Automatic magnetic tile pushing machine

A magnetic tile machine and magnetic tile technology, applied in the direction of manufacturing motor generators, electromechanical devices, electric components, etc., can solve the problems of manufacturing troubles, pushing magnetic tiles, troublesome production costs, etc., and achieve complex manufacturing, simple structure, and design. novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

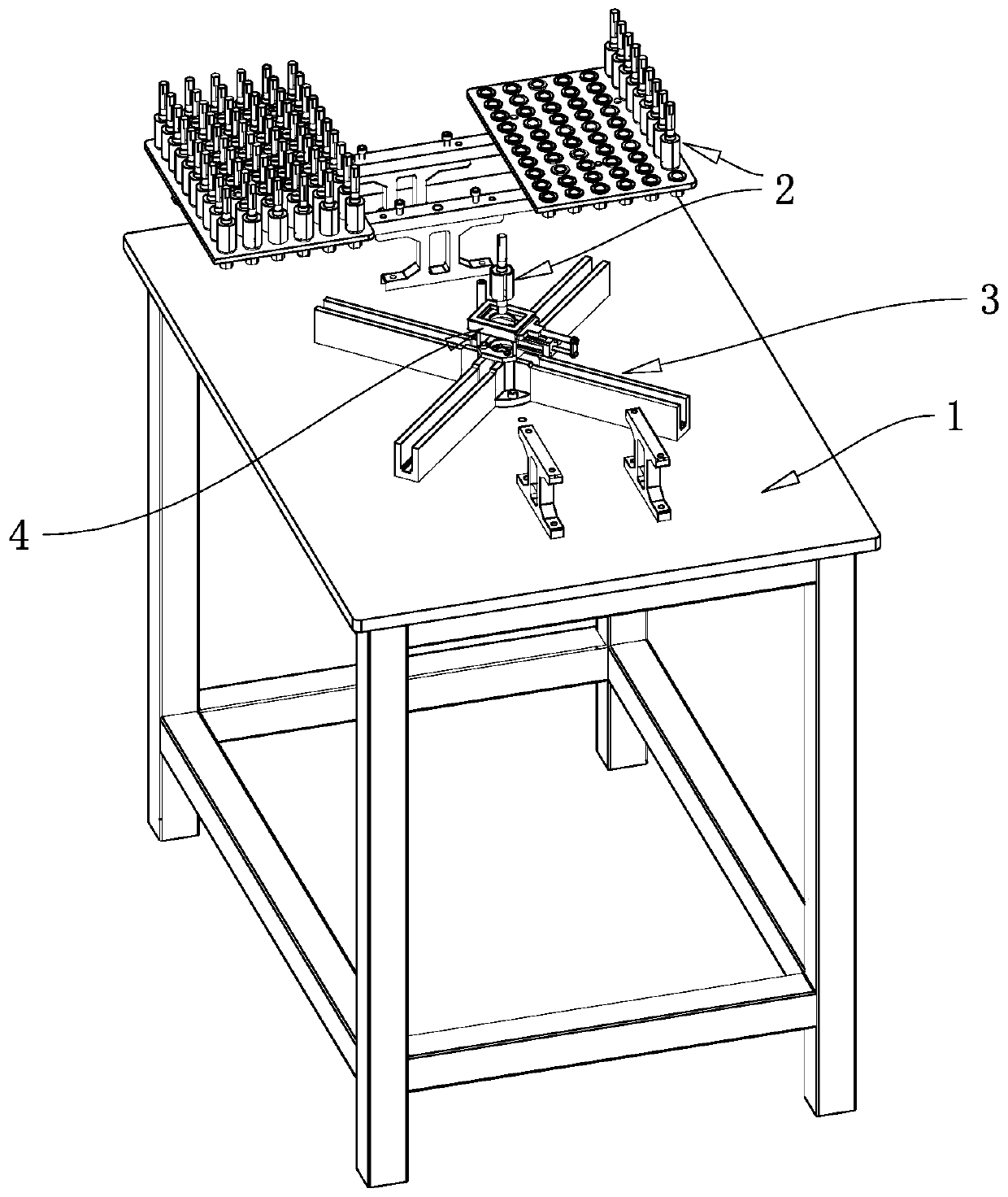

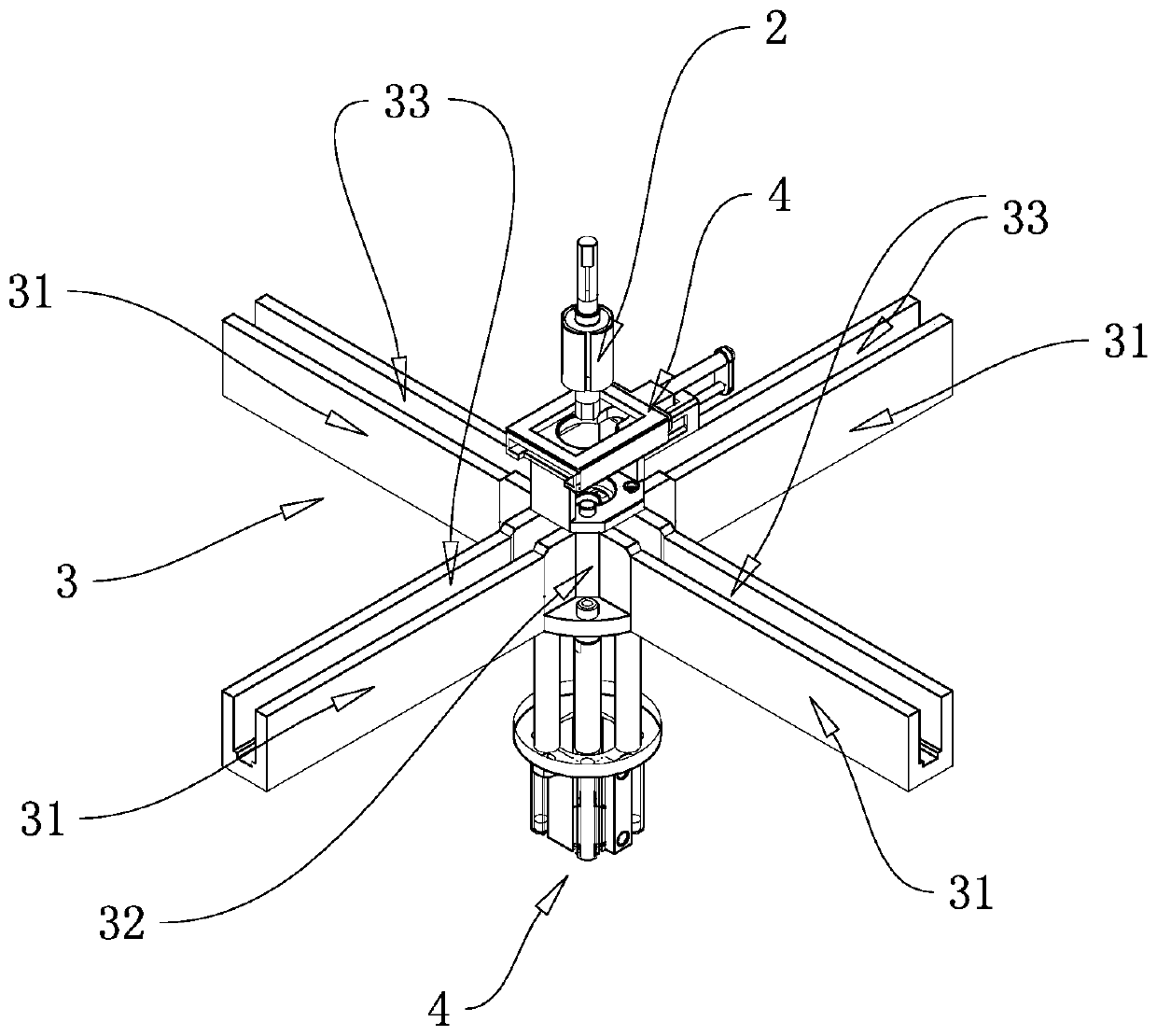

[0024] exist figure 1 and Figure 6 Among them, an automatic magnetic tile pusher of the present application has a platform table 1, a feeder 3 and a pusher 4, including a rotor (2), a magnetic tile (7), a trough (31), and a magnetic tile guide groove (33), the magnetic tile (7) is placed in the magnetic tile guide groove (33) of non-ferrous material, it is characterized in that the feeder 3 is installed on the platform table 1, and the The pusher 4 is installed at the center of the feeder 3, the platform table 1 has a through hole, the through hole is located at the center of the feeder 3, and the pusher 4 is arranged on the feeder 3, the pusher 4 is installed through the platform table 1, and the platform table 1 is made of non-ferrous materials.

[0025] This application uses the above-mentioned automatic magnetic tile pusher to push the magnetic tile 7 into the slot of the rotor 2, so that the rotor 2 and the magnetic tile 7 are fixedly combined, which facilitates the as...

Embodiment 2

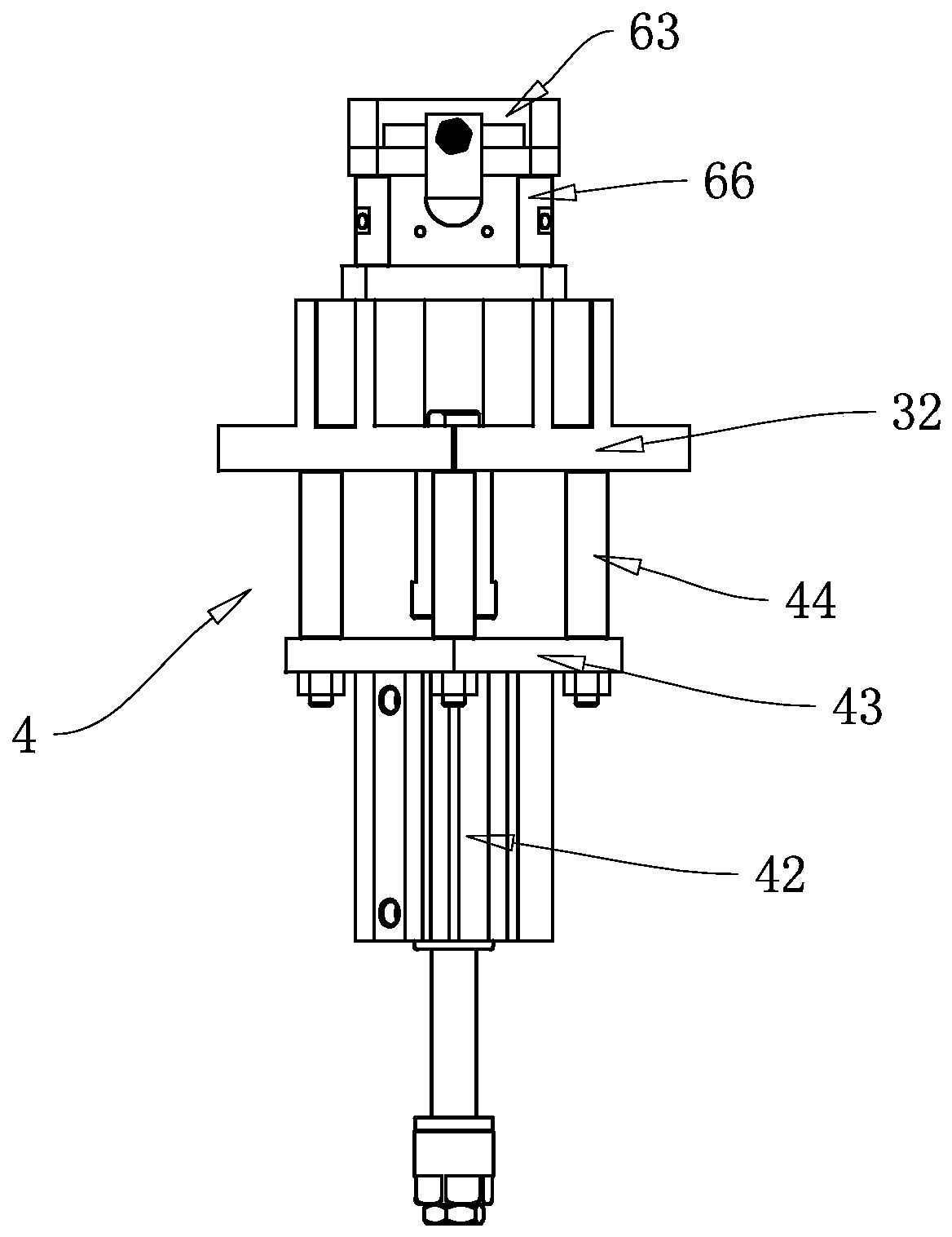

[0035] In the accompanying drawings, an automatic magnetic tile pusher of the present application has a pusher 4, including a rotor 2, a magnetic tile 7, a material trough 31, and a magnetic tile guide groove 33. The magnetic tile 7 is placed on a non-ferrous In the magnetic tile guide groove 33 of the material, it is characterized in that the above-mentioned pusher 4 has a pushing mechanism, a magnetic suction mechanism and a clamp mechanism, and the described pushing mechanism is installed and fixed under the magnetic suction mechanism, and the described clamp The plate mechanism is installed and fixed on the magnetic suction mechanism, and the push-off mechanism and the clamp mechanism are fixed on the magnetic suction mechanism with screws. The above-mentioned push-off mechanism has an upper cylinder 42 and a magnetic tile push rod 41. The above-mentioned supply The feeder has a magnetic tile guide groove 33, and the above-mentioned clamp mechanism has a limit clamp 61. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com