Moving end knife and knife load switch

A technology of load switch and switch knife, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of switch safety and low reliability, and achieve improved reliability and safety, reduced damage, and arc ablation resistance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

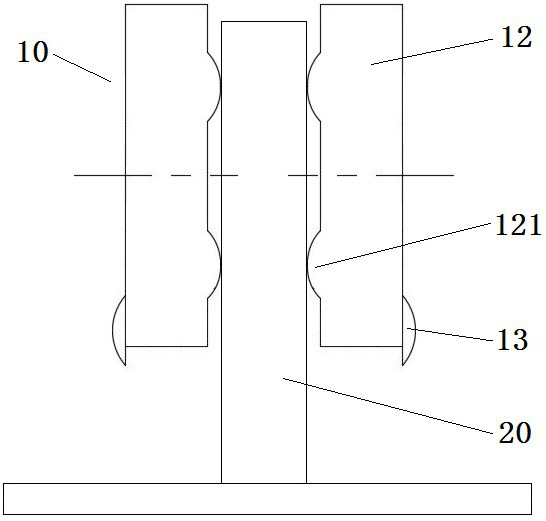

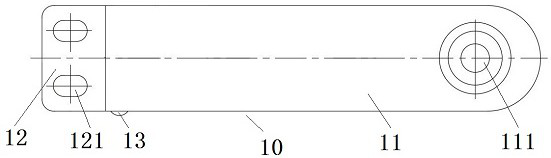

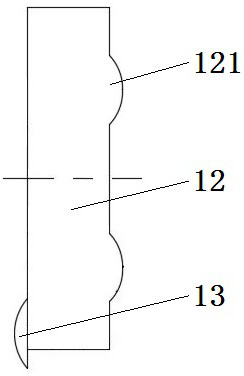

[0037] The specific implementation of the switch knife at the middle moving end and the switch knife type load switch of the present invention will now be described in conjunction with the accompanying drawings.

[0038] Such as figure 1 Shown is an embodiment of the knife-type load switch in the present invention, which is mainly used in power distribution switchgear. The knife-type load switch includes a moving-end knife switch and a static-end knife switch. The moving-end knife switch is rotated through the hinged seat that matches it. Knife 20 contacts, also need to rotate moving end switch knife 10 to make it separate with static end switch knife 20 when needing to open. The switch knife type load switch in the present invention adopts the structure that two movable end switch blades 10 cooperate with the static end switch blade 20 at the same time, the two moving end switch blades 10 are arranged in parallel, and the two moving end switch blades 10 can be Clamp the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com