Semi-submersible type laser cutting method for high-speed aircraft empennage

A high-speed aircraft and laser cutting technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of slow cutting speed, low material utilization rate, high production cost and resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

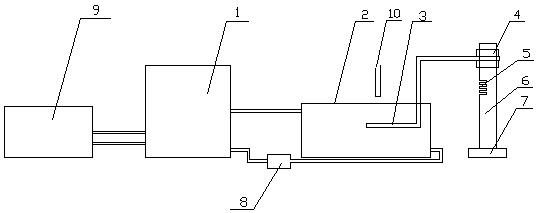

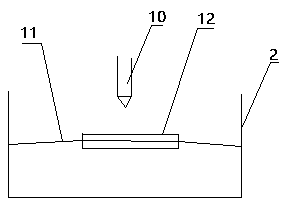

[0014] like figure 1 The high-speed aircraft empennage semi-submersible laser cutting device includes: 2-liquid tank, which provides the necessary environment for the processing of empennage samples; 10-laser head, which emits laser beams and is used to cut the empennage samples to be processed; 3-clamp, used to fix and clamp the 12-fin sample; 4-fixing nut, used to assist the fixing of the 3-fixture; 5-card slot, used to adjust the immersion depth of the 12-tail sample in the working fluid; 6-fix The rod and 7-fixed base are responsible for fixing the entire clamping and positioning system; 8-filter, connected to 2-liquid tank and 1-chiller through pipes, is a part of the circulation system, used to filter out the residue in the working fluid , to ensure the cleanliness of the working fluid in the entire circulation system; 1-chiller, connected with 2-liquid tank, 8-filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com