Industrial mechanical steel pipe positioning and welding device

A technology of positioning welding and industrial machinery, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of cumbersome operation, prone to shaking, uneven welding joints of steel pipes, etc., to avoid sputtering phenomenon, improve the application A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

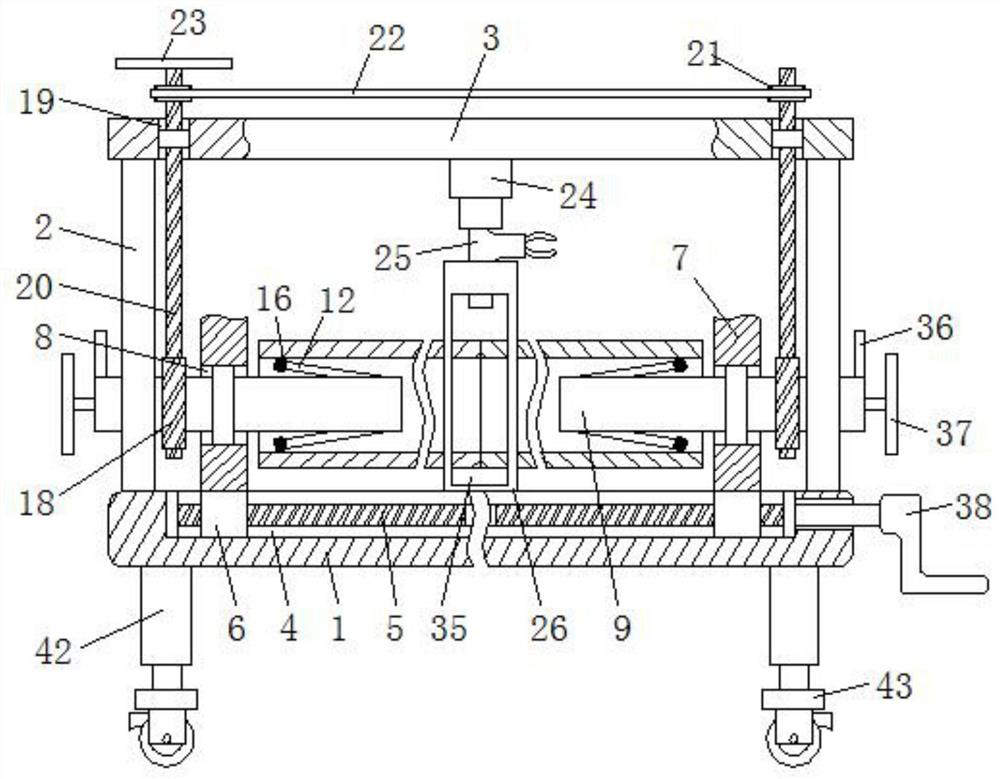

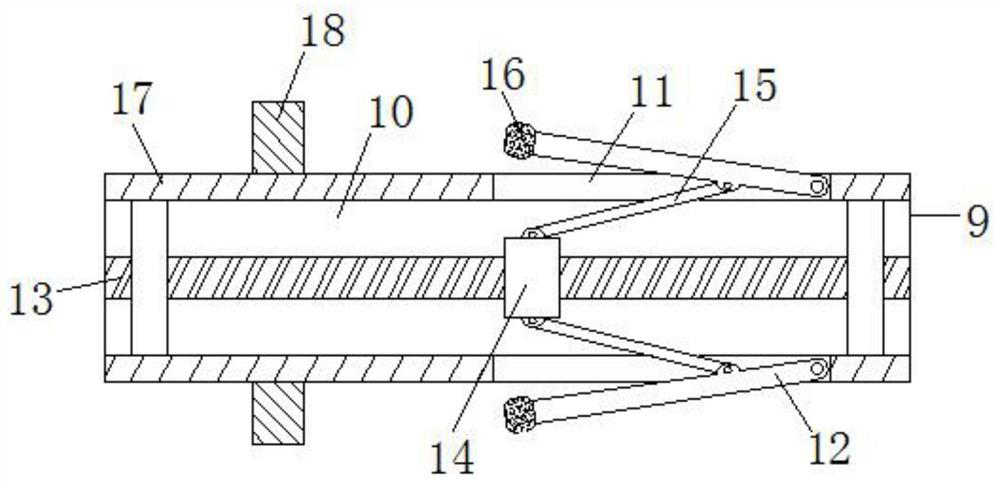

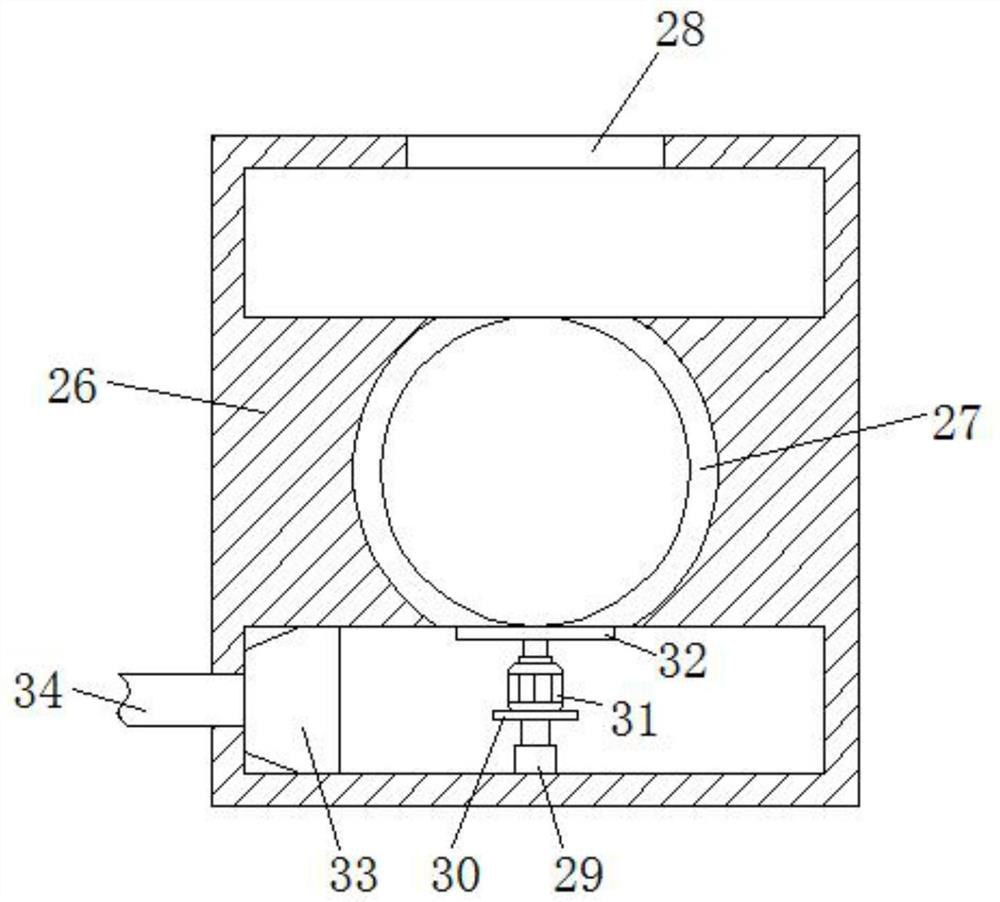

[0027] refer to Figure 1-6 , an industrial mechanical steel pipe positioning welding device, including a workbench 1, the four corners of the lower end of the workbench 1 are respectively fixedly connected with supporting legs 42, and the lower ends of the four supporting legs 42 are respectively fixedly connected with casters 43, and the casters 43 are self-locking. The steering wheel can be braked and locked when the device is working to ensure the working stability of the device. The supporting leg 42 includes a supporting rod 44 fixedly connected with the workbench 1. The inside of the supporting rod 44 is provided with a fourth empty slot 45, and the fourth empt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com