Method, device and loading well/cleaning well for dealing with dropped spent fuel container

A spent fuel and container technology, applied in the field of nuclear power, can solve the problems of being unable to reduce the impact, without changing the "hard impact" contact method between the spent fuel container and the floor, and achieve the effect of simple structure, avoiding strong vibration, and reducing the impact of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment discloses a method for coping with the falling of the spent fuel container, and the specific steps are as follows:

[0033] Vibration damping is provided inside the loading well or cleaning well, that is, the vibration damping setting is arranged inside the loading well or cleaning well, so that when the spent fuel container falls, the impact energy caused by the falling of the spent fuel container can be absorbed.

[0034] Specifically, the vibration damping setting inside the loading well or cleaning well is as follows: a vibration damping unit can be installed at the bottom of the loading well or cleaning well, and the huge impact caused by the falling of the spent fuel container on the loading well or cleaning well can be weakened by the vibration damping unit In addition, a support unit is provided in the loading well or cleaning well and outside the damping unit to protect the damping unit, and then steel cladding is set on the support unit to prote...

Embodiment 2

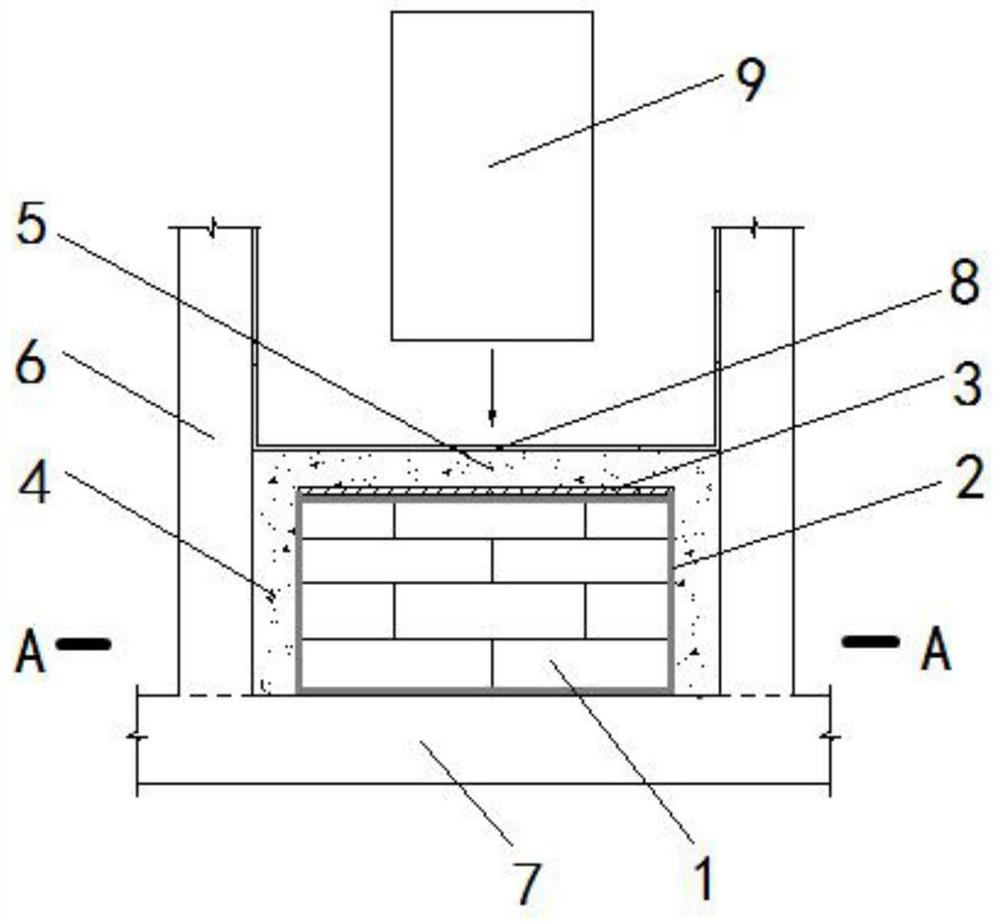

[0036] This embodiment discloses an anti-drop impact device, that is, a device for dealing with the drop of a spent fuel container, including a vibration-damping unit and a support unit, wherein: the vibration-damping unit includes a vibration-damping body 1 to reduce the impact force of the drop; the support unit is designed It is outside the vibration-damping unit and is used to protect the vibration-damping unit so as to prevent the vibration-damping body 1 from being damaged under normal working conditions.

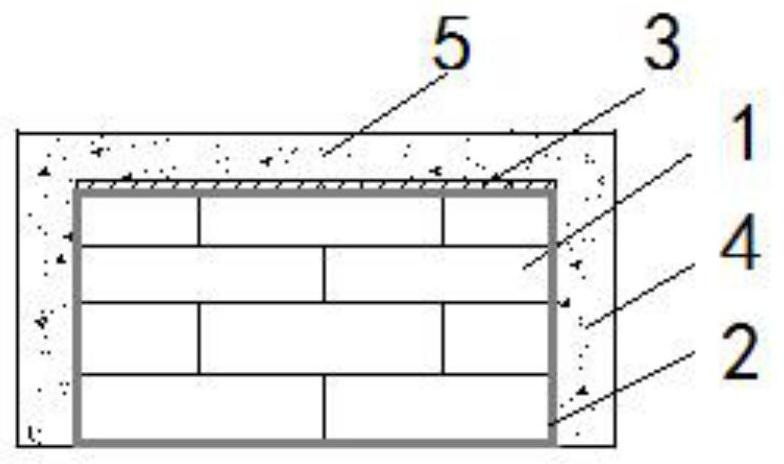

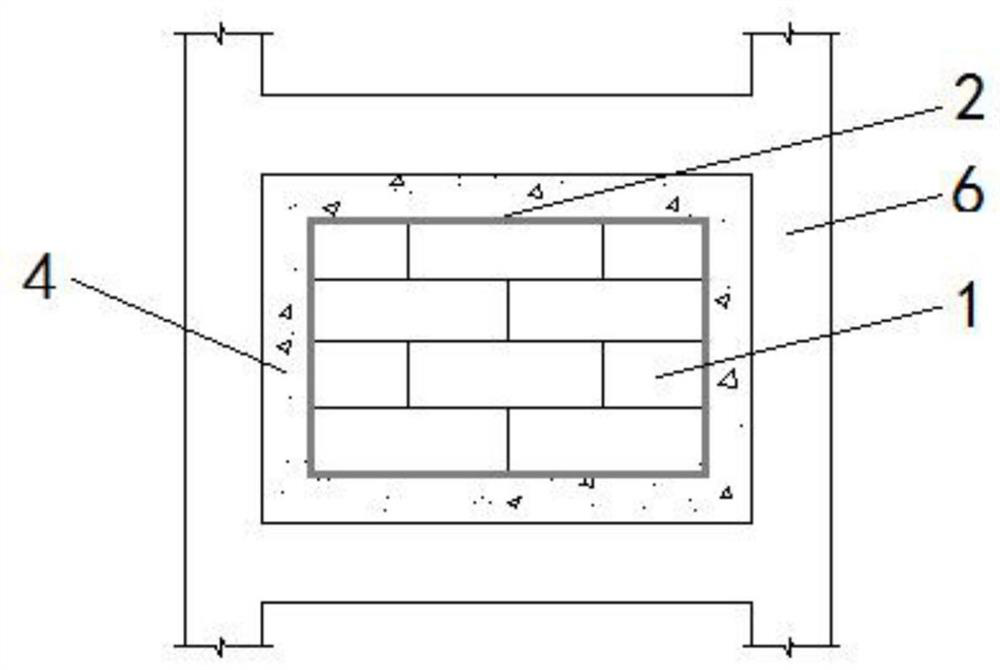

[0037] Specifically, such as Figure 1-3 As shown, the damping body 1 is preferably an autoclaved aerated concrete block (hereinafter referred to as a cut block). The specific parameters of the block are not further limited in this embodiment. Specifically, it can be determined by reducing the scale experiment and software analysis and calculation. Sure. The number of damping bodies 1 can be one or multiple. In this embodiment, there are preferably multiple damping b...

Embodiment 3

[0045] This embodiment discloses a loading well / cleaning well of a nuclear fuel plant. The loading well / cleaning well includes a wall and a bottom plate, and also includes the anti-drop impact device described in Embodiment 2. The anti-drop impact device is located in the loading well / cleaning well. Clean the floor of the well.

[0046] Further, the supporting unit on the anti-drop impact device forms a false joint with the inner wall of the wall, and the upper surface of the supporting unit is provided with a steel cladding.

[0047] Specifically, such as Figure 2-3 As shown, the side plate 4 on the support unit and the inner side of the wall of the loading well / or cleaning well form a false seam (false seam, that is, between the side plate 4 on the supporting unit and the inner side of the wall of the loading well / or cleaning well. Closely attached, but not connected by reinforcement, are independent of each other). The upper surface of the top plate 5 of the anti-drop im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com