Clamp for sputtering and method for sputtering semiconductor package

A technology for semiconductors and packages, which is applied in the field of sputtering fixtures and semiconductor packages for sputtering, and can solve problems such as defective products and easy overflow plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

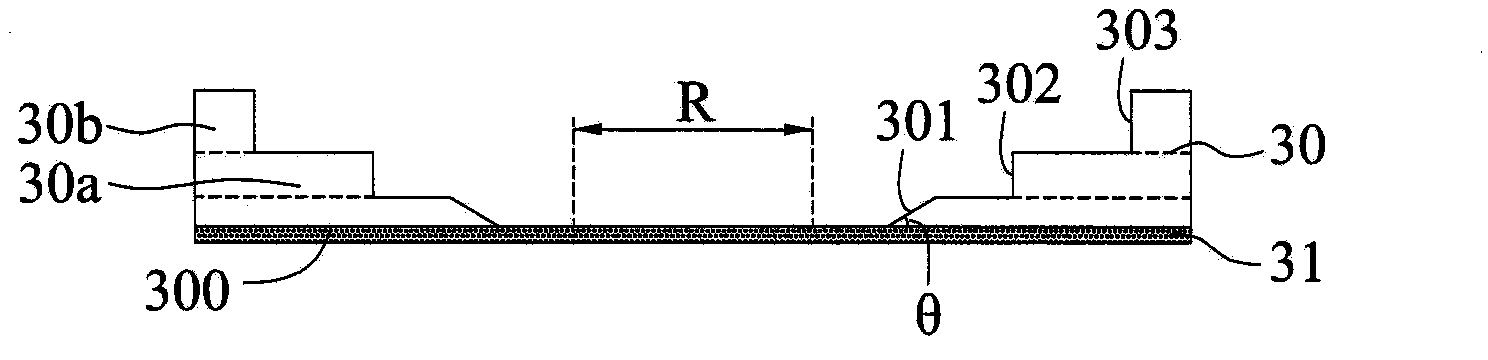

[0051] Such as Figure 3A to Figure 3E What is shown is a schematic cross-sectional view of the first embodiment of the method for sputtering a semiconductor package and the jig used for the sputtering process of the present invention.

[0052] Such as Figure 3A As shown, a fixture plate 30 is provided, which has a first opening 301 passing through the fixture plate 30, and the cross section of the first opening 301 of the fixture plate 30 is tapered with a narrow bottom and a wide top, and the first The range of the angle θ between the conical slope of the opening 301 and the bottom surface of the jig plate 30 is preferably between 10° and 90°, and the jig plate 30 also includes a first stepped layer 30a and a second stepped layer 30b, the first stepped layer 30a is arranged on the top surface of the jig plate 30, and has a second opening 302 correspondingly exposing the first opening 301, in addition, the second stepped layer 30b is arranged on the first stepped layer 30a ...

no. 2 example

[0057] Figure 4 It is a schematic cross-sectional view of the second embodiment of the method for sputtering a semiconductor package and the jig used for the sputtering process of the present invention.

[0058] This embodiment is substantially the same as the first embodiment, the main difference is that the jig plate 35 of this embodiment does not have the first stepped layer 30a and the second stepped layer 30b, and the top surface 322 of the semiconductor package 32 It is flush with the top surface 352 of the jig plate 35 .

no. 3 example

[0060] Figure 5 It is a schematic cross-sectional view of a third embodiment of the method for sputtering a semiconductor package and the jig used for the sputtering process according to the present invention.

[0061] This embodiment is substantially the same as the second embodiment, the main difference being that the top surface 361 of the semiconductor package 36 in this embodiment is higher than the top surface 352 of the fixture board 35 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com