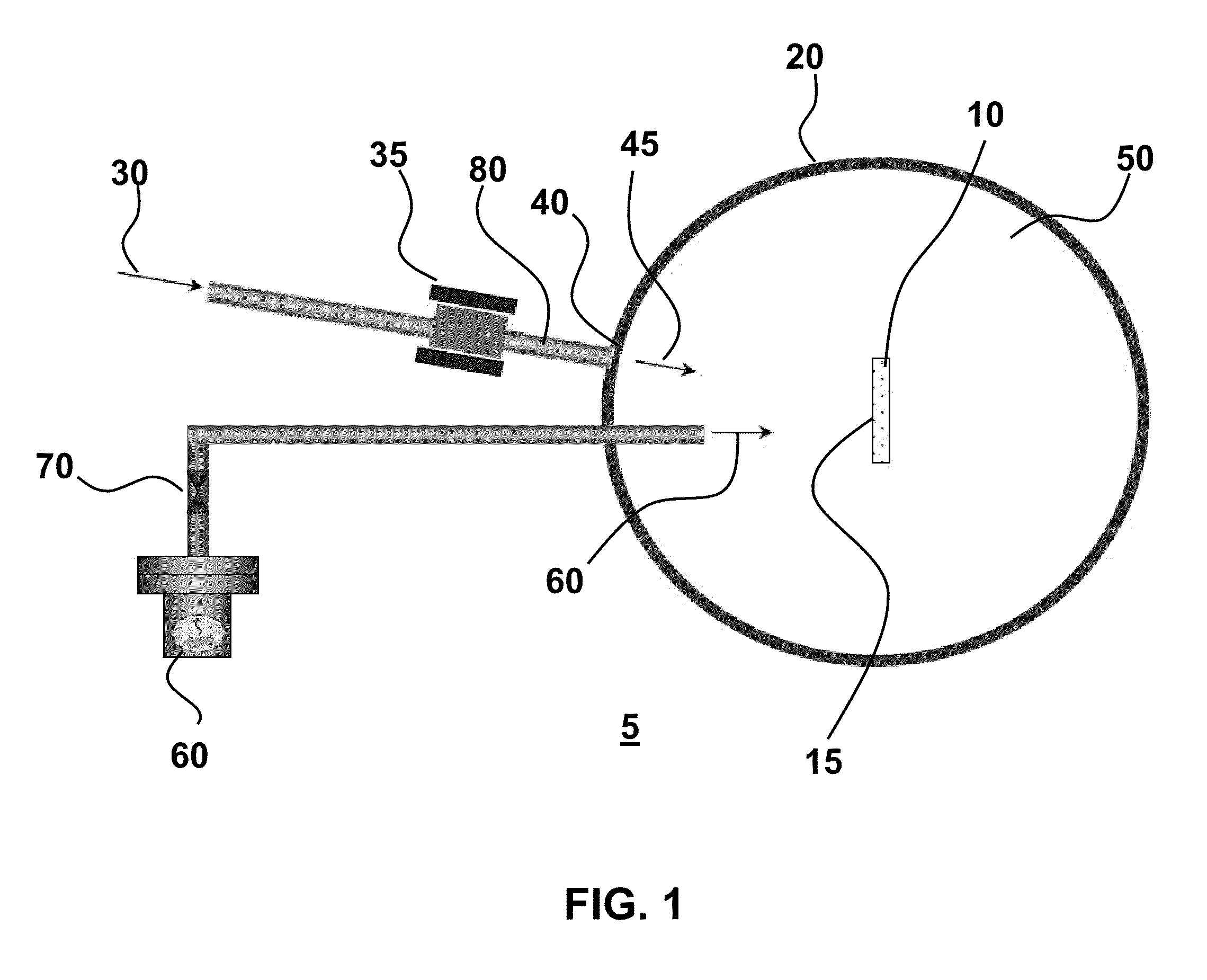

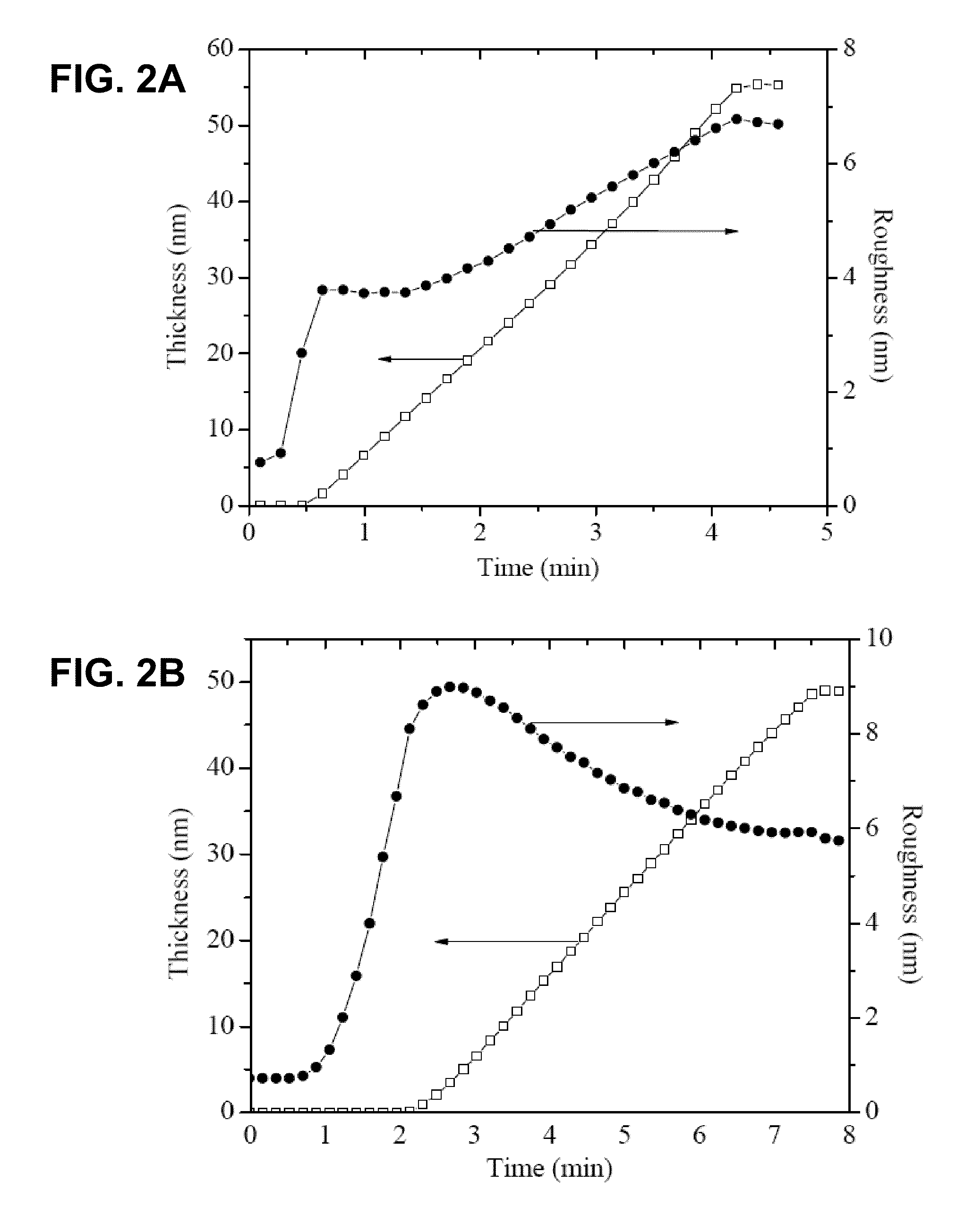

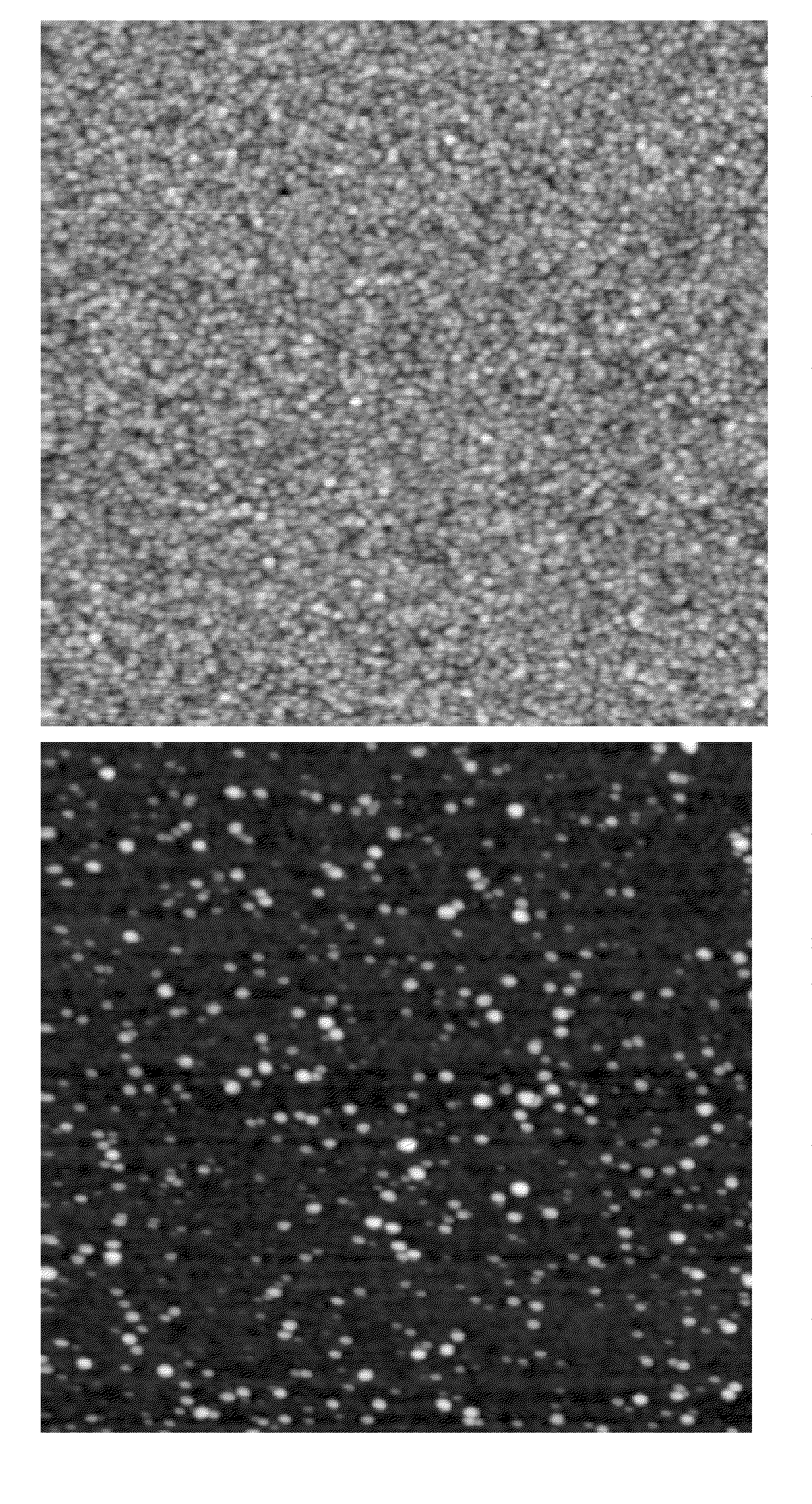

Various processes and related systems are provided for making structures on substrate surfaces. Disclosed are methods of making a structure supported by a substrate by providing a substrate having a receiving surface and exposing at least a portion of the receiving surface to output from a remote plasma of an inert gas. The remote plasma has an energy low enough to substantially avoid etching or sputtering of the receiving surface but sufficient to generate a treated receiving surface. The treated surface is contacted with a deposition gas, thereby making the structure supported by the substrate.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

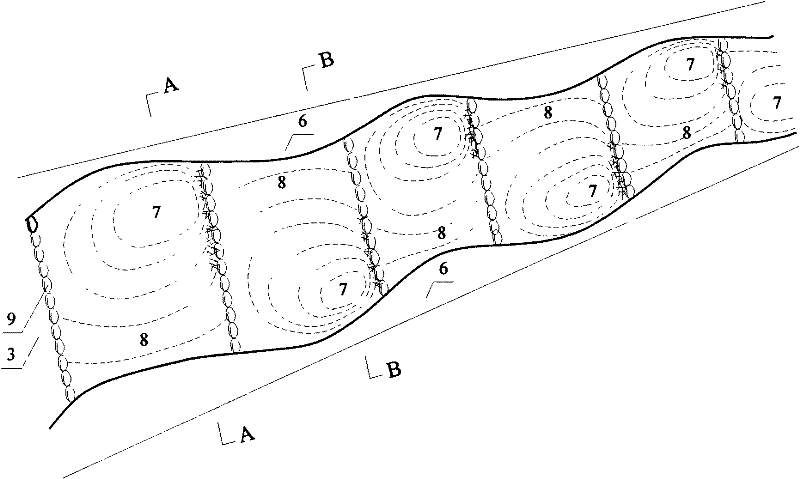

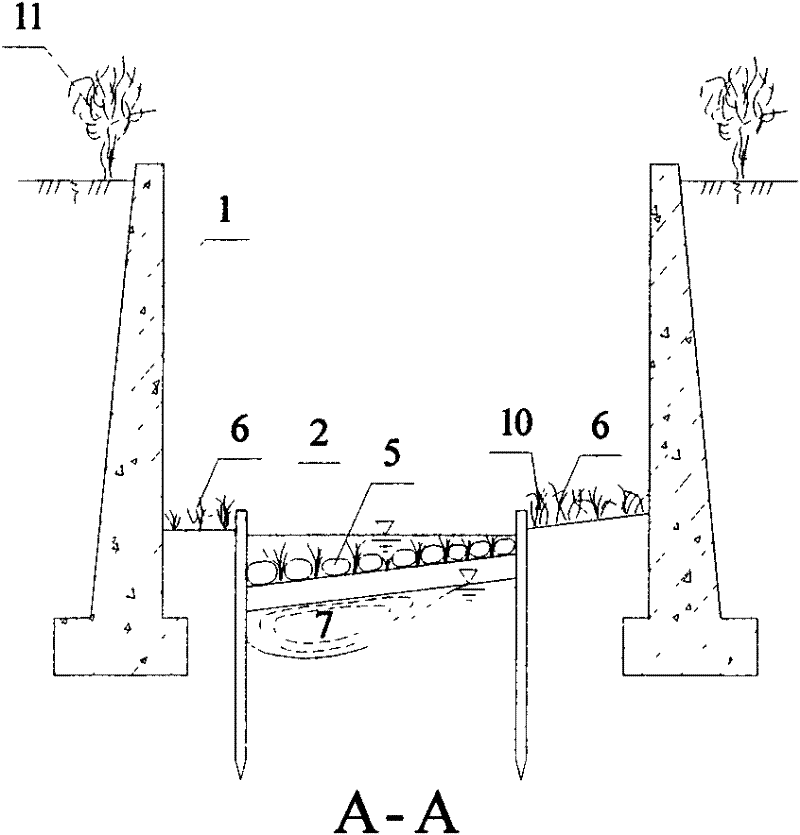

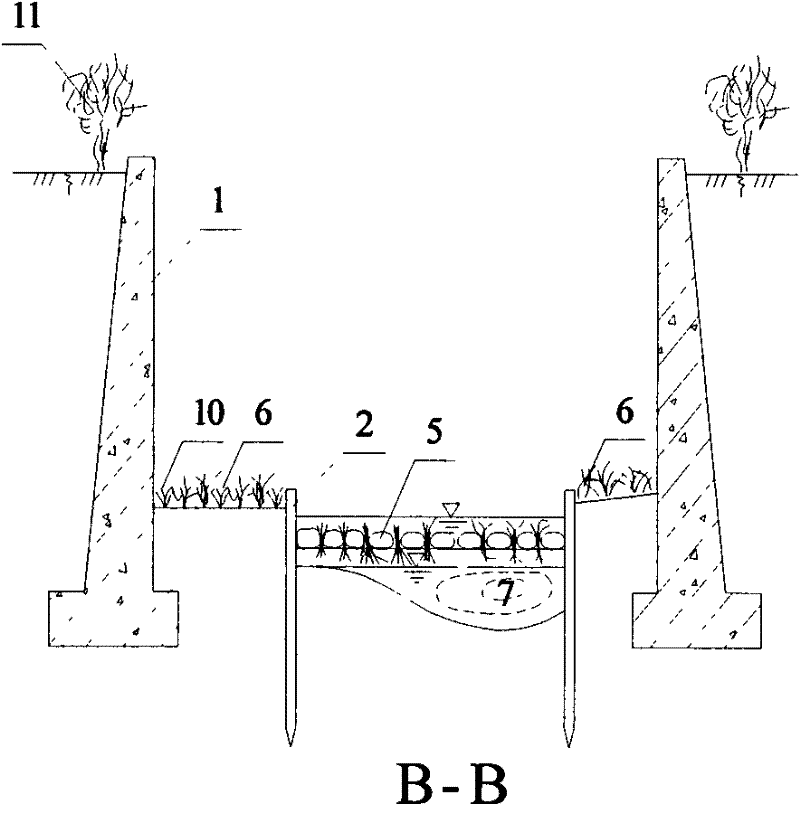

Method for improving water quality of steep-slope river by drop-aeration

InactiveCN102219313ALow costImprove permeabilityClimate change adaptationWater aerationAquatic animalCrushed stone

The invention relates to a method for improving water quality of a steep-slope river by drop-aeration. The invention comprises the following steps: driving wood piles at two sides of a river channel, backfilling a mixture of crushed stones and soil into a riverbed between a revetment and the piles, covering vegetation to form a plant platform, pouring a trapezoid concrete pier across the river channel to form a overflow weir, and stacking block stones on the overflow weir, wherein the block stones are divided into two sides; the side with higher block stones has small gaps, and the side with lower block stones has large gaps. The invention solves the defects that existing river treatment method results in the loss of deep pools and shoals in natural rivers; primary producers such as various phytoplankton and zooplankton can not reproduce; and benthic and large animals which eat them can not inhabit the river. The invention has low cost, and good permeability, can provide aquatic animals and plants with habitat space, can form a multi-flow changing zone, a multi-organism growing zone, and a multi-fish hideout, has good drop-aeration effect, and can reduce soil loss.

Owner:HOHAI UNIV

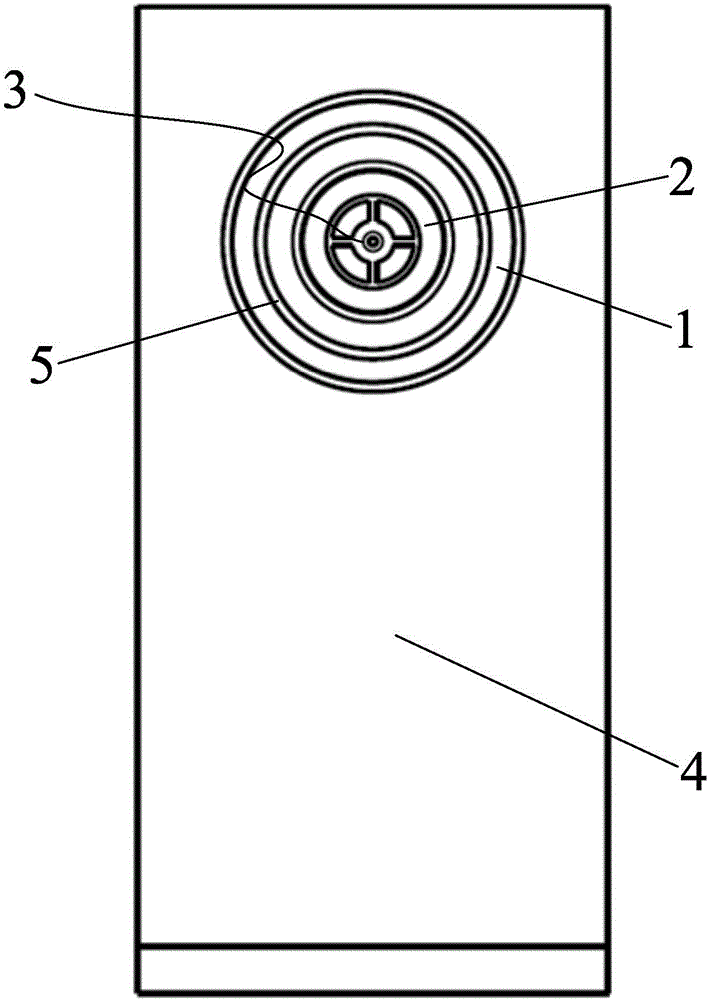

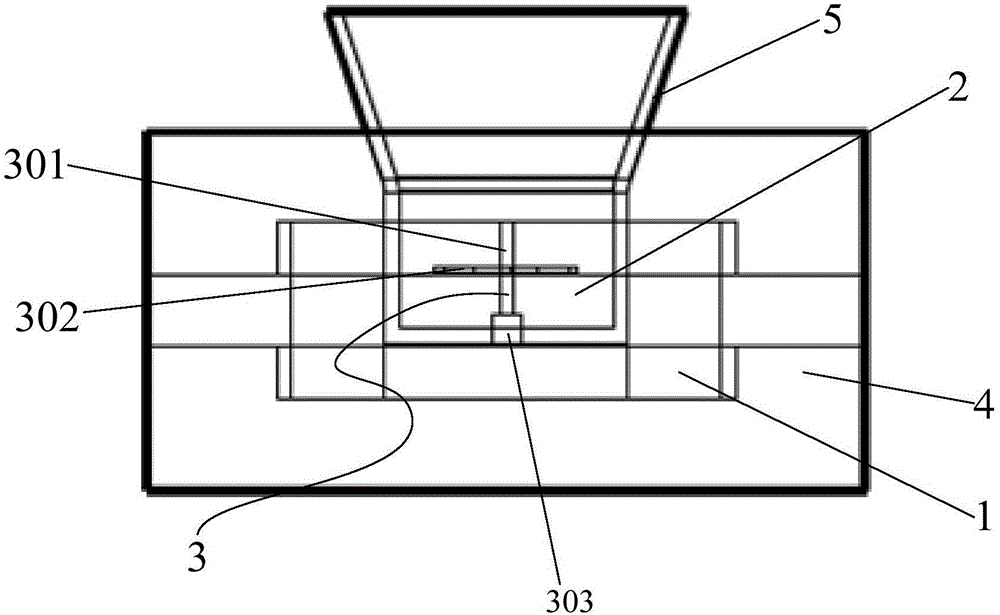

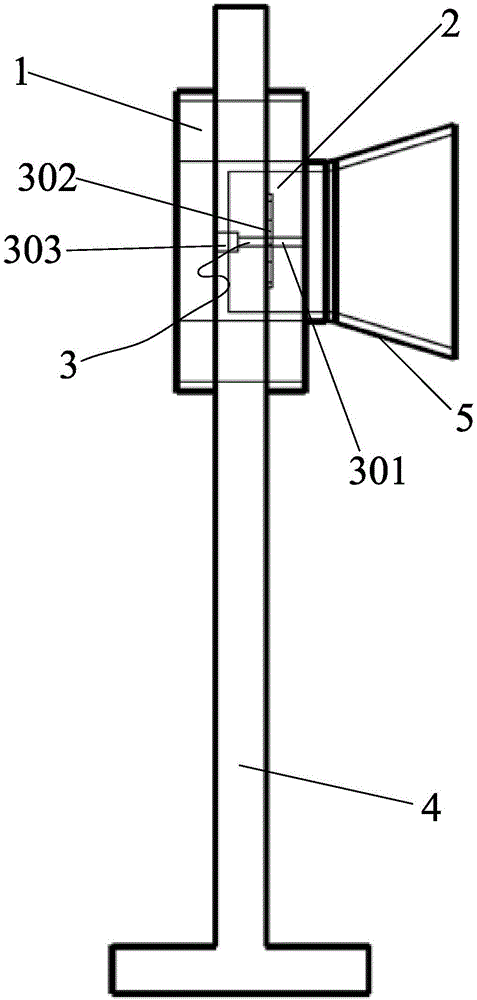

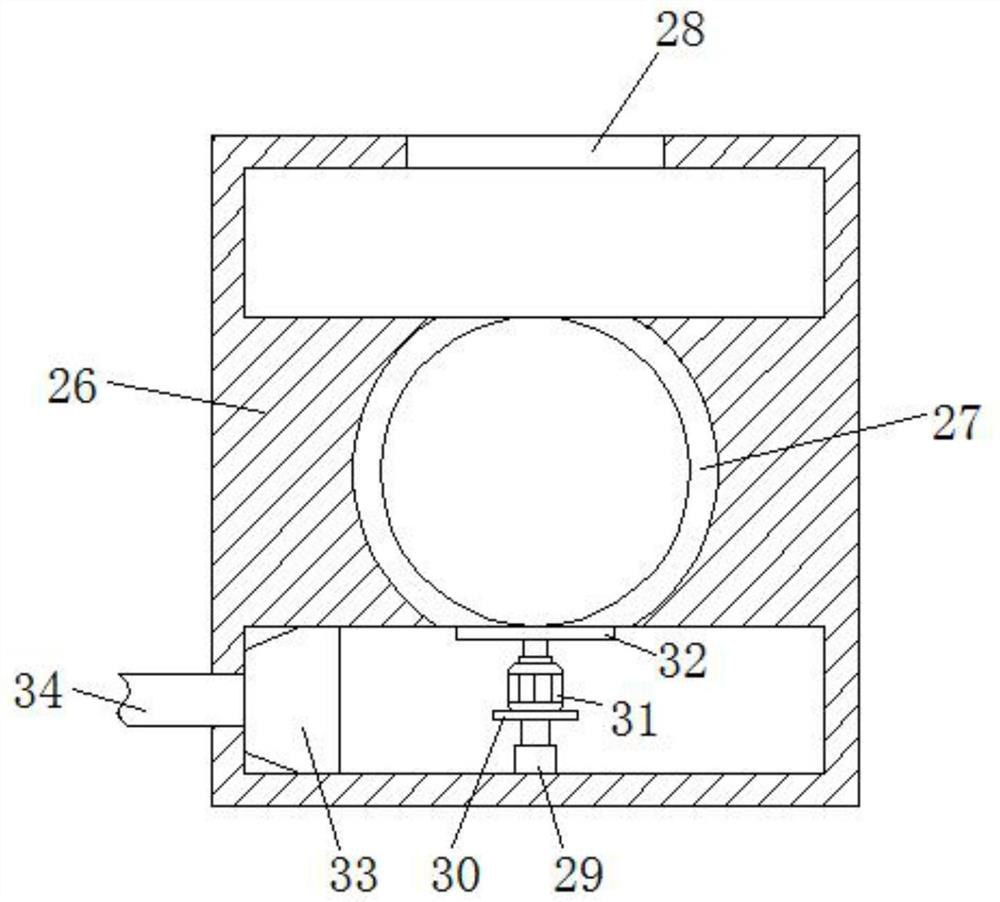

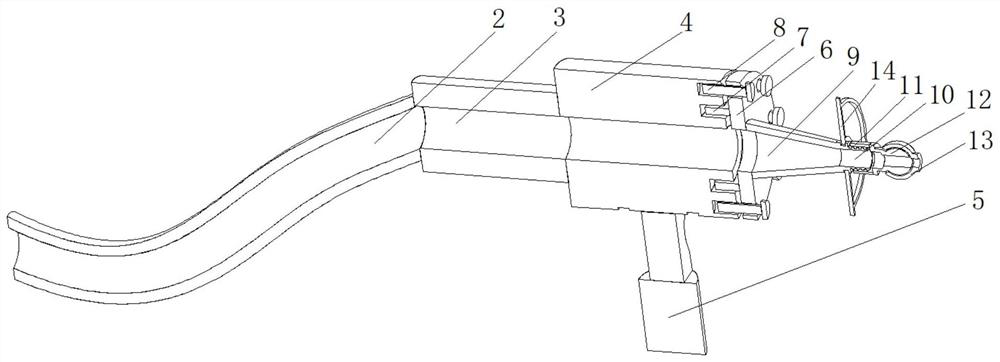

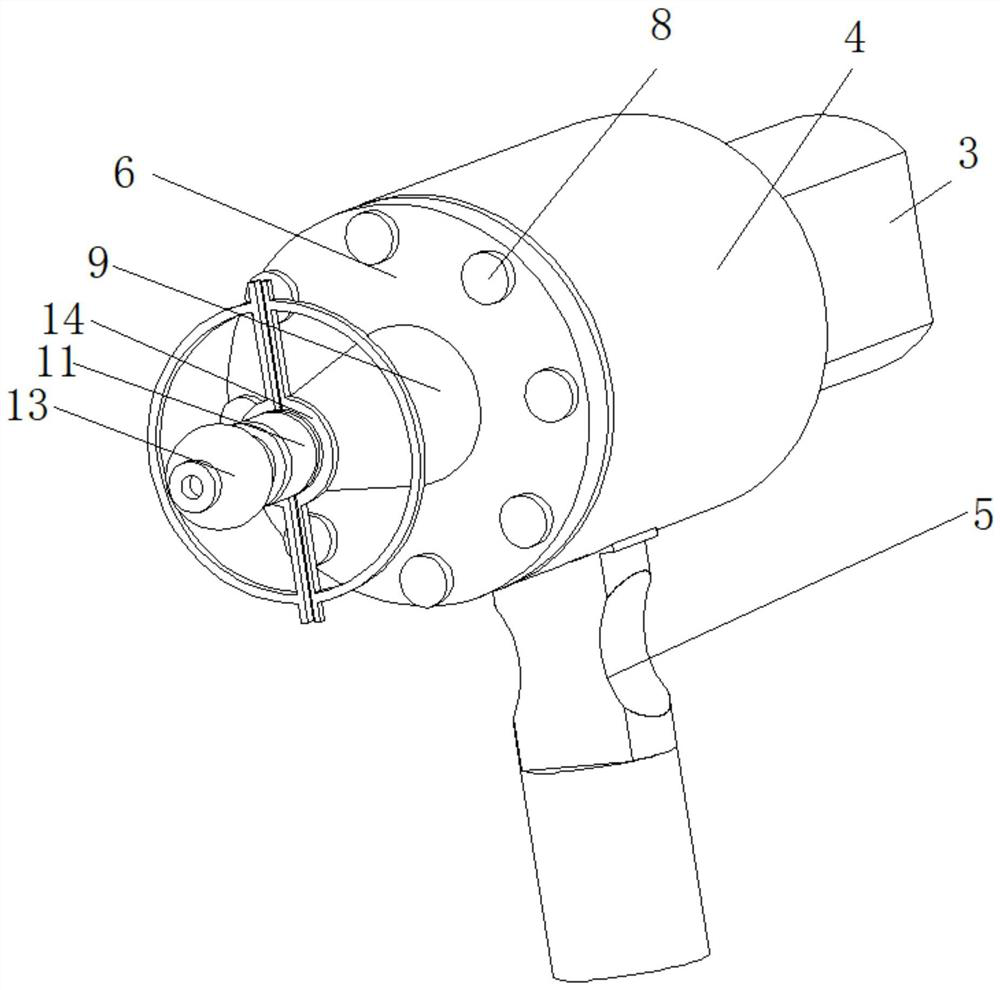

Surface plasma resonance and electron cyclotron resonance double-excitation type microwave thruster

InactiveCN106304595ASmall sizeSimple structureMachines/enginesUsing plasmaMicrowaveElectron cyclotron resonance

The invention discloses a surface plasma resonance and electron cyclotron resonance double-excitation type microwave thruster, relates to the technical field of spacecraft power, and relates to the thruster which is based on low-temperature non-equilibrium plasma, namely surface plasma, resonance and electron cyclotron resonance and is applied to a microsatellite power system for performing the tasks of satellite formation, deep space exploration and the like. The surface plasma resonance and electron cyclotron resonance double-excitation type microwave thruster is fixed into a vacuum environment through a thruster supporting frame, and comprises a permanent magnet ring, a discharge chamber, a metal antenna and a tail spraying pipe; the permanent magnet ring is mounted at the external part of the discharge chamber in a sleeving manner; the metal antenna is embedded into the interior of the discharge chamber; the permanent magnet ring is embedded into the thruster supporting frame; the tail spraying pipe is butted with an outlet of the discharge chamber. The surface plasma resonance and electron cyclotron resonance double-excitation type microwave thruster has the characteristics of being novel in structure, convenient in machining, small in size, high in stability, strong in specific impulse, long in thruster service life and the like.

Owner:DALIAN UNIV OF TECH

Slope planting engineering structure with nonwoven fabrics for protection of culture media

The method includes following steps: non-woven fabric clings to slop, the anchor bolt and anchor nail fix the non-woven fabric, the three-dimensional network on the non-woven fabric, wire netting, and planting substrate. The plant-growing strip is laid above the plant substrate, and is made to cling to the plant substrate.

Owner:深圳市颐和美地生态环境有限公司

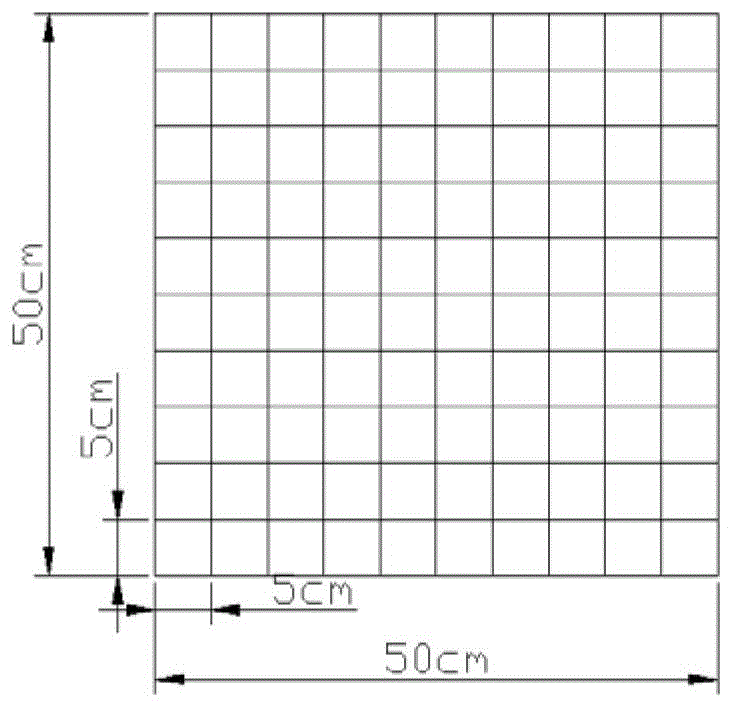

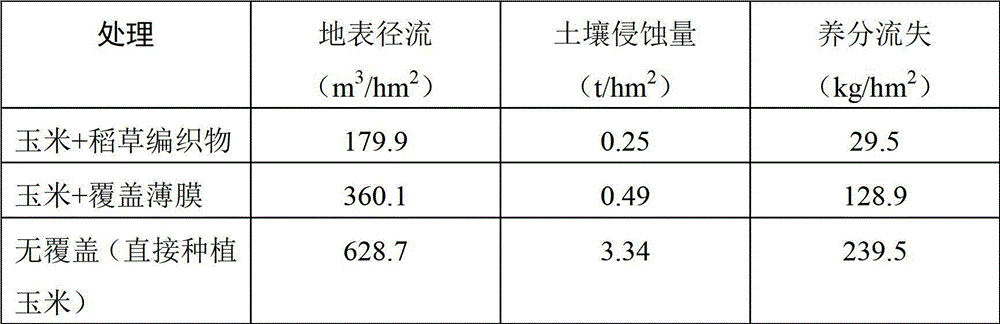

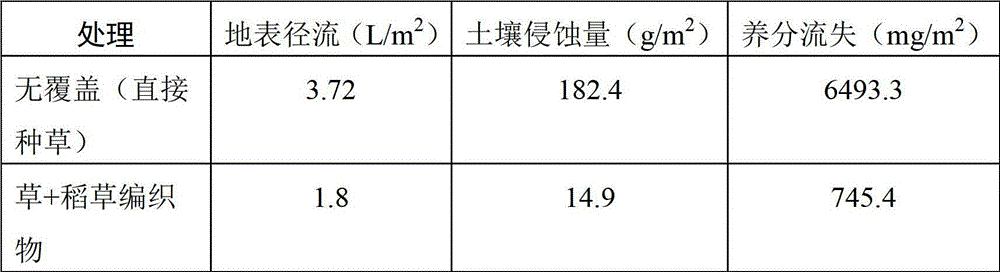

Degradable braided fabric and application thereof

InactiveCN102943349ASimple production processNo pollution in the processCoastlines protectionExcavationsLand coverEngineering

The invention provides a degradable braided fabric in a net structure and knit by knittable plant materials. The knittable plant materials are knit or twisted into rope forms firstly, then knit into a net structure, the diameter of the rope-form structure is 1.2-1.4cm, and the grid size of the net structure is (4-6cm)*(4-6cm). The invention further provides an application of fabric covering in water and soil conservation. A degradable braided fabric cover can not only resist direct rain impact on the soil and prevent the soil from splash erosion, but also reduce the flow velocity and relieve water erosion caused by slow runoff and scour caused by runoff. The degradable braided fabric is an environmental-friendly, economical, friendly and novel land cover material, crop straws are adopted for raw materials, the environment is not polluted, and the soil fertility can be increased through decomposed straws. Additionally, the production technique of the fabric is simple without strict technical requirements, rural vulnerable groups can be fully used, and additional family incomes can be created.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

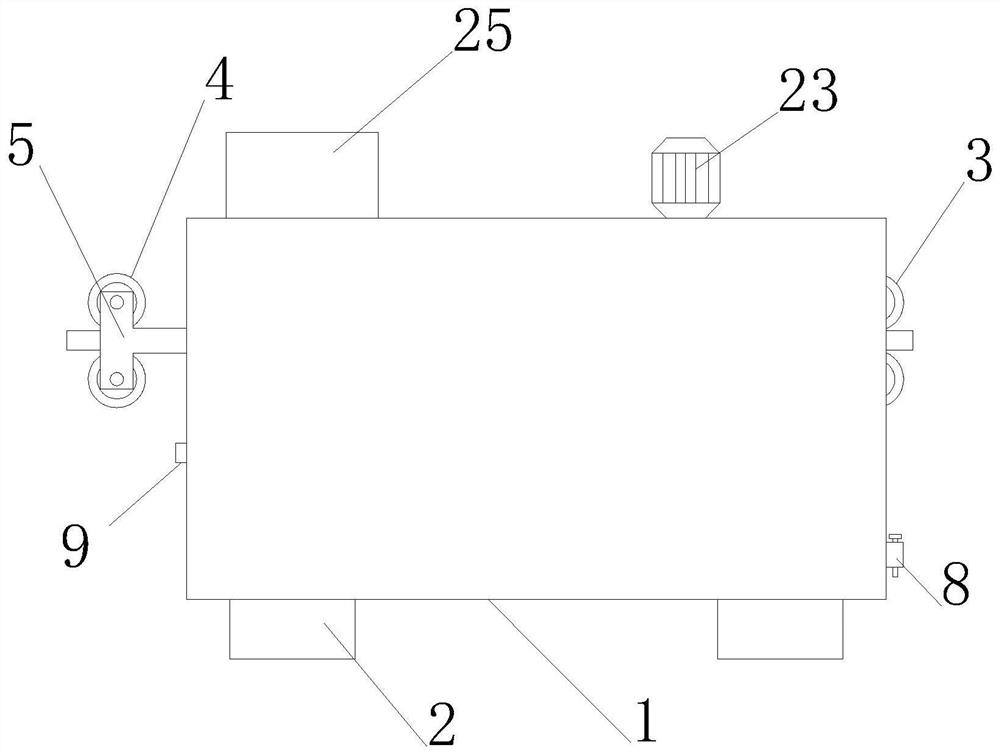

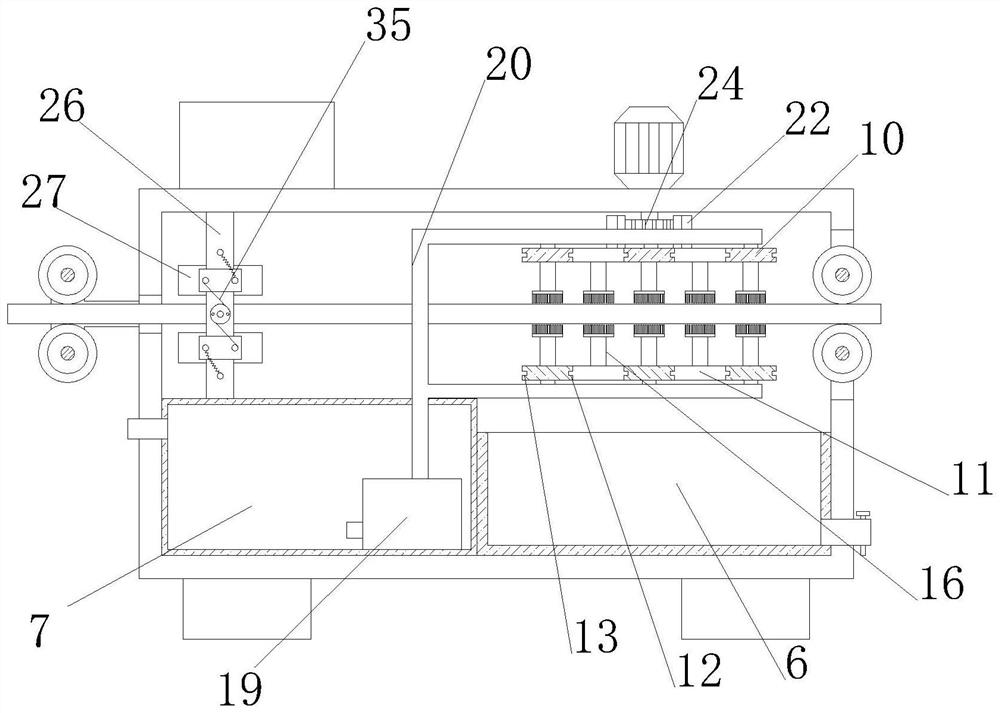

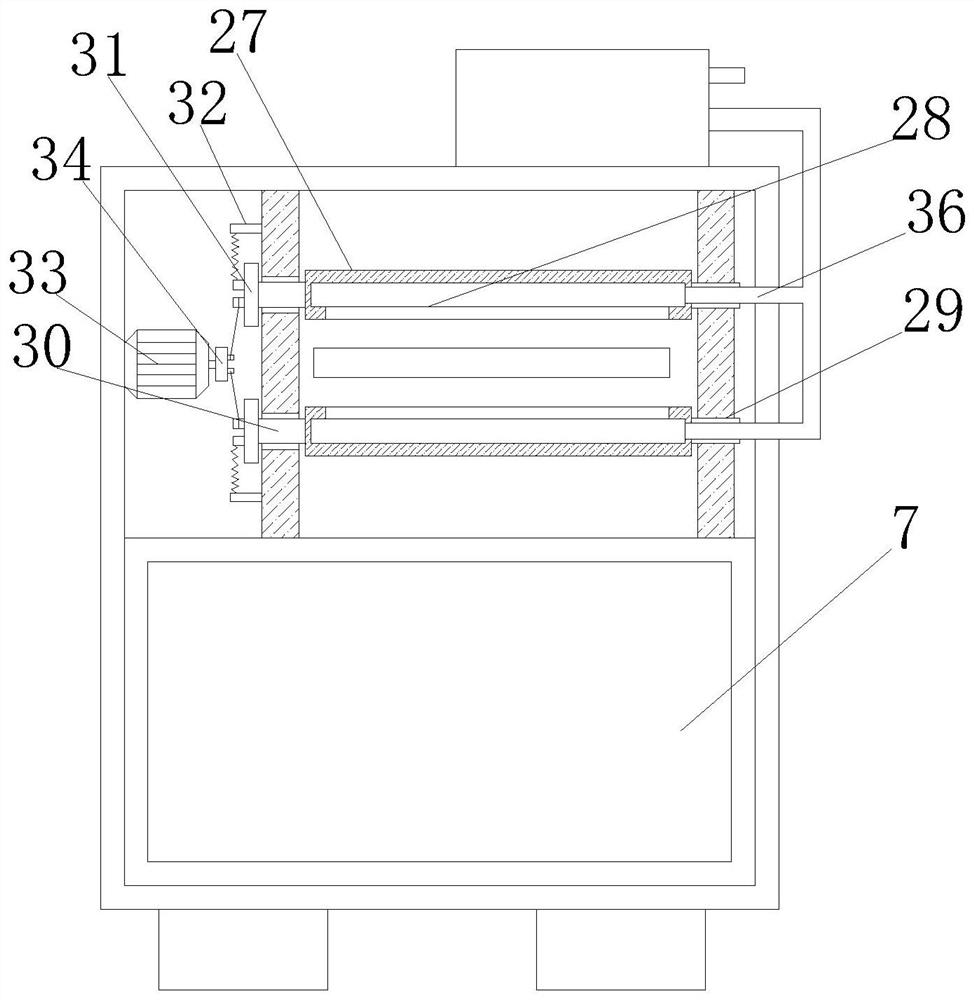

Cleaning device for environment-friendly packaging machinery

InactiveCN108787543AGood cleaning effectReduce resistanceSpecific water treatment objectivesCleaning using toolsActivated carbonEngineering

The invention discloses a cleaning device for environment-friendly packaging machinery. The cleaning device comprises a housing, wherein a two-axis motor is fixedly connected to the top of the inner chamber of the housing; output ends of the two sides of the two-axis motor are fixedly connected to threaded rods; a threaded sleeve is arranged on the surface of each threaded rod in a sleeving manner; a connecting plate is fixedly connected to the bottom of each threaded sleeve; a partition is fixedly connected to the inner chamber of the housing; and a through opening is formed in the surface ofthe partition. As the housing, the threaded rods, the threaded sleeves, the two-axis motor, the connecting plates, fixed blocks, the partition, motors, through pipes, sprayers, water outlet pipes, water pumps, water inlet pipes, support legs, water suction pipes, a water tank, brushes, rollers, an activated carbon plate, the through opening, a chute, a rotary bar, a connecting rod, a pulley and awater passing hole are used in cooperation, the problem that a conventional cleaning device for the environment-friendly packaging machinery has a poor cleaning effect is solved. The cleaning devicefor the environment-friendly packaging machinery has the advantage of the good cleaning effect.

Owner:HENAN ZHONGBAO TECH

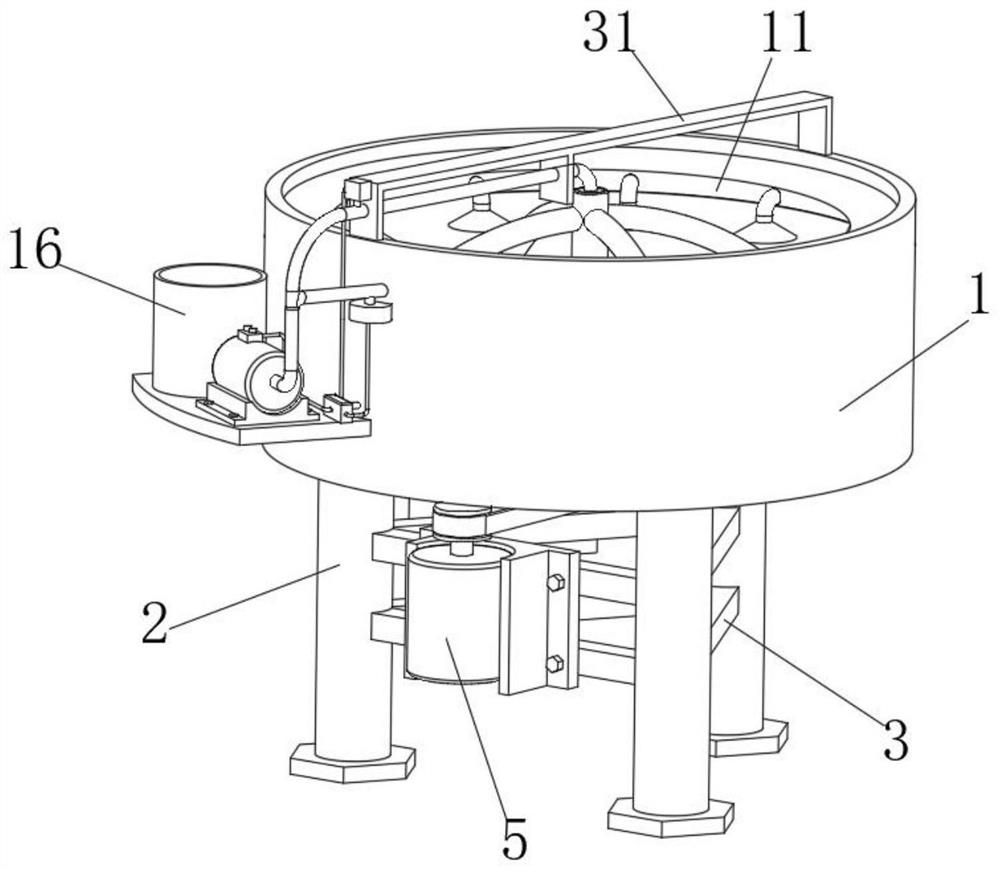

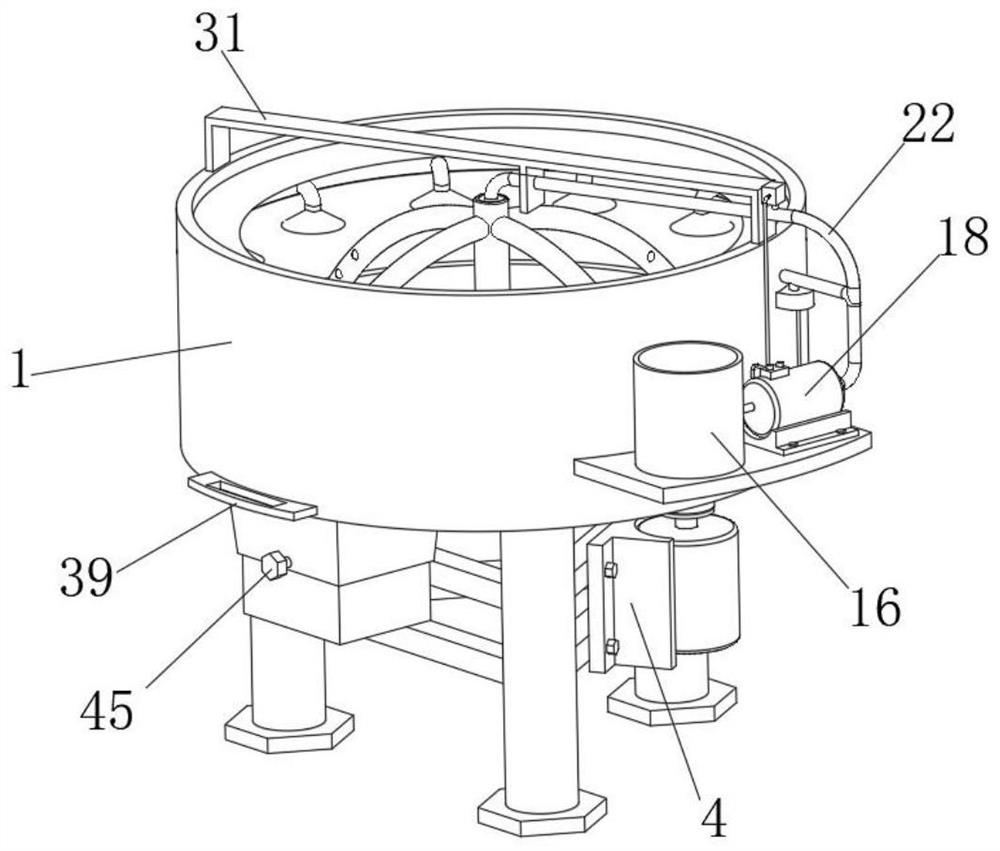

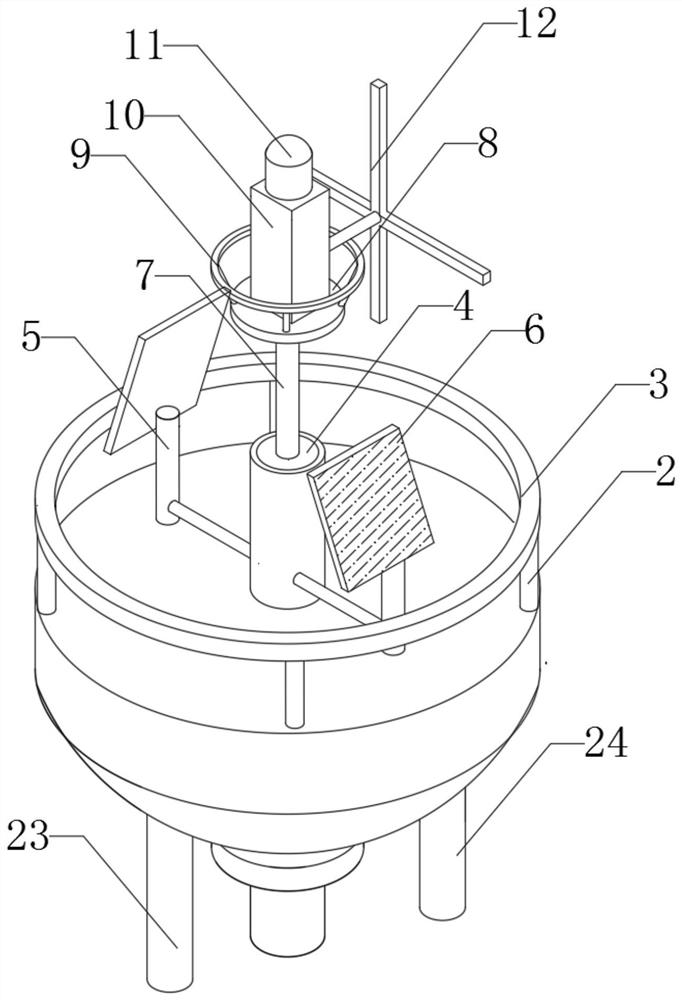

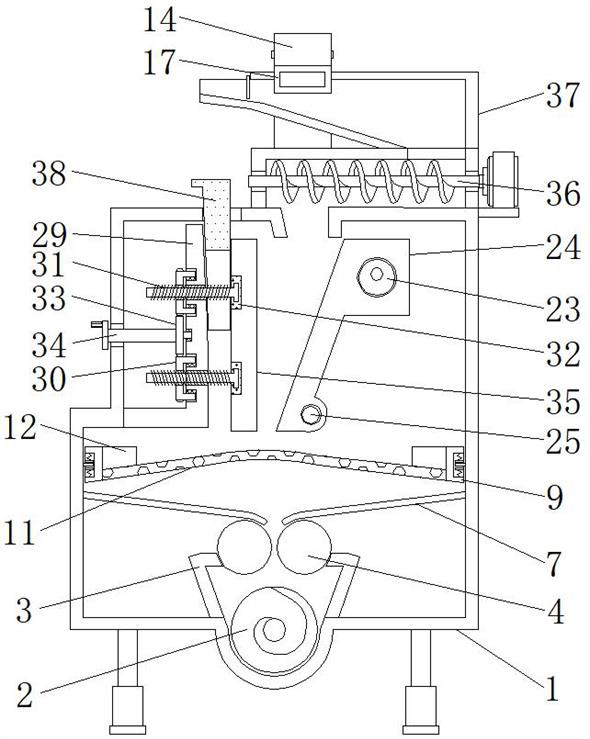

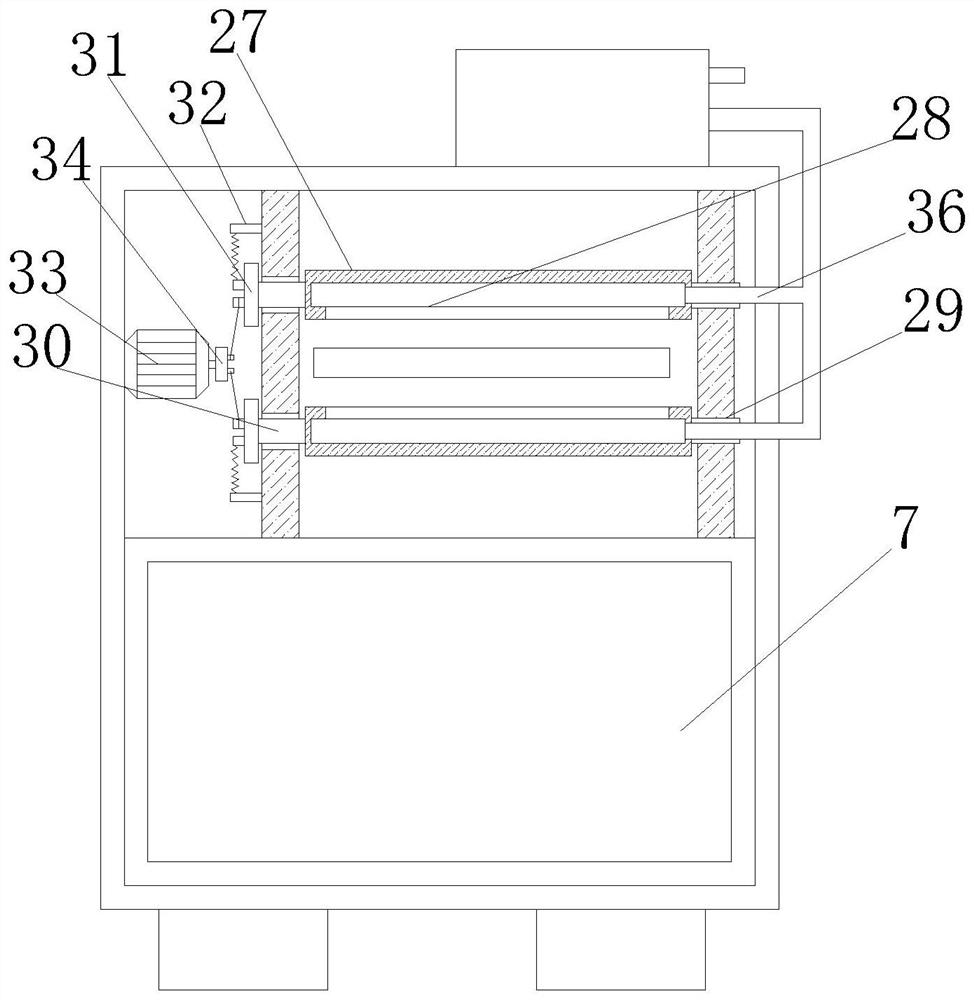

Concrete mixer not prone to caking

InactiveCN112428431ANot easy to knotAvoid affecting useCement mixing apparatusControl apparatusRotational axisDrive motor

The invention relates to the technical field of concrete mixer devices, and discloses a concrete mixer not prone to caking. The output end of a driving motor drives an input shaft to rotate through acoupling, the input shaft enables a driving pulley to rotate, a rotating shaft is made to rotate through a transmission belt, and the rotating shaft drives a stirring through pipe to mix cement. Whenwater is too little in the stirring process, a sensor transmits a signal into an electromagnetic valve controller through a data transmission line, the electromagnetic valve controller transmits the signal into a cleaning pump through a water pump control line, then the cleaning pump is started, the cleaning pump starts a second electromagnetic valve through a second control line, and meanwhile afirst electromagnetic valve is closed. A water inlet pipe discharges water in a water tank into the cleaning pump, the water is discharged into a water outlet pipe through the pressurization effect ofthe cleaning pump and flows out through a multifunctional pipe, the stirring through pipe and a water injection hole, and therefore water adding stirring can be achieved in the stirring process, andthe situation that the use standard is affected due to over-dry concrete is prevented.

Owner:合肥市日月新型材料有限公司

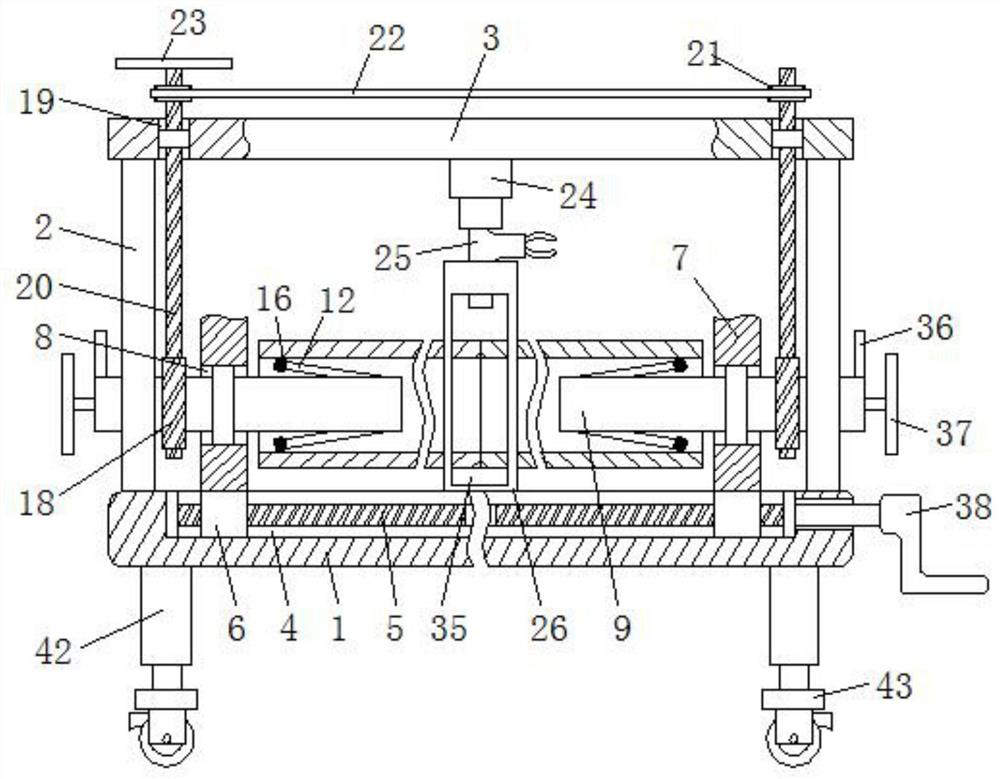

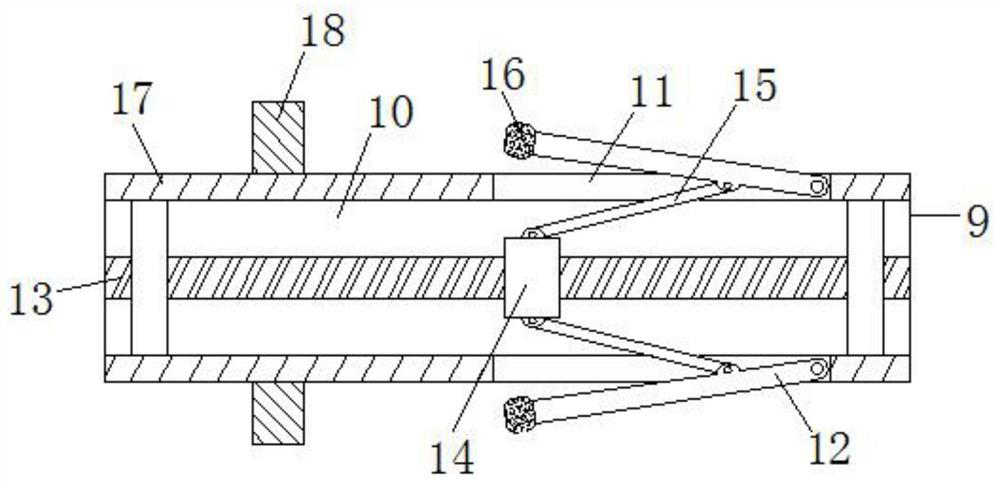

Industrial mechanical steel pipe positioning and welding device

InactiveCN112247469AConvenient welding workEasy to useEdge grinding machinesGrinding drivesWorking environmentMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to an industrial mechanical steel pipe positioning and welding device. The device comprises a workbench, trundles are fixedly connected to the lower ends of four supporting legs correspondingly, a top plate is fixedly connected to the upper ends of four supporting columns, a first screw rod is rotatably connected to the interior of a first empty groove through a bearing, a threaded block is in threaded connection with the outer side of the first screw rod, a connecting plate is fixedly connected to the upper end of the threaded block, a first through groove is formed in the middle of the connecting plate, a positioning device is rotatably connected to the interior of the first through groove through a bearing, a welding gun is fixedly connected to the lower end of the first hydraulic rod, and a protective shell is fixedly connected to the middle of the upper end of the workbench. The industrial mechanical steel pipe positioning and welding device is reasonable in structural design, convenient to use, high in practicability and functionality, high in applicability, wide in application range, capableof guaranteeing the better welding effect, capable of protecting the working environment, more convenient to use and worthy of popularization.

Owner:李高师

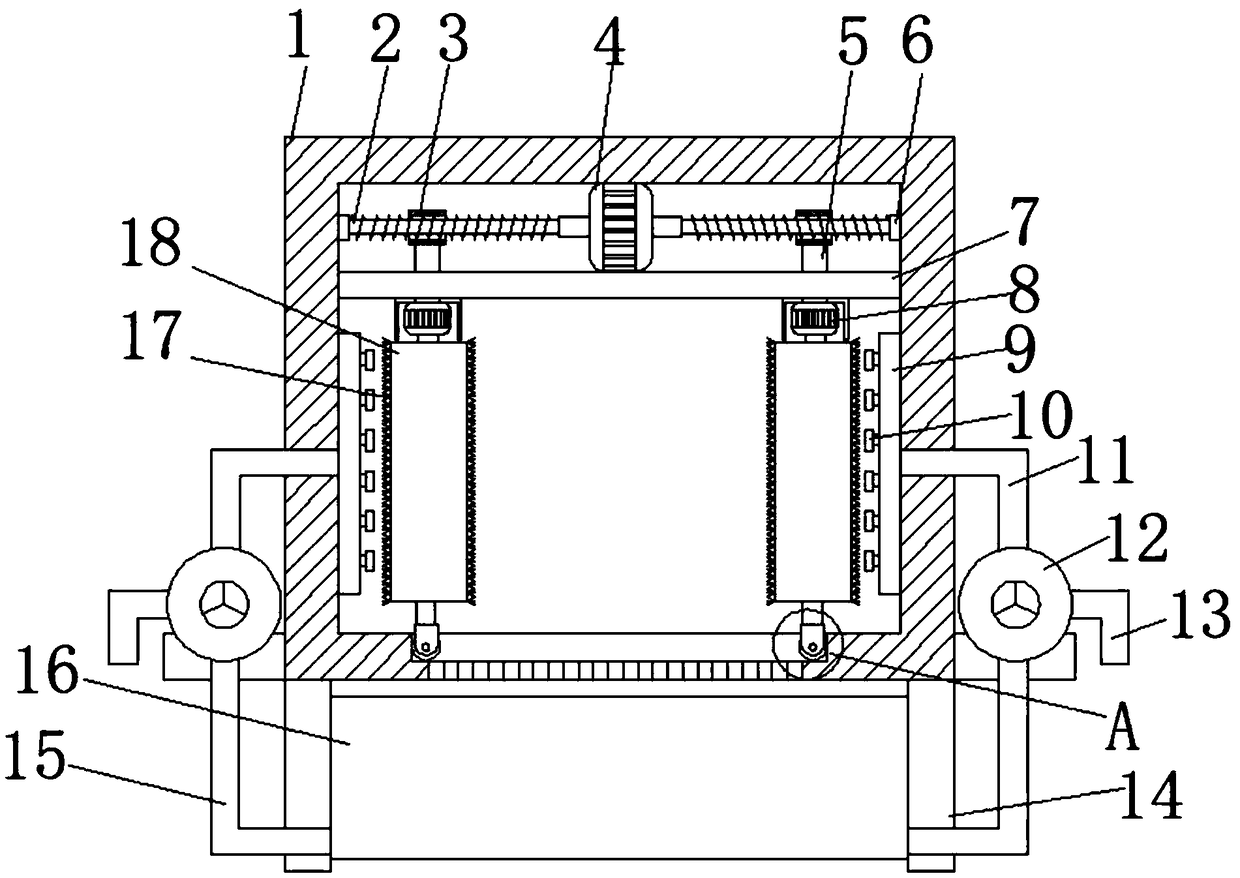

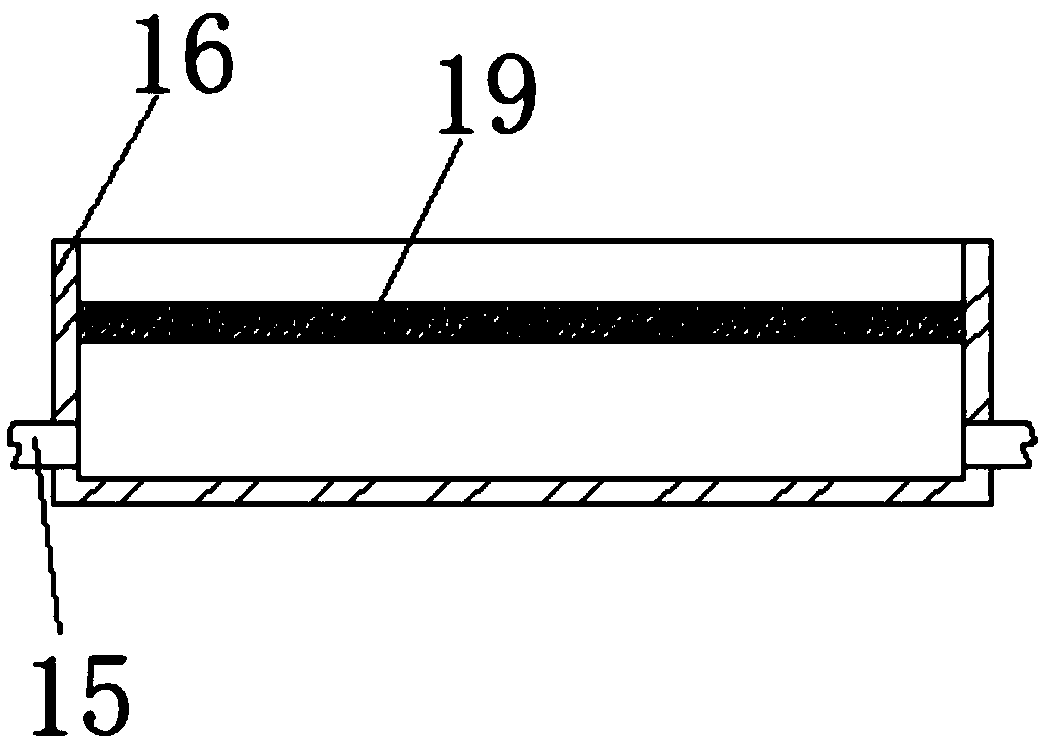

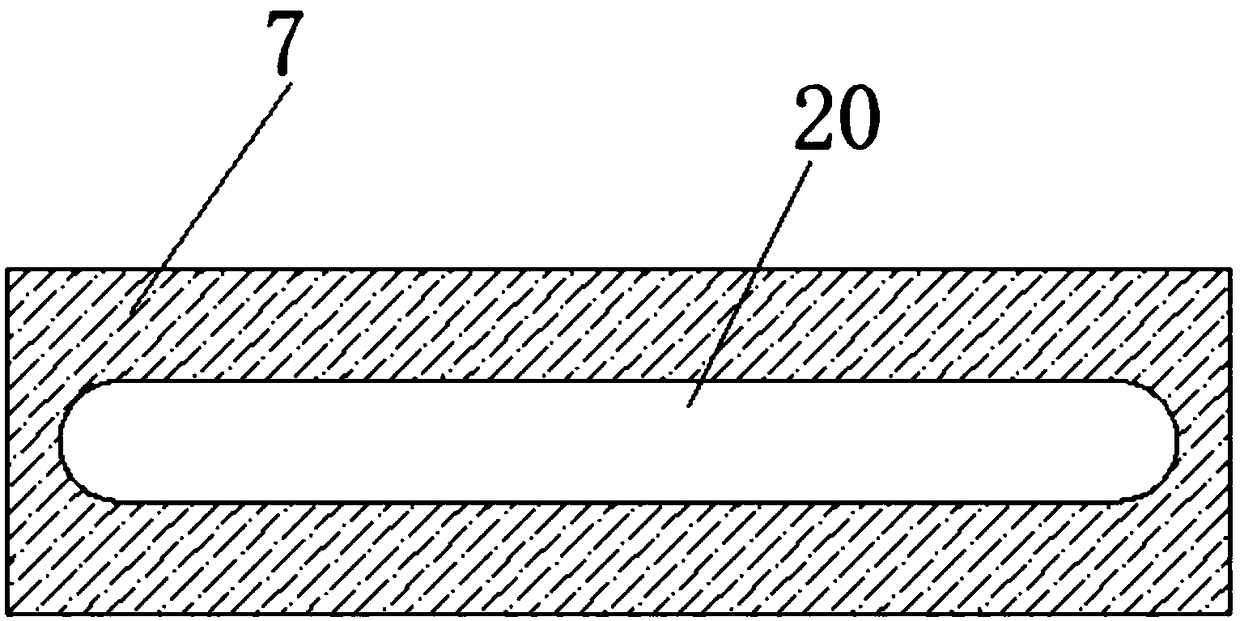

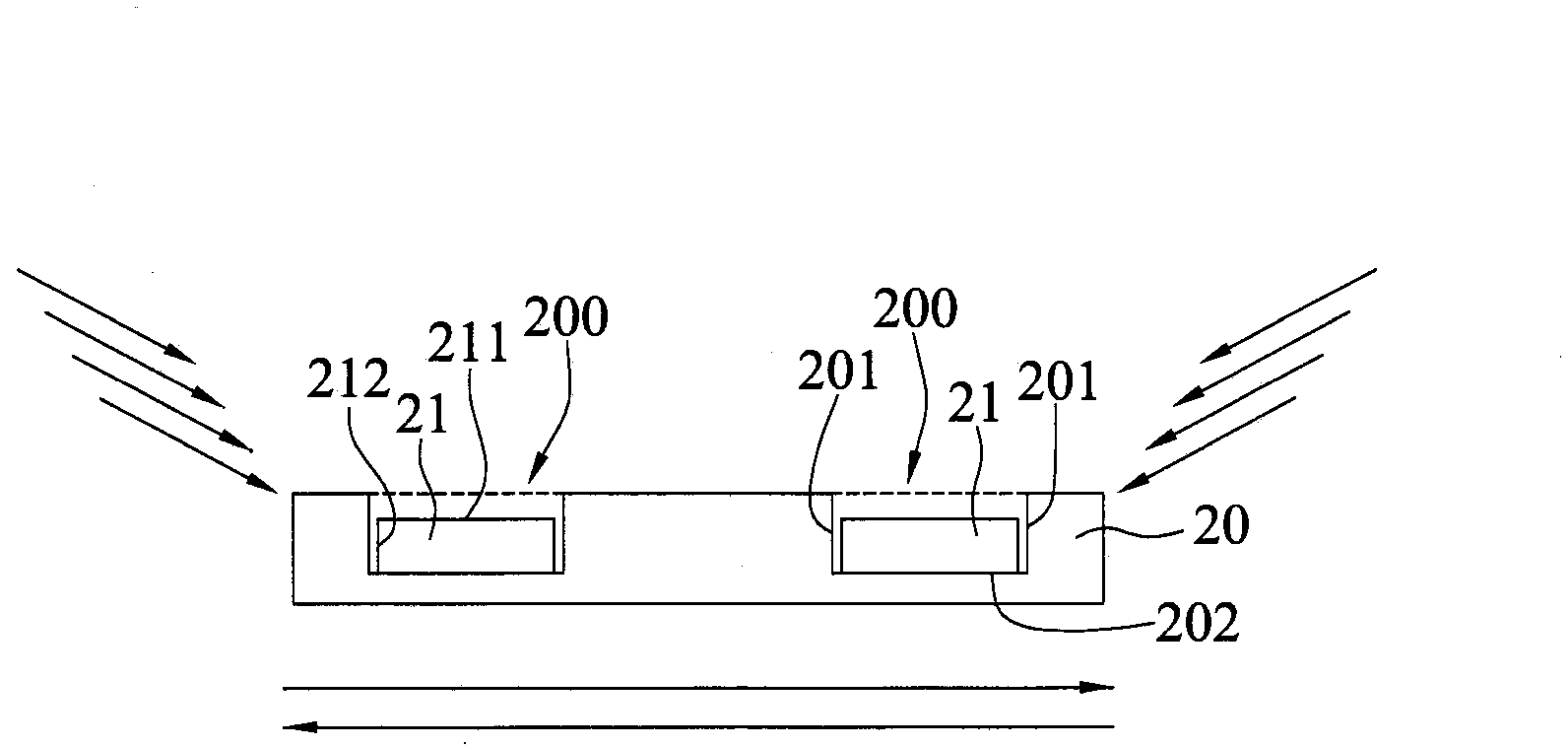

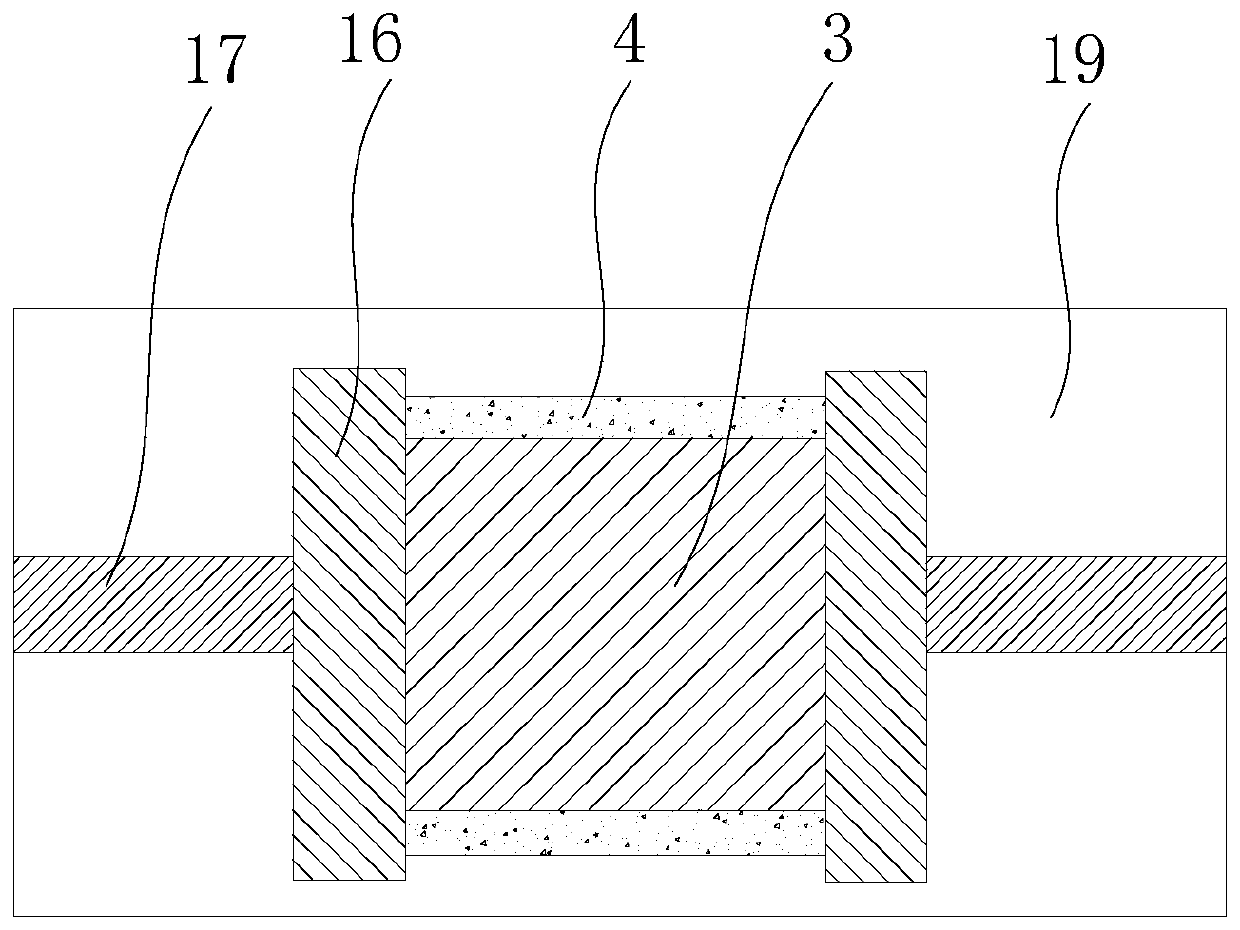

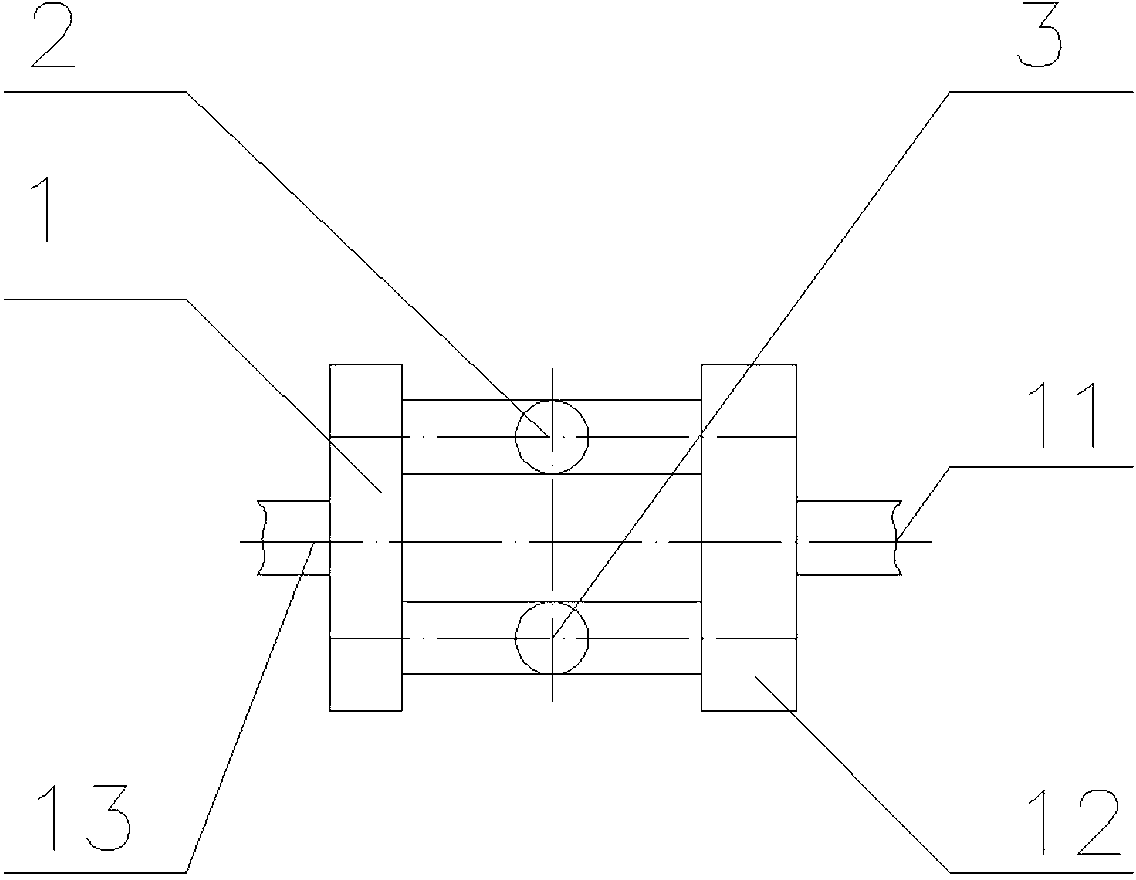

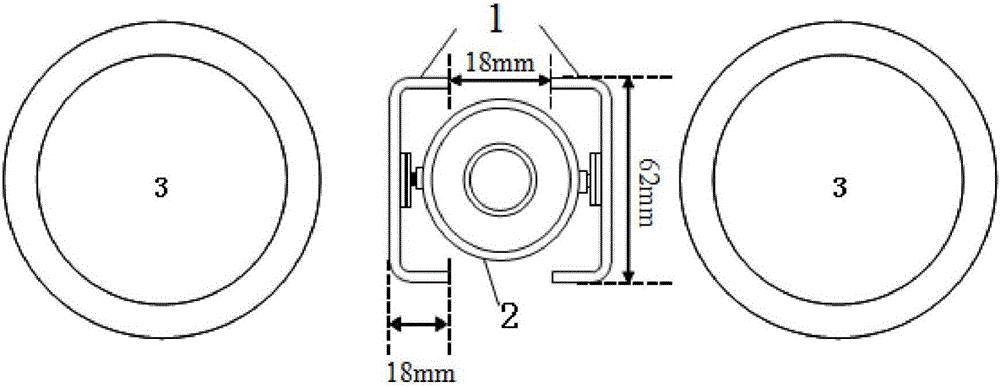

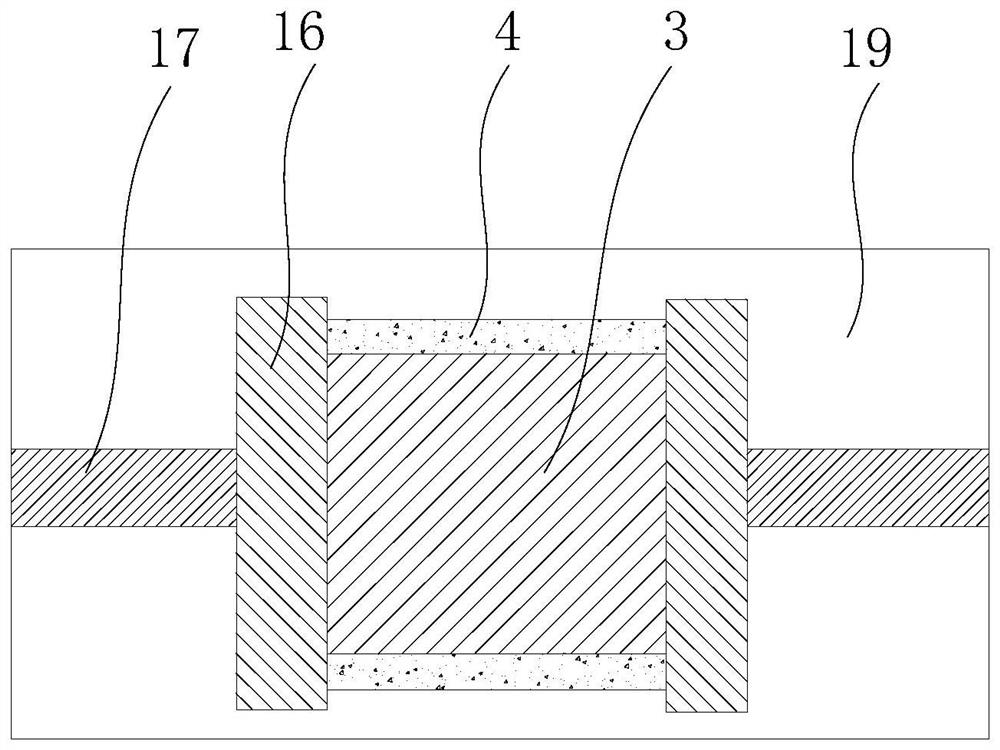

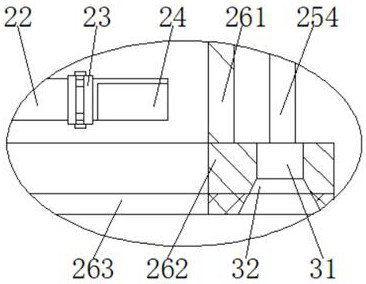

Clamp for sputtering and method for sputtering semiconductor package

ActiveCN103805950AImprove subsequent problems caused by insufficient thicknessBlock sputteringVacuum evaporation coatingSputtering coatingSputteringMarine engineering

The invention provides a clamp for sputtering and a method for sputtering a semiconductor package. The clamp comprises a bearing plate having a groove, an adhering layer disposed at the bottom face of the groove and provided with an object setting area at the top face, and a jig plate which is combined with the adhering layer and is embedded in the groove of the bearing plate and is provided with a first opening corresponding to the object setting area. The cross section of the first opening of the jig plate is in the shape of an oval, which is narrow at bottom and wide at top, and a predetermined distance is disposed between the edge of the object setting area and the bottom end of the first opening. Accordingly, the bottom part of the semiconductor package can be prevented from sputtering, and the yield of the semiconductor packages can be increased.

Owner:SILICONWARE PRECISION IND CO LTD

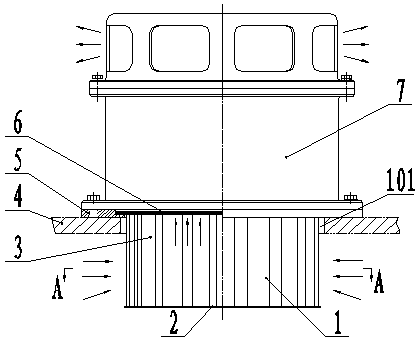

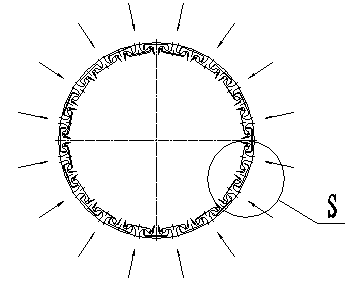

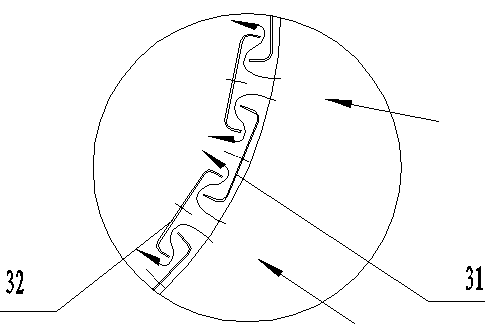

Lubricating-oil mist discharging device for oil groove of sliding bearing of generator set

ActiveCN103216720AAvoid accessTo achieve the purpose of purifying oil mistLubrication elementsAir filterSlider bearing

The invention discloses a lubricating-oil mist discharging device for an oil groove of a sliding bearing of a generator set. The lubricating-oil mist discharging device comprises an oil groove cover, wherein an air inlet and an air exhaust port are formed in the oil groove cover; an air filter is arranged on the air inlet, and outside air is filtered by the air filter and then enters the oil groove; the air exhaust port is provided with a splash-proof oil retaining cover which is provided with an oil-mist discharging device; the splash-proof oil retaining cover is provided with an enveloping part which is arranged in the circumferential direction; the outer edge of the top part of the enveloping part is provided with a first connecting part; a bottom plate is arranged at the bottom part of the enveloping part; the enveloping part is internally provided with a labyrinth passage; and a labyrinth-passage inlet as an air inlet of the splash-proof oil retaining cover is arranged at the side wall of the enveloping part, and a labyrinth-passage outlet as an air exhaust port of the splash-proof oil retaining cover is arranged at the top part of the enveloping part. The lubricating-oil mist discharging device disclosed by the invention has the advantages that the purpose of purifying oil mist can be achieved, the oil mist discharging device also can be protected, and a first groove plate and a second groove plate are mutually embedded to play a role of accelerating the backflow of reflux and liquefied lubricating oil into the oil groove.

Owner:重庆华能水电设备制造有限公司

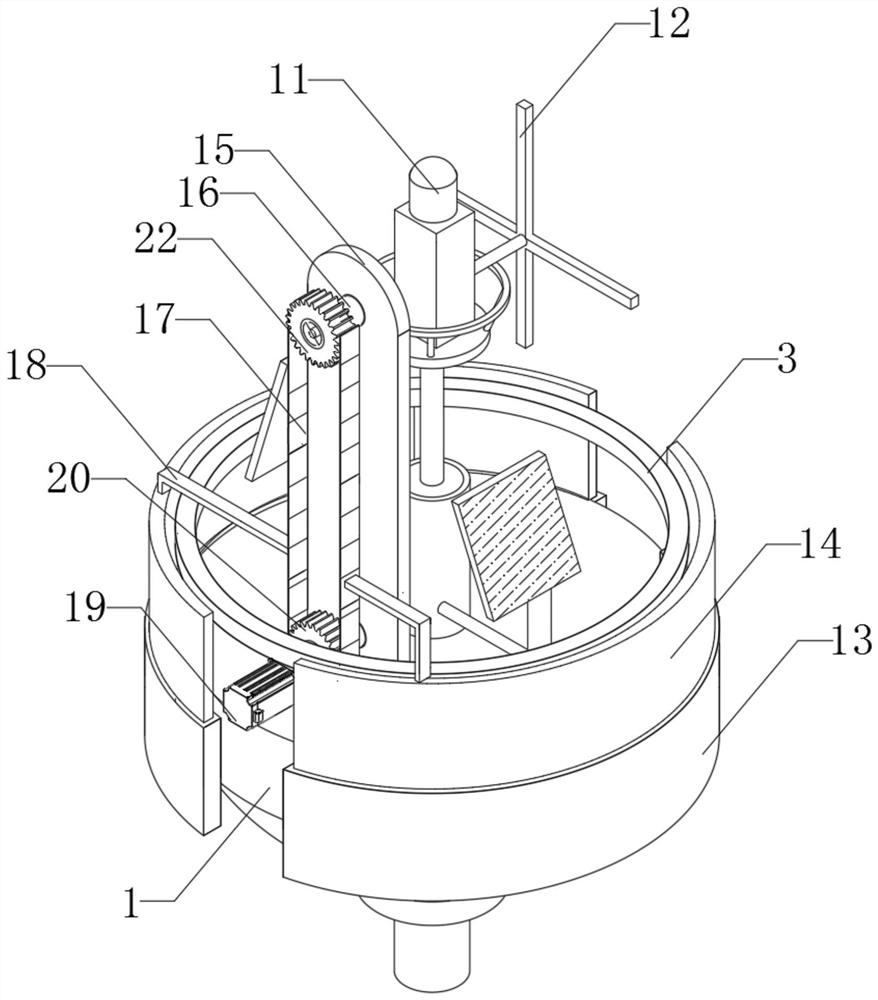

Buoy station system for water area detection

InactiveCN112078730ABlock sputteringAvoid affecting service lifeWaterborne vesselsVolume indication and recording devicesGear wheelBuoy

The invention provides a buoy station system for water area detection. The buoy station system for water area detection comprises a buoy station body, first protection plates are fixedly arranged on the two sides of the buoy station body, second protection plates are connected into two storage grooves in a penetrating and inserting mode, and a first gear and a second gear are connected to the twosides of the front face of a supporting plate in a penetrating and inserting mode through connecting shafts correspondingly; and transmission rods are fixedly arranged on the outer walls of the two sides of a chain, one ends of the two transmission rods are fixedly connected with the tops of the two second protection plates correspondingly, the two first protection plates are arranged on the outerside of the buoy station body, and the second protection plates are inserted into the first protection plates in a penetrating mode. When the weather in the detected area is bad, the two gears can bedriven by a servo motor to rotate, the chain is driven to move at the same time, the two second protection plates can be driven to ascend in the chain moving process, impact and sputtering of waves are blocked, equipment and a structure arranged at the top of the buoy station body are effectively protected, and the equipment structure is prevented from being damaged by impact.

Owner:上海怀誉自动化科技有限公司

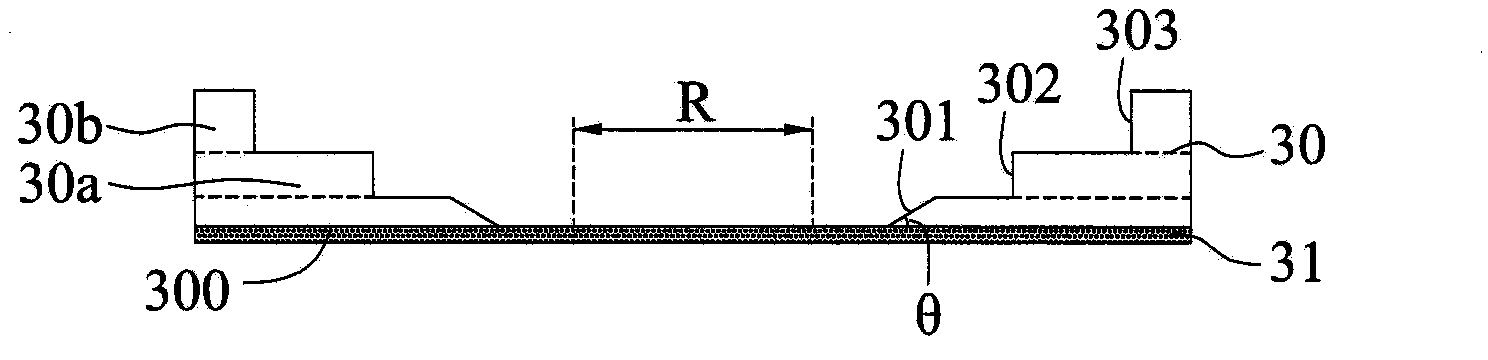

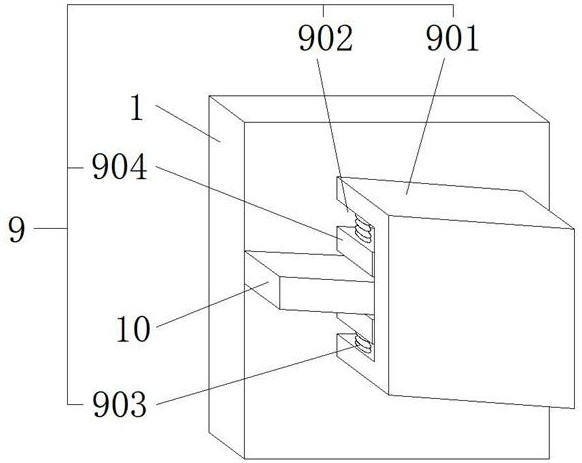

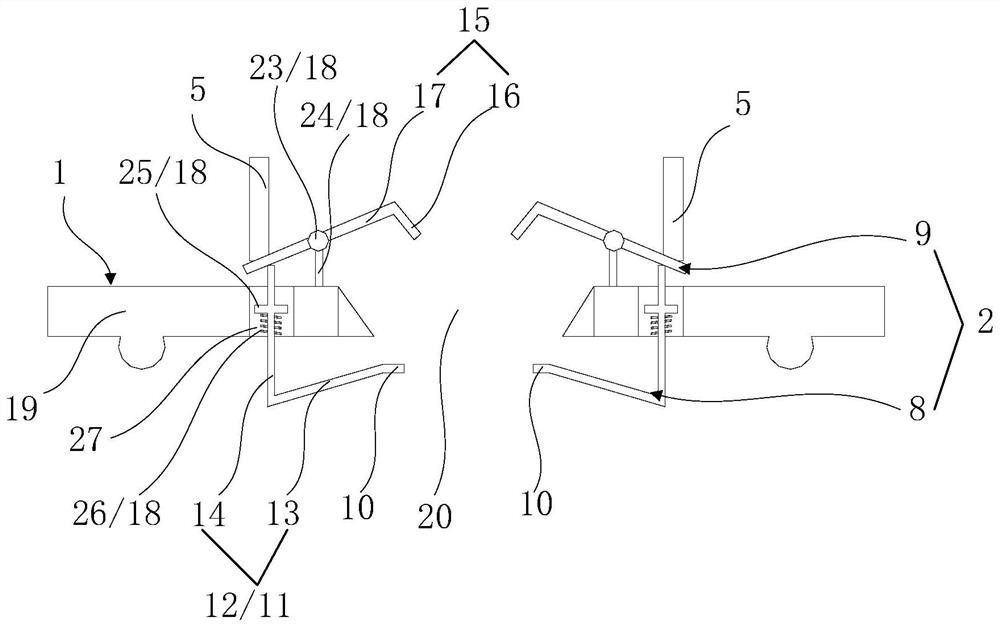

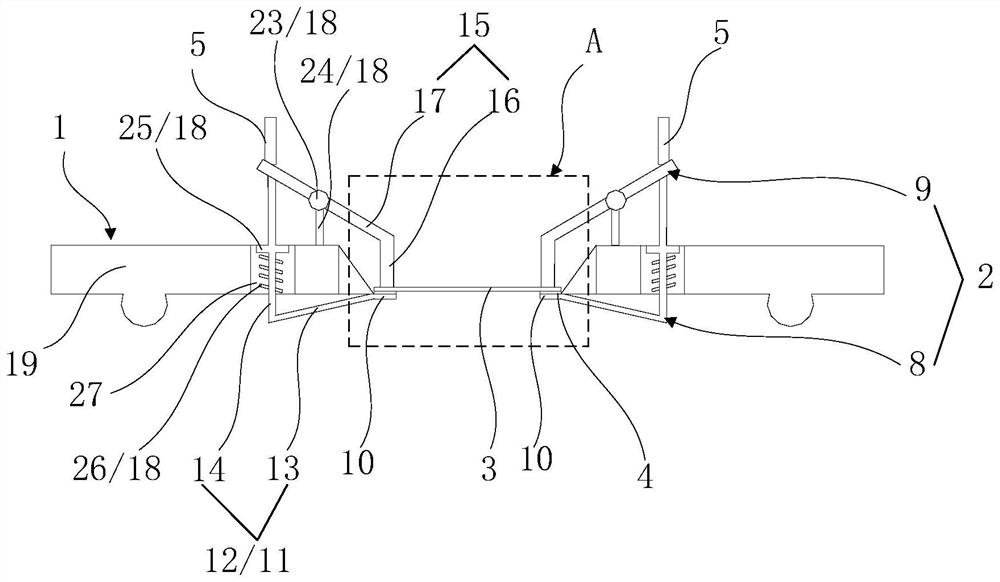

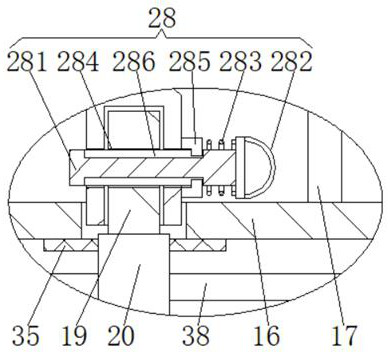

Clamping device applied to sputtering coating equipment, and sputtering coating equipment

ActiveCN110172667AImprove fitAvoiding the Problem of Filming ShadowsVacuum evaporation coatingSputtering coatingBiomedical engineeringCoating

The invention discloses a clamping device applied to sputtering coating equipment, and the sputtering coating equipment. The clamping device comprises a clamp and a driving device, wherein the clamp is used for correspondingly clamping a substrate and a mask, and the driving device is connected with the clamp and is used for driving the clamp to clamp or release the substrate and the mask; an opening which is matched with an opening of the mask in shape and size is formed in the clamp, so that after the clamp clamps the mask and the substrate, the orthographic projection of the mask on the substrate is completely covered with the orthographic projection of the side, close to the mask, of the clamp on the substrate; and the opening of the clamp communicates with the opening of the mask in an aligned mode, so that a sputtering coating area of the substrate is exposed to be sputtering-coated by the sputtering coating equipment. By adoption of the clamping device applied to the sputteringcoating equipment, and the sputtering coating equipment, the mask can be prevented from being covered by a sputtering coating in the sputtering coating process of the substrate, so that buckling deformation of the mask, contamination of the sputtering coating falling off from the mask to a sputtering coating cavity, and coating shadows of the substrate are avoided.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Ceramic production recycling device capable of ensuring sufficient crushing

The invention discloses a ceramic production recycling device capable of ensuring sufficient crushing. The ceramic production recycling device comprises a crushing box, an output packing auger, a miniature vibration motor and a material conveying packing auger, wherein the output packing auger is arranged on the middle part of the bottom end of the crushing box; a material drawing plate is fixedlyarranged on the outer surface of a conveyer belt; a recycling pipe is welded to the top end of a shell; the miniature vibration motor is arranged on the front end of a bearing mechanism; a regulationrod penetrates through the middle part of a regulation ring; a rubber block wraps the right end of the regulation rod; a fluted disc is rotatably arranged on the middle part of a fixing plate; a rotary rod is welded to the left side surface of the fluted disc; and the material conveying packing auger is arranged on the upper end of the crushing box. According to the ceramic production recycling device capable of ensuring sufficient crushing, a sufficient crushing effect can be effectively realized through circular crushing; the crushing effect is ensured; recycling and reusing of raw materials are facilitated; and besides, a dust flying phenomenon can be effectively avoided, so that harm caused to workers by flying dust is avoided.

Owner:佛山市金舵陶瓷有限公司

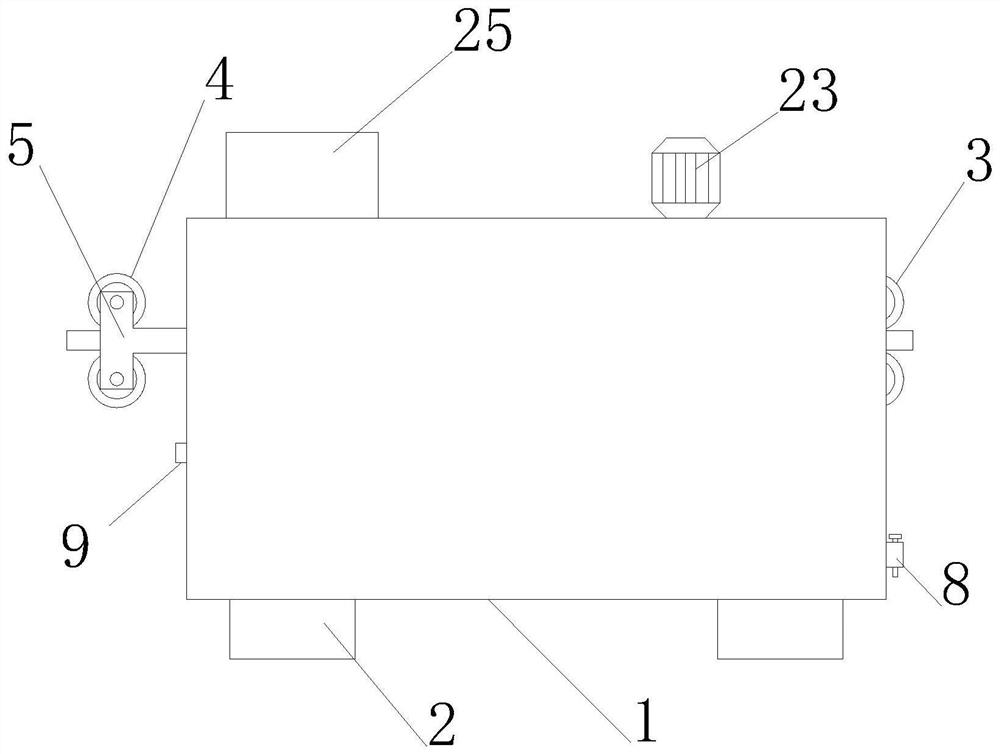

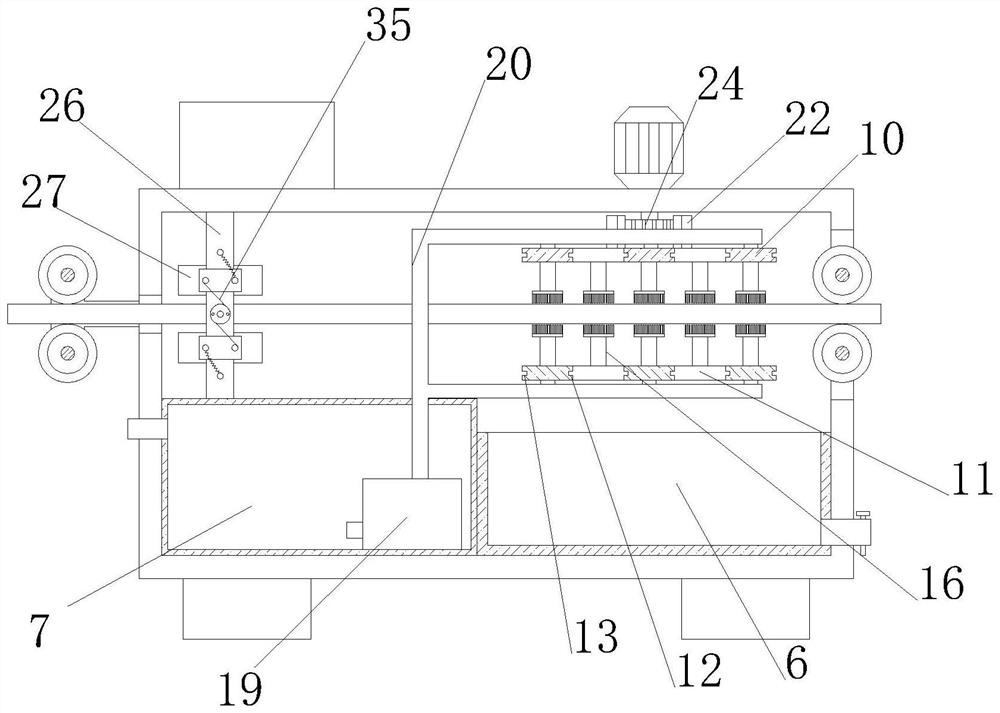

Steel pipe cutting robot

InactiveCN107717108ABlock sputteringSimple and fast operationMetal sawing devicesMetal sawing accessoriesVertical barGear wheel

The invention discloses a steel pipe cutting robot. The steel pipe cutting robot comprises a shell; an outer gear and a square through groove A are arranged on the shell; a sliding plate is arranged in the square through groove A; a square through groove B is arranged on the sliding plate; a rack is arranged in the square through groove B; a motor A and a connection block are arranged on the sliding plate; a gear A is arranged on the motor A; a boss is arranged on the shell; a baffle plate A, a baffle plate B and a motor B are arranged on the boss; a lead screw is arranged on the baffle plateA; a nut is arranged on the lead screw; a blade is arranged on the lower part of the rack; an ejection plate is arranged in the shell; pressure sensors are arranged on the ejection plate; a rubber padis arranged on the ejection plate; a vertical rod A is arranged in the shell; a guide wheel is arranged on the vertical rod A; an opening is arranged on the lower part of the shell; a support is arranged on an annular groove; a cushion block, a PLC, a support rod A, a motor D and multiple vertical rods B are arranged on a base; a gear B is arranged on a gear C; a sleeve is arranged on the supportrod A; a support rod B and a spring are arranged in the sleeve; the motor D is connected with a rotary shaft belt; and glass is arranged on the shell. The steel pipe cutting robot is simple and convenient for operation, capable of feeding materials automatically, and applicable to steel pipes of different thicknesses; and safety hazards are reduced.

Owner:广西环游信息技术开发有限公司

Water-saving sanitary toilet bowl

A water-saving sanitary toilet bowl comprises a cylindrical structure, a conical cylindrical structure and a cylindrical drain outlet which are sequentially in butt joint from top to bottom. The drain outlet is directly matched with a vertical drainpipe in an inserted and connected manner, a frustum-shaped flap valve is hinged at the upper end opening of the drain outlet, a flap valve cavity is arranged at the corresponding conical cylindrical structure after the flap valve is opened, a spring matched with the upper end of the flap valve is arranged in the flap valve cavity, the middle of the flap valve is connected with a pedal at the bottom of the outer side of the toilet bowl through an open and close steel wire rope in a driving manner, at least three water spraying devices are uniformly arranged on the periphery of the upper inner wall of the cylindrical structure of the toilet bowl and are connected with a water supply pipeline through flow control valves, each water spraying device comprises a nozzle which is inclined downwards, the included angle between each nozzle and the horizontal direction is 3 degrees, and the water spraying direction is tangent to the inner wall of the toilet bowl. By the aid of the water-saving sanitary toilet bowl, blockage is avoided, bacteria cannot be spread, peculiar smell is prevented, and water is saved.

Owner:XINXIANG UNIV

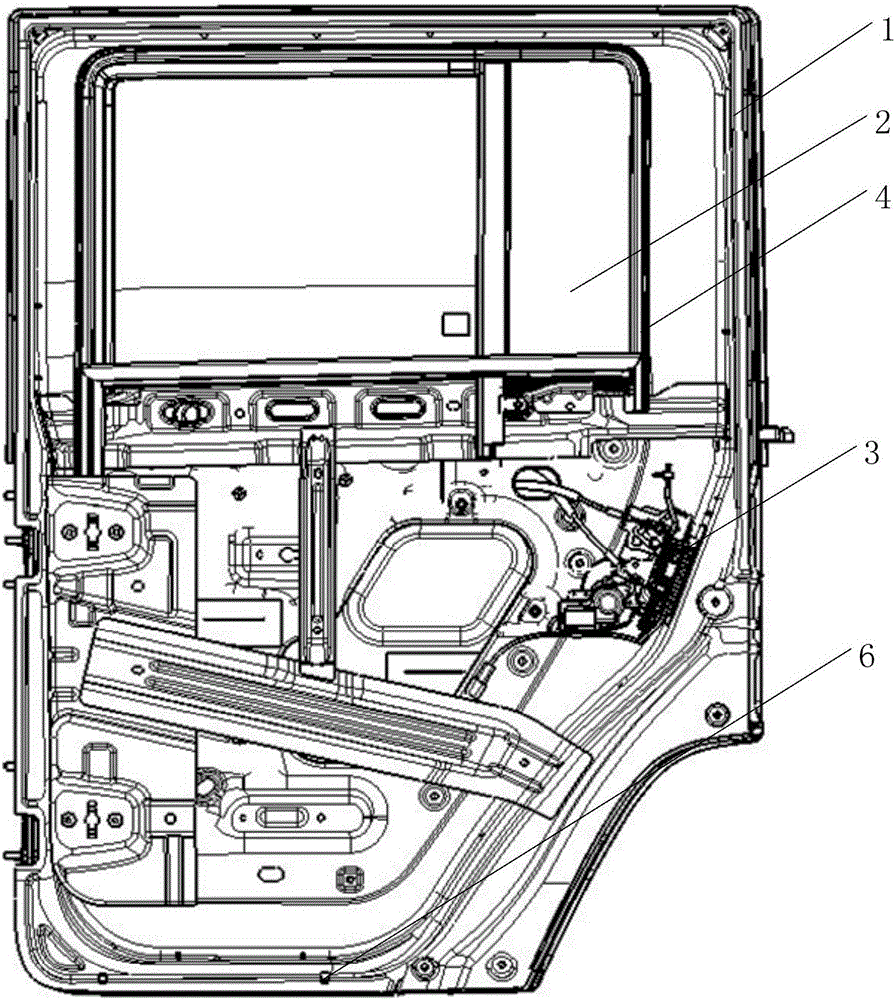

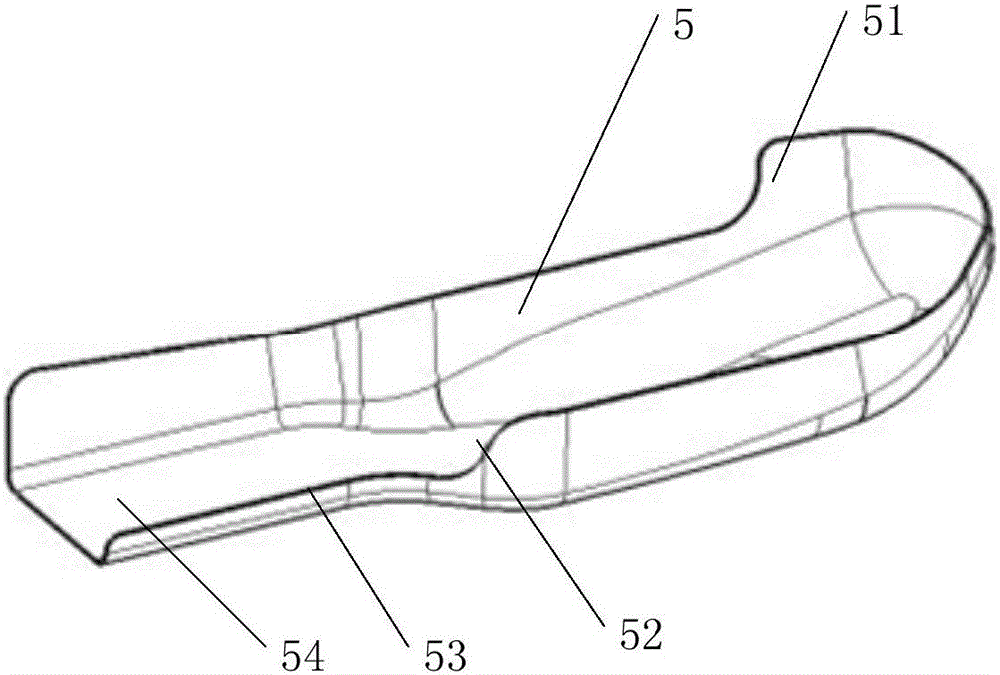

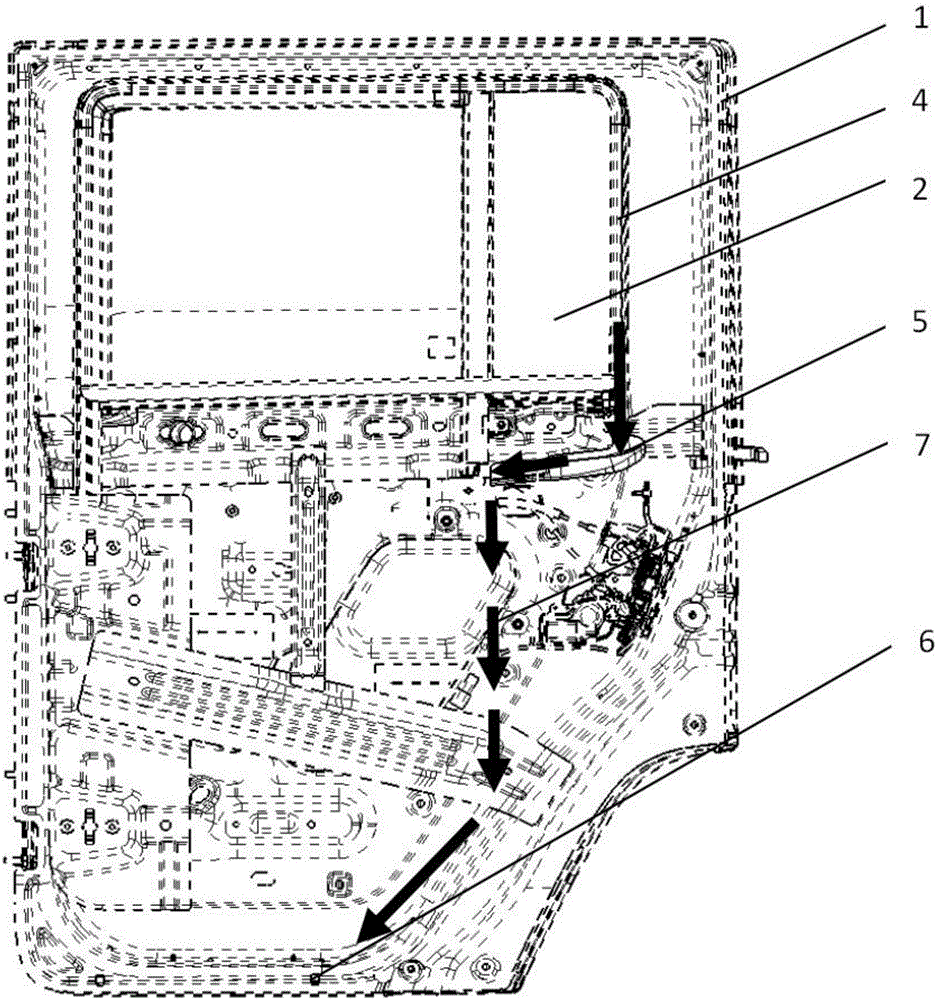

Rear vehicle door with water guiding structure and vehicle

ActiveCN106696661ALow costDischarge in timeEngine sealsVehicle sealing arrangementsWater flowEngineering

The invention provides a rear vehicle door with a water guiding structure and a vehicle. The rear vehicle door with the water guiding structure comprises a rear vehicle door body, rear corner window glass installed on the upper portion of the rear vehicle door body and a door lock installed in the middle of the right side of the rear vehicle body, and a sealing strip is installed between the rear corner window glass and the rear vehicle body; a water guiding groove is formed in the portion, close to the inner side surface, of the rear vehicle body and located below the lower end of the sealing strip and above the door lock of the rear vehicle door body; the water guiding groove is a shell body with openings in the upper portion and the left end; a drain hole for draining water is formed in the bottom of the rear vehicle door body. Through the water guiding groove, the water can be guided to the drain hole in the bottom of the rear vehicle body in time after flowing into the rear vehicle door body; and the water avoids a rear vehicle body lock body through the water guiding groove, so that the rear vehicle body lock body does not need to be provided with a waterproof shell, the design cost of the rear vehicle body lock body is reduced, and the phenomena of corrosion and clamping stagnation in cold weather of the rear vehicle door body lock body because of being stained with water are avoided; and the water guiding groove can be directly formed by pressing and is connected in a point welding mode, so that the machining technique is simplified.

Owner:BAIC GRP ORV CO LTD

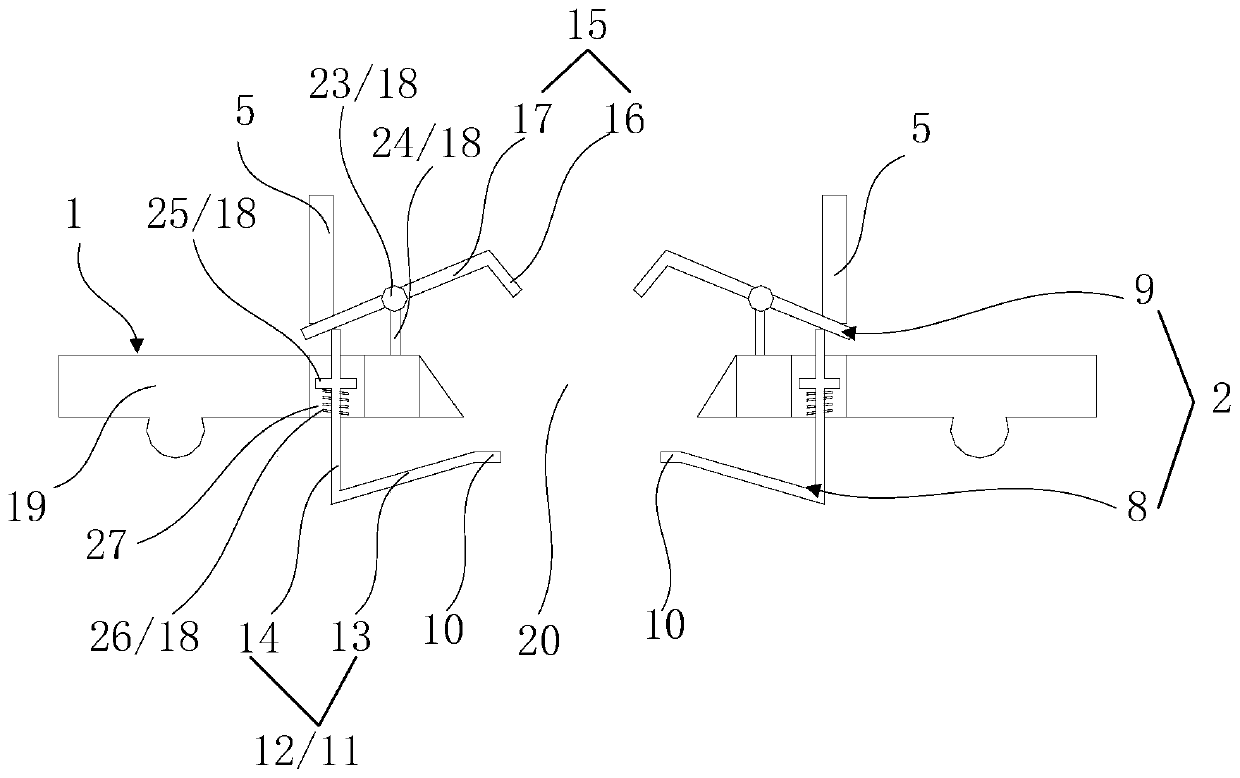

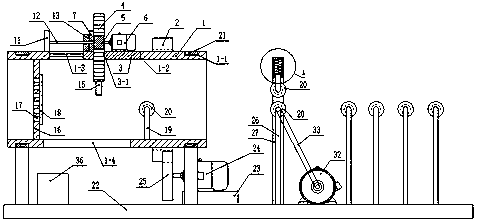

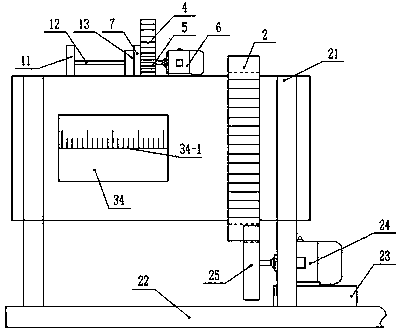

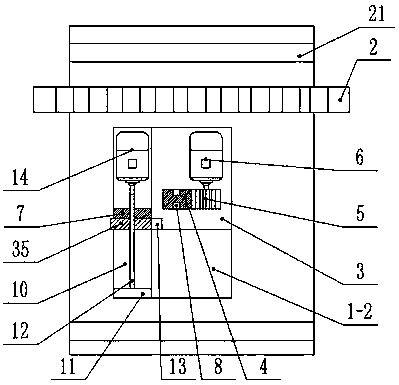

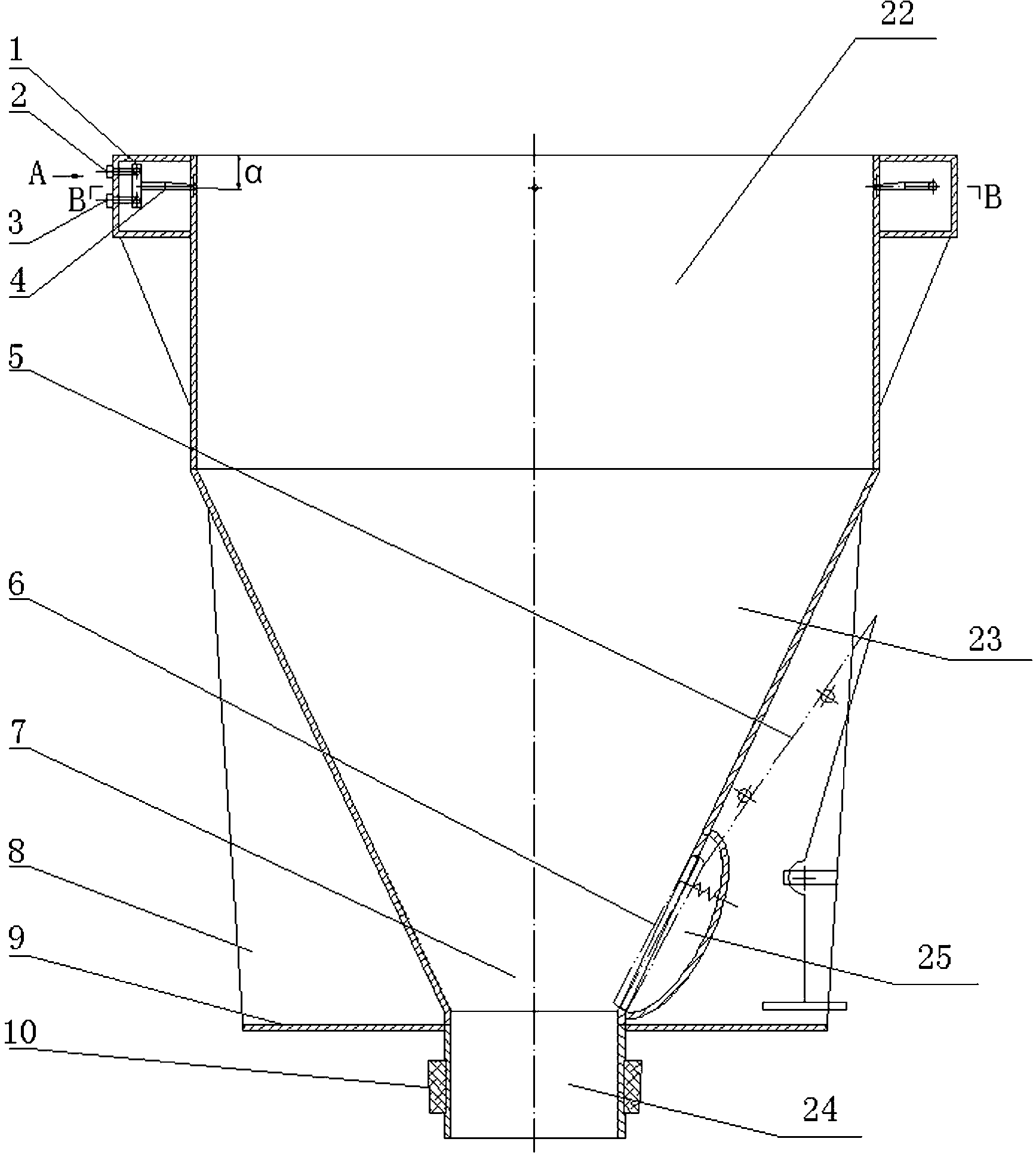

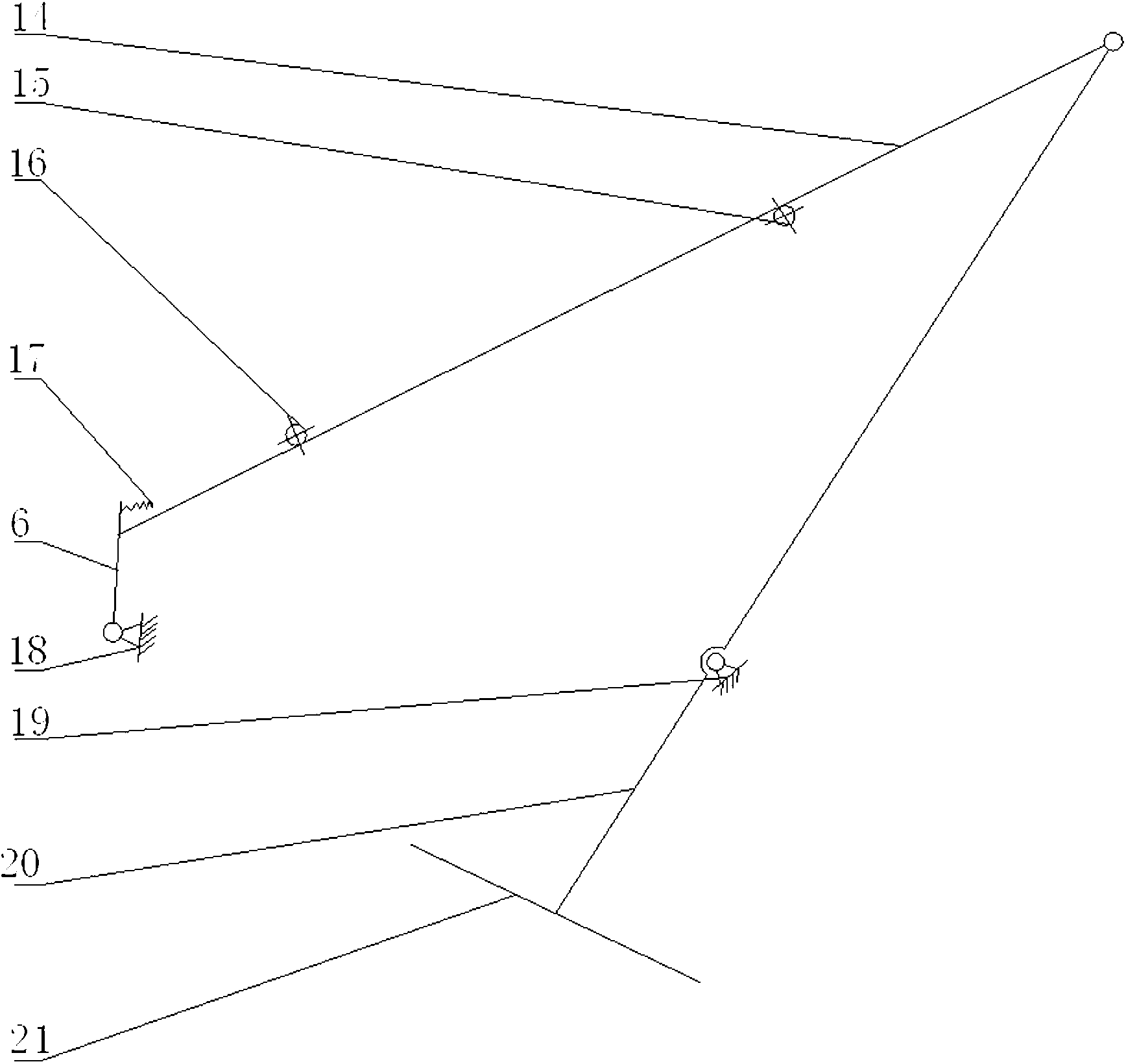

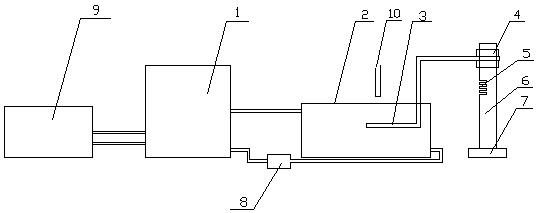

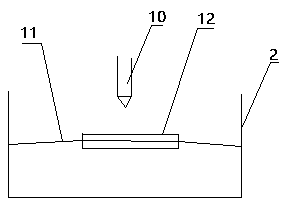

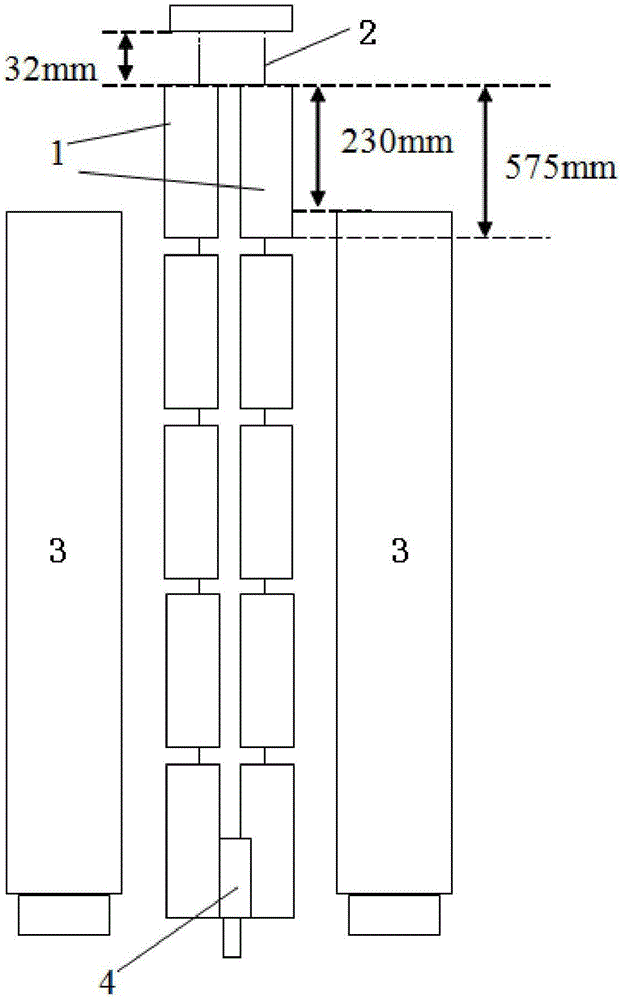

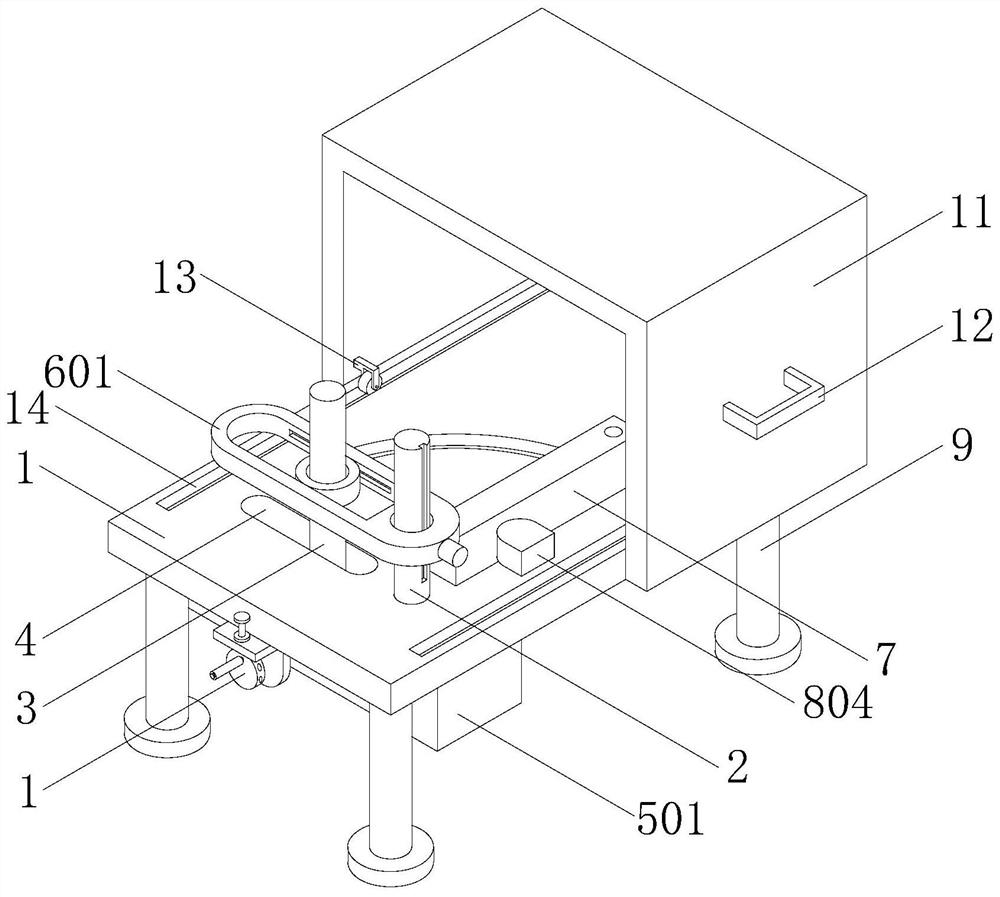

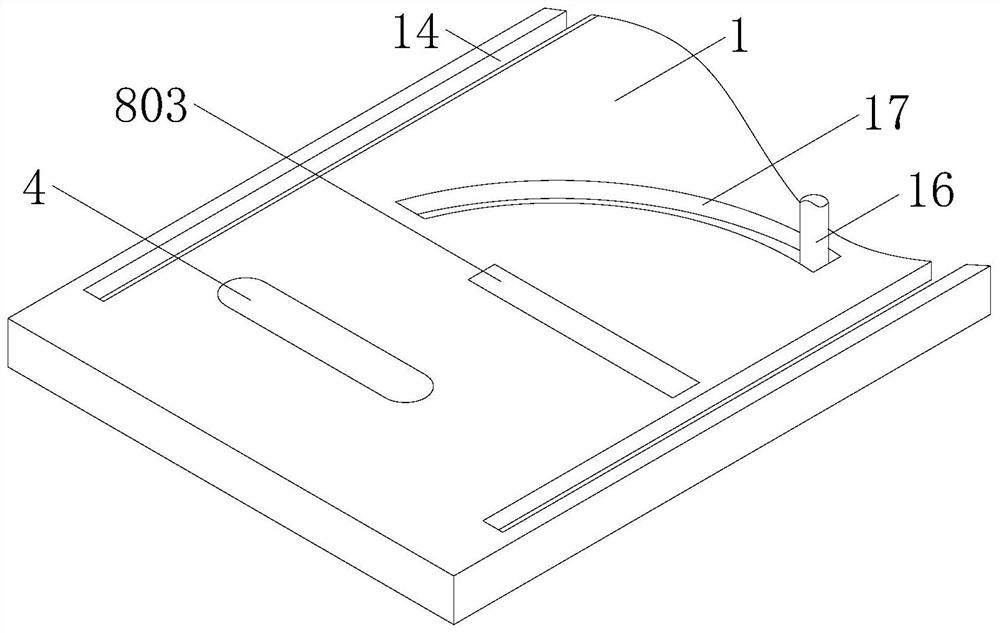

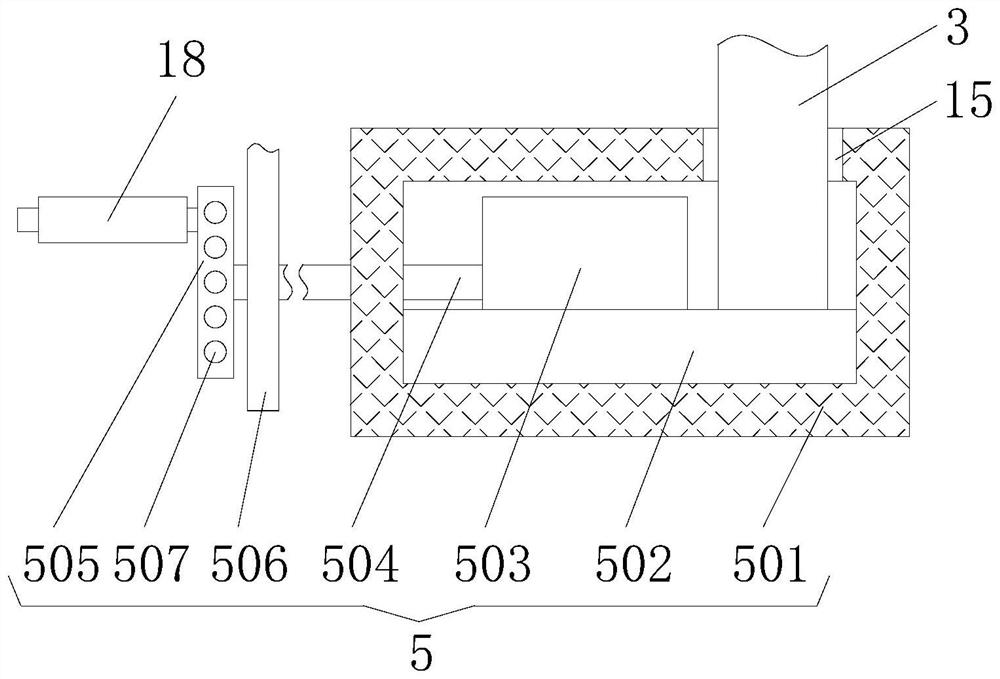

Semi-submersible type laser cutting method for high-speed aircraft empennage

InactiveCN109940287AImprove cutting efficiencyImprove processing efficiencyLaser beam welding apparatusHeat-affected zoneLight beam

The invention provides a semi-submersible type laser cutting method for a high-speed aircraft empennage. The semi-submersible type laser cutting method for the high-speed aircraft empennage comprisesthe following steps that an empennage sample piece 12 is put into a fixture 3 and fixed and clamped; a working solution is added into a liquid groove 2, the lower surface of the empennage sample piece12 is immersed by the working solution, but the working solution does not exceed the upper surface of the empennage sample piece 12, and the specific immersing height is adjusted through the fixture;a cooling-water machine 1 is turned on, the temperature and the flowing speed are set, and by means of a filter 8, the constant temperature and the constant flowing speed of the working solution arekept among the liquid groove 2, the cooling-water machine 1 and a working solution storage tank 9; and according to the size of the empennage sample piece 12 and requirements, laser machining parameters are input, and a laser head 10 begins to carry out machining. According to the semi-submersible type laser cutting method, a high-power pulse laser is used for carrying out machining, the machiningefficiency is greatly improved, the empennage sample piece is semi-immersed in the working solution, the situation that laser beams direct beat the surface of the working solution, a sputtering phenomenon occurs, and unnecessary energy losses are caused cannot occur, meanwhile, the working solution flows on the lower part, cutting residues are brought away, a cutting face heat affected zone is also reduced, and high-precision, high-efficiency, low-cost and large-batch machining can be achieved.

Owner:SHANDONG UNIV OF TECH +1

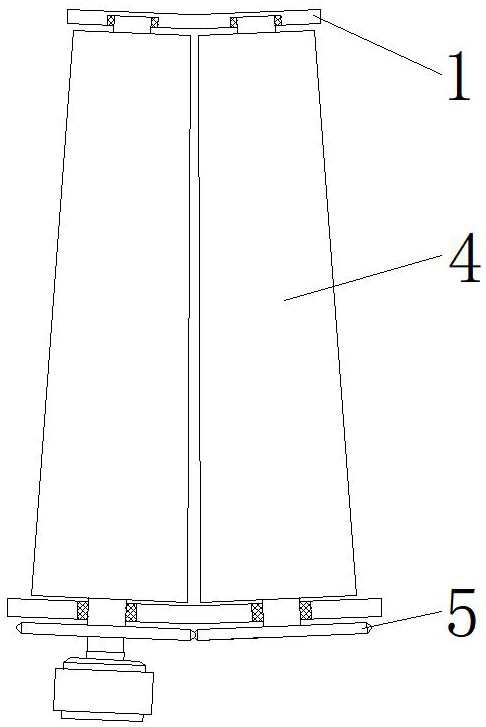

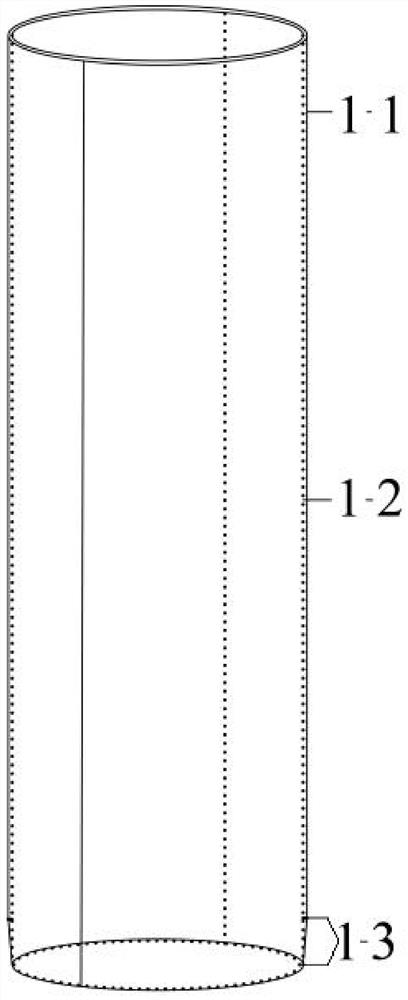

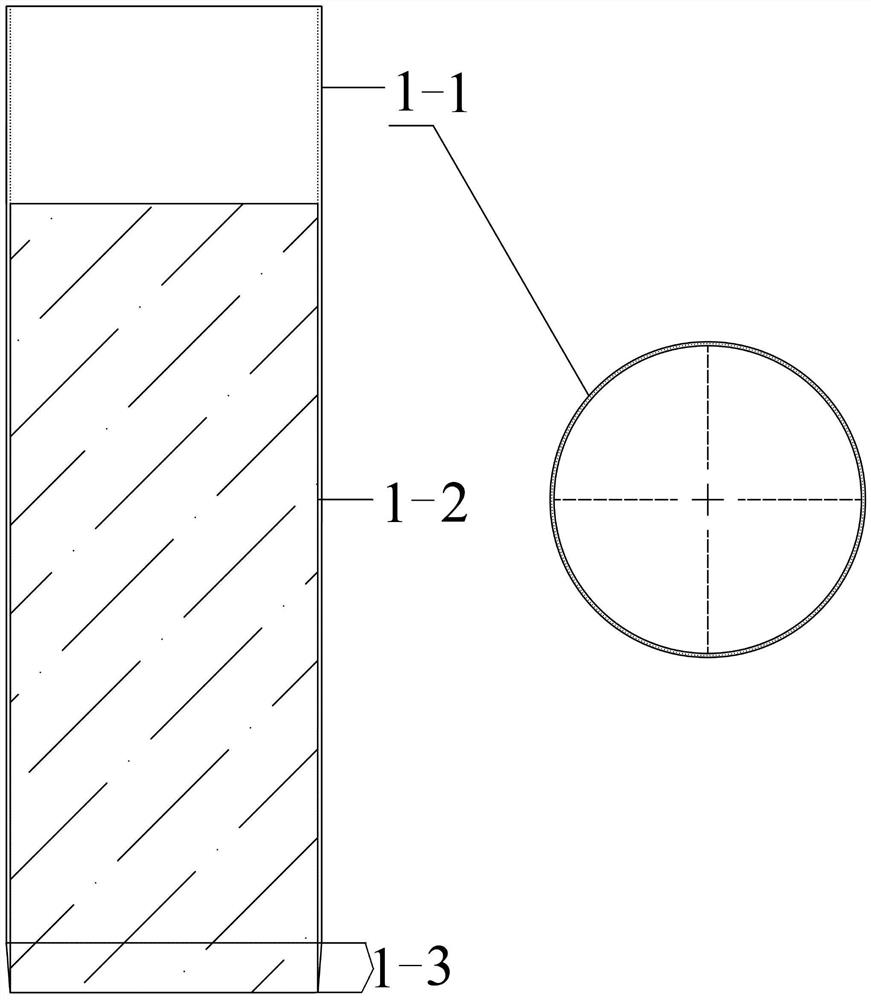

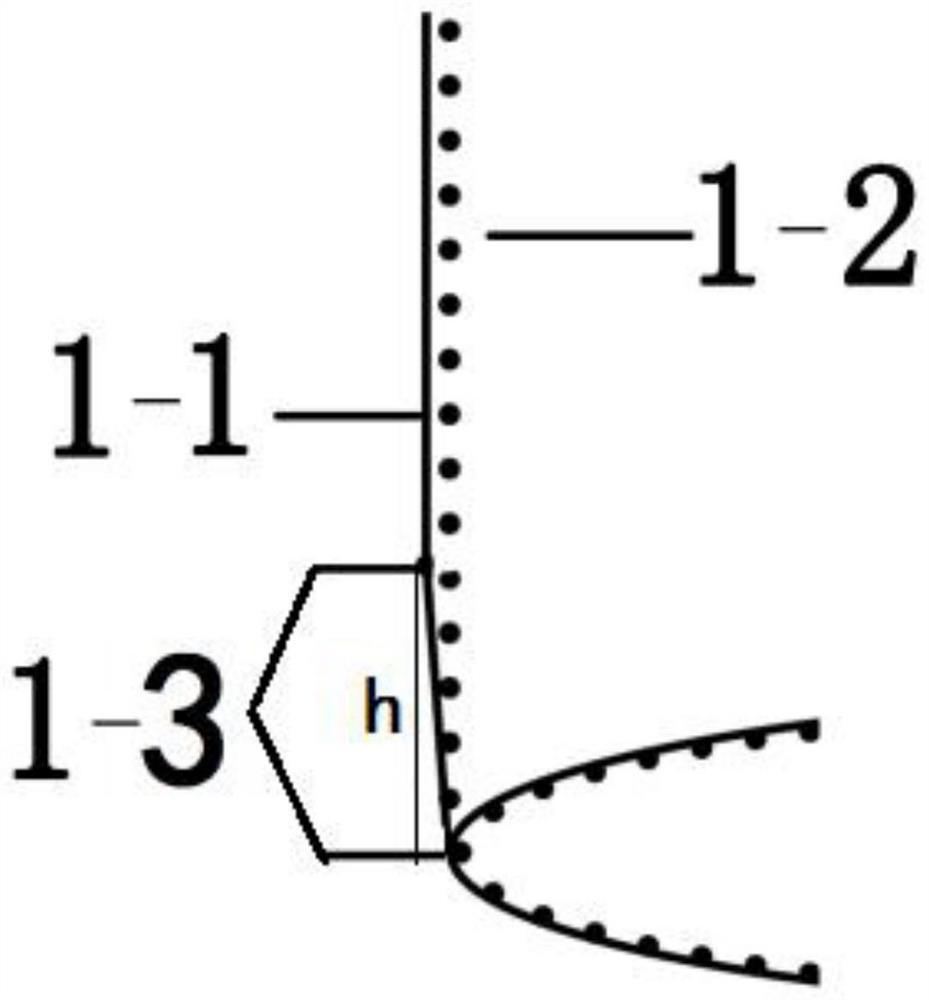

Sampling device and leaching device for nitrogen migration and transformation, sampling method and method for researching nitrogen migration and transformation

PendingCN114002007AGuarantee structureImprove accuracyWithdrawing sample devicesPreparing sample for investigationSoil scienceStraight tube

The invention belongs to the technical field of soil science, and particularly relates to a sampling device and leaching device for nitrogen migration and transformation, a sampling method and a method for researching nitrogen migration and transformation. The sampling device provided by the invention comprises a sampler (1); the sampler (1) is in the shape of a cylindrical straight tube, the top of the sampler is flat, a knife edge inclined plane is designed at the bottom of the sampler, and the width of the inclined plane is 10-15mm. The sampler (1) is in the shape of a cylindrical straight tube, the shape of soil is directly fixed, a soil sample is not disturbed during sampling, undisturbed soil column soil which is as close as possible under field natural conditions is obtained, the natural water content and structure of the soil are kept, and various physicochemical indexes and biological indexes of the sampled soil are not affected.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

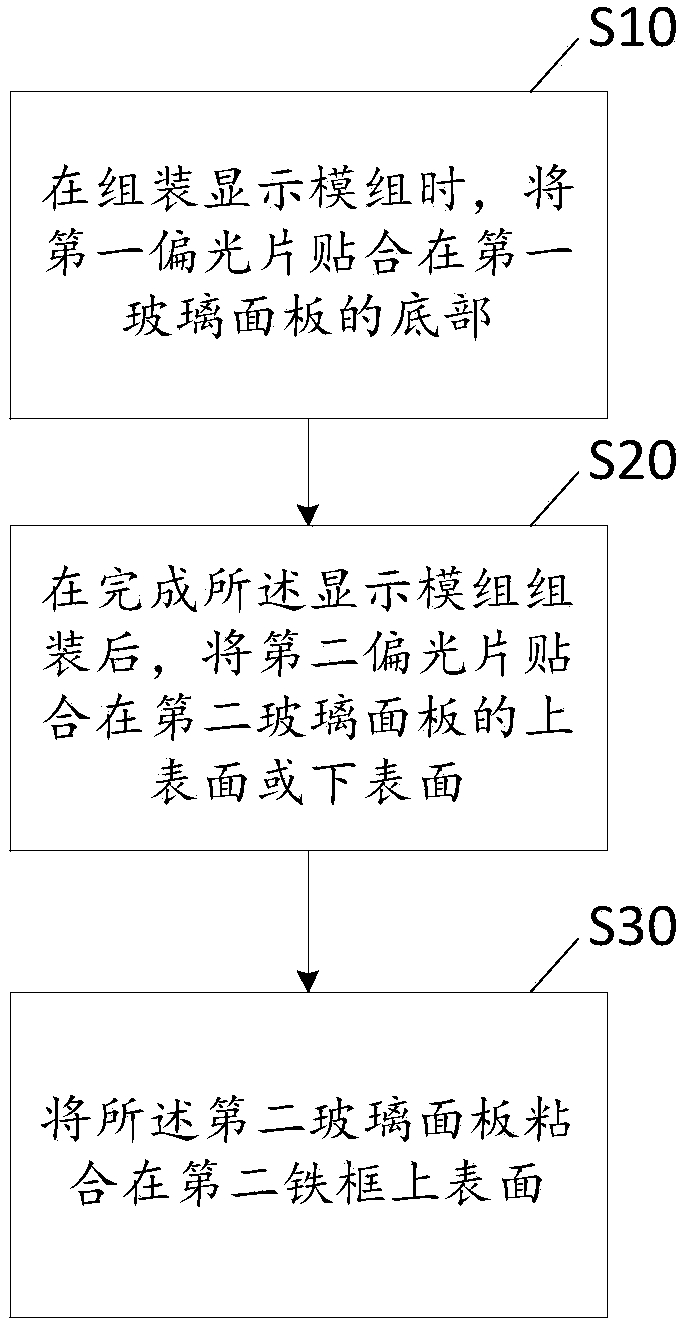

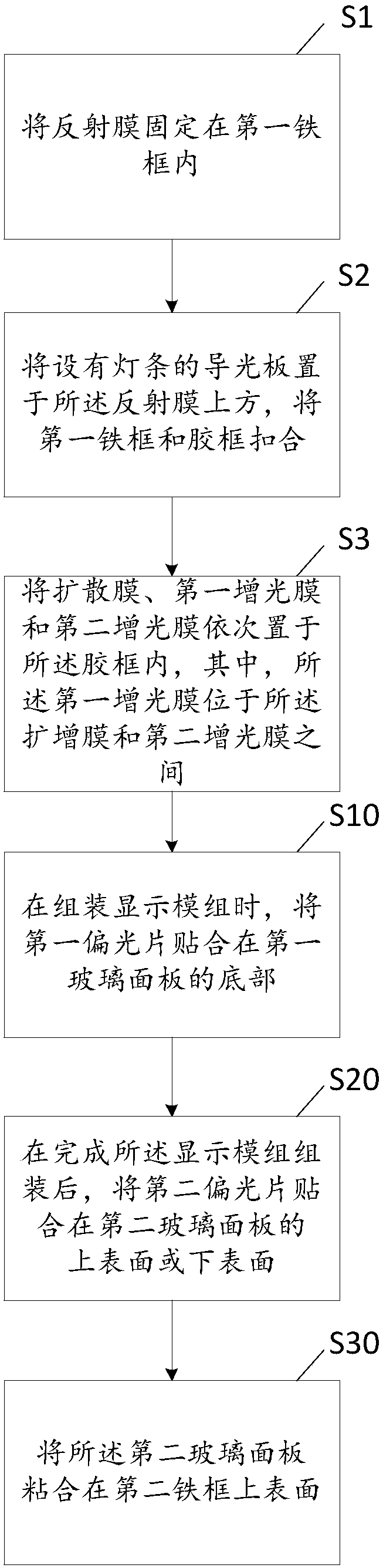

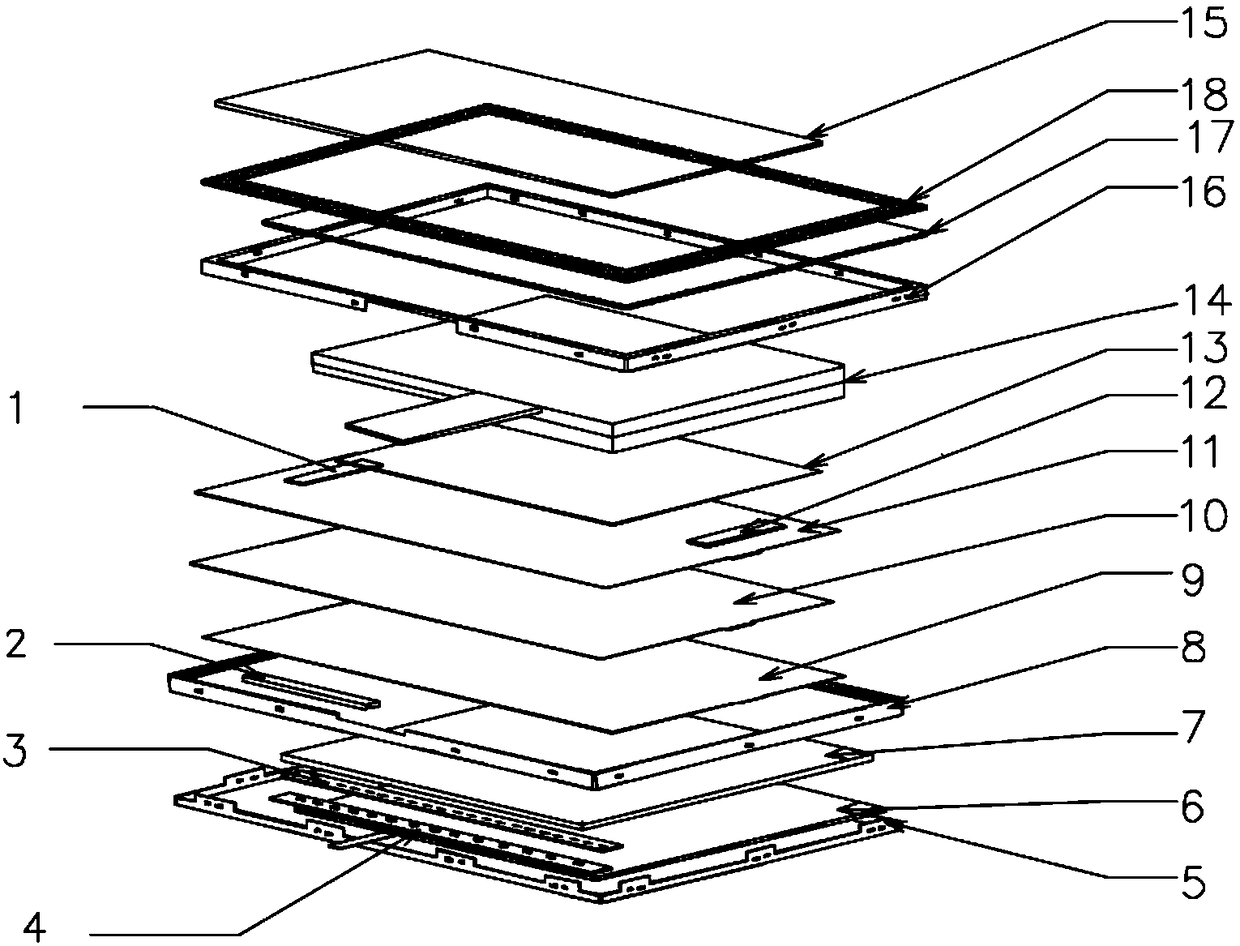

LCD module making method

InactiveCN108319053AHigh control precisionFast productionGlass/slag layered productsNon-linear opticsEngineeringForeign matter

Owner:SHENZHEN ZHONGSHEN OPTOELECTRONICS

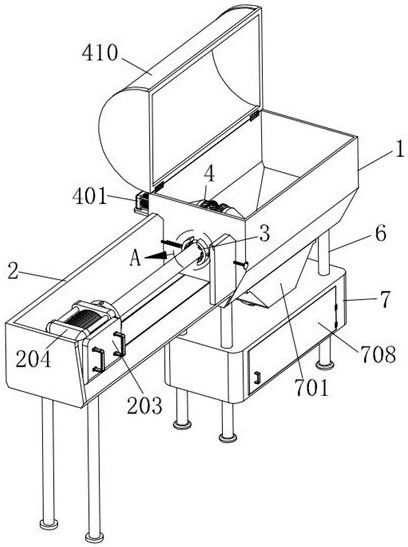

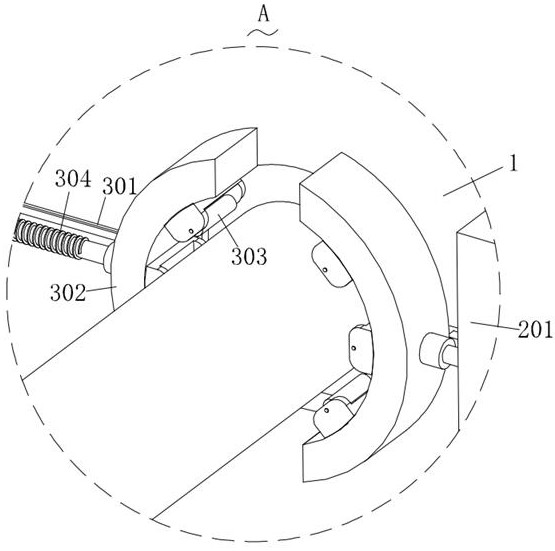

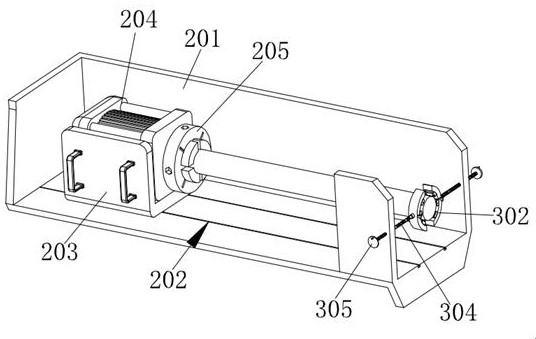

Polishing device for building engineering machine part maintenance

ActiveCN113561029AImprove sanding qualityAvoid the phenomenon of eccentric swingGrinding drivesGrinding machinesSteel tubeScrap

The invention relates to the technical field of polishing devices, in particular to a polishing device for building engineering machinery part maintenance, which comprises a box body, a pushing structure is mounted at one end of the box body, a correcting structure is mounted at one end of the box body, a polishing structure is mounted in the box body, and a height adjusting structure is mounted on one side of the box body; supporting columns are fixedly connected to the bottom end of the box body, a powdered scrap collecting structure is installed at the bottom end of the box body, and the polishing structure comprises a rotating shaft; the surface of a polished round steel pipe fitting can be cleaned through brushes, and meanwhile, the polishing height of a grinding wheel can be adjusted through the height adjusting structure; the phenomenon of eccentric swinging of the other end of the round steel pipe fitting in the rotating process can be prevented through the correcting structure, so that the polishing quality of the round steel pipe fitting is improved; and metal substances in the dust can be separated from common dust through magnetic suction plates.

Owner:江苏淮海新材料科技有限公司

Thin film battery cleaning device

ActiveCN111618012ASave time at workGood cleanlinessDrying gas arrangementsCleaning using toolsLiquid storage tankElectrical and Electronics engineering

The invention relates to the technical field of cleaning devices and discloses a thin film battery cleaning device. The thin film battery cleaning device comprises a cleaning box. The two ends of thecleaning box are provided with feeding rollers and discharging rollers. A dirty water tank and a liquid storage tank are arranged in the cleaning box. The bottom face of the dirty water tank and the bottom face of the liquid storage tank are fixedly connected with the bottom face in the cleaning box. Fixed cleaning plates and movable cleaning plates are horizontally arranged in the cleaning box and are staggered. The front end and the back end of each fixed cleaning plate are fixedly connected with the contact positions of the inner wall of the cleaning box. The bottom faces of the fixed cleaning plates are fixedly connected with the top face of a liquid passing plate. The thin film battery cleaning device accelerates the continuous updating rate of the contact interface between cleaning liquid and a thin film battery in the cleaning process, continuously and efficiently cleans and removes matter insoluble with the surface of the thin film battery, promotes and enhances the thin film battery cleaning effect, improves the cleaning efficiency of the thin film battery, shortens the cleaning travel of the thin film battery, lowers equipment configuration cost and production and operation cost, saves energy and lowers consumption.

Owner:昆山倩超亮光伏科技有限公司

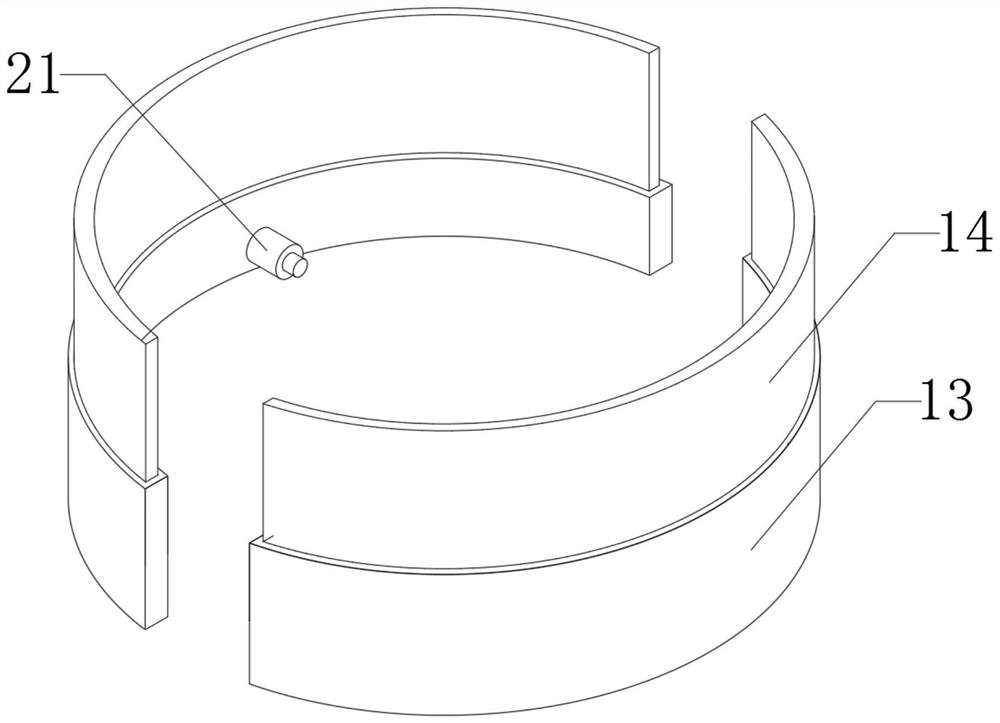

Anode stabilizing device of IGZO film formation equipment

ActiveCN106637103AExtended service lifeUniform electric fieldVacuum evaporation coatingSputtering coatingHeat effectElectric field

The invention discloses an anode stabilizing device of IGZO film formation equipment. The anode stabilizing device comprises isolation assemblies arranged on the periphery of an anode. The isolation assemblies are provided with channels allowing electrons to be guided out of the anode. The isolation assemblies are additionally arranged on the periphery of the IGZO film formation anode and can effectively prevent target material molecules from sputtering to the anode, and therefore the high potential is kept on the surface of the anode, the electrons can be guided out effectively and fast, the whole space electron distribution is more uniform, the heat effect brought by electron concentration is reduced, the service life of the anode is prolonged, the anode is kept stable, and the equipment activation rate is increased; meanwhile, the bottom of the anode is all covered with the isolation assemblies, and therefore the electrons can be prevented from being concentrated at the bottom; and in addition, the anode avoids IGZO insulation film deposition through the isolation assemblies, electric fields of the whole anode are uniform, the problem that due to thin film layers at the upper end and the lower end, the electric field in the middle is weak, and the electric fields at the two ends are strong cannot be caused, and the film formation rate is stable.

Owner:NANJING CEC PANDA LCD TECH

A clamping device and sputtering equipment used in sputtering equipment

ActiveCN110172667BImprove fitAvoiding the Problem of Filming ShadowsVacuum evaporation coatingSputtering coatingSputteringEngineering

The present application discloses a clamping device used in sputtering equipment and sputtering equipment. The clamping device includes: a clamp for clamping a substrate and a mask correspondingly; a driving device connected with the clamp for driving The clamp is clamped or loosened; wherein, an opening matching the shape and size of the opening of the mask is provided on the clamp, so that after the clamp clamps the mask and the substrate, the side of the clamp close to the mask is on the substrate The orthographic projection on the mask completely covers the orthographic projection of the mask on the substrate, and the opening of the fixture is in alignment with the opening of the mask, exposing the sputtering area of the substrate for the sputtering equipment to perform sputtering on the sputtering area of the substrate. Sputtering. This application can prevent the mask plate from being covered by the sputtered film layer during the sputtering film formation process of the substrate, thereby avoiding the warping deformation of the mask plate, falling off of the sputtered film layer on the mask plate and polluting the sputtering chamber and There is a shadow problem in substrate film formation.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Bending device for accessories for engineering machinery cab and using method

PendingCN113546999AEasy to moveImprove stabilityMetal-working feeding devicesShaping safety devicesStructural engineeringMachining

The invention belongs to the technical field of vehicle accessory machining, and particularly relates to a bending device for accessories for an engineering machinery cab and a using method. The device comprises a table top, a fixing column and a moving column are arranged on the front side and the rear side of the left side of the top of the table top correspondingly, an opening used in cooperation with the moving column is formed in the left side of the top of the table top, an adjusting mechanism used in cooperation with the moving column is arranged on the left side of the bottom of the table top, a positioning mechanism is arranged between the surface of the fixing column and the surface of the movable column, the bending device solves the problems that most of existing bending devices for the accessories for the engineering machinery cab adopt manual bending treatment, protection is lacked in the bending treatment of the accessories, damaged accessories are prone to being damaged in the bending process, the accessories are splashed, potential safety hazards are brought to life safety of a user, the manual bending is needed in the treatment process, the efficiency is low, and time is wasted.

Owner:扬州市扬子钣金制造有限公司

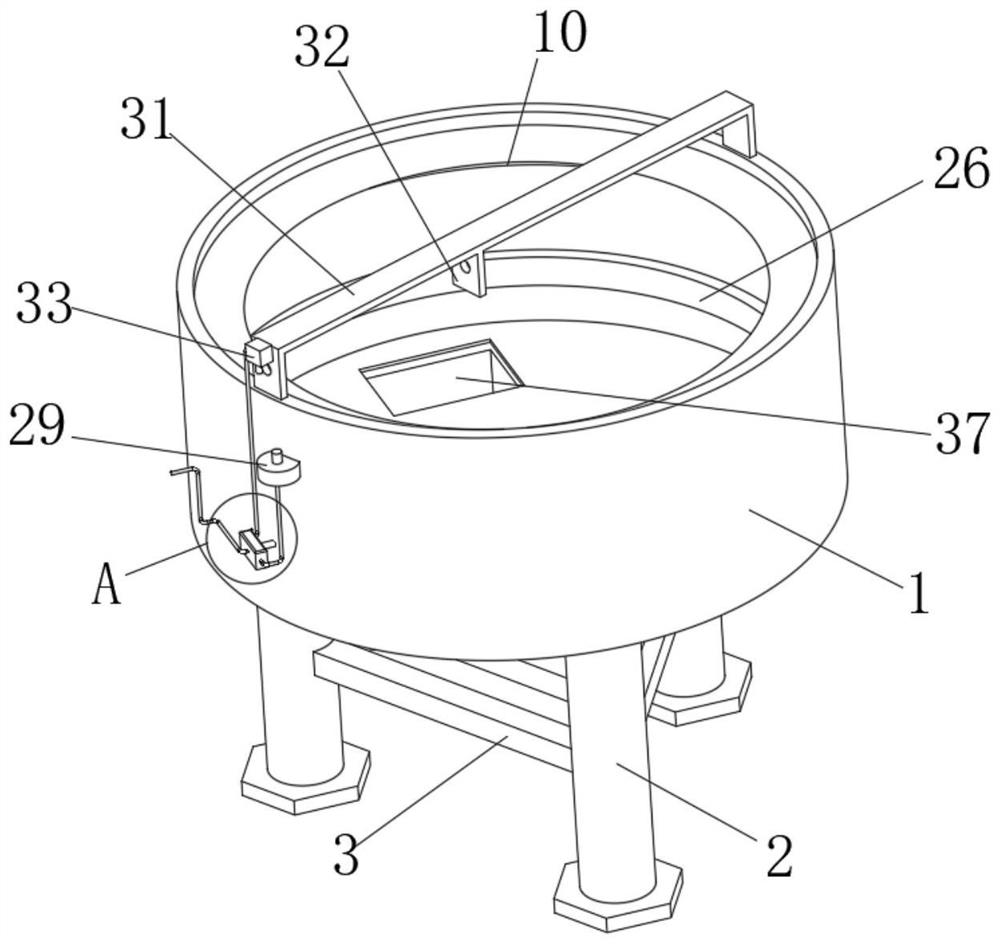

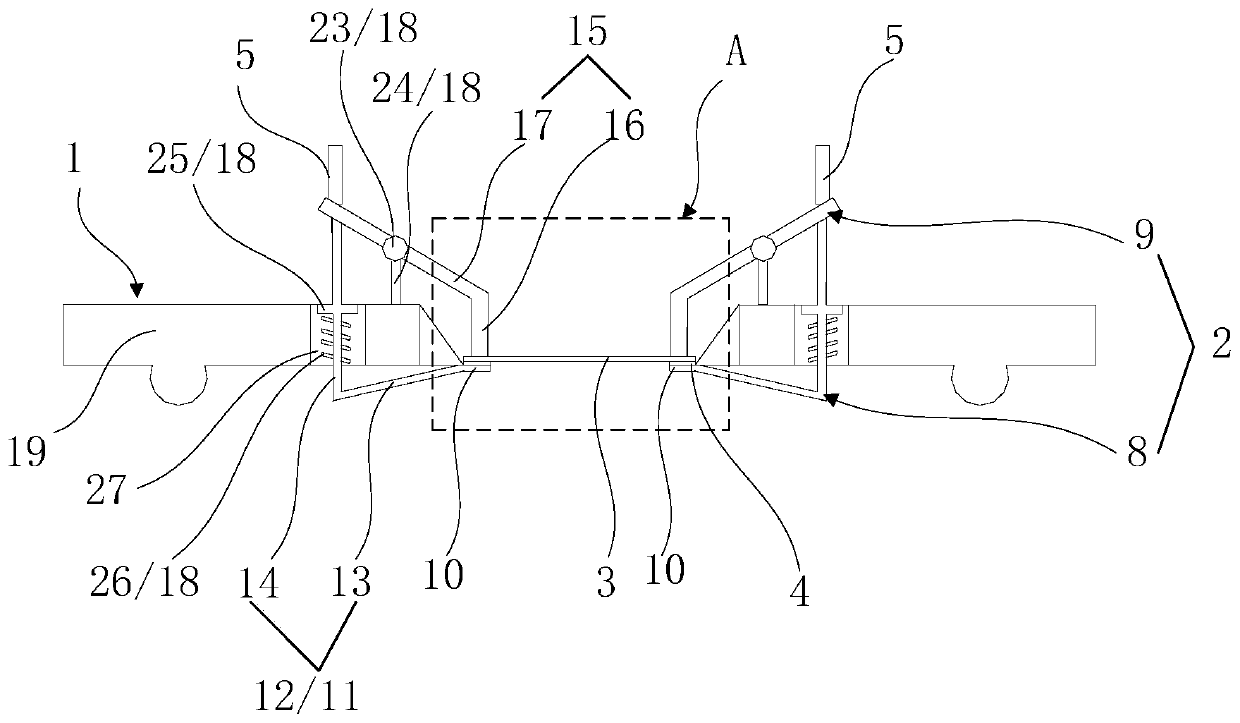

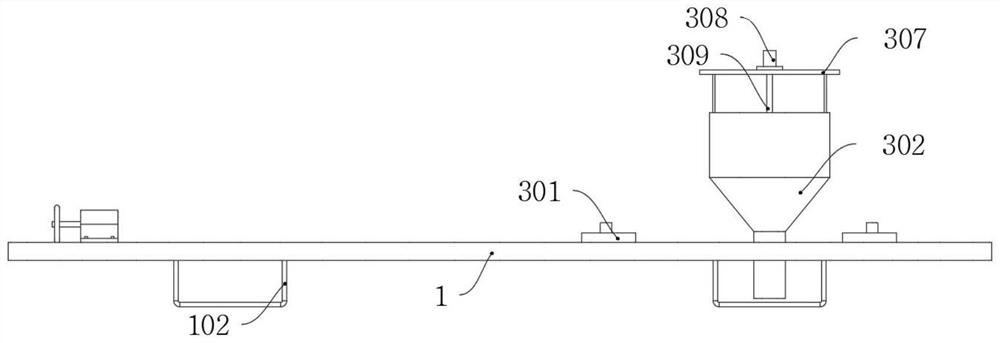

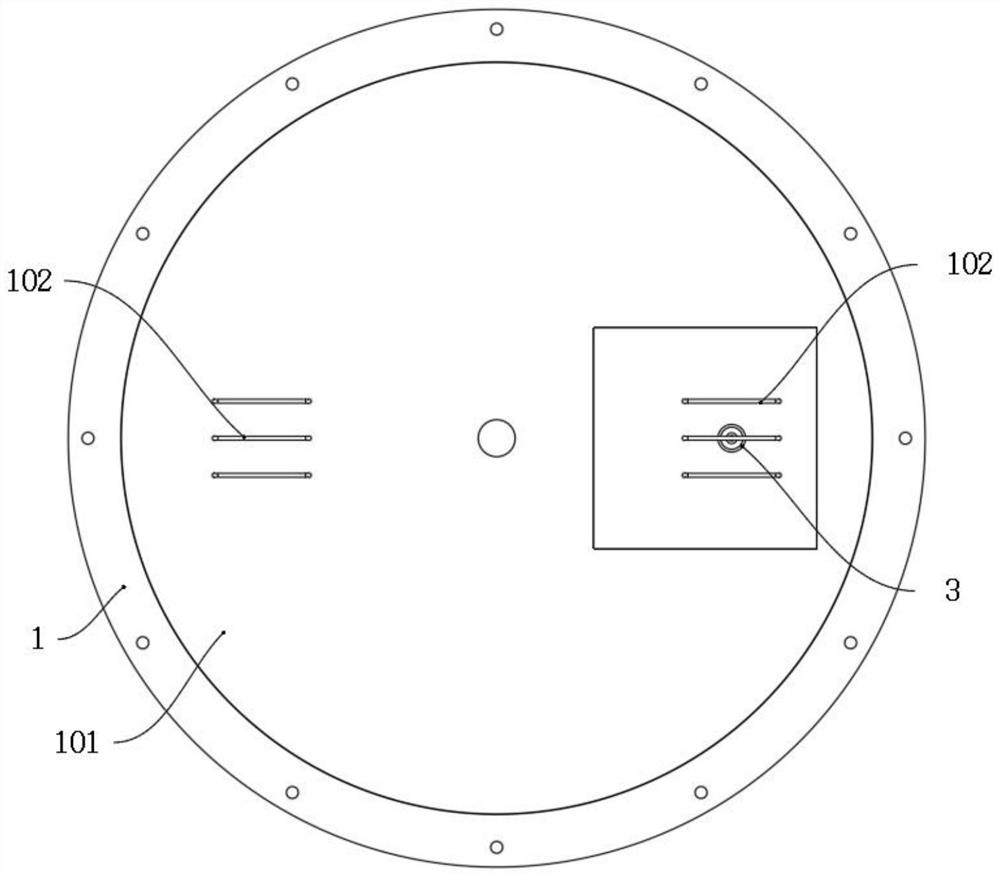

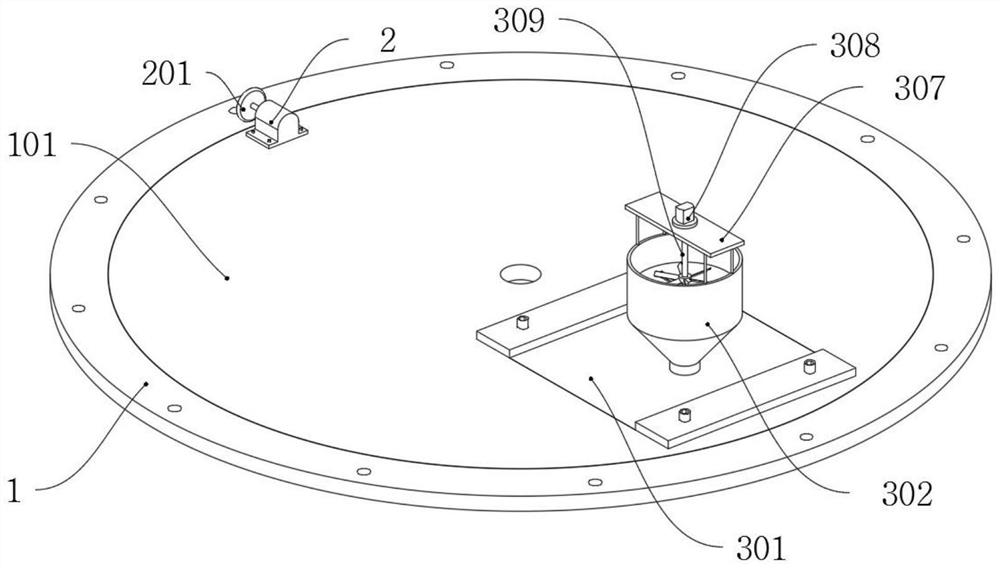

Fermentation auxiliary feeding device based on probiotics

InactiveCN114517146AEnsure comprehensivenessAchieve premixBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyProbiotic bacteria

The invention provides a probiotic-based fermentation auxiliary feeding device, and relates to the technical field of feeding devices, the probiotic-based fermentation auxiliary feeding device comprises a cover plate, a driving motor A and a feeding part; the cover plate is fixedly connected to a probiotic fermentation barrel through bolts, and an auxiliary plate is rotationally connected to the cover plate; and the driving motor A is fixedly connected to the auxiliary plate through a bolt. The three auxiliary seats are welded to the left side of the bottom end face of the auxiliary plate in the linear array shape, the three auxiliary seats are also welded to the right side of the bottom end face of the auxiliary plate in the linear array shape, and the six auxiliary seats jointly form a supporting and protecting structure of the cover plate. Therefore, the cover plate can be prevented from being in contact and collided with hard objects on the ground when being placed, so that the edge of the cover plate is prevented from being deformed to influence the sealing with the fermentation barrel, and the problems that raw materials and additives are easy to adhere to the feeding hopper during feeding and incomplete feeding is caused are solved; and raw materials adhered to the feeding hopper cannot be automatically shaken off in the feeding process.

Owner:蒋钊

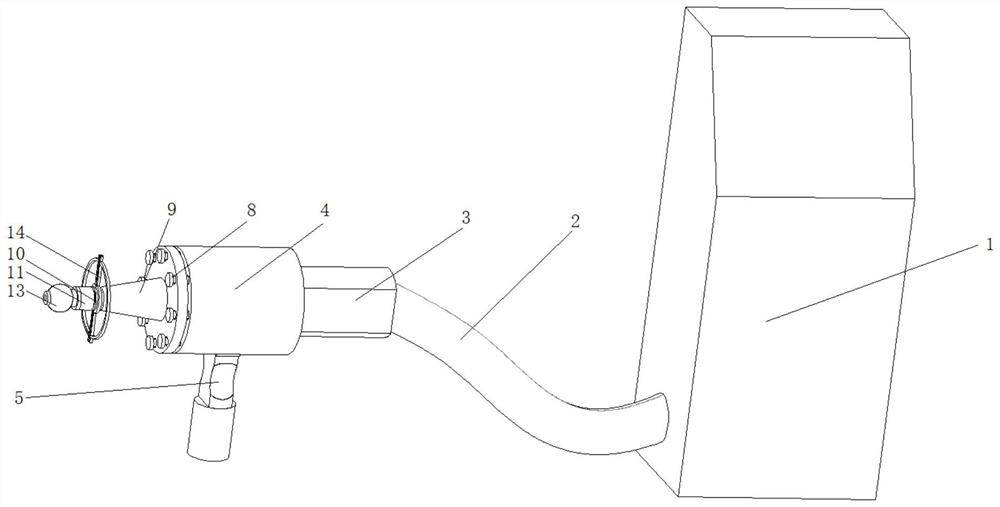

Handheld laser welding machine

InactiveCN112404717ABlock sputteringHarm Reducing PhenomenonLaser beam welding apparatusSputteringHand held

The invention relates to the technical field of laser welding machines, and discloses a handheld laser welding machine. The handheld laser welding machine comprises a welding body, a welding connecting pipeline is fixedly connected to one side of the welding body, a tail connecting plate is fixedly connected to one side of the welding connecting pipeline, and a handheld welding machine body is fixedly connected to one side of the tail connecting plate. According to the handheld laser welding machine, the outer portion of a device connector is movably connected with lens frames in a sleeved manner, the two lens frames are spliced into a circle to be connected to the connector in a clamped manner, meanwhile, during use, the function of facilitating device moving can be achieved through device hinges, and meanwhile, on the other side, through buckle rotating, the lens frames at the two ends are in clamped connection and fixed; and meanwhile, during use, sparks are protected through dark glasses, the function of reducing the brightness is achieved, meanwhile, the function of protecting the sparks is achieved, the phenomenon of spark sputtering is avoided, and therefore during use, disassembly is convenient, and the phenomenon that the sparks injure eyes is reduced.

Owner:大篆(广州)科技有限公司

Thin film battery cleaning device

InactiveCN111618012BSave time at workImprove cleanlinessDrying gas arrangementsCleaning using toolsMechanical engineeringBattery cell

The invention relates to the technical field of equipment, and discloses a thin-film battery cleaning device, which includes a cleaning box, feeding rollers and discharging rollers are arranged at both ends of the cleaning box, a sewage tank and a liquid storage tank are arranged inside the cleaning box, and the bottom surface of the sewage tank is It is fixedly connected with the bottom surface of the liquid storage tank and the inner bottom surface of the cleaning box. The inside of the cleaning box is horizontally equipped with a fixed cleaning plate and a movable cleaning plate. The fixed cleaning plate and the moving cleaning plate are arranged in a staggered manner. Fixed connection, the bottom surface of the fixed cleaning plate is fixedly connected with the top surface of the liquid passing plate. The thin-film battery cleaning device accelerates the continuous renewal rate of the contact interface between the cleaning liquid and the thin-film battery during the cleaning process of the thin-film battery, continuously and efficiently cleans and strips the incompatible substances on the surface of the thin-film battery, promotes the enhancement of the cleaning effect of the thin-film battery, and improves the performance of the thin-film battery. Cleaning efficiency, shorten the cleaning process of thin-film batteries, reduce equipment configuration and production and operation costs, save energy and reduce consumption.

Owner:昆山倩超亮光伏科技有限公司

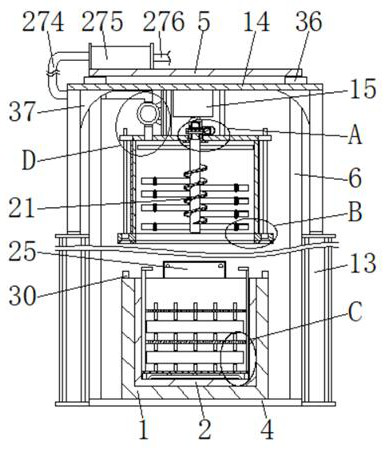

Isothermal quenching system and quenching process based on metal heat treatment

The invention discloses an isothermal quenching system and quenching process based on metal heat treatment. The isothermal quenching system comprises a shell, wherein a crucible is fixedly connected to the interior of the shell, a heating electrode is fixedly connected to the bottom of the inner wall of the crucible, and a bottom plate is fixedly connected to the bottom of the shell. According to the isothermal quenching system and quenching process, a metal blank is supported by a filtering disc through a supporting disc and a metal slender rod, then an electric cylinder drives a protection mechanism to protect the crucible through a base plate and a transmission box, and finally the transmission mechanism drives salt solution and fixing plates to rotate through a rotating rod and stirring blades, so that the temperature uniformity of the salt solution is improved; and meanwhile, the metal blank can make effective contact with the salt solution, so that the quneching system has the advantages of supporting and precipitation prevention, and solves the problems that because an existing isothermal quenching system does not have a certain supporting and precipitation prevention function, cannot stir the salt solution and cannot support and push the metal blank simultaneously, the metal blank cannot fully contact with the salt solution, and the processing efficiency is low.

Owner:李求福

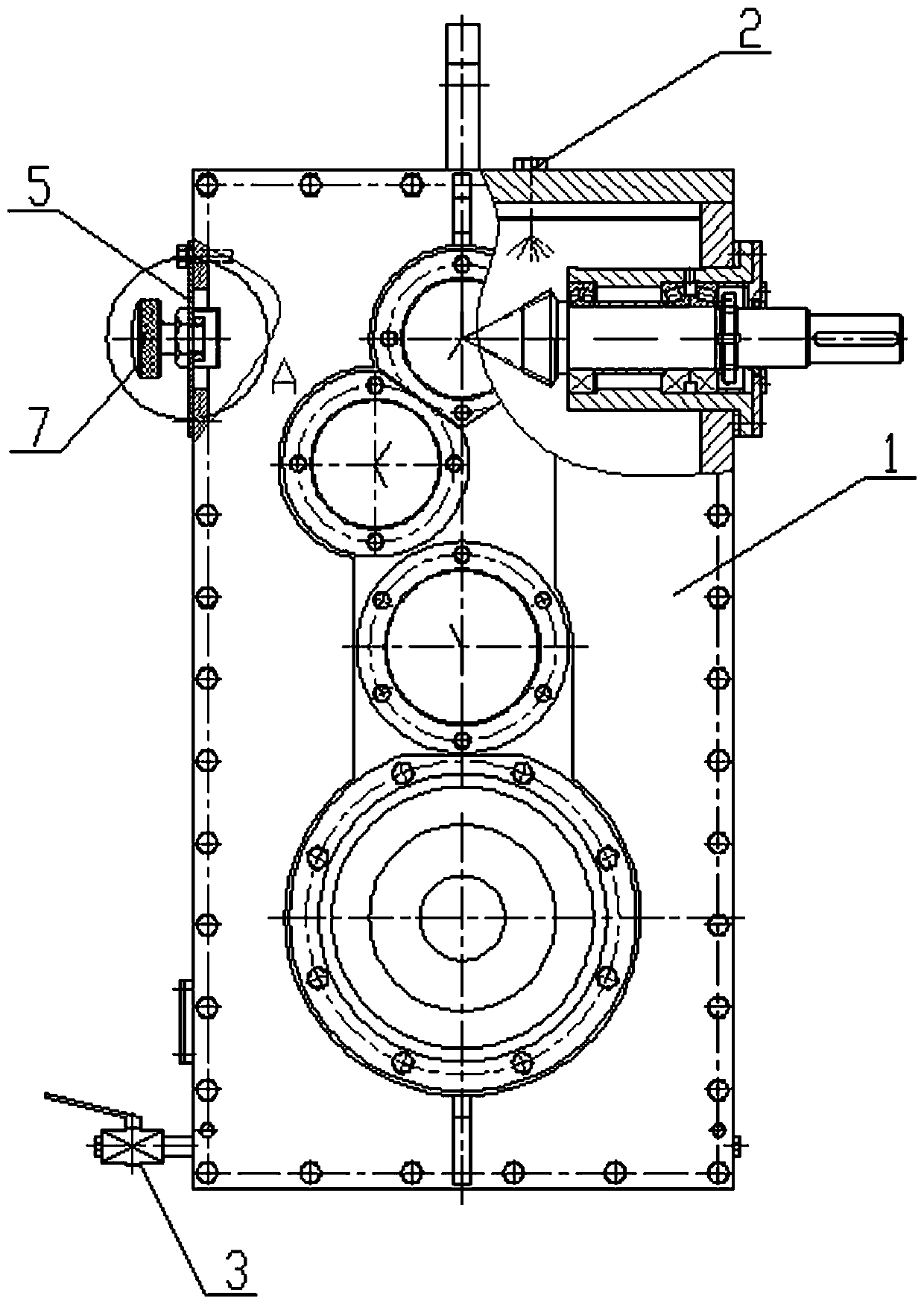

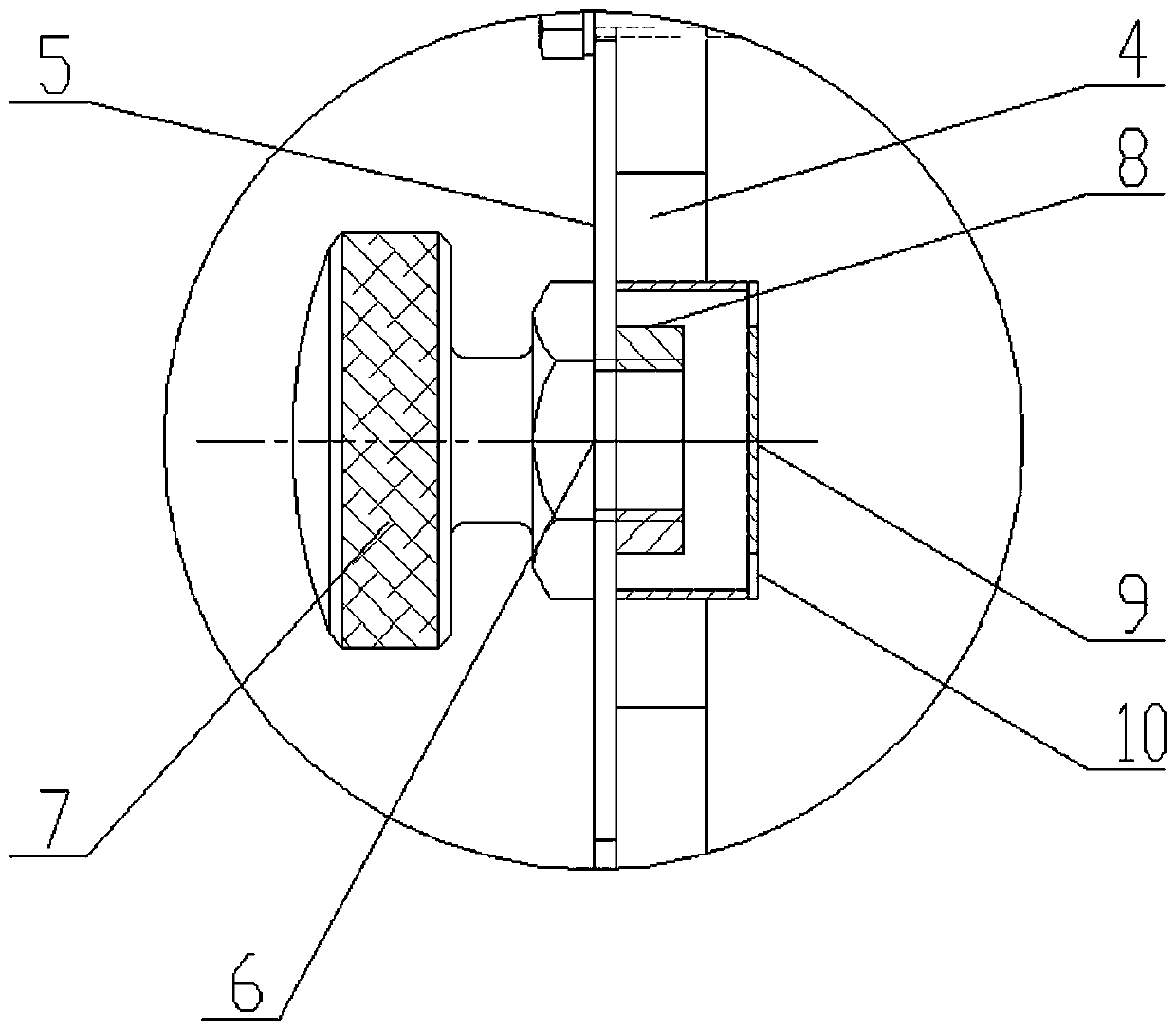

Metallurgy speed reducer

InactiveCN110762191ASimple processingReduce production costGear lubrication/coolingPhysicsLubrication

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com